1.1

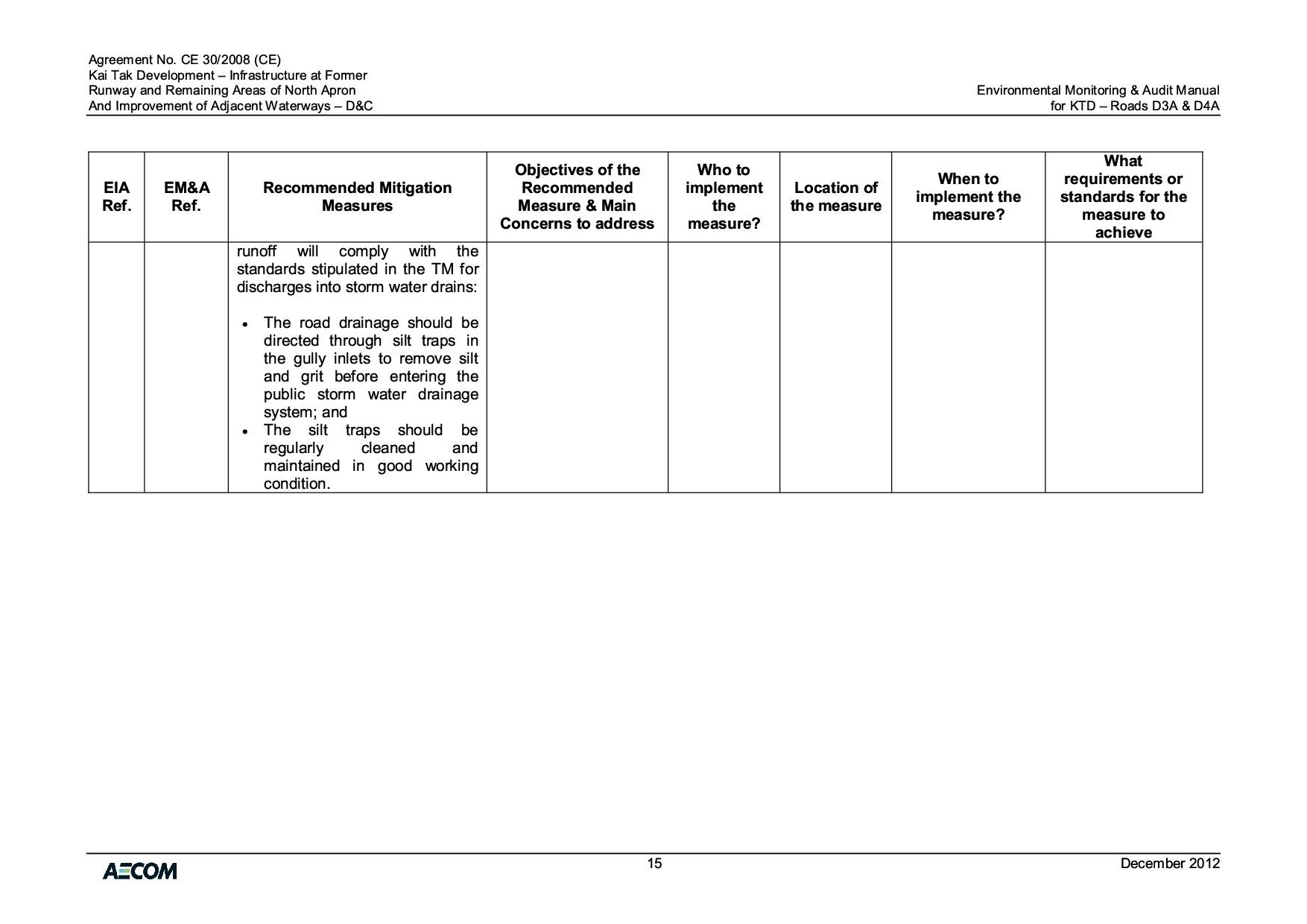

Project Background

1.1.1

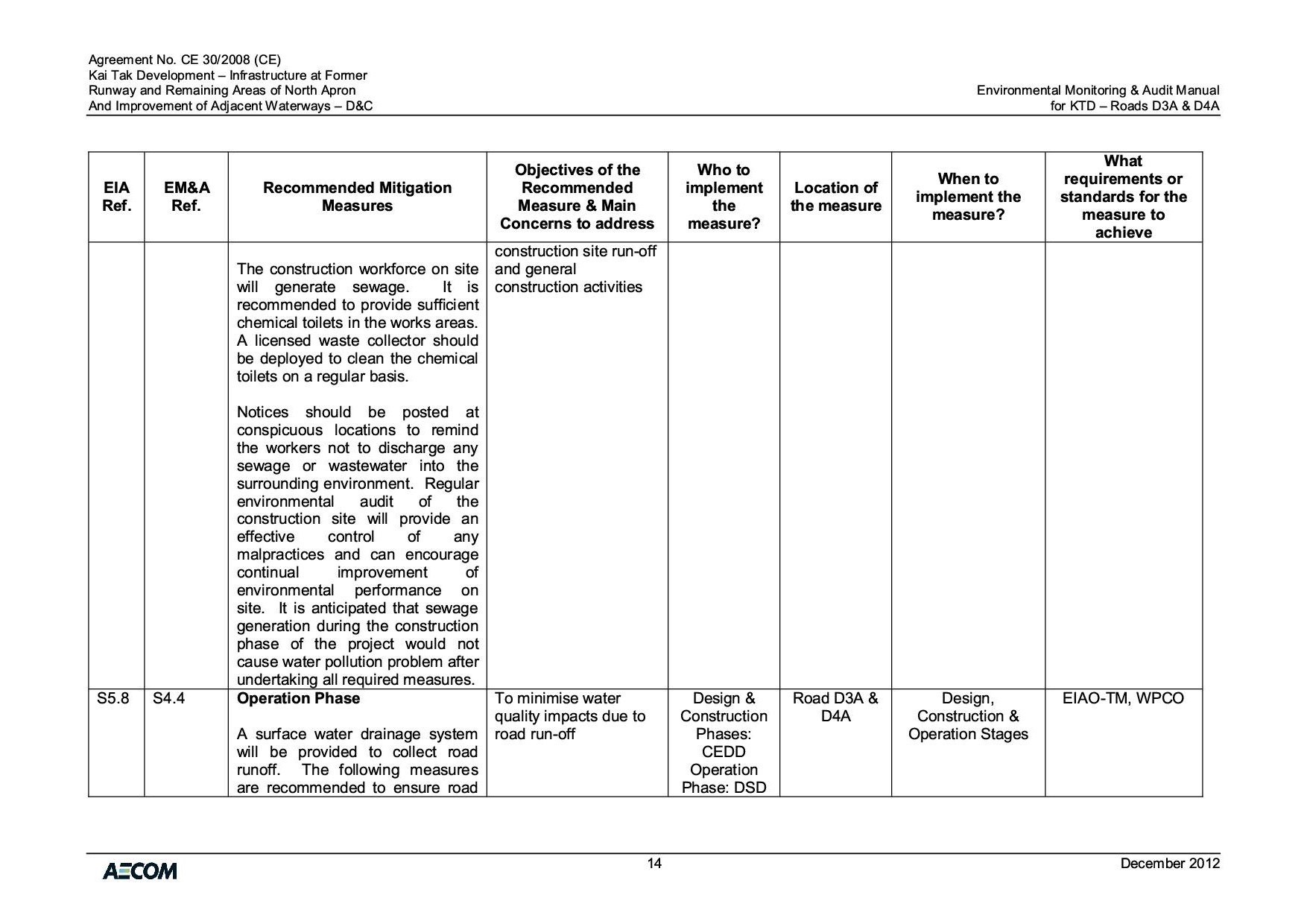

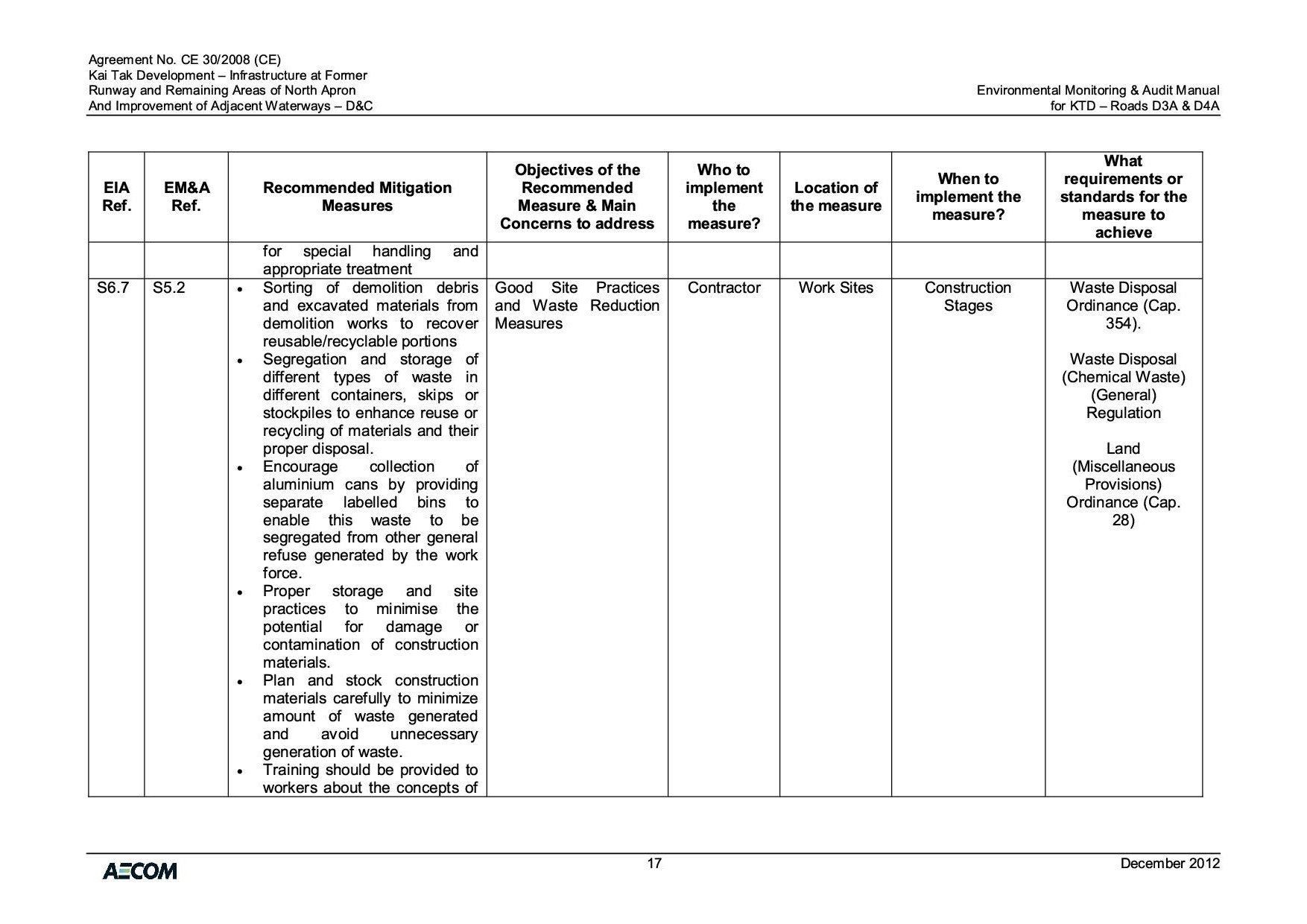

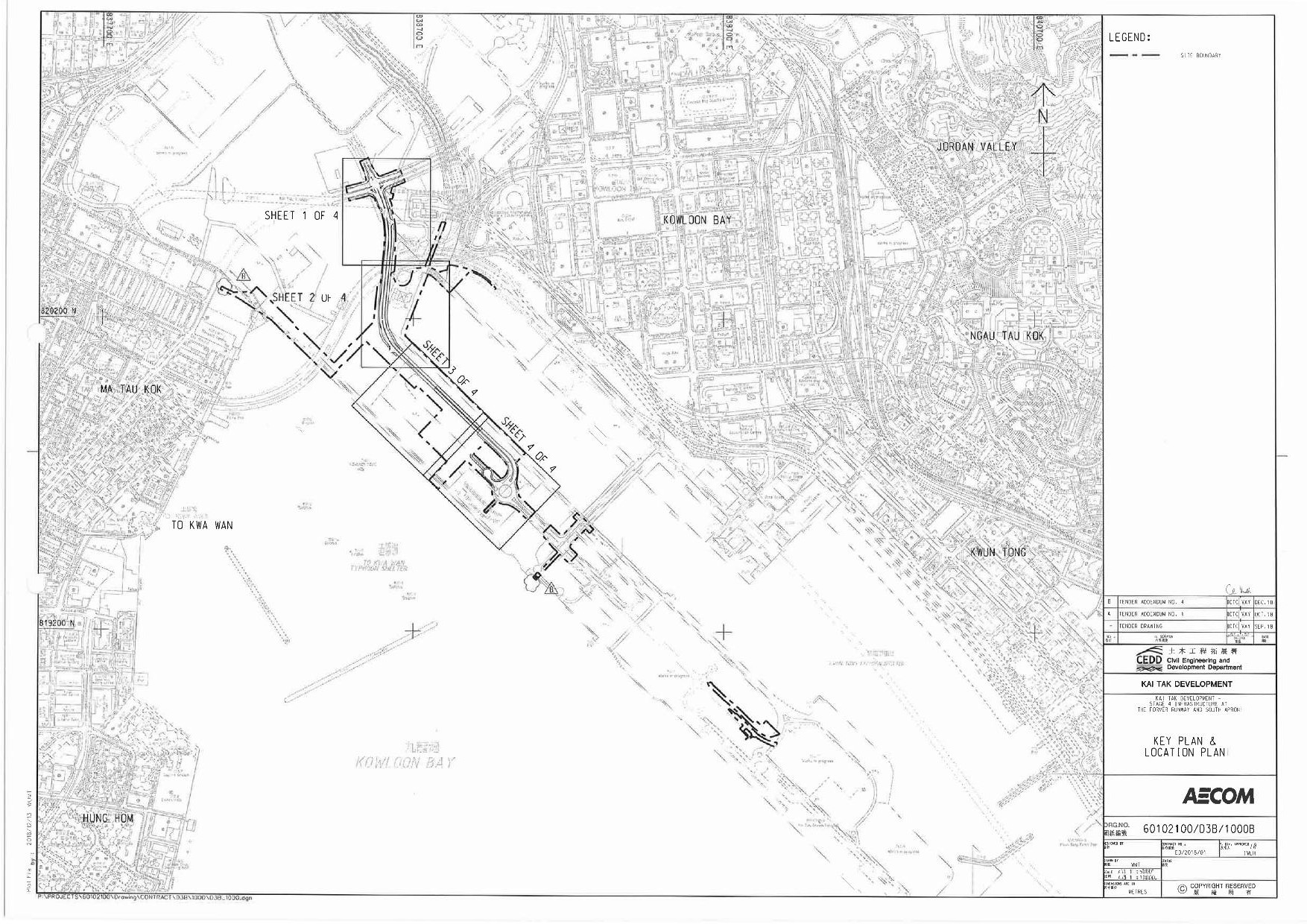

The Project is located in the south-eastern

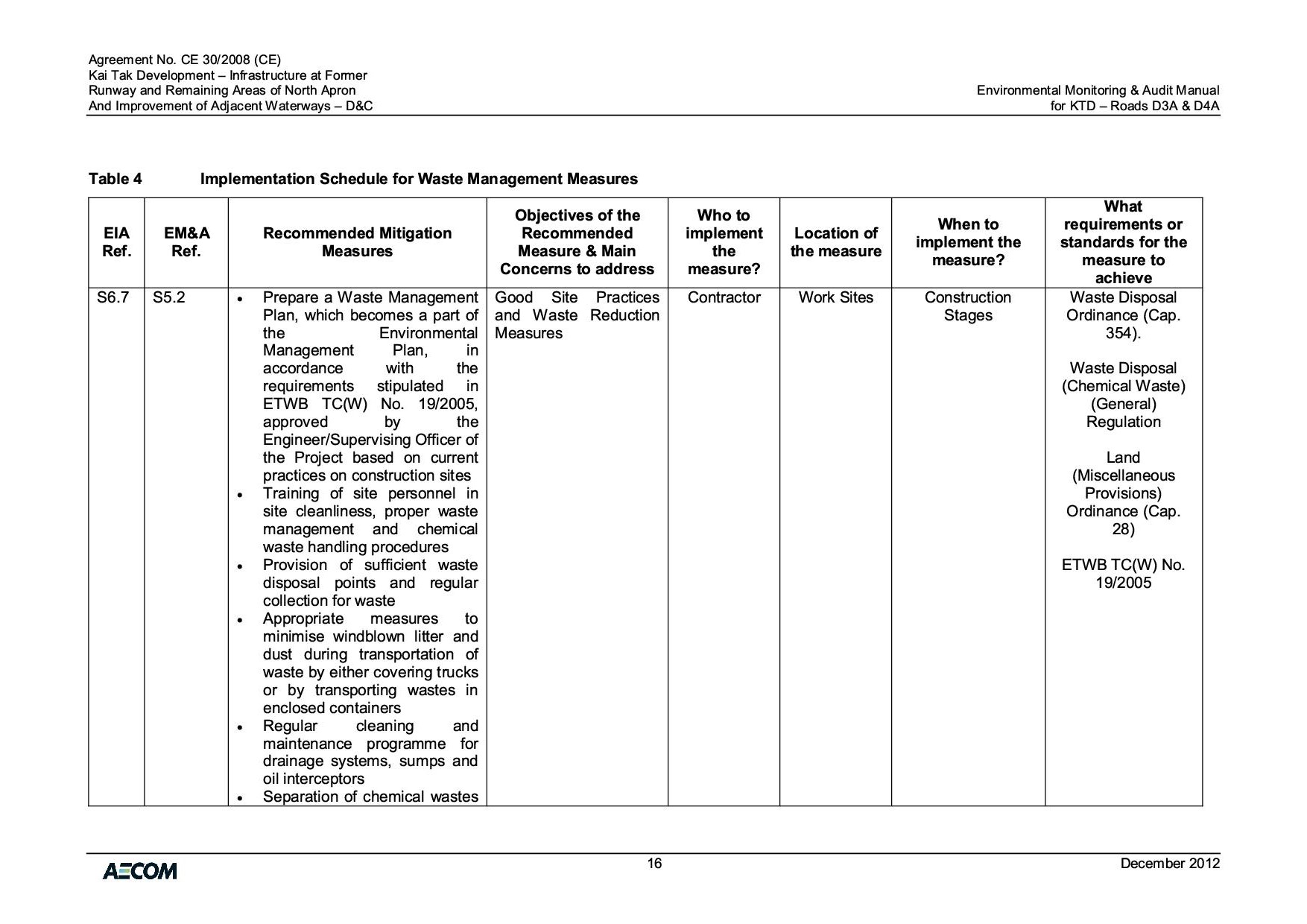

part of Kowloon

Peninsula, comprising the apron and runway areas of the

former Kai Tak

Airport and existing waterfront areas at To Kwa

Wan, Ma Tau Kok, Kowloon Bay, Kwun Tong and Cha Kwo

Ling. It covers a land area of

about

328 hectares. The Project also covers Kowloon

Bay and Kwun Tong

Typhoon

Shelter and the adjacent water bodies.

1.1.2

The Kai Tak Airport was

the international airport of Hong Kong until 6 July 1998, which was

replaced by

the new Hong Kong International Airport at the Chek

Lap Kok. After closure, the airport site

has been

occupied by various temporarily uses such as public fill banks, bus

depots, car

sales exhibitions, and recreational grounds. Besides, most of the

original

buildings and structures within the former airport site have been

cleared and

the ground contamination identified at the north apron had been

decontaminated.

1.1.3

In 2002, the Chief Executive in Council

approved the Kai Tak Outline Zoning Plans

(No.

S/K19/3 and S/K21/3) to provide the statutory framework to proceed

with the

South East Kowloon Development at the former Kai Tak

Airport. However, following the judgment of the Court of Final Appeal

in

January 2004 regarding the Harbour

reclamation, the

originally proposed development which involved reclamation has to be

reviewed.

The Kai Tak Planning Review (KTPR) has

resulted a

Preliminary Outline Development Plan (PODP) for Kai Tak

in October 2006.

1.1.4

Based on the PODP, Planning Department have

prepared the Draft Kai Tak Outline Zoning

Plan (OZP)

No. S/K22/1 and was submitted to the Town Planning Board for

consideration on

10 November 2006 and was gazetted under

the Town Planning

Ordinance on 24 November 2006 and the OZP No. S/K22/2 was approved by

CE in C

on 6 November 2007.

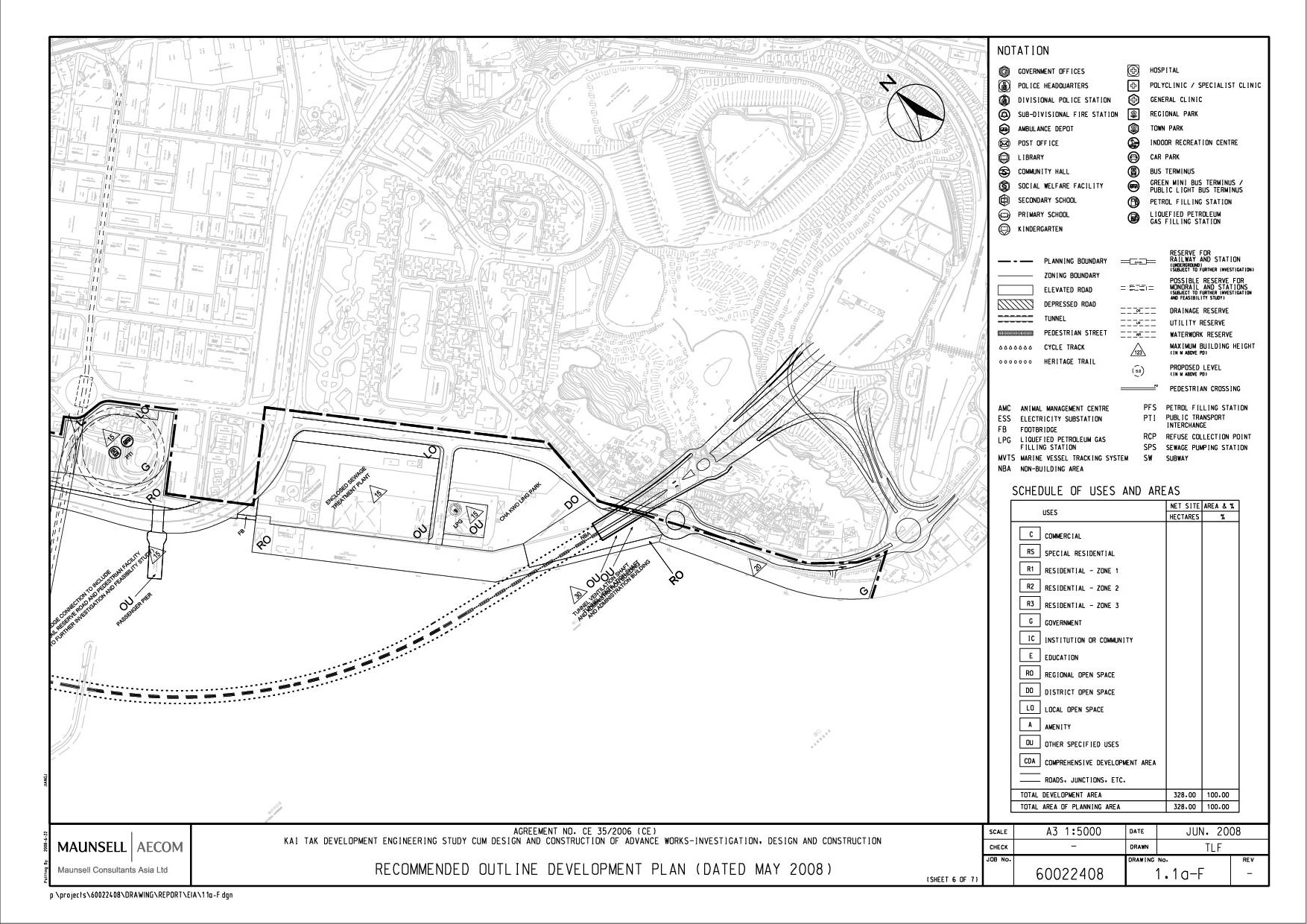

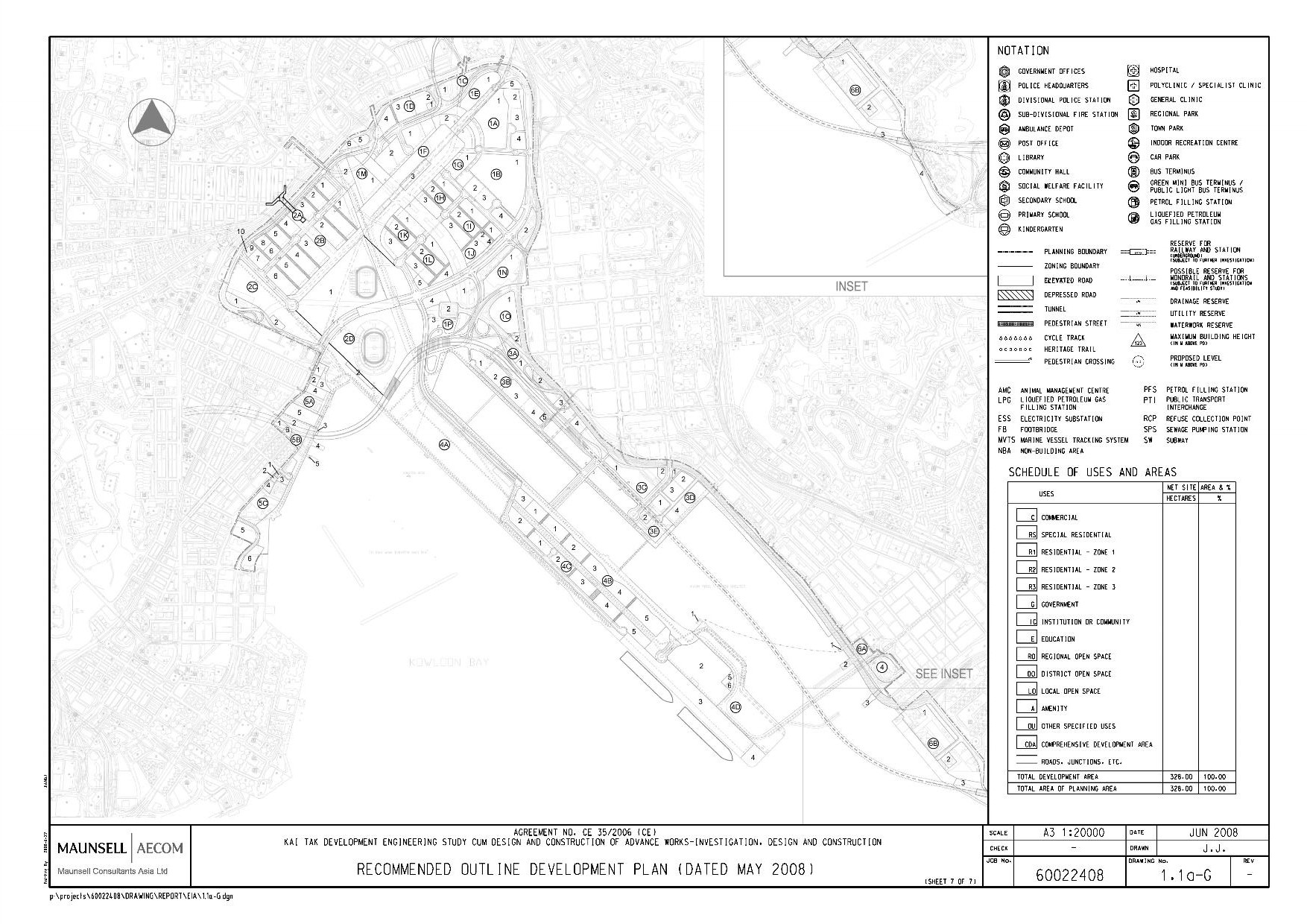

1.1.5

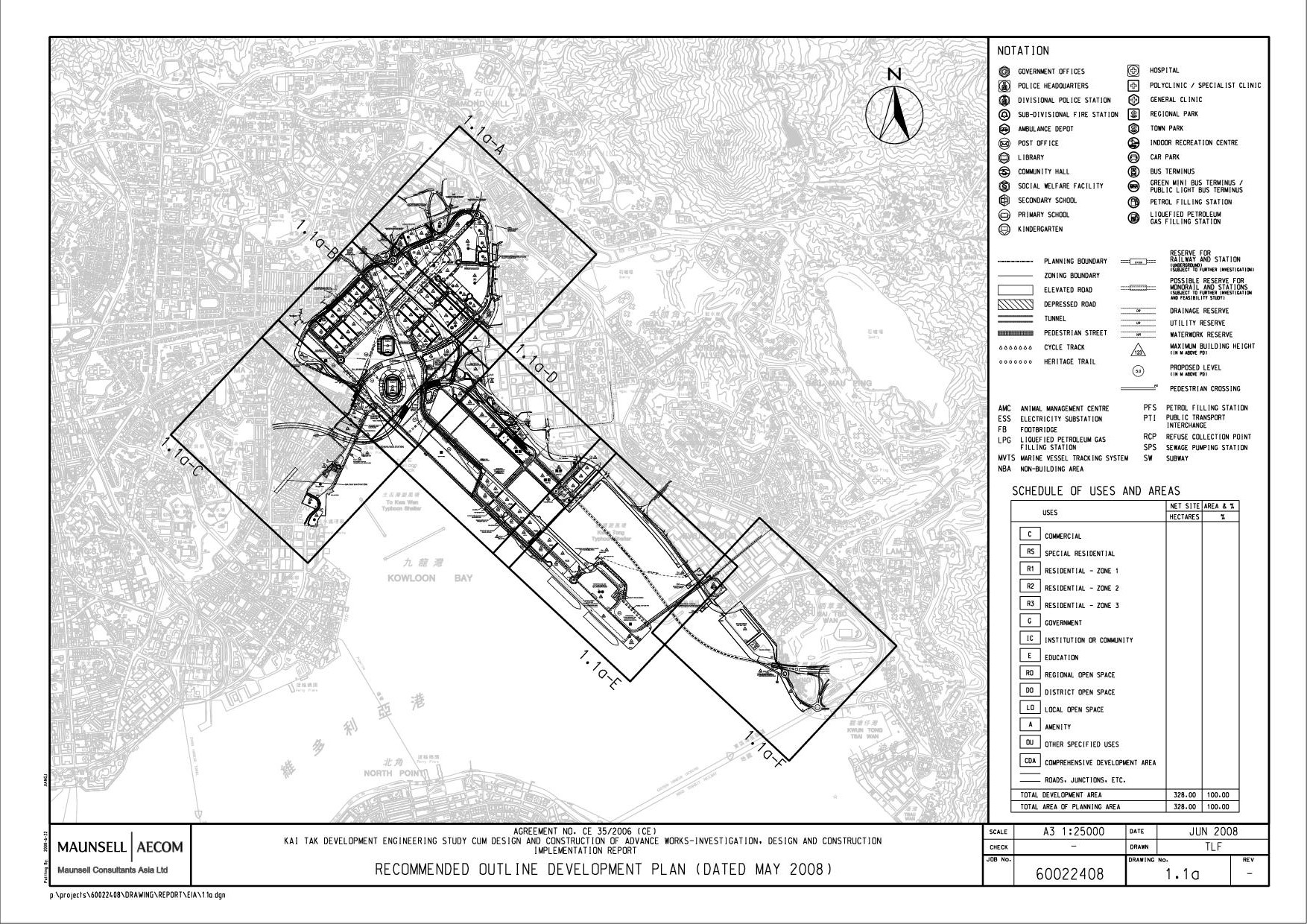

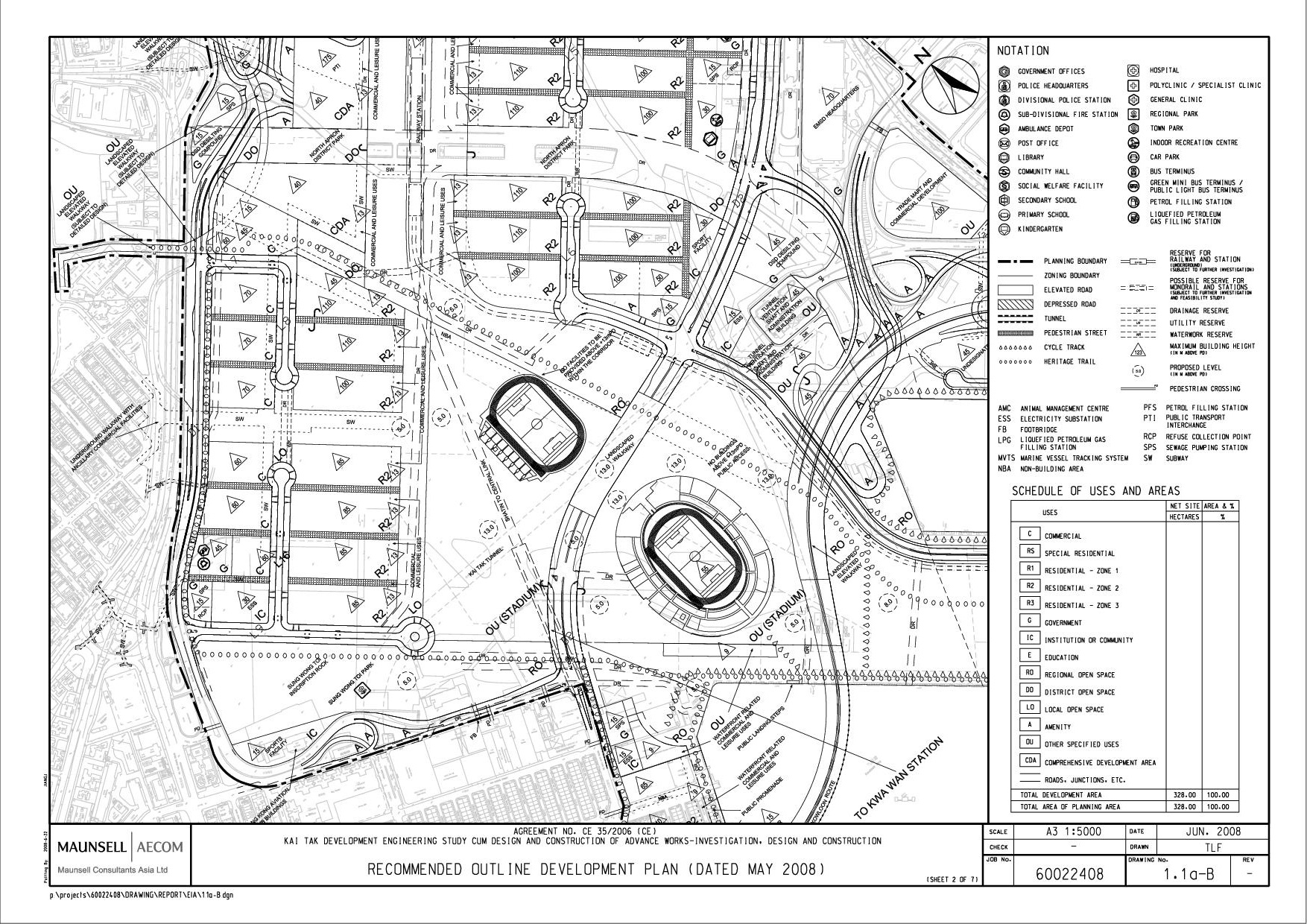

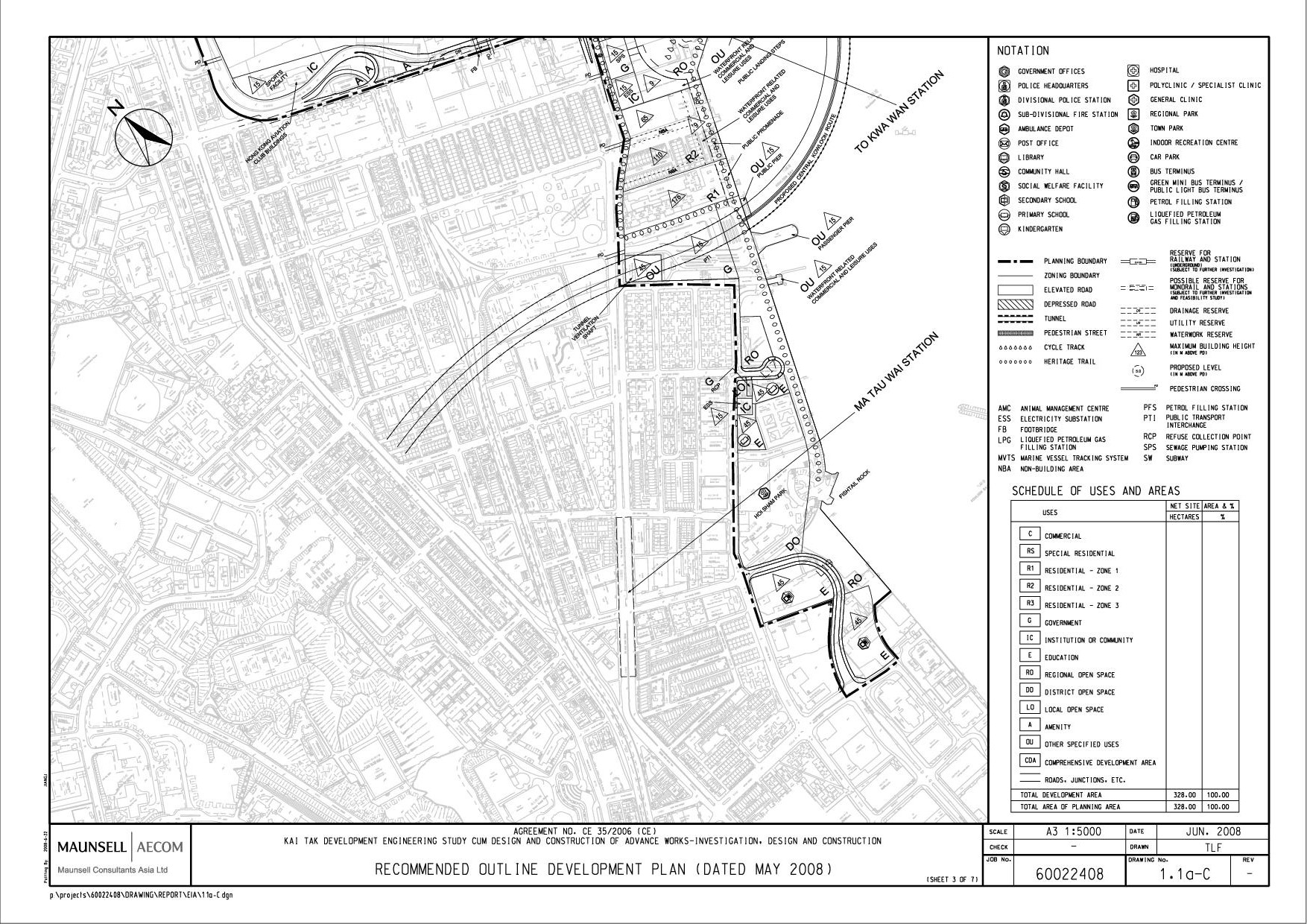

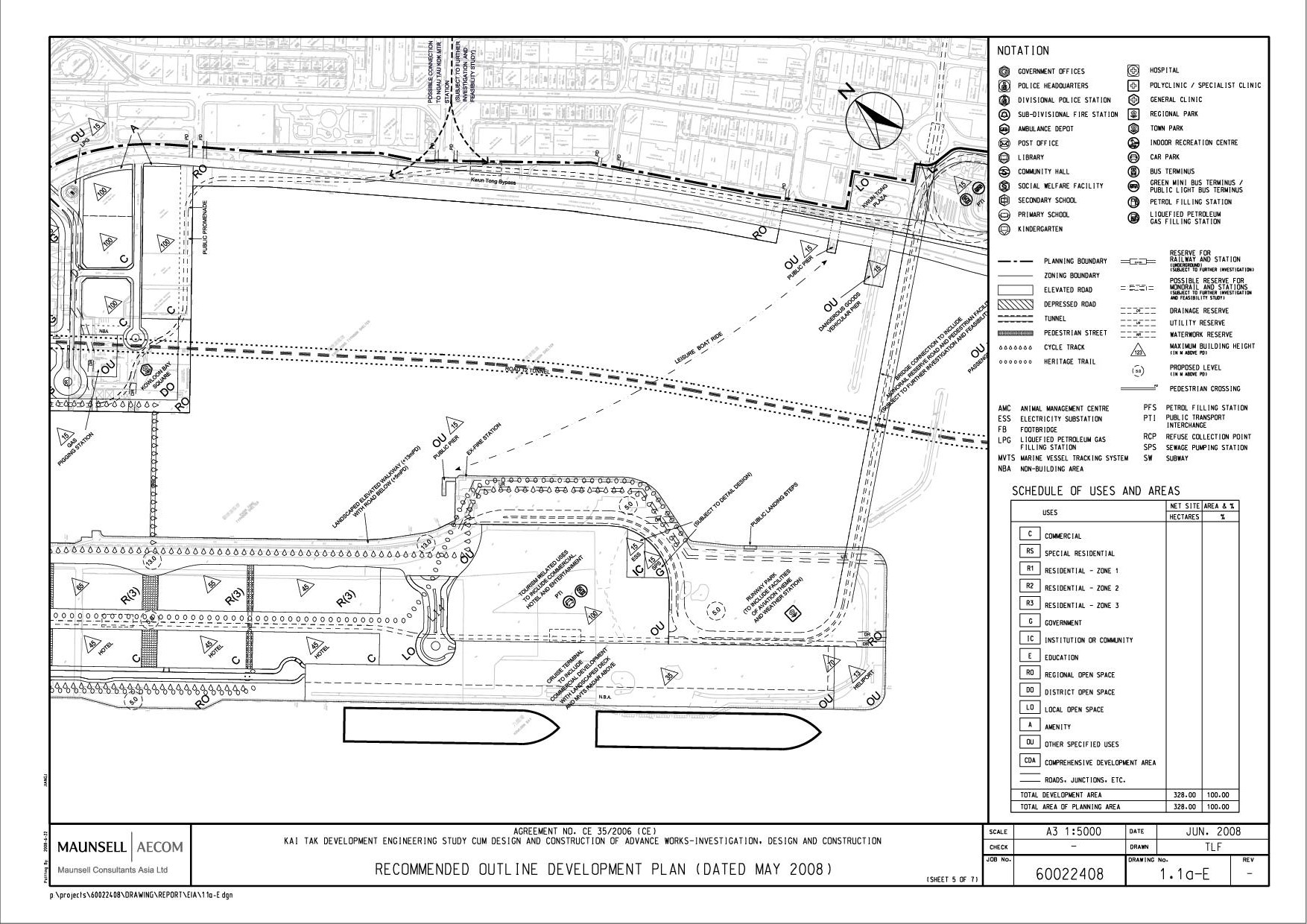

A Recommended Outline Development Plan (RODP) of

Kai Tak Development has been prepared by

resembling

the changes to the PODP and the Kai Tak

Outline

Zoning Plan (OZP). The RODP (dated May 2008) becomes the basis for

conducting

the EIA study for the feasibility study of the Kai Tak

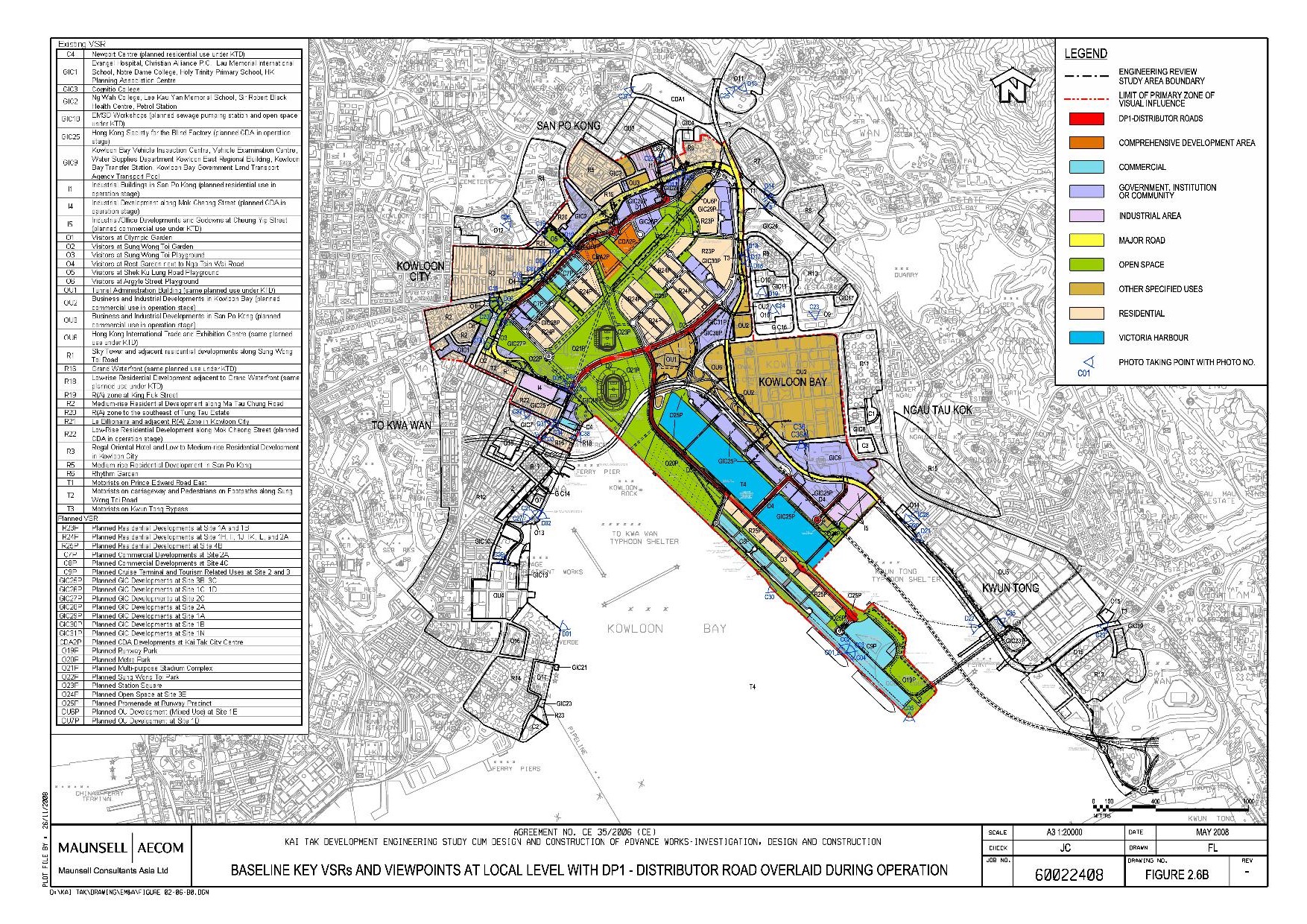

Development. A copy of the RODP (dated May 2008) is shown in Figure

1.1a.

1.1.6

This Project falls within item 1 under Schedule

3 of the EIAO, i.e. engineering feasibility study of urban development

project

with a study area covering more than 20 hectares or involving a total

population of more than 100,000.

1.1.7

This Project also contains various Schedule 2

Designated Projects (DPs) that, under the EIAO, require Environmental

Permits

(EPs) to be granted by the DEP before they may be either constructed

or

operated. Details of the Schedule 2 DPs are described in the EIA

Report.

1.1.8

Three of the Schedule 2 DPs, namely the

Decommissioning of the Former Kai Tak

Airport other

than the North Apron, Kai Tak North Apron

Decommissioning, and the Dredging Works for Proposed Cruise Terminal

at Kai Tak, have already been covered

under separate EIA Reports

that were approved under the EIAO. The EM&A requirements for these

3

Schedule 2 DPs have already been detailed in the respective EM&A

Manual.

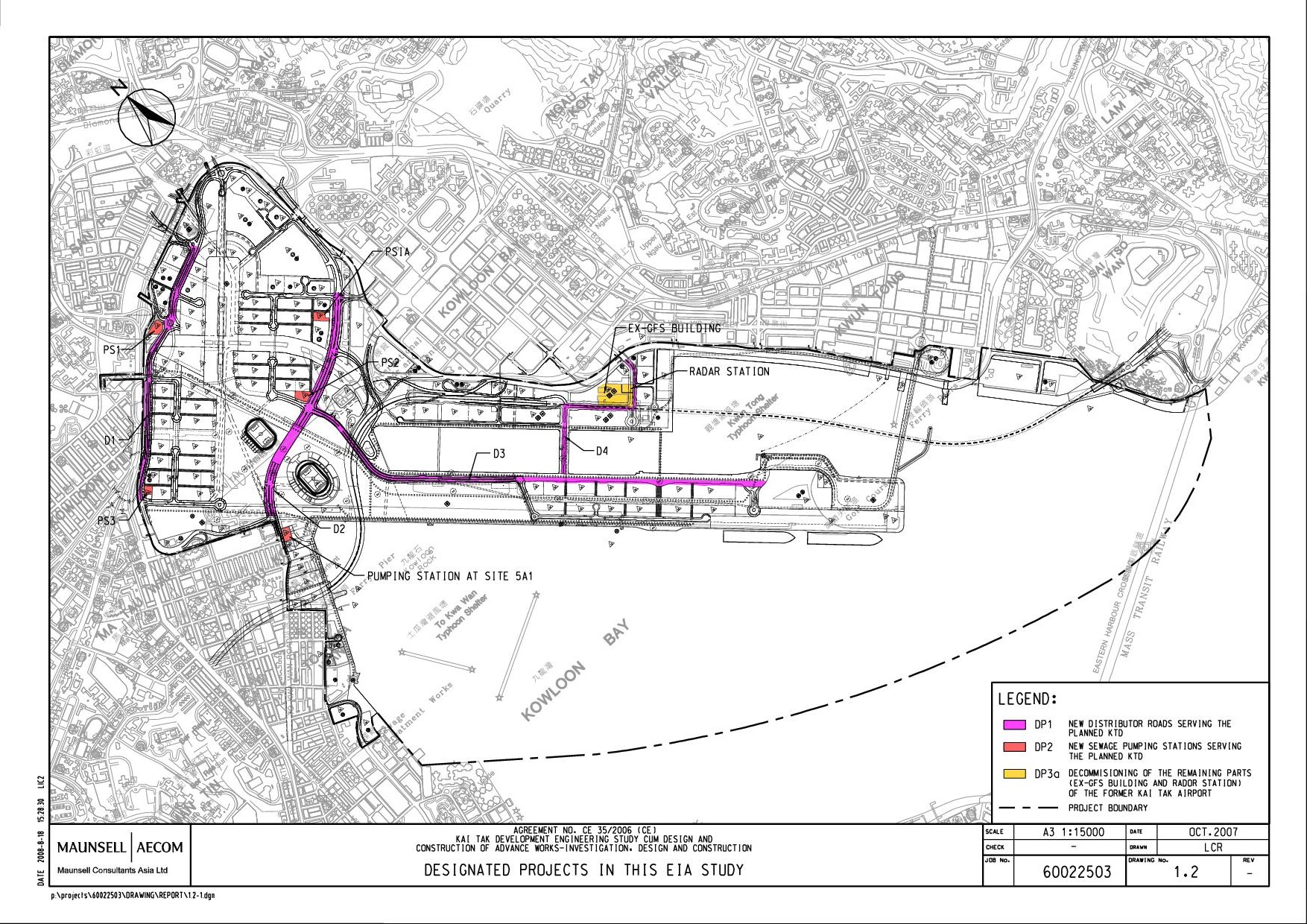

1.1.9

The environmental impacts of another three

Schedule 2 DPs as listed in Table 1.1 below namely new distributor

roads

serving the planned KTD (DP1), new sewage pumping stations serving the

planned

KTD (DP2), and decommissioning of the remaining parts of the former

Kai Tak Airport (DP3) have been

adequately addressed in this

Schedule 3 EIA Report. Figure 1.2 shows the locations of these

Schedule 2 DPs. The

remaining Schedule 2 DPs will be addressed in further detailed EIA

studies by

the respective project proponents in the future.

Table

1.1 List of

Schedule 2 Designated Projects Contained within the Kai Tak

Development that have been Adequately Addressed in this Schedule 3

EIA Report

|

Item

|

Designated

Project

|

EIAO

Reference

|

|

DP1

|

New distributor roads

serving the planned KTD

|

Schedule 2, Part I,

Items A.1, A.8 & A.9. Partly referred in Section 1.3 (ii)

of EIA Study Brief No. ESB- 152/2006.

|

|

DP2

|

New sewage pumping

stations serving the planned KTD

|

Schedule 2, Part I, Item

F.3. Partly referred in Section

1.3 (iii) of EIA Study

Brief No. ESB-152/2006.

|

|

DP3a

|

Decommissioning of the

remaining parts (Ex-GFS Building and Radar Station) of the

former Kai Tak Airport

|

Schedule 2, Part II,

Item 1

|

1.1.10

Broad descriptions of the Schedule 2 DPs listed

in Table 1.1 above are given in the following paragraphs.

1.1.11

DP1 - New distributor roads serving the planned

KTD

l

The major

elements of the future ground level road system within KTD include

four

district distributor roads namely Roads D1, D2, D3 and D4. No new

primary

distributor road is proposed within KTD. As Roads D1 to D4 are

district

distributor roads, they are classified as DPs under Item A.1, Part I,

Schedule

2 of the EIAO. A section of Road D2 will be running underneath the

podium structure

of the proposed Stadium Complex. Based on the latest available

information,

that section of Road D2 is fully enclosed by decking above and by

structure on

the sides for more than 100 m and is thus classified as DP under Item

A.9, Part

I, Schedule 2 of the EIAO. For Road

D3, a section of road bridge will be constructed above the 600m gap

opening.

Therefore, it is classified as DP under Item A.8, Part I, Schedule 2

of the EIAO.

1.1.12

DP2 - New sewage pumping stations serving the

planned KTD

l

Six sewage pumping

stations (SPSs), excluding the proposed SPS of the DWFI compound at

JVBC

(JVBC-PS) as described under DP15 below, are located within KTD. As

part of the

sewerage improvement scheme in the hinterland to reduce the pollution

loading

in KTAC, DSD will initially construct two new SPSs, namely PS1 and

PS3. These

two SPSs are tentatively programmed to be completed in 2012 to convey

sewage

flow generated from the hinterland to To

Kwa Wan Preliminary

Treatment Work. PS6 will have to be completed in later 2011 in time

for

commissioning of the Phase I Berth of the Cruise Terminal in 2012.

PS1A is

designed to convey sewage flow generated from the public housing

sites, schools

and residential sites. It has been determined that PS1A is not

required for the

initial population intake of public housing developments in Sites 1A

and 1B in

September 2012. Instead the initial sewage flow collected from these

housing

sites will be discharged directly to the existing sewer along Eastern

Road via

new gravity sewer as an interim measures.

PS1A is planned

to be available 2014 or earlier. The reprovision

of SPS

(NPS) located in the Site 5A1 will be available in 2014. PS2 is

located at the

Site 1L5 and designed to convey sewage flows generated in the

developments in

Sites 1M, 1P, 1K, 1L 2A and 2B.

l

All these

SPSs, except PS6, are with an installed capacity of more than 2000 m3

per day

and are located within 150m from existing and/or planned residential

area or

educational institution, therefore these SPSs are classified as DPs

under Item

F.3, Part I, Schedule 2 of the EIAO.

l

The proposed

PS6 is located near the southern tip of the former Kai Tak

Airport runway. The installed capacity of PS6 is more than 2,000m3

but less than 300,000m3 per day. PS6 is located at more

than 150m

away from any existing or planned residential area, place of worship,

educational institution, health care institution, site of special

scientific

interest, site of cultural heritage, bathing beach, marine park or

marine

reserve, fish culture zone, or seawater intake point. Therefore

with reference to Item f.3, Part I, Schedule 2 of the EIAO, the

proposed PS6 is

not classified as a DP under the EIAO.

1.1.13

DP3a - Decommissioning of the remaining parts

(Ex-GFS Building and Radar Station) of the former Kai Tak

Airport

l

The scope of

this DP is primarily to decommission the Ex-GFS Building and Radar

Station

within the former Kai Tak Airport that

were not

covered under the previous EIAs on decommissioning of former Kai Tak Airport (namely EIAs for DP4 and DP5).

l

The decommissioning

of airport facilities is classified as DP under Item 1, Part II,

Schedule 2 of

the EIAO.

1.1.14

Road D3A and Road D4A are dual 2-lane district

distributor roads within the Runway Precinct of the Kai Tak

Development (KTD) as shown in Figure 1.1. Road D3A is running along

the centre of the Runway Precinct and is

replacing the original

southern section of Road D3 that runs along the waterfront of the

Runway

Precinct. Road D4A is an extension of Road D4A connecting Road D4 with

the

proposed Road D3A (AEIAR/170-2013).

1.1.15

Both Road D3A and Road D4A will play an

important role in linking up all the development areas in Runway

Precinct of

KTD with the hinterland (AEIAR/170-2013).

1.2

Project

Scope and Programme

1.2.1

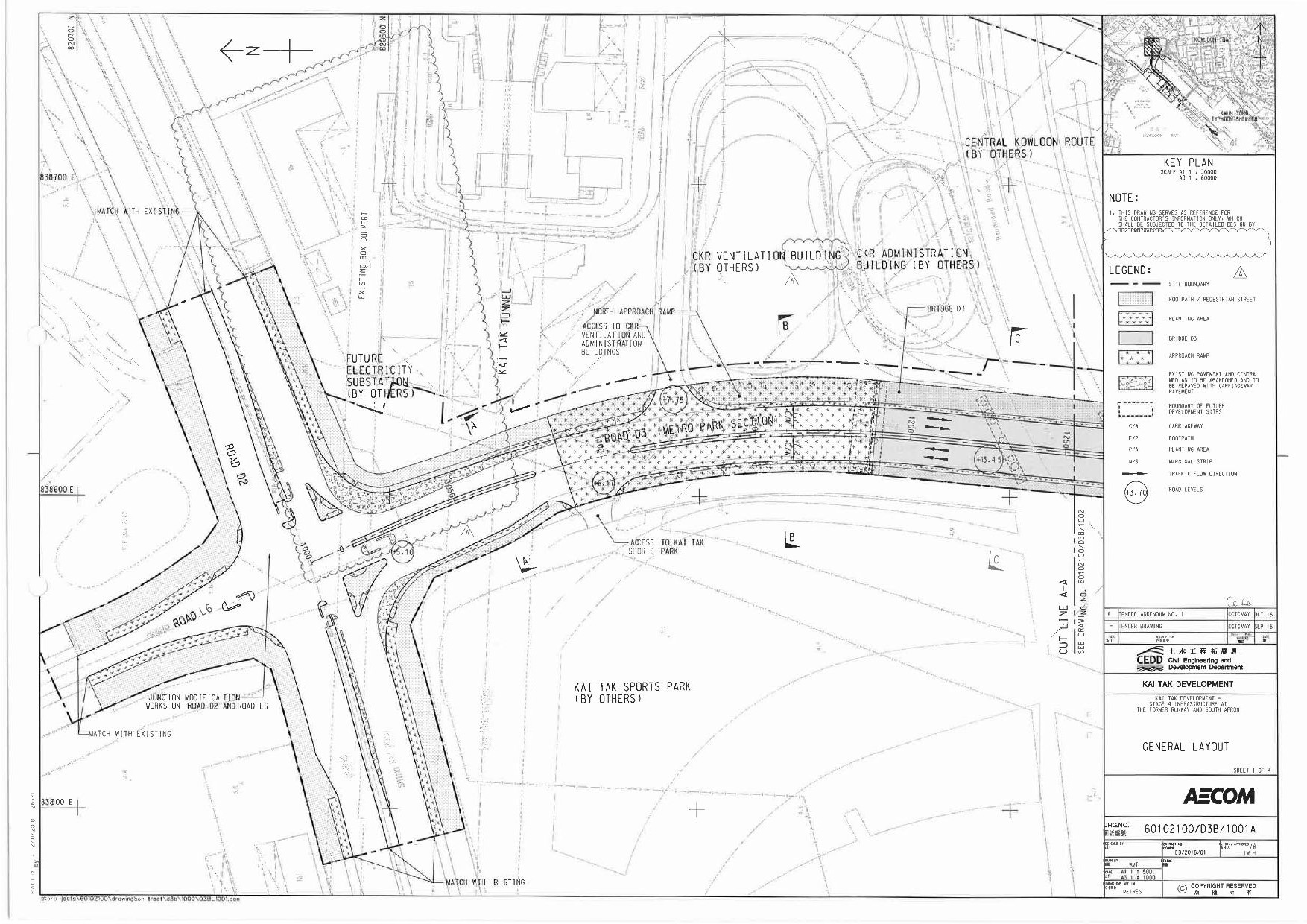

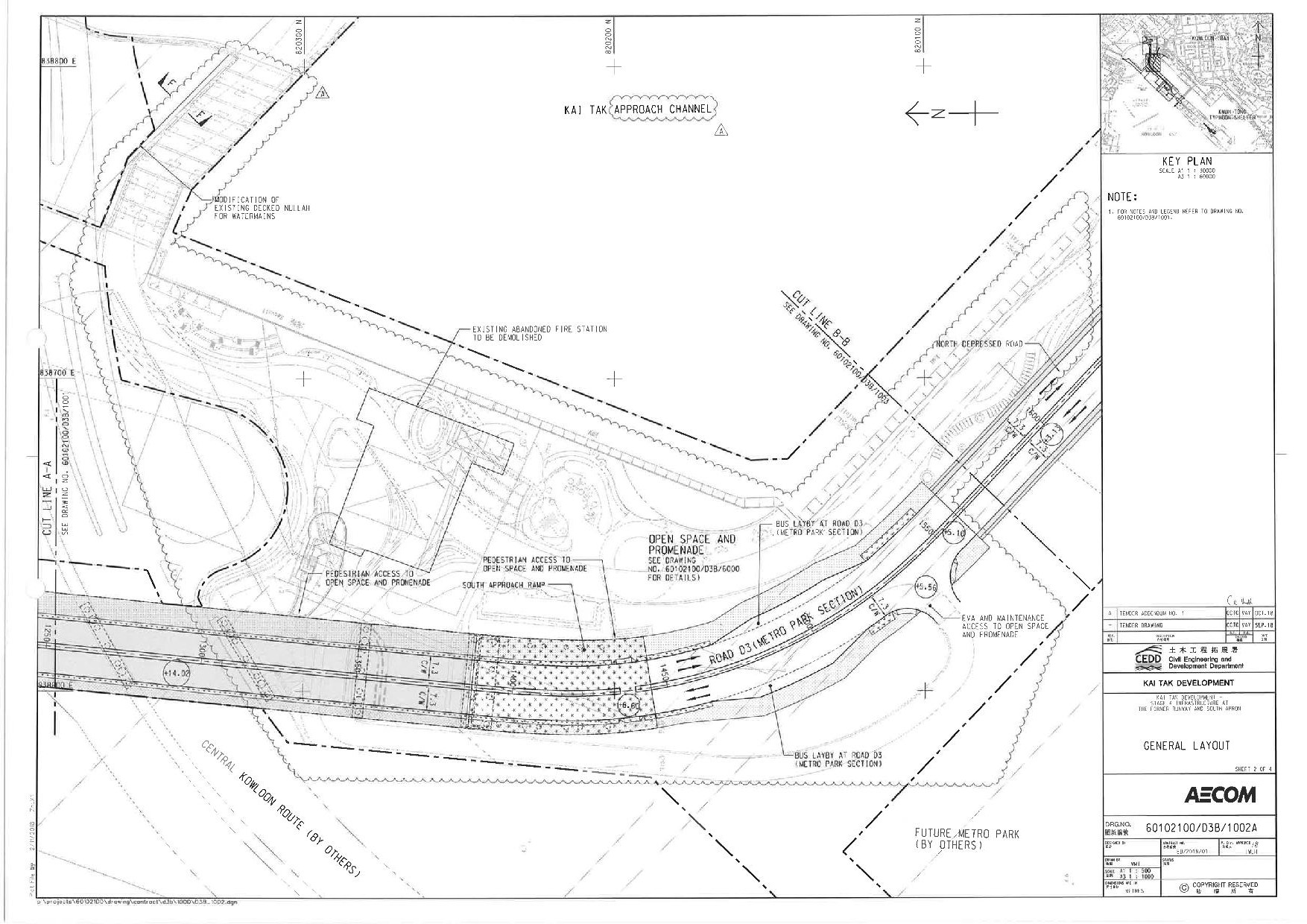

The scope of the works include

:

(i)

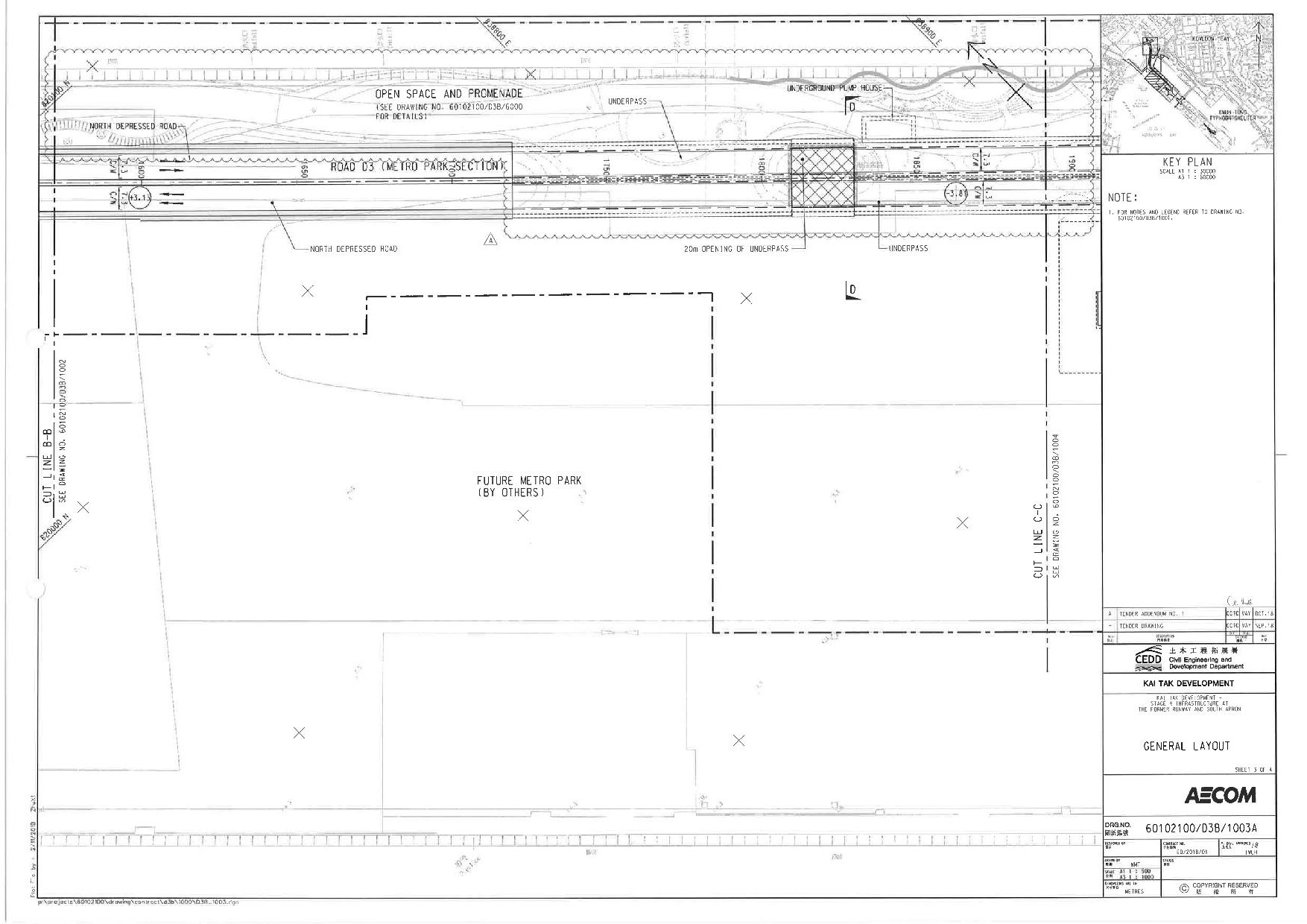

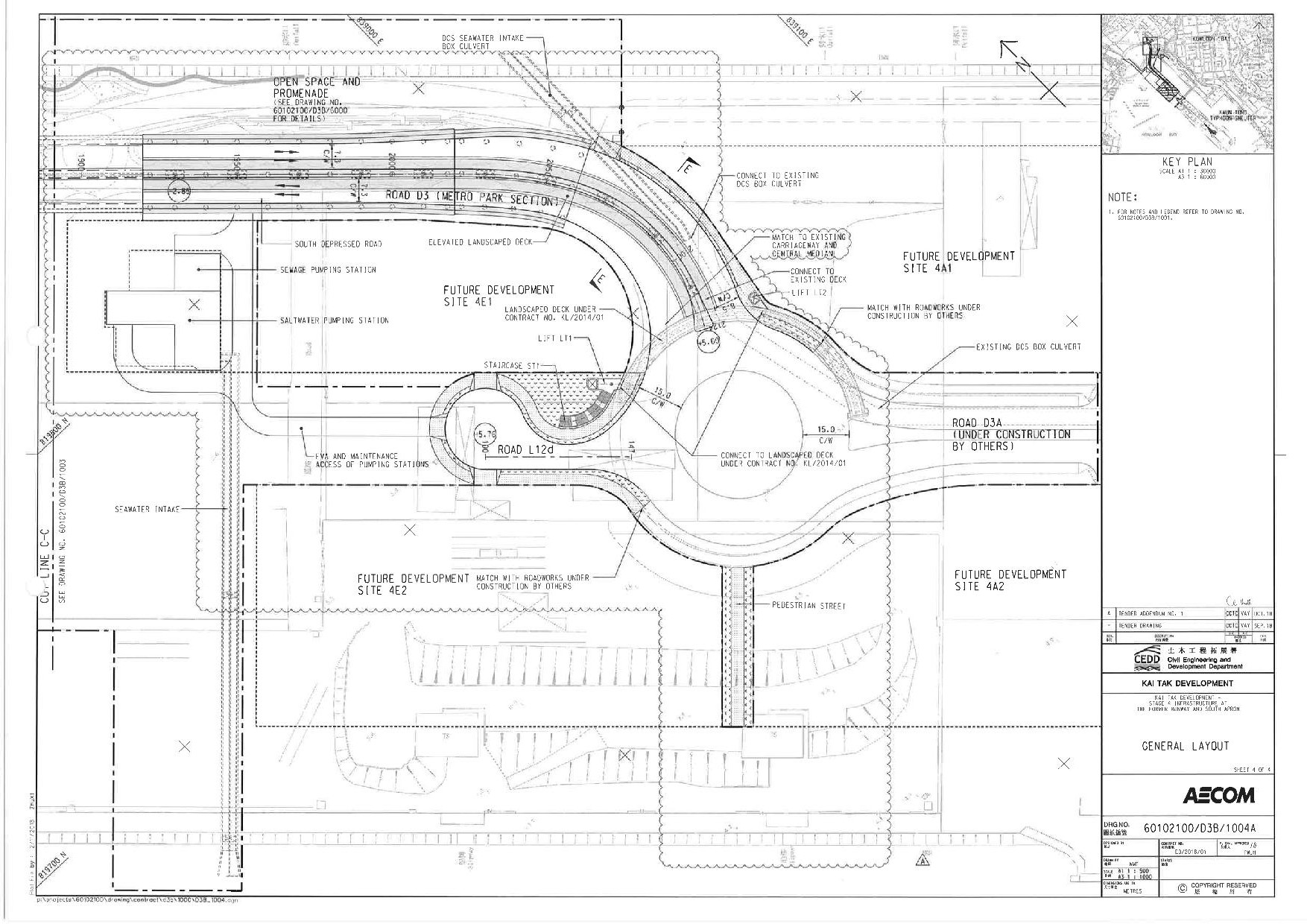

Construction of a section of dual two-lane Road

D3 (Metro Park Section) (MPS) of about 1,130 metres

(m) long connecting Road D2 at the former north apron and Road D3A at

the

former runway, including about 200m under a section of dual two-lane

Road D3

(Metro Park Section) (MPS) of about 1,130 metres

(m)

long connecting Road D2 at the former north apron and Road D3A at the

former

runway, including 200m underpass with associated 320m depressed road,

360m

elevated road and 250m at grade road;

(ii)

A single two-lane Road L12d of about 47m long

connecting Road D3A at the former runway;

(iii)

A salt water pumping station and associated

water intake;

(iv)

A sewage pumping station; and

(v)

Landscaped deck of about 380m long in total

with a minimum width of about 11m above Road D3 (MPS) and landscaped

area

adjoining Road D3 (MPS) providing a total of about 3.9 hectares of

public open

space.

1.2.2

The scope of the Project comprises

(AEIAR/170-2013):

a)

Construction of approximately 1.5km long dual

2-lanecarriageway along the former runway;

b)

Construction of footpath;

c)

Construction of approximately 1.5km long

landscaped deck above the dual 2-lane carriageway along the former

runway; and

d)

Ancillary works including drains, sewers, fresh

and salt water supply mains, utilities, landscape softwork

and hardworks.

1.3

Purpose

of this Manual (AEIAR/130-2009

and AEIAR/170-2013)

1.3.1

The

purpose of this

Environmental Monitoring

and Audit

(EM&A) Manual is to guide

the set up of

an EM&A

programme to ensure compliance

with the

EIA study

recommendations, to assess

the effectiveness of

the recommended mitigation measures and

to

identify any

further need for additional mitigation

measures or remedial

action. This Manual

outlines the

monitoring and audit programme for

the proposed Project. It aims

to provide systematic procedures

for monitoring, auditing and

minimising environmental impacts

associated with Project activities.

1.3.2

Hong

Kong environmental regulations and the Hong Kong

Planning Standards and Guidelines

have served as environmental

standards and

guidelines in the preparation

of this

Manual. In addition,

the EM&A Manual

has been

prepared in accordance

with the

requirements stipulated in Annex

21 of the

EIAO-TM.

1.3.3

This

Manual contains the following

information:

l

Responsibilities

of the Contractor, the Project Manager or Supervisor, Environmental

Team (ET)

and Independent Environmental Checker (IEC) with respect to the

environmental

monitoring and audit requirements during the course of the Project;

l

Project organisation;

l

The basis

for, and description of the broad approach underlying the EM&A

programme;

l

Requirements

with respect to the construction programme schedule and the necessary

environmental monitoring and audit programme to track the varying

environmental

impact;

l

Details of

the methodologies to be adopted, including all field laboratories and

analytical procedures, and details on quality assurance and quality

control

programme;

l

The

rationale on which the environmental monitoring data will be evaluated

and

interpreted;

l

Definition

of Action and Limit Levels;

l

Establishment

of Event and Action Plans;

l

Requirements

for reviewing pollution sources and working procedures required in the

event of

non-compliance with the environmental criteria and complaints;

l

Requirements

for presentation of environmental monitoring and audit data and

appropriate

reporting procedures; and

l

Requirements

for review of EIA predictions and the effectiveness of the mitigation

measures

/ environmental management systems and the EM&A programme.

1.3.4

For

the purpose of this manual, the ET leader, who shall be responsible

for and in

charge of the ET, shall refer to the person delegated the role of executing

the EM&A requirements.

1.4

Project

Organization (AEIAR/130-2009

and AEIAR/170-2013)

1.4.1

The

roles and responsibilities of the various parties involved in the EM&A process are outlined

in

the following

paragraphs. The

proposed Project organization and

lines of communication with

respect to environmental management for

the Project

are shown

in Figure

1.3 (Figure 1.2 of (AEIAR/170-2013).

Figure 1.3 Project

Organisation

1.4.2

The

duties and responsibilities of respective parties are as follows:

The Contractor

1.4.3

The

Contractor shall report to

the Engineer.

The duties and responsibilities

of

the Contractor are:

l

To provide

assistance to ET in

carrying out monitoring;

l

To submit proposals

on mitigation measures in case of exceedances of Action and

Limit Levels in accordance with the

Event and Action Plans;

l

To implement measures

to reduce impact where Action

and

Limit Levels are exceeded;

l

To implement the corrective

actions instructed by the Engineer;

l

To accompany joint

site inspection undertaken by the ET;

and

l

To adhere to the

procedures for carrying out complaint

investigation.

Environmental Team

1.4.4

The ET Leader and the ET shall

be employed to conduct the EM&A

programme and ensure

the Contractor’s compliance with

the Project’s

environmental

performance requirements

during construction.

The ET

Leader

shall be an independent party from

the Contractor and have relevant

professional

qualifications, or have sufficient

relevant EM&A

experience subject to

the approval

of the Engineer’s

Representative (ER). The ET shall

be led and managed by the ET

leader. The ET

leader shall

possess

at least

7 years

experience in EM&A

and/or environmental

management.

1.4.5

The duties and responsibilities of the ET are:

l

To monitor

various environmental parameters as required in this EM&A

Manual;

l

To analyse the environmental

monitoring and audit data and

review the success of EM&A

programme to cost-effectively confirm

the

adequacy of mitigation

measures

implemented and the validity of the EIA predictions and to identify

any adverse

environmental impacts arising;

l

To carry out

regular site inspection to investigate and audit the Contractors' site

practice, equipment and work methodologies

with

respect to pollution

control and environmental

mitigation, and effect

proactive action to pre-empt problems; carry out

ad hoc site inspections if significant environmental problems

are identified;

l

To audit and prepare monitoring and audit

reports on the environmental monitoring data and site environmental conditions;

l

To report on the environmental monitoring and

audit results to the IEC, Contractor, the ER and EPD or its delegated representative;

l

To recommend suitable mitigation measures to

the Contractor in the case of exceedance

of Action and Limit

Levels in

accordance with the Event and Action Plans;

and

l

To adhere to the procedures for carrying out

complaint investigation.

Engineer or Engineer’s

Representative

1.4.6

The Engineer is responsible for overseeing

the construction

works and

for ensuring that the

works undertaken

by the Contractor in

accordance with the

specification

and contractual

requirements. The duties

and

responsibilities of the

Engineer with respect

to EM&A may

include:

l

Supervising the Contractor’s activities and ensure

that the requirements in the

EM&A Manual are fully complied

with;

l

Informing the Contractor when

action is required to reduce

impacts in accordance with the

Event and Action Plans;

l

Participating in joint site inspection

undertaken by the ET; and

l

Adhering to the procedures for carrying out

complaint investigation.

Independent

Environmental Checker

1.4.7

The Independent

Environmental Checker (IEC) shall advise the Engineer’s Representative

on

environmental issues related to the Project. The IEC shall possess at

least 7 years experience in EM&A

and/or environmental

management. The IEC shall be an independent part from the Contractor

and the

ET.

1.4.8

The duties and

responsibilities of the IEC are:

l

To review the EM&A works performed by the

ET (at least at monthly intervals);

l

To carry out random sample check and audit the

monitoring activities and results (at least at monthly intervals);

l

To review the EM&A reports submitted by the

ET;

l

To review the effectiveness of environmental

mitigation measures and project environmental performance;

l

To review the proposal on mitigation measures

submitted by the Contractor in accordance with the Event and Action

Plans; and

l

To adhere to the procedures for carrying out

complaint investigation.

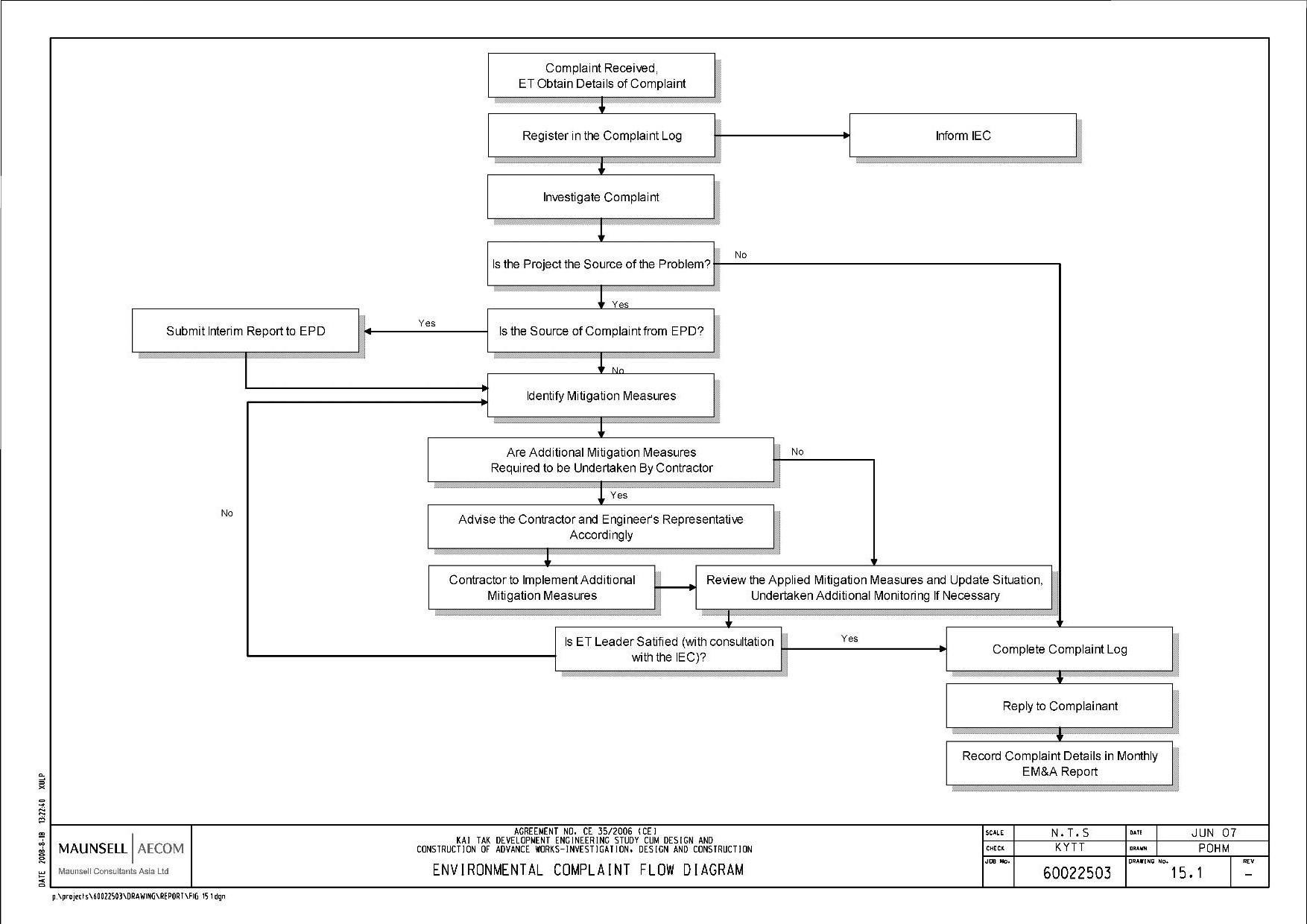

1.4.9

Sufficient and suitably

qualified professional and technical staff shall be employed by the

respective

parties to ensure full compliance with their duties and

responsibilities, as

required under the EM&A programme for the duration of the Project.

1.5

Key Location Plan of contract

ED/2018/01

The key location plan of

this contract is attached in Appendix C.

1.6

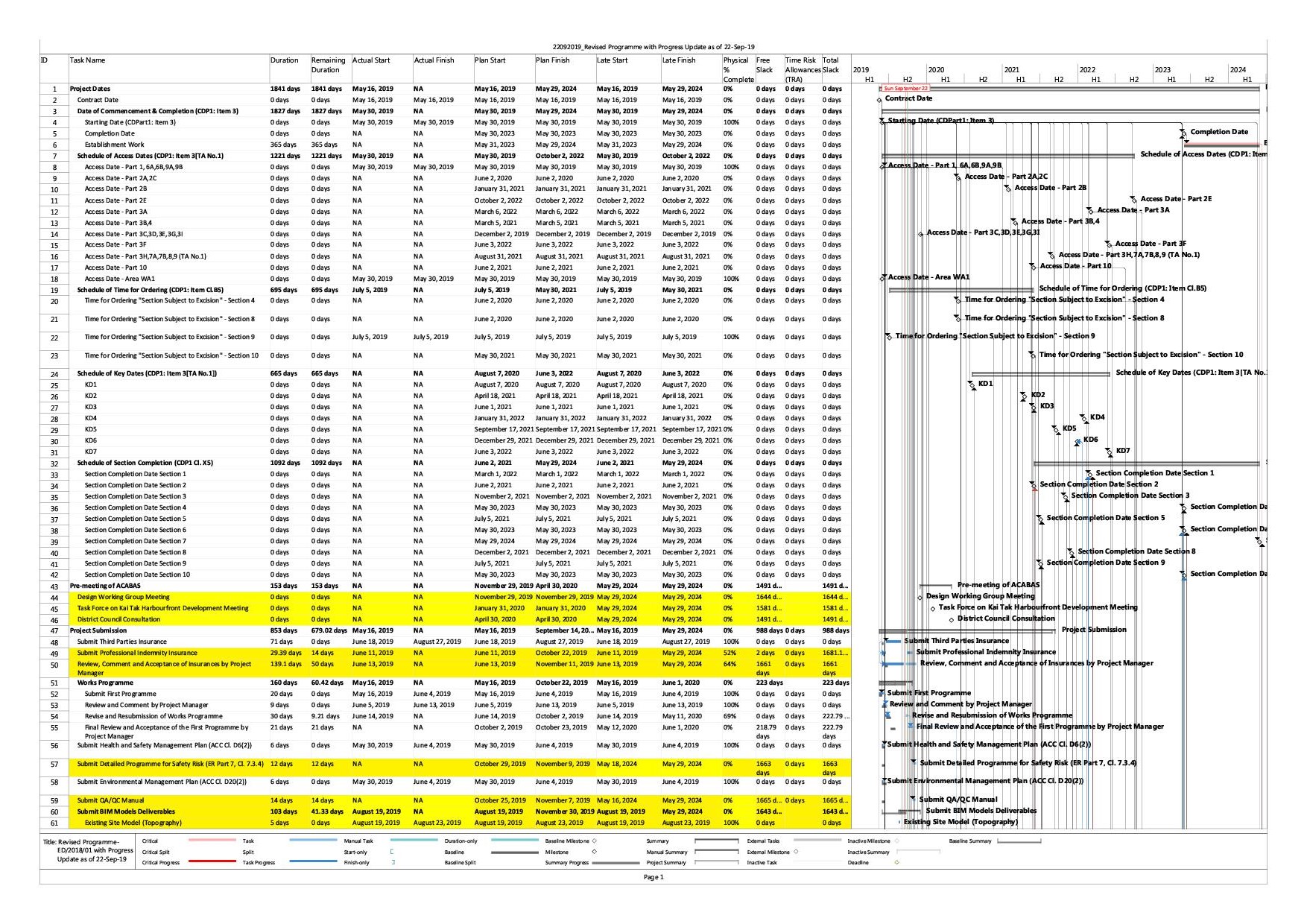

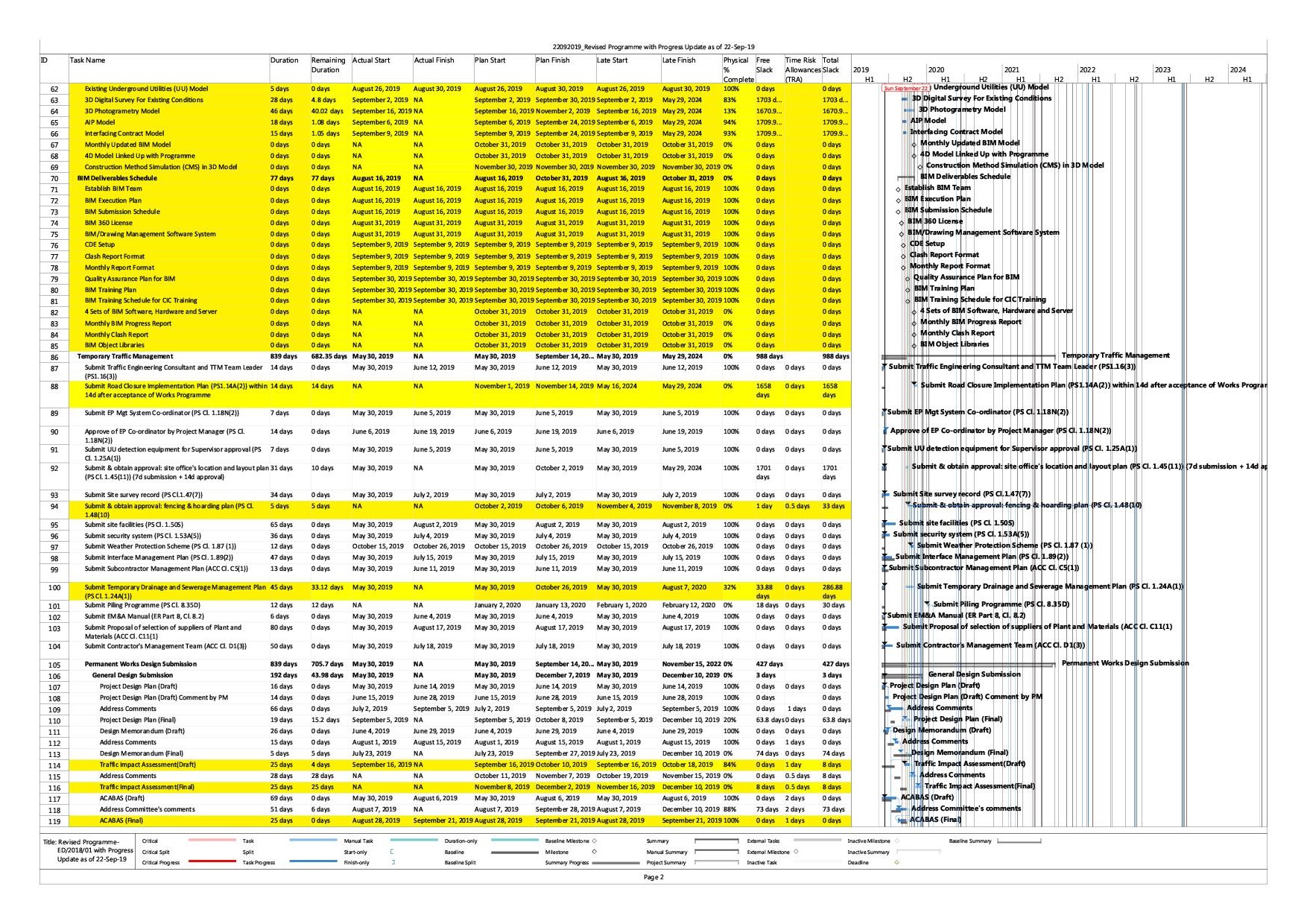

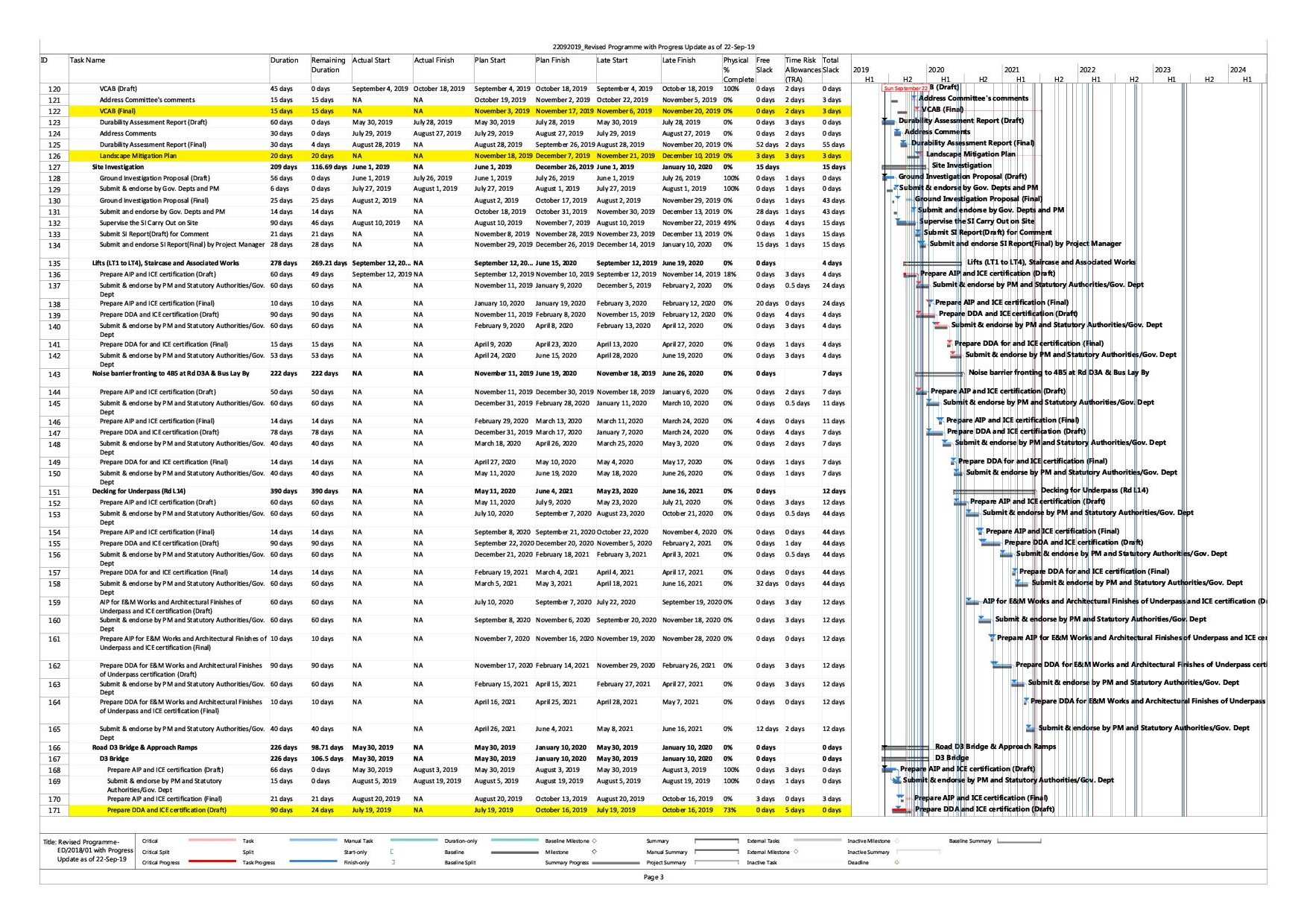

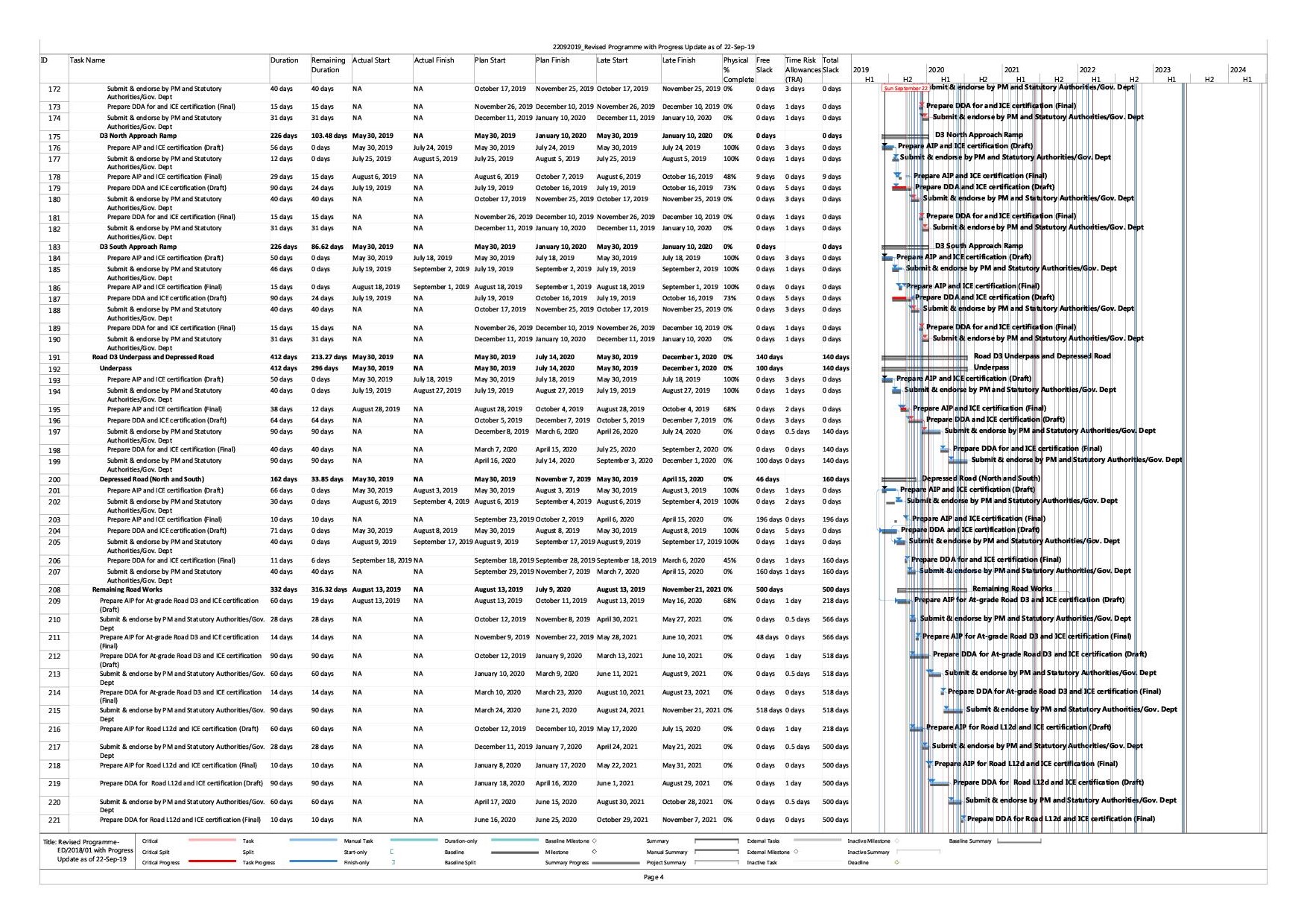

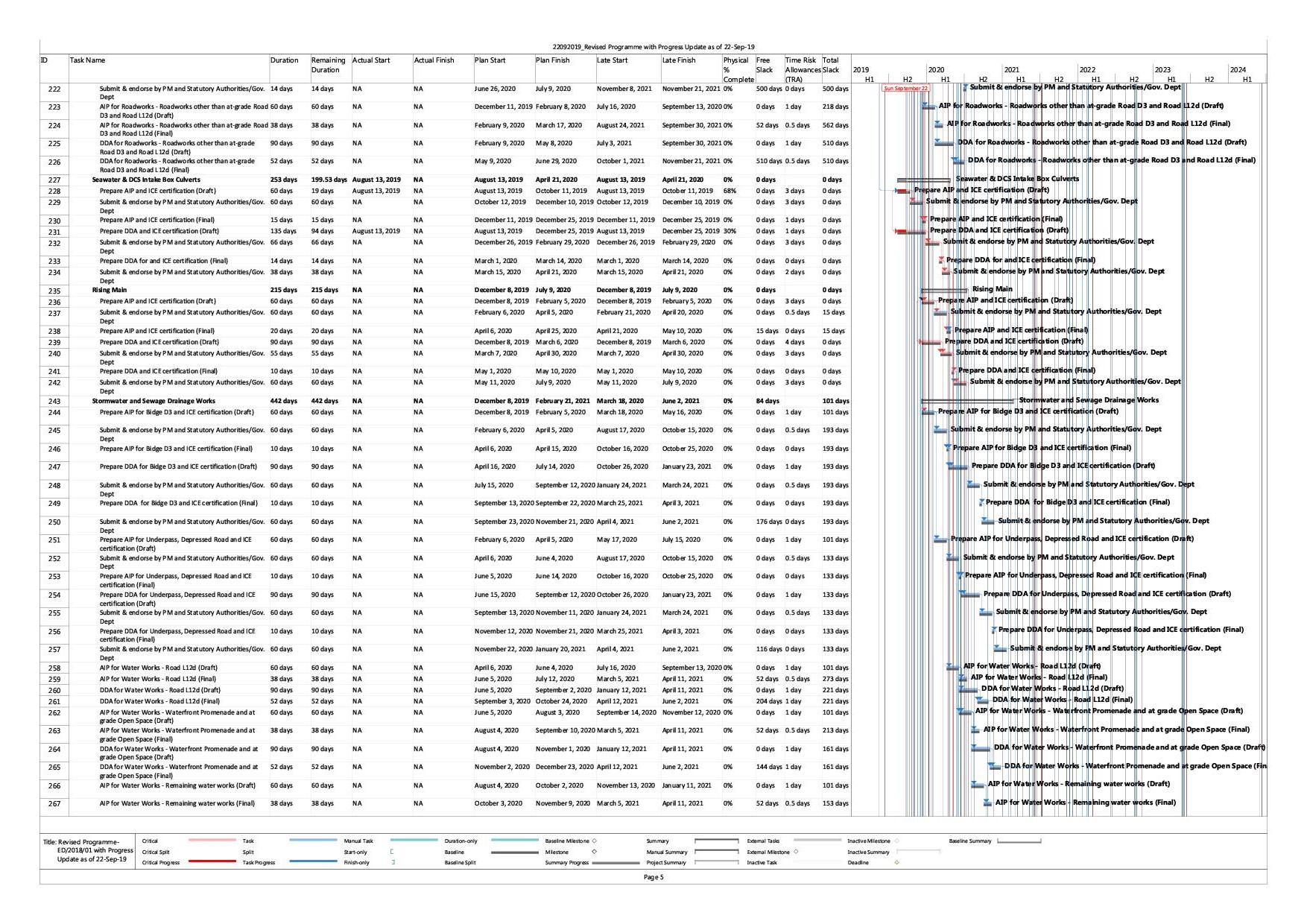

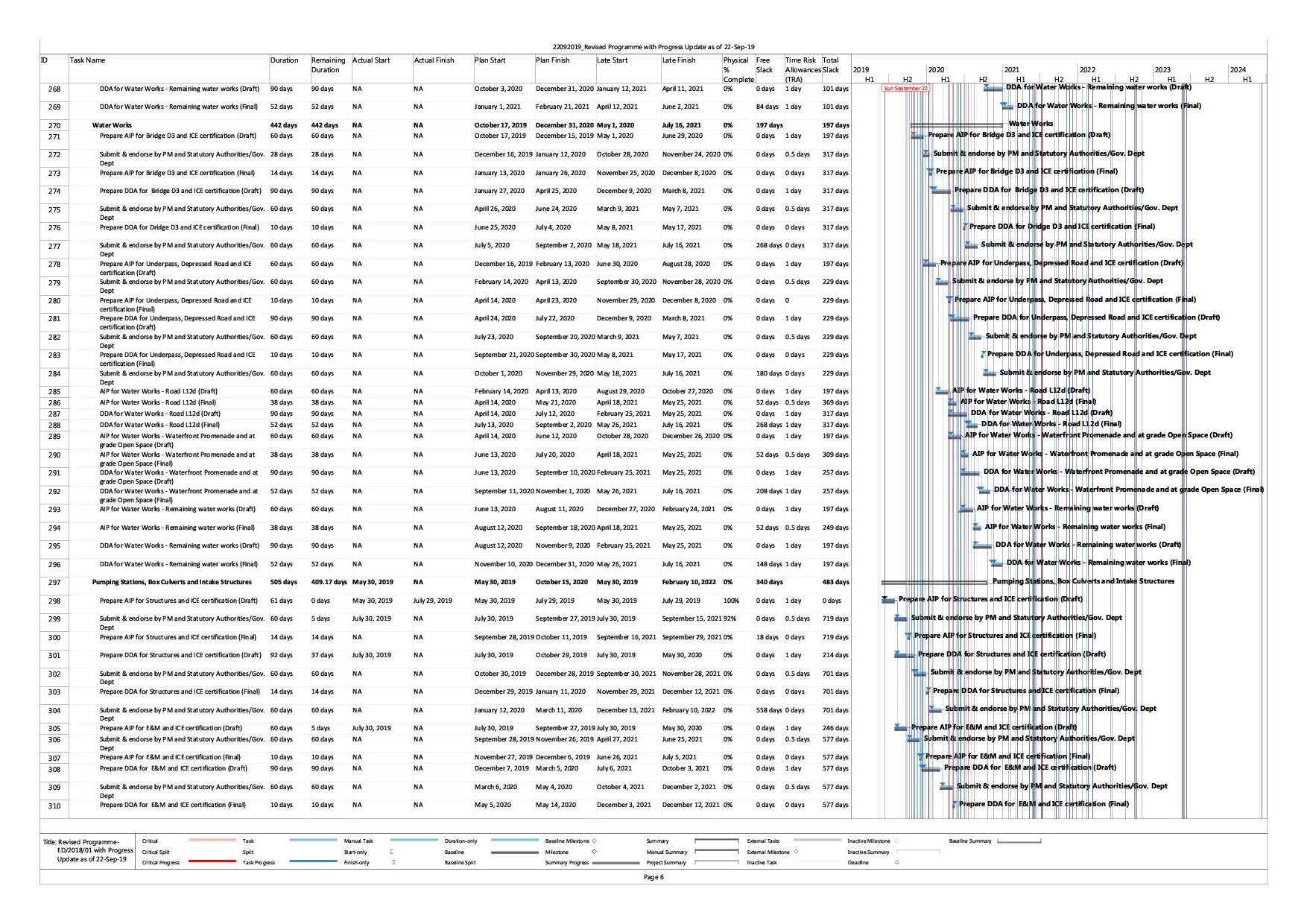

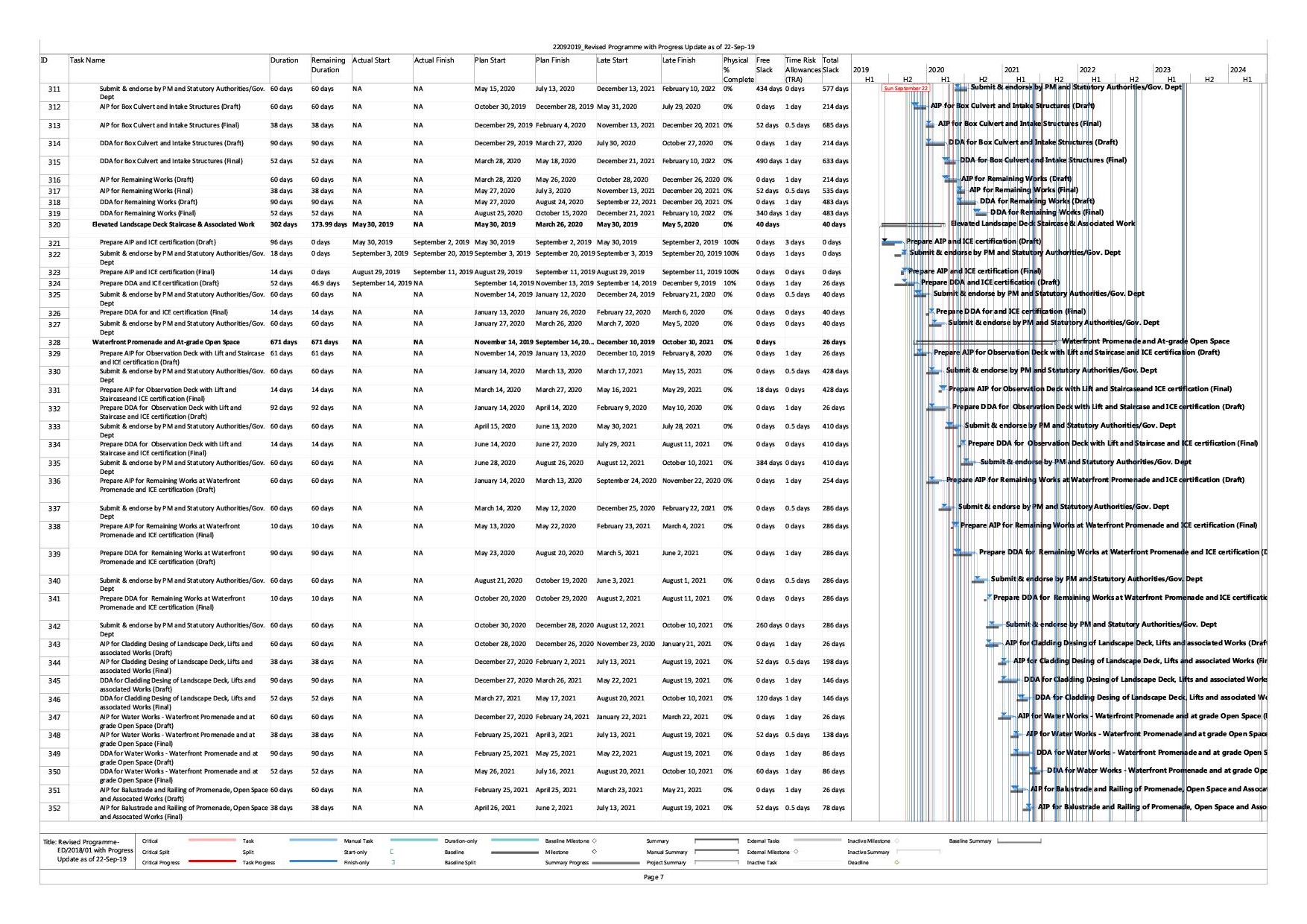

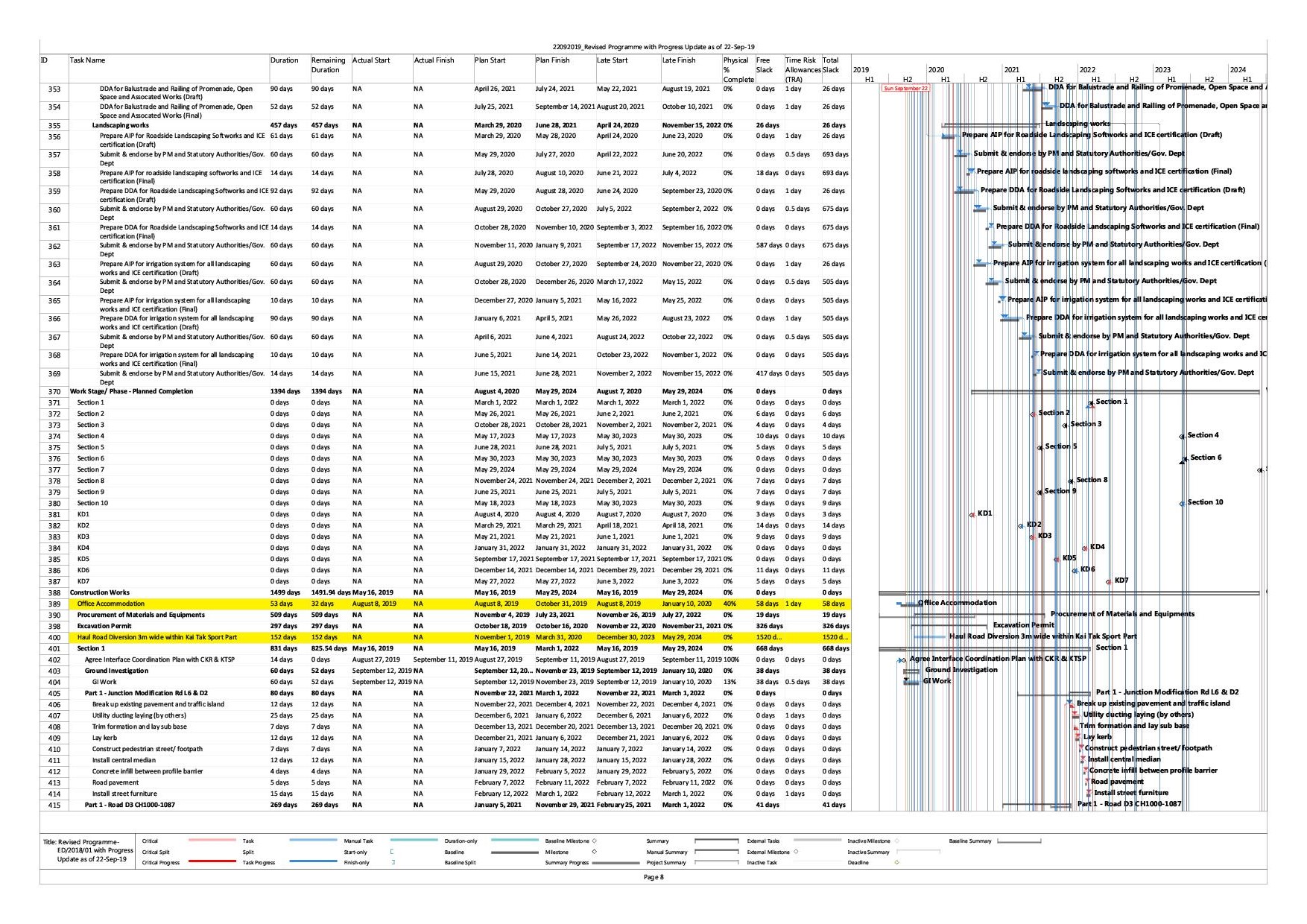

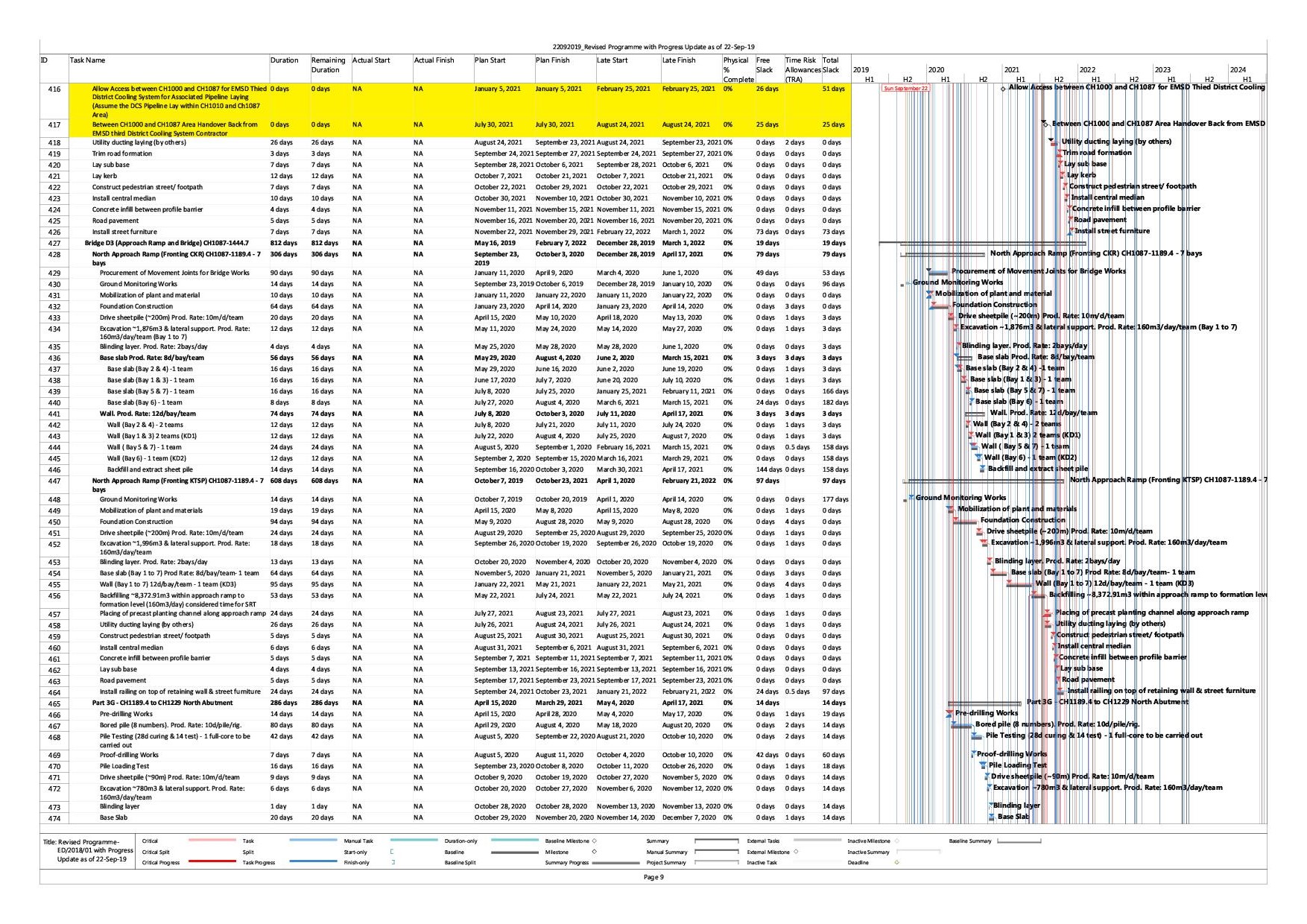

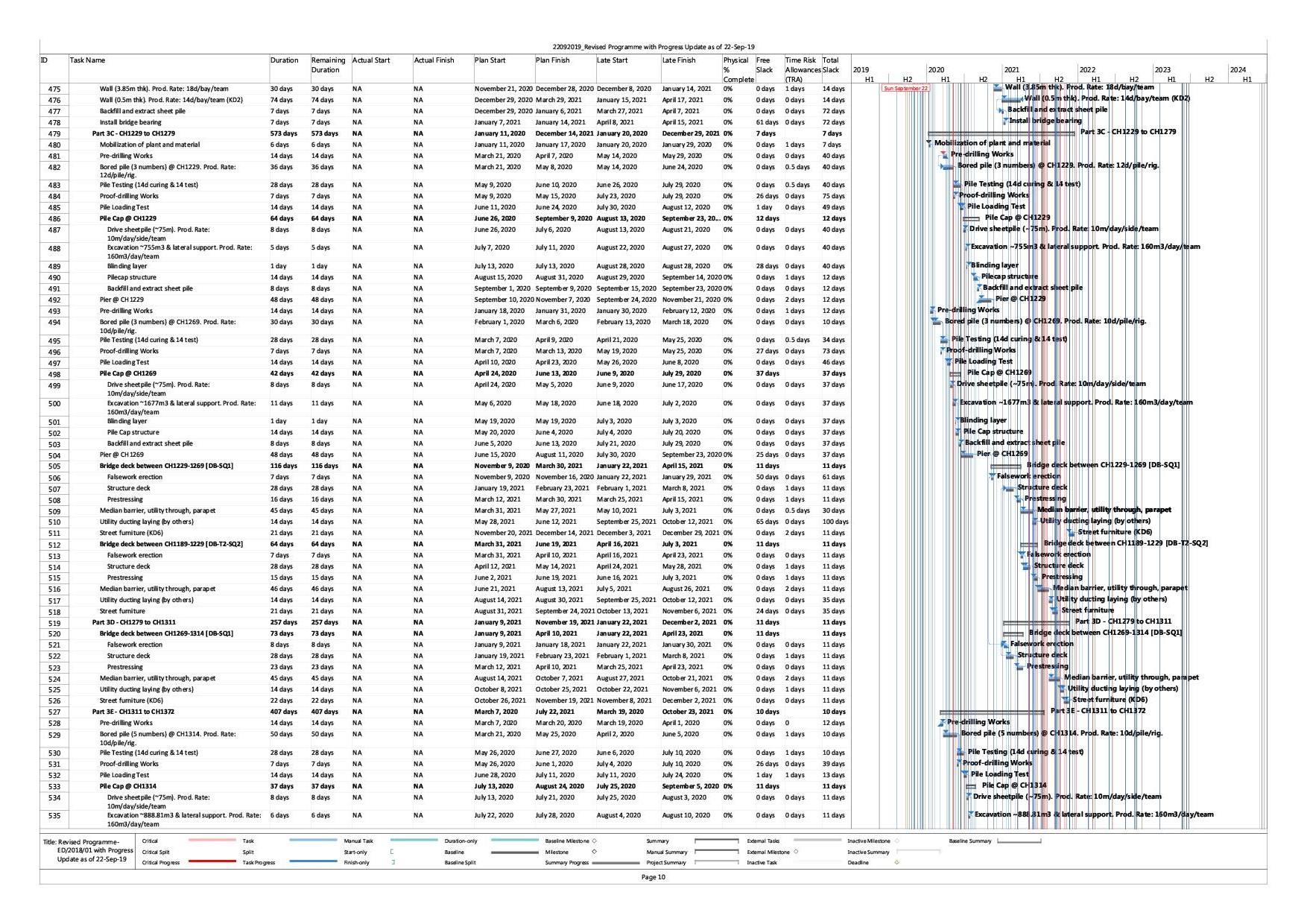

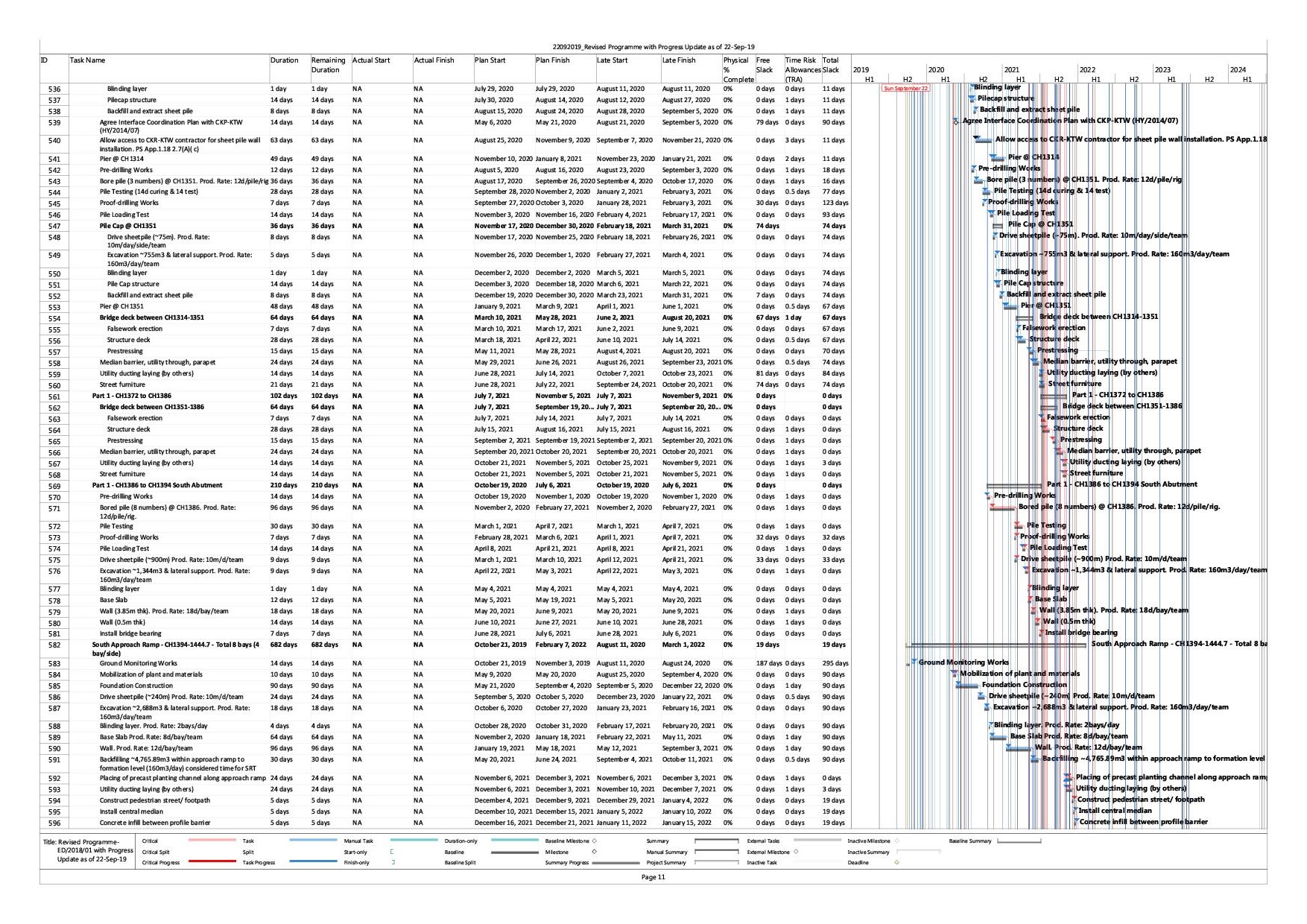

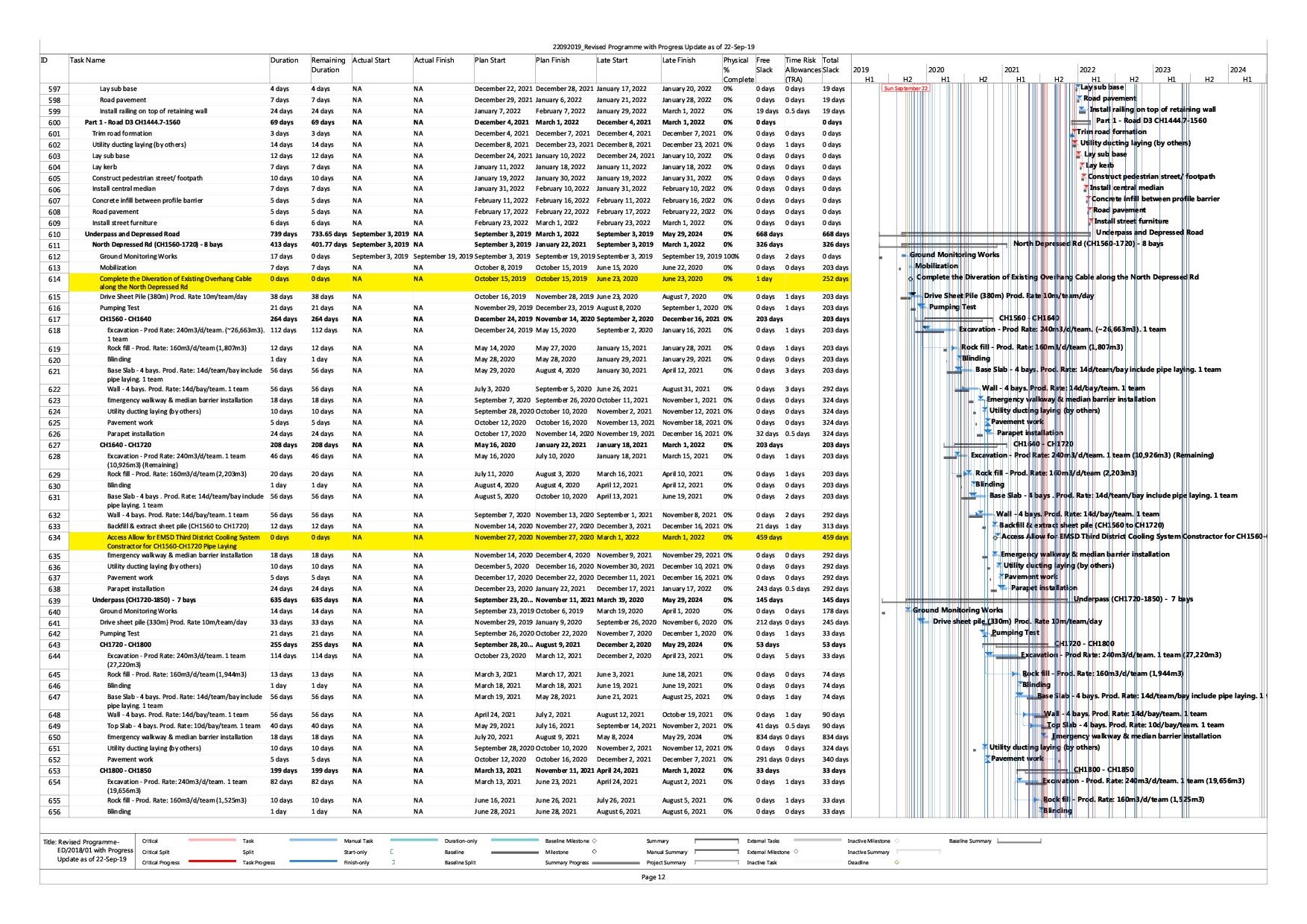

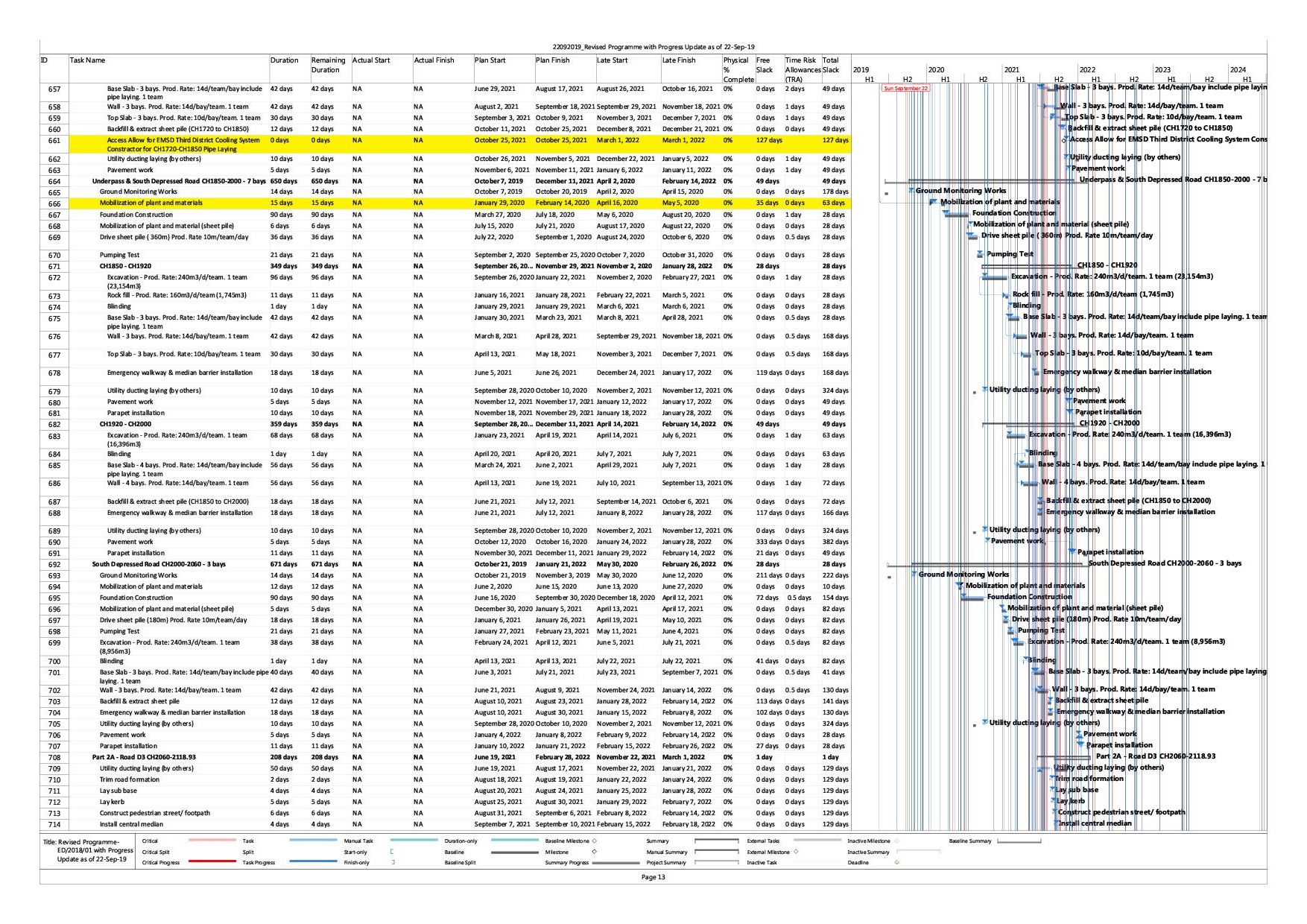

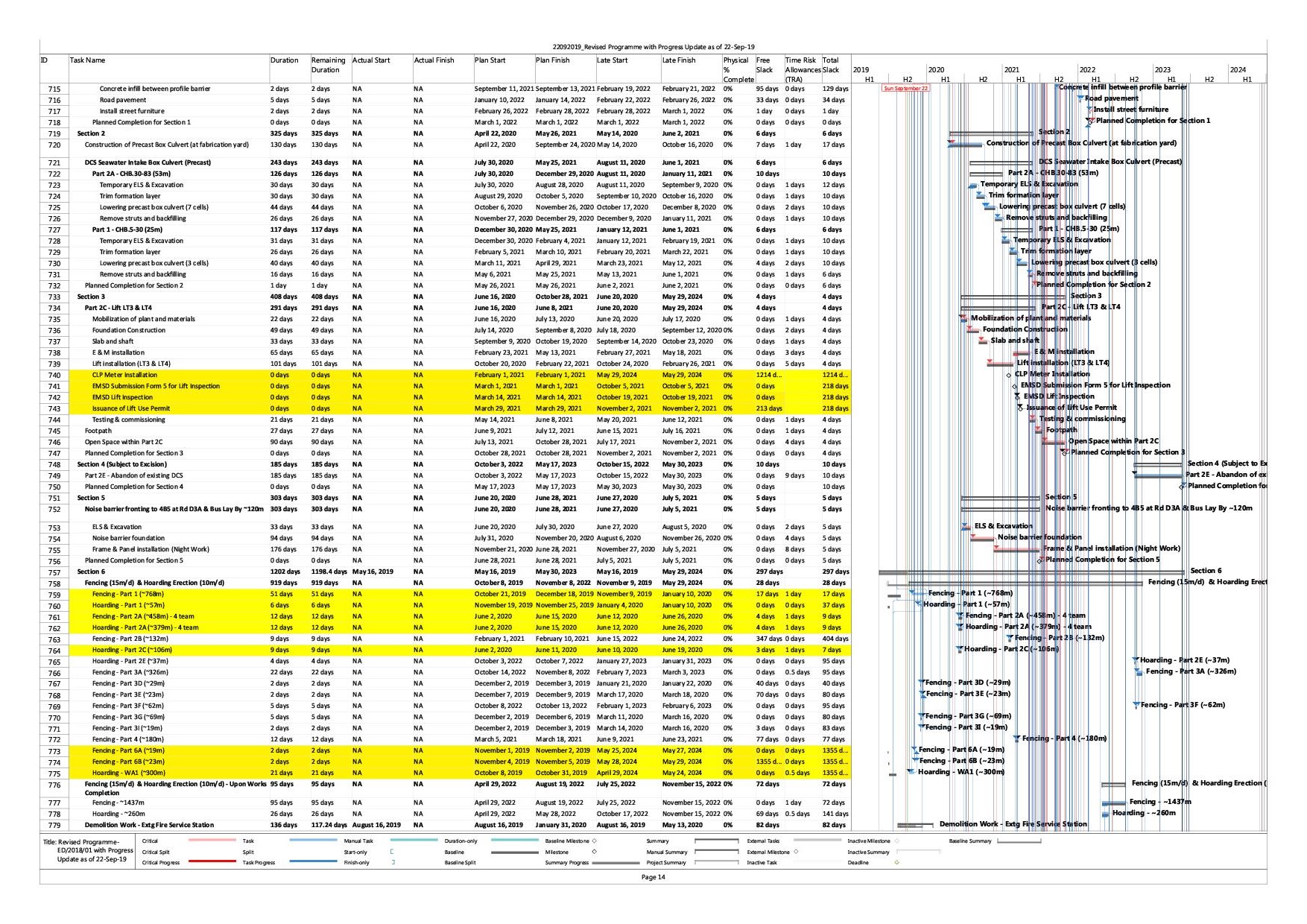

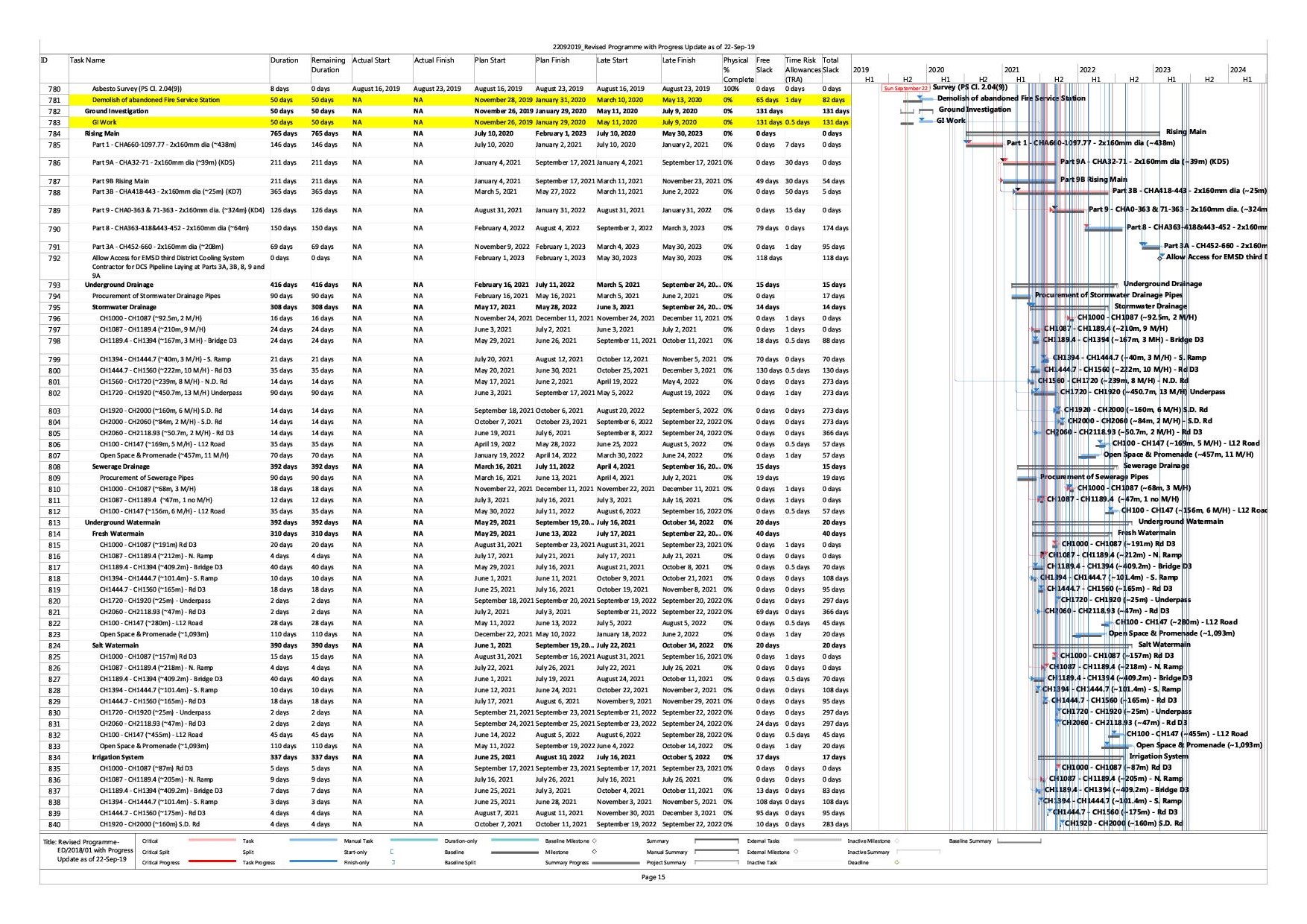

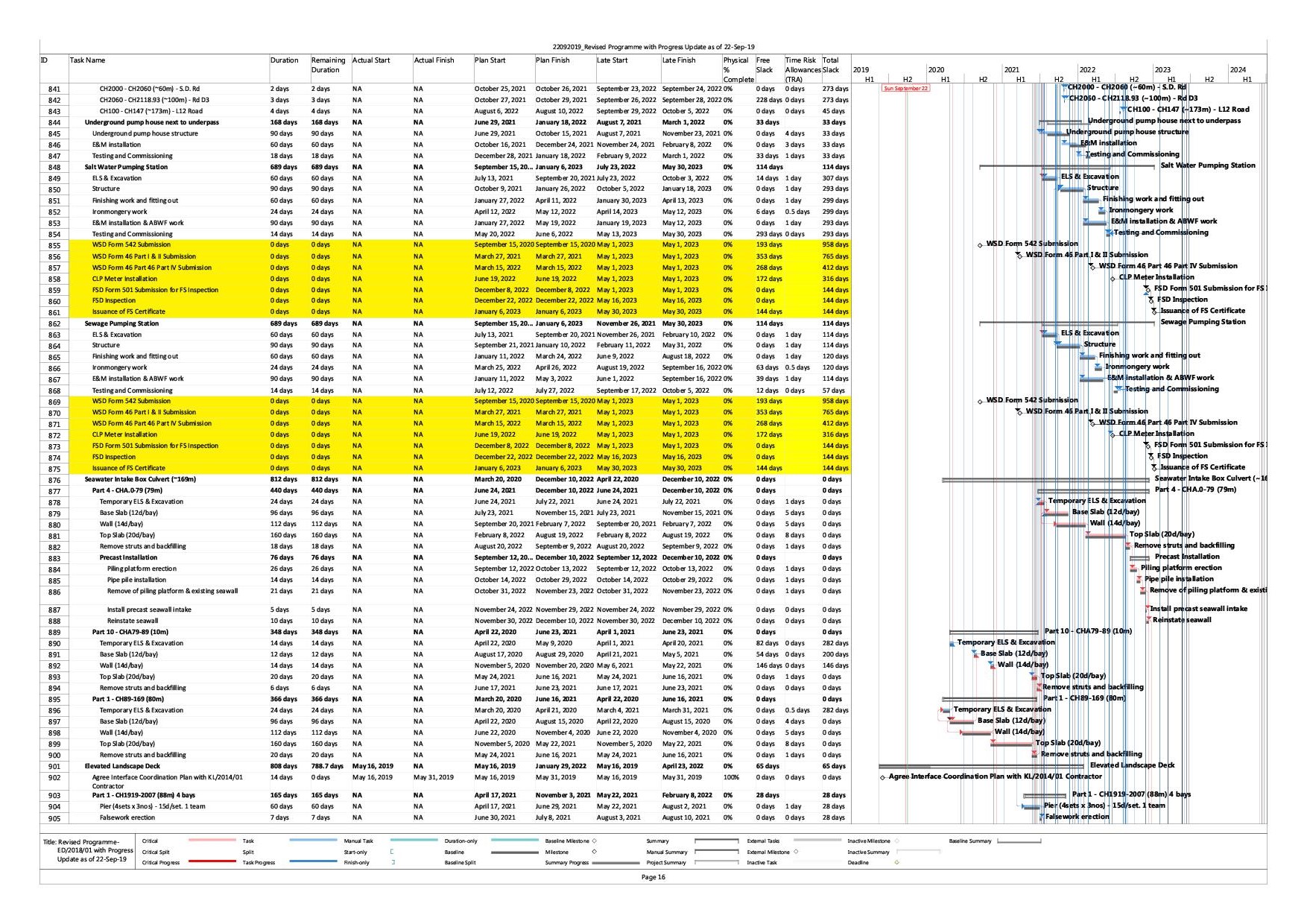

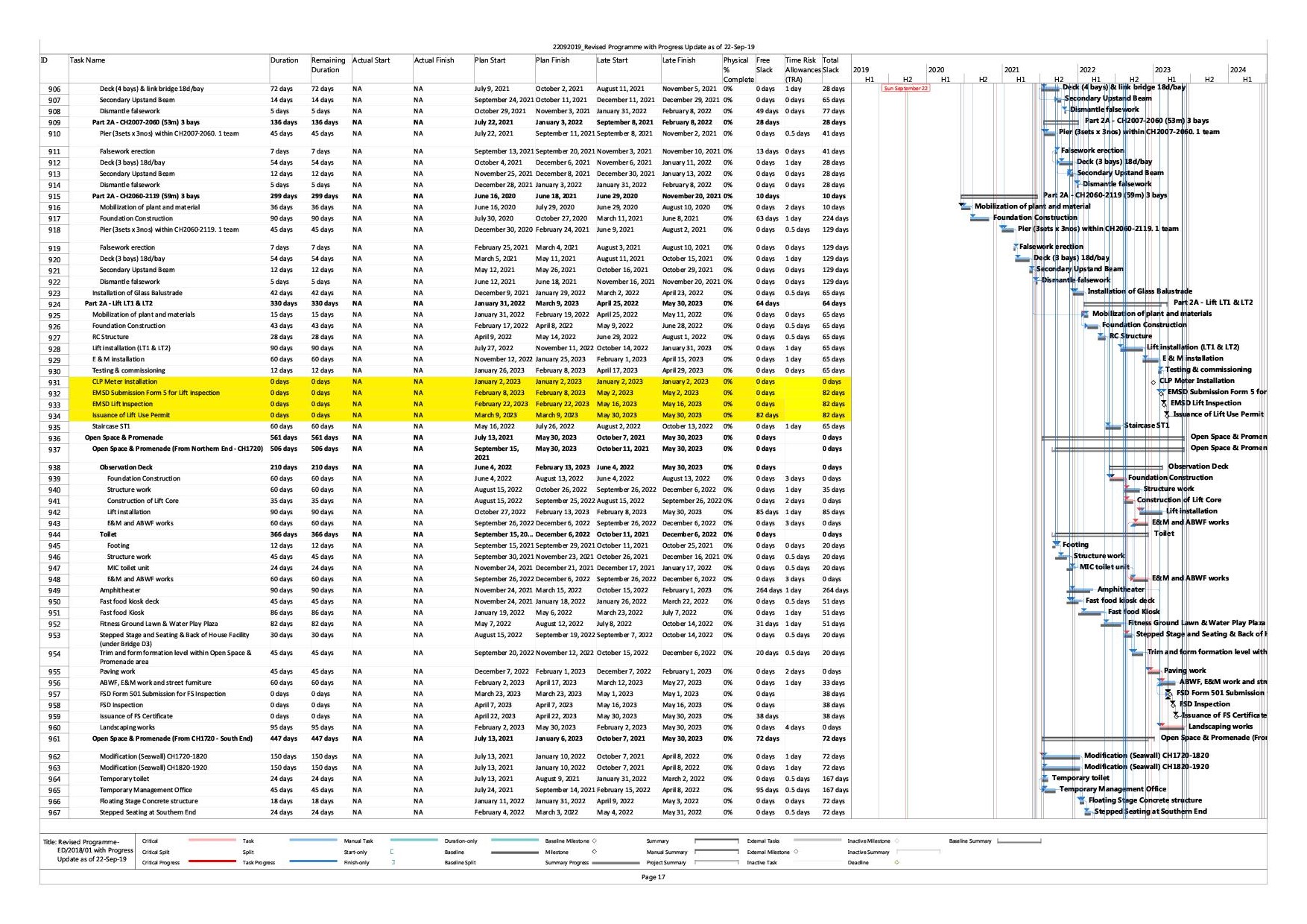

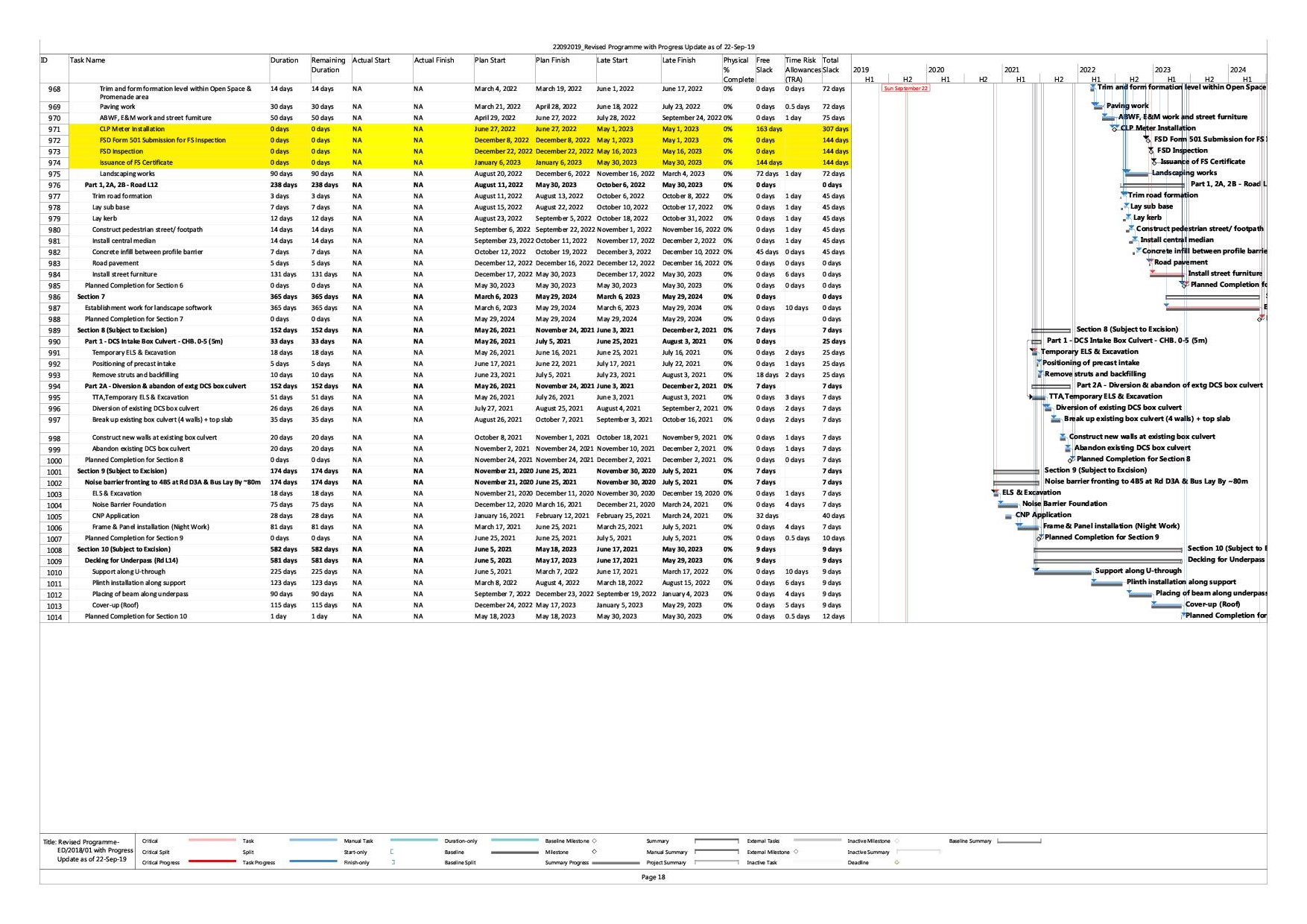

Programme of contract ED/2018/01

The Accepted Programme of

this contract is attached in Appendix D.

1.7

EM&A Programme of Register No.

AEIAR-130/2009

According to Condition 3.1 of the Environmental Permit No.

EP-337/2009, the EM&A Programme shall be implemented in accordance

with the

procedures and requirements as set out in sections 1, 2, 15 & 16

of the

EM&A Manual of the approved EIA Report (Register No.

AEIAR-130/2009),

therefore Sections 3 to 14 of the Kai Tak

Development

EM&A Manual are not applicable to this contract.

1.8

EM&A Programme of Register No.

AEIAR-170/2013

According

to

Condition 3.1 of the EM&A Manual with Register No. AEIAR-170/2013

under Environmental

Permit Nos. EP-445/2013 & EP-445/2013/A respectively, the EM&A

Programme shall be implemented in accordance with the procedures and

requirements as set out in the EM&A Manual. We considered section

6 is

relevant to the Project

and thus we

incorporate this section in the EM&A Manual.

2.1

Introduction

2.1.1

This section details the

specific EM&A requirements for Schedule 2 DP1: New Distributor

Roads

Serving the Planned KTD. The requirements, methodology, equipment,

monitoring

locations, criteria and protocols for the monitoring and audit of this DP are presented. The

project

organisation, site environmental audit and reporting requirements are

stipulated in Chapters 1, 15 & 16 of this Manual respectively.

2.2

Air

Quality Impact

2.2.1

Monitoring and audit of

the TSP levels shall be carried out during the construction phase by

the ET to

ensure that any deteriorating air quality could be readily detected

and timely

action taken to rectify the situation.

2.2.2

1-hour and 24-hour average

TSP levels shall be measured to indicate the impacts of construction

dust on

air quality. The 24-hour average TSP levels shall be measured by

following the

standard high volume sampling method as

set out in the

Title 40 of the United States Code of Federal Regulations, Chapter 1

(Part 50),

Appendix B. Upon agreement from the Engineer’s Representative (ER) and

the IEC,

1-hour average TSP levels can be measured by direct reading methods to

indicate

short-term impacts.

2.2.3

All relevant data

including temperature, pressure, weather conditions, elapsed-time

meter reading

for the start and stop of the sampler, identification and weight of

the filter

paper, other local atmospheric factors affecting or affected by site

conditions

and work progress of the concerned site etc. shall be recorded in

detail. A sample data record sheet based

on the

one presented in the EM&A Guidelines for Development Projects in

Hong Kong

is shown in Appendix B. The ET Leader may modify the data record sheet

for this

EM&A programme, of which the format should be agreed by the ER and

the IEC.

Monitoring Equipment

2.2.4

High volume samplers

(HVSs) in compliance with the following specifications shall be used

for

carrying out the 1-hour and 24-hour TSP monitoring:

•

0.6 - 1.7 m3

per minute (20 - 60 standard cubic feet per minute) adjustable flow range;

•

Equipped with a

timing / control device with ± 5 minutes accuracy for 24 hours

operation;

•

Installed with

elapsed-time meter with ± 2 minutes accuracy for 24 hours

operation;

•

Capable of providing

a minimum exposed area of 406 cm2 ;

•

Flow control

accuracy: ± 2.5% deviation over 24-hour sampling

period;

•

Equipped with a

shelter to protect the filter and

sampler;

•

Incorporated with an

electronic mass flow rate controller or other equivalent

devices;

•

Equipped with a flow

recorder for continuous monitoring;

•

Provided with a

peaked roof

inlet;

•

Incorporated with a

manometer;

•

Able to hold and seal

the filter paper to the sampler housing

at

horizontal position;

•

Easy to change the

filter;

•

Capable of operating

continuously for 24-hour period.

2.2.5

The ET shall be

responsible for the provision of the monitoring equipment. The ET shall provide

sufficient number of

HVSs with appropriate calibration kit for carrying out the baseline,

regular

impacts monitoring and ad-hoc monitoring. The HVSs shall be equipped

with an

electronic mass flow controller and be calibrated against a traceable

standard

at regular intervals. All the equipment, calibration kit, filter

papers, etc, shall be clearly labelled.

2.2.6

Initial calibration of the

dust monitoring equipment shall be conducted upon installation and

prior to commissioning,

and at bi-monthly intervals subsequently. The transfer standard shall be traceable to the internationally recognised

primary standard and be calibrated annually. The calibration data

shall be

properly documented for future reference by the concerned parties such

as the

IEC. All the data shall be converted into standard temperature and

pressure

condition.

2.2.7

The flow-rate of the

sampler before and after the sampling exercise with the filter in

position

shall be verified to be constant and be recorded on the data sheet as

shown in Appendix

B.

2.2.8

If the ET proposes to

use a direct reading dust meter to measure 1-hour average TSP levels,

he/she

shall submit sufficient information to the ER and the IEC to prove

that the

instrument is capable of achieving

a comparable result as that of

the

HVS before it may be used for

the monitoring works. The

instrument shall also be

calibrated

regularly, and the 1-hour sampling

shall

be determined periodically by HVS to check

the validity and accuracy of

the

results measured by direct reading

method.

2.2.9

Wind data monitoring

equipment shall also be

provided by the ET and set

up at conspicuous locations for logging wind speed

and wind direction near

to

the dust monitoring

locations. The equipment

installation location shall be proposed by the ET

and agreed with the ER in consultation with the IEC. For

installation and operation of

wind

data monitoring equipment, the following points shall be

observed:

(i)

The

wind sensors shall be

installed 10m above ground so that they are

clear of

obstructions or turbulence caused by the

buildings;

(ii)

The

wind data shall be captured by a data logger. The

data shall be downloaded for analysis at least once a

month;

(iii)

The

wind data monitoring equipment shall be re-calibrated at least once

every six months; and

(iv)

Wind

direction should be divided into 16 sectors of 22.5 degrees

each.

2.2.10

In exceptional

situations, the ET may propose alternative methods to obtain

representative

wind data

upon approval from the ER and agreement from the

IEC.

Laboratory Measurement

/ Analysis

2.2.11

A clean laboratory with

constant temperature and humidity

control and equipped with necessary measuring and conditioning

instruments to

handle the dust samples

collected,

shall be available for sample analysis, and equipment calibration and

maintenance. The laboratory shall be HOKLAS accredited or other

internationally

accredited laboratory.

2.2.12

If a site laboratory

is set up or a

non-HOKLAS accredited

laboratory is hired for carrying out

the

laboratory analysis, the laboratory equipment shall be approved by the

IEC.

Measurement performed by the laboratory shall be demonstrated to the

satisfaction of the

IEC.

2.2.13

The IEC shall conduct

regular audit of the

measurement

performed by the laboratory so

as to

ensure the accuracy of measurement

results.

The ET shall provide

the ER

and the IEC with one copy of the Title 40 of

the Code of Federal

Regulations,

Chapter 1 (Part 50), Appendix B for their

reference.

2.2.14

Filter paper of size

8"x10" shall be labelled before sampling. It shall be a clean filter

paper with no pinholes, and shall be conditioned in a

humidity-controlled

chamber for over 24-hour and be pre-weighed before use for the

sampling.

2.2.15

After sampling, the

filter paper loaded with dust shall be kept in a clean and tightly

sealed bag.

The filter paper shall then be returned to the laboratory for

reconditioning in

the humidity-controlled chamber followed by accurate weighing by an

electronic

balance with a readout down to 0.1mg. The balance shall be regularly

calibrated

against a traceable standard.

2.2.16

All the collected samples shall be kept in a

good condition for 6 months before

disposal.

Monitoring

Locations

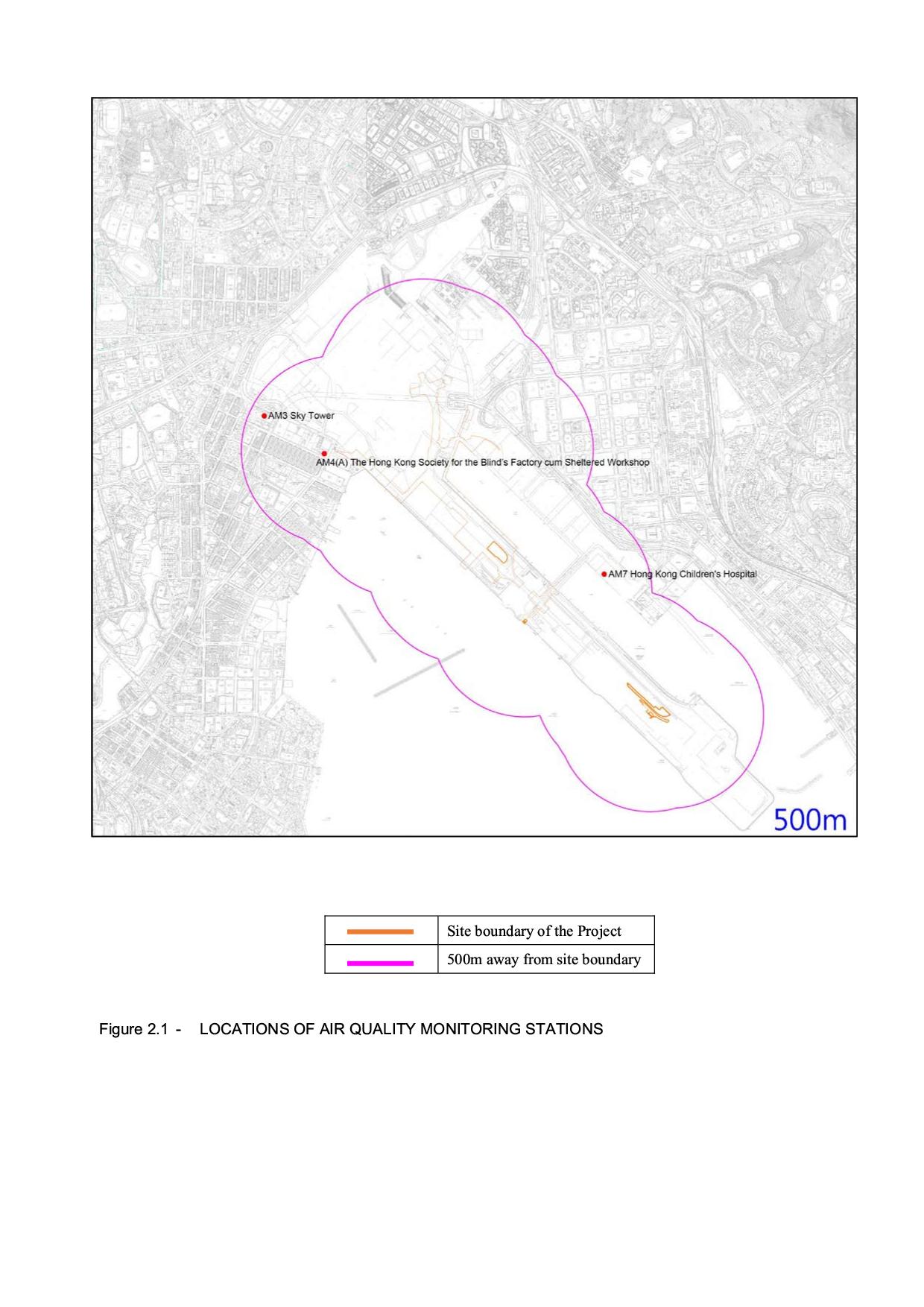

2.2.17

The dust monitoring

locations

are shown in Figure

2.1. The selected monitoring

locations are the ASRs located near to the construction site(s) of

this DP. The

proposed air quality monitoring locations are listed in Table

2.1 below.

Table 2.1 Air Quality Monitoring Locations

|

Location

|

ASR

ID in EIA

|

Description

|

|

AM3

|

A40

|

Sky

Tower

|

|

AM4(A)

|

A43

|

The

Hong Kong Society for the Blind’s Factory cum Sheltered

Workshop

|

|

AM7

|

PA59

|

Hong

Kong Children’s Hospital

|

2.2.18

The status and locations of the ASRs

may change after issuing this Manual.

The ET shall propose

updated

monitoring locations and seek approval from EPD, and agreement from

the ER and

the IEC before baseline monitoring

commences.

2.2.19

When alternative monitoring locations are

proposed, the following criteria, as far as practicable, shall

be

followed:

(i)

At the site boundary or such

locations close to

the

major dust emission source;

(ii)

Close to the ASRs;

(iii)

Proper

position/sitting and orientation of

the

monitoring equipment; and

(iv)

Take into

account the prevailing meteorological

conditions.

2.2.20

The ET shall

agree with the ER on the position of

the

HVS for installation of the

monitoring

equipment. When positioning the samplers, the following points shall

be noted:

(i)

A horizontal platform

with appropriate support

to

secure the samplers against gusty wind shall be

provided;

(ii)

No two samplers

shall

be placed less than 2 metres apart;

(iii)

The distance between

the sampler and an obstacle, such

as

buildings, must be at least twice the height that the obstacle

protrudes above

the sampler;

(iv)

A minimum of

2 metres of

separation from walls, parapets and penthouses is required for

rooftop samplers;

(v)

A minimum of 2 metres

of separation from any supporting structure, measured horizontally is

required;

(vi)

No furnace or incinerator flue is nearby;

(vii)

Airflow around the sampler is unrestricted;

(viii)

The sampler is more than 20 metres

from the dripline;

(ix)

Any wire fence and gate, to protect the

sampler, shall not cause any obstruction during monitoring;

(x)

Permission must be obtained to set up the

samplers and to obtain access to the monitoring stations; and

(xi)

A secured supply of electricity is needed to

operate the samplers.

Baseline Monitoring

2.2.21

Baseline monitoring shall be carried out to

determine the ambient 1-hour and 24-hour average TSP levels at the

monitoring

locations prior to the commencement of the construction works. During

the baseline

monitoring, there shall not be any construction or dust generating

activities

in the vicinity of the monitoring stations. The baseline monitoring

will

provide data for the determination of the appropriate Action Levels

with the

Limit Levels set against statutory or otherwise agreed limits.

2.2.22

Before commencing the baseline monitoring, the

ET shall inform the IEC of the baseline monitoring programme such that

the IEC

can conduct on-site audit to ensure accuracy of the baseline

monitoring

results.

2.2.23

Baseline monitoring shall be carried out at all

of the designated monitoring locations for at least 14 consecutive

days prior

to the commissioning of the construction works to obtain daily 24-hour

TSP

samples. One-hour sampling shall also be done at least 3 times per

day.

Baseline monitoring shall be carried out under typical weather

conditions.

General meteorological conditions (wind speed, direction and

precipitation) and

notes regarding any significant adjacent dust producing sources shall

also be

recorded throughout the baseline monitoring period.

2.2.24

In case the baseline monitoring cannot be

carried out at the designated monitoring locations during the baseline

monitoring

period, the ET Leader shall carry out the monitoring at alternative

locations

which can effectively represent the baseline conditions at the impact

monitoring locations. The alternative baseline monitoring location

shall be

approved by the ER and agreed with the IEC.

2.2.25

In exceptional cases, when insufficient

baseline monitoring data or questionable results are obtained, the ET

Leader shall

liaise with the ER, the IEC and EPD to agree on an appropriate set of

data to

be used as a baseline reference and submit to the ER and the IEC for

agreement

and EPD for approval.

2.2.26

Baseline checking of ambient TSP levels shall

be carried out every three months at each monitoring location, when no

dusty

works activities are in operation. If the ET considers that

significant changes

in the ambient conditions have arisen, a repeat of the baseline

monitoring may

be carried out to update the baseline levels. The revised baseline

levels, and

hence the revised Action and Limit Levels, shall be agreed with the

ER, EPD and

the IEC.

Impact Monitoring

2.2.27

The ET shall carry out impact monitoring during

the construction phase of

the DP.

For regular impact monitoring, a sampling frequency of

at least once in every six days shall be strictly observed at

all of the monitoring stations

for 24-hour

TSP monitoring. For 1-hour TSP

monitoring, the sampling frequency of at least three times in every six days shall be

undertaken when the

highest dust impact occurs.

2.2.28

Before commencing the impact

monitoring, the ET shall

inform the

IEC of the impact

monitoring

programme such that the IEC can conduct on-site audit to ensure

accuracy of the

impact monitoring results.

2.2.29

The specific time to start and stop the 24-hour

TSP monitoring shall be clearly defined for each location and

be strictly

followed by the field operator.

2.2.30

In case of non-compliance

with

the Action and Limit Levels, more frequent monitoring, as specified in

the

Event and Action Plan

in Table 2.2,

shall be conducted within 24 hours after the non-compliance is known.

This

additional monitoring shall be continued until the excessive dust

emission or the deterioration in air quality

is rectified.

Event and Action Plan

2.2.31

The baseline monitoring results form the basis

for determining the Action and Limit Levels for the impact monitoring.

The ET

shall compare the impact monitoring results with the Action and Limit

Levels

for 1-hour and 24-hour average TSP. Table

2.2 shows the

Action and Limit

Levels to be used. Should non-compliance of the Action and Limit

Levels occurs, action in accordance with

the Event and Action

Plan in Table 2.3 shall be carried

out.

Table 2.2 Action and Limit Levels for Construction Dust Monitoring

|

Parameter

|

Action

Level (1)

|

Limit

Level

|

|

24-hour

average TSP

|

BL ? 200 μg m-3,

AL = (BL * 1.3 + LL)/2 BL > 200 μg m-3, AL = LL

|

260

μg m-3

|

|

1-hour

average TSP

|

BL ? 384 μg m-3,

AL = (BL * 1.3 + LL)/2 BL > 384 μg m-3, AL = LL

|

500

μg m-3

|

Note:

(1)

BL = Baseline level, AL = Action Level, LL = Limit

Table 2.3

Event

and Action Plan for Construction

Dust Monitoring

|

EVENT

|

ACTION

|

|

ET

|

IEC

|

ER

|

CONTRACTOR

|

|

Action Level being

exceeded by one sampling

|

1.

Identify source and investigate

the causes of exceedance;

2.

Inform Contactor, IEC and

ER;

3.

Repeat measurement to

confirm finding.

|

1.

Check monitoring data

submitted by ET;

2.

Check Contractor’s

working method.

|

1.

Notify Contractor.

|

1.

Rectify any unacceptable

practice;

2.

Amend working methods

if appropriate.

|

|

Action Level being

exceeded by two or more consecutive sampling

|

1.

Identify source and investigate

the causes of exceedance;

2.

Inform Contractor, IEC and

ER;

3.

Increase monitoring frequency

to daily;

4.

Discuss with IEC and

Contractor on remedial actions

required;

5.

Assess the effectiveness of

Contractor’s remedial

actions;

6.

If exceedance continues,

arrange meeting with IEC and

ER;

7.

If exceedance stops,

cease additional

monitoring.

|

1.

Check monitoring data

submitted by ET;

2.

Check Contractor’s

working method;

3.

Discuss with ET and Contractor on possible

remedial measures;

4.

Advise the ER on the

effectiveness of

the proposed remedial measures.

|

1.

Confirm receipt of

notification of

exceedance in writing;

2.

Notify Contractor;

3.

In consolidation with the IEC, agree with the

Contractor on the

remedial measures to be implemented;

4.

Supervise implementation of

remedial measures;

5.

Conduct meeting with ET and

IEC if exceedance

continues.

|

1.

Discuss with ET and IEC on

proper remedial actions;

2.

Submit proposals for remedial actions to ER and

IEC within three

working days of notification;

3.

Implement the agreed

proposals;

4.

Amend proposal if

appropriate.

|

|

Limit Level being

exceeded by one sampling

|

1.

Identify source and investigate

the causes of exceedance;

2.

Inform Contractor, IEC, ER, and

EPD;

3.

Repeat measurement to

confirm finding;

4.

Assess effectiveness of

Contractor’s remedial actions and

keep EPD, IEC and ER informed of

the results.

|

1.

Check monitoring data

submitted by ET;

2.

Check Contractor’s

working method;

3.

Discuss with ET and Contractor on possible

remedial measures;

4.

Advise the ER on the

effectiveness of

the proposed remedial measures.

|

1.

Confirm receipt of

notification of

exceedance in writing;

2.

Notify Contractor;

3.

In consolidation with the IEC, agree with the

Contractor on the

remedial measures to be implemented;

4.

Supervise implementation of

remedial measures;

5.

Conduct meeting with ET and

IEC if exceedance

continues.

|

1.

Take immediate action to

avoid further exceedance;

2.

Discuss with ET and IEC on

proper remedial actions;

3.

Submit proposals for remedial actions to ER and

IEC within three

working days of notification;

4.

Implement the agreed

proposals.

|

|

Limit Level being

exceeded by two or more consecutive sampling

|

1.

Notify IEC, ER, Contractor

and EPD;

2.

Repeat measurement to

confirm findings;

|

1.

Check monitoring data

submitted by ET;

2.

Check Contractor’s

working method;

|

1.

Confirm receipt of

notification of

exceedance in writing;

2.

Notify Contractor;

3.

In consolidation with the

IEC,

|

1.

Take immediate action to avoid further

exceedance;

2.

Discuss with ET, ER and

IEC on proper remedial

actions;

|

Table 2.3

Event

and Action Plan for Construction

Dust Monitoring

|

EVENT

|

ACTION

|

|

ET

|

IEC

|

ER

|

CONTRACTOR

|

|

|

3.

Carry out analysis of

Contractor’s working procedures to identify source

and investigate the causes

of

exceedance;

4.

Increase monitoring frequency to daily;

5.

Arrange meeting with IEC, ER and Contractor to

discuss the remedial actions to be taken;

6.

Assess effectiveness of Contractor’s remedial

actions and keep EPD, IEC and ER informed of the results;

7.

If exceedance stops, cease additional monitoring

|

3.

Discuss

amongst ER, ET, and

Contractor on the potential remedial actions;

4.

Review Contractor’s remedial actions whenever

necessary to

assure their effectiveness and advise the ER

accordingly.

|

agree with the Contractor

on the remedial measures to be implemented;

4.

Supervise implementation of

remedial measures;

5.

If exceedance continues,

consider stopping the Contractor to continue working on

that portion of work

which causes the exceedance

until the exceedance is

abated.

|

3.

Submit proposals for remedial actions to

IEC within three working days

of notification;

4.

Implement the agreed

proposals;

5.

Submit further remedial actions if problem still

not under control;

6.

Stop the relevant portion of works as instructed

by the ER until the exceedance is abated.

|

Mitigation

Measures

2.2.32

Mitigation measures

for construction dust are

recommended

in the EIA Report. The Contractor shall

be responsible for the design and implementation

of these

measures.

2.2.33

In order to ensure

compliance with the acceptable

criteria at the ASRs at all

time, requirements of the

Air Pollution Control (Construction Dust)

Regulation shall be adhered to during the construction period.

Misting for

any stockpile of materials

and

provision of windbreaks

on three

sides are proposed to prevent wind erosion. An environmental

monitoring and

auditing program shall

be implemented to monitor the construction process in order to enforce

controls

and modify methods of work if dusty conditions are arisen.

In addition, the following good site practices are recommended to minimise dust

and

other air pollutants impacts during excavation, transportation, and

loading and

unloading of dusty

material:

•

Stockpiling

site(s) should be lined with impermeable sheeting and bunded.

Stockpiles should

be fully covered by impermeable sheeting to reduce dust emission.

•

Misting for the dusty

material should be carried out before

being

loaded into the vehicle.

•

Any

vehicle with an open load carrying area should have properly fitted

side and

tail boards.

•

Material

having the potential to create dust

should

not be loaded from a

level higher

than the side and tail boards and should be dampened and covered by a

clean

tarpaulin.

•

The

tarpaulin should be properly secured and should extent at least 300 mm

over the

edges of the sides and tailboards. The material should

also be dampened if necessary

before transportation.

•

The

vehicles should be restricted to maximum speed

of 10 km

per hour and confined haulage and delivery vehicle to

designated roadways insider the site. On-site unpaved roads should be

compacted

and kept free of lose materials.

•

Vehicle washing facilities

should be provided at

every vehicle exit point.

•

The

area where vehicle washing takes place and the

section of the road between the washing

facilities and the exit point

should be paved with concrete,

bituminous materials or hardcores.

•

Every

main haul road should be scaled with concrete and kept clear of

dusty materials or sprayed with water so

as to maintain the entire road surface

wet.

•

Every

stock of more than 20 bags of cement should be covered entirely by

impervious

sheeting placed in an

area sheltered

on the top and the three sides.

•

Every

vehicle should be washed to

remove

any dusty materials from its body and

wheels

before leaving the construction

sites.

2.2.34

The implementation

schedule for the recommended air quality impact mitigation measures is

presented in Appendices A and A1

respectively.

2.3

Noise Impact

Noise Parameters

Construction

Phase

2.3.1

The construction noise level shall be measured in

terms of the A-weighted equivalent

continuous sound pressure level (Leq).

Leq (30 minutes)

shall be used as the

monitoring parameter for the

time period between 0700

and 1900

hours on normal weekdays. For all

other

time periods, Leq (5 minutes) shall be

employed for

comparison with the Noise Control Ordinance (NCO)

criteria.

2.3.2

Supplementary information for data

auditing, statistical results such

as L10 and L90

shall also be obtained for reference. A sample data record sheet based

on the

one presented in the EM&A Guidelines for Development Projects in

Hong Kong

is shown in Appendix B. The

ET Leader may modify the data

record sheet for this

EM&A programme, of which the format should

be agreed by the

ER and the IEC.

Monitoring Equipment

2.3.3

As referred to in the Technical Memorandum (TM)

issued under the NCO, sound level

meters

in compliance with the International Electrotechnical Commission

Publications 651: 1979 (Type 1) and 804: 1985 (Type 1) specifications

shall be used

for carrying out the noise

monitoring.

Immediately prior to and following each noise measurement the accuracy

of the sound level

meter shall be checked

using an acoustic calibrator generating a known

sound pressure level at a known frequency. Measurements may be

accepted

as valid only if the calibration level from before and after the noise measurement agree to

within 1.0 dB.

2.3.4

Noise measurements shall

not be made in fog, rain, wind with a steady speed

exceeding 5 m/s or wind with gusts exceeding 10 m/s. The wind speed

shall be checked with a portable

wind speed meter capable of measuring

the

wind speed in m/s.

2.3.5

The ET is responsible for the provision of

the monitoring equipment. He shall

ensure that sufficient noise

measuring equipment and associated instrumentation are available for

carrying

out the baseline monitoring, regular impact monitoring and ad hoc

monitoring.

All the equipment and associated instrumentation shall be clearly labelled.

Monitoring Locations

2.3.6

The locations of

construction and operational noise monitoring stations are

summarized in

Table 2.4 and shown

in Figure

2.2. These locations represent the worst

affected sensitive receivers during

construction.

Table 2.4 Noise

Monitoring Stations

|

Noise

Monitoring

Station

|

NSR

ID in EIA

Report

|

Noise

Monitoring Location

|

|

Construction

Noise

|

|

M11

|

N18

|

The Hong Kong Society

for the Blind’s Factory cum Sheltered Workshop

|

|

M12

|

PN83,

PN84 and PN84A

|

Hong Kong Children’s

Hospital

|

2.3.7

The status and locations of

noise

sensitive receivers may change after issuing this Manual. If such

case exists, the ET Leader shall propose updated monitoring

locations

and seek approval from

EPD and agreement

from the ER and the IEC before baseline monitoring

commences.

2.3.8

When alternative monitoring locations are

proposed, the monitoring locations shall be chosen based on the

following criteria:

(i)

Monitoring

at sensitive receivers close to the major site activities which are

likely to

have noise impacts;

(ii)

Monitoring

at the noise sensitive receivers as defined in the Technical

Memorandum; and

(iii)

Assurance of

minimal disturbance to the occupants

during monitoring.

2.3.9

The monitoring station shall normally be at a

point 1 m from the exterior of the sensitive receiver building facade

and be at

a position 1.2 m above the ground. If there is problem with access to

the normal

monitoring position, an alternative position may be chosen, and a

correction to

the measurements shall be made. For reference, a correction of

+3 dB(A) shall be made to the free field

measurements. The ET shall agree

with

the IEC on the monitoring position and the corrections adopted. Once

the

positions for the monitoring stations are chosen, the baseline

monitoring and

the impact monitoring shall be carried out

at

the same positions.

Baseline Monitoring

Construction

Phase

2.3.10

The ET shall carry out baseline noise

monitoring prior to the commencement of

the

construction works. The

baseline

monitoring shall be carried out daily for a period of

at least two weeks. Before

commencing

the baseline monitoring, the ET shall

develop and submit to the IEC the baseline monitoring programme

such that the IEC can

conduct on-site

audit to ensure accuracy of the

baseline

monitoring results.

2.3.11

There shall not be any construction activities

in the vicinity of the stations during the

baseline monitoring.

2.3.12

In exceptional cases,

when insufficient baseline monitoring data or

questionable results are obtained,

the

ET Leader shall liaise with the ER, EPD and IEC to agree on an

appropriate set of

data to be used as a baseline

reference and submit to the ER and IEC for agreement and EPD for approval.

Impact Monitoring

Construction

Phase

2.3.13

Noise monitoring shall

be carried out at all the designated

monitoring stations. The monitoring frequency shall

depend on the scale of the construction activities. The following is

an initial

guide on the regular monitoring frequency for each station on a weekly

basis

when noise generating activities are

underway:

·

one set of

measurements

between 0700 and 1900 hours on normal

weekdays.

2.3.14

If construction works

are extended to include works

during the hours of 1900 – 0700 as well as public holidays and

Sundays,

additional weekly impact monitoring shall be carried out

during respective restricted hours periods. Applicable

permits under NCO shall be obtained by the

Contractor.

2.3.15

If a school

exists near the construction activity, noise

monitoring shall be carried out at

the

monitoring stations for the schools during the school examination

periods. The

ET Leader shall liaise

with the

school’s personnel and the Examination Authority to ascertain the

exact dates

and times of all

examination periods

during the course of

the contract.

2.3.16

In case of non-compliance

with

the construction noise criteria,

more

frequent monitoring, as specified in the Action Plan in Table

2.6,

shall be carried out. This additional

monitoring shall be continued until the recorded noise levels are

rectified or

demonstrated to be unrelated to the construction

activities.

Event and Action Plan

Construction

Phase

2.3.17

The Action and Limit levels for construction

noise are defined in Table 2.5.

Should non- compliance of the criteria occur, action in accordance

with the

Event and Action Plan in Table 2.6 shall

be implemented.

Table 2.5 Action and Limit Levels for Construction Noise

|

Time

Period

|

Action

Level

|

Limit

Level

|

|

0700

– 1900 hours on

normal

weekdays

|

When one documented

compliant is received

|

75

dB(A) *

|

Notes: If works are to be carried

out during restricted hours, the

conditions stipulated in the Construction Noise Permit (CNP) issued by

the

Noise Control Authority

have to be

followed.

*

70 dB(A) and 65 dB(A) for schools during normal teaching periods and

school

examination periods, respectively.

Mitigation Measures

Construction

Phase

2.3.18

To alleviate the construction noise impact on

the affected NSRs, movable noise barriers and acoustic mats are

proposed to be

provided for particular items of plant and construction works. It is

anticipated that a movable noise barrier with a cantilevered upper

portion

located within 5m from any static or mobile plant can provide 5 dB(A)

noise

reduction for mobile plant and 10 dB(A) noise reduction for static

plant. The

barrier material shall have a surface mass of not less than 14 kg/m2

on skid

footing with 25mm thick internal sound absorptive lining to achieve

the maximum

screening effect.

2.3.19

In addition, the good site practices listed

below should be adopted by all the Contractors to further ameliorate

the noise

impacts.

·

Only well-maintained plant should be operated

on-site and plant should be serviced regularly during the construction program.

·

Silencers or mufflers on construction equipment

should be utilised and should be properly

maintained

during the construction program.

·

Mobile plant, if any,

should be sited as far away

from NSRs as possible.

·

Machines and plant (such as trucks) that may be

in intermittent use should

be shut down between

works periods or should

be throttled down to a minimum.

·

Plant known to emit noise strongly in one

direction should, wherever possible, be orientated so that the noise

is

directed away from the

nearby

NSRs.

·

Material stockpiles and other structures should

be effectively utilised, wherever practicable, in

screening noise from

on-site construction activities.

2.3.20

If the above measures are not sufficient to

restore the construction noise quality to acceptable levels upon the

advice of

ET Leader, the Contractor shall liaise with the ET Leader to

identify

further mitigation measures. They shall be proposed to ER for

approval, and the

Contractor shall then implement these additional mitigation measures.

2.3.21

The implementation schedule for the recommended

mitigation measures is presented

in Appendices

A and A1 respectively.

Table 2.6

Event/Action Plan for Construction Noise

|

EVENT

|

ACTION

|

|

ET

|

IEC

|

ER

|

CONTRACTOR

|

|

|

Action Level being

exceeded

|

1.

Notify ER, IEC and

Contractor;

2.

Carry out

investigation;

3.

Report the results of

investigation to the IEC, ER and Contractor;

4.

Discuss with the IEC and Contractor on remedial

measures required;

5.

Increase monitoring frequency to check mitigation effectiveness.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

1.

Review the

investigation results submitted

by the ET;

2.

Review the

proposed remedial measures by the Contractor and advise the ER accordingly;

3.

Advise the ER on the effectiveness

of the proposed

remedial measures.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

1.

Confirm receipt of

notification of failure in

writing;

2.

Notify Contractor;

3.

In consolidation with the IEC, agree with the

Contractor on the remedial measures to be implemented;

4.

Supervise the implementation of remedial

measures.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

1.

Submit

noise

mitigation proposals

to IEC and ER;

2.

Implement noise mitigation proposals.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

|

|

Limit

Level being

exceeded

|

1.

Inform IEC, ER,

Contractor and EPD;

2.

Repeat

measurements to

confirm findings;

|

1.

Discuss amongst ER,

ET, and Contractor on the potential

remedial actions;

2.

Review Contractor’s

remedial actions whenever

necessary to assure their effectiveness

and advise the ER

accordingly.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

1.

Confirm receipt of

notification of failure in

writing;

2.

Notify Contractor;

3.

In consolidation with the IEC, agree with the

Contractor on the remedial measures to be implemented;

4.

Supervise the implementation of remedial

measures;

5.

If exceedance

continues, consider stopping the Contractor to

continue working on that portion of

work which causes the exceedance until the exceedance

is abated.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

1.

Take immediate action to avoid further exceedance;

2.

Submit proposals for remedial actions to IEC and

ER within 3 working days of notification;

3.

Implement the agreed

proposals;

4.

Submit further proposal if problem

still not

under control;

5.

Stop the relevant portion of works as

instructed by the ER until the exceedance is abated.

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

|

|

|

3.

Increase monitoring

frequency;

|

|

|

|

4.

Identify source and

investigate the cause of exceedance;

|

|

|

|

5.

Carry out analysis of Contractor’s

working procedures;

|

|

|

|

6.

Discuss with the IEC, Contractor

and ER on remedial measures

required;

|

|

|

|

7.

Assess effectiveness of Contractor’s remedial

actions and keep IEC,

EPD and ER

informed of the results;

|

|

|

|

8.

If

exceedance stops, cease

additional monitoring.

|

|

|

|

(The above actions should

be taken within 2 working days after the exceedance is

identified)

|

|

2.4

Water

Quality Impact

Introduction

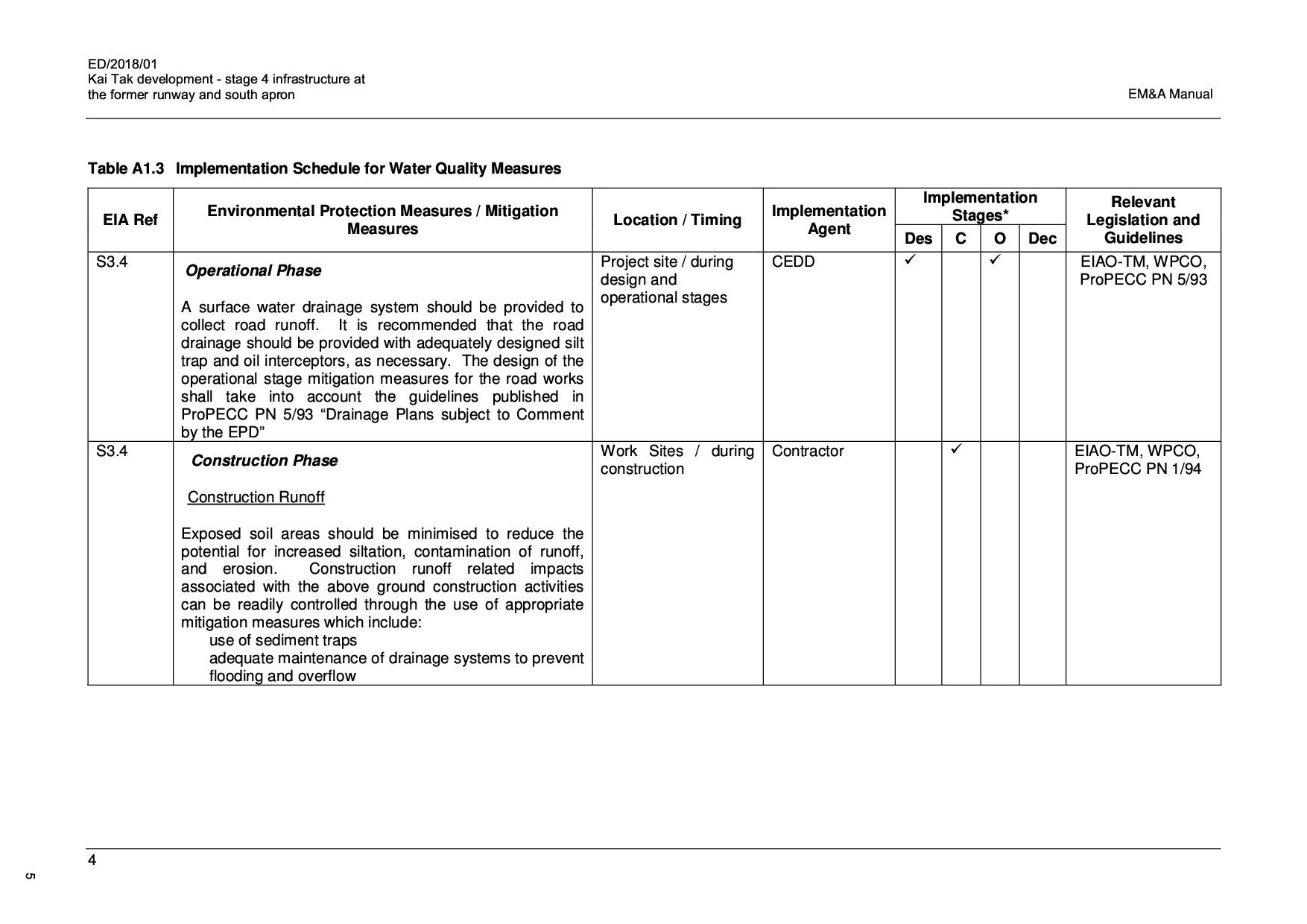

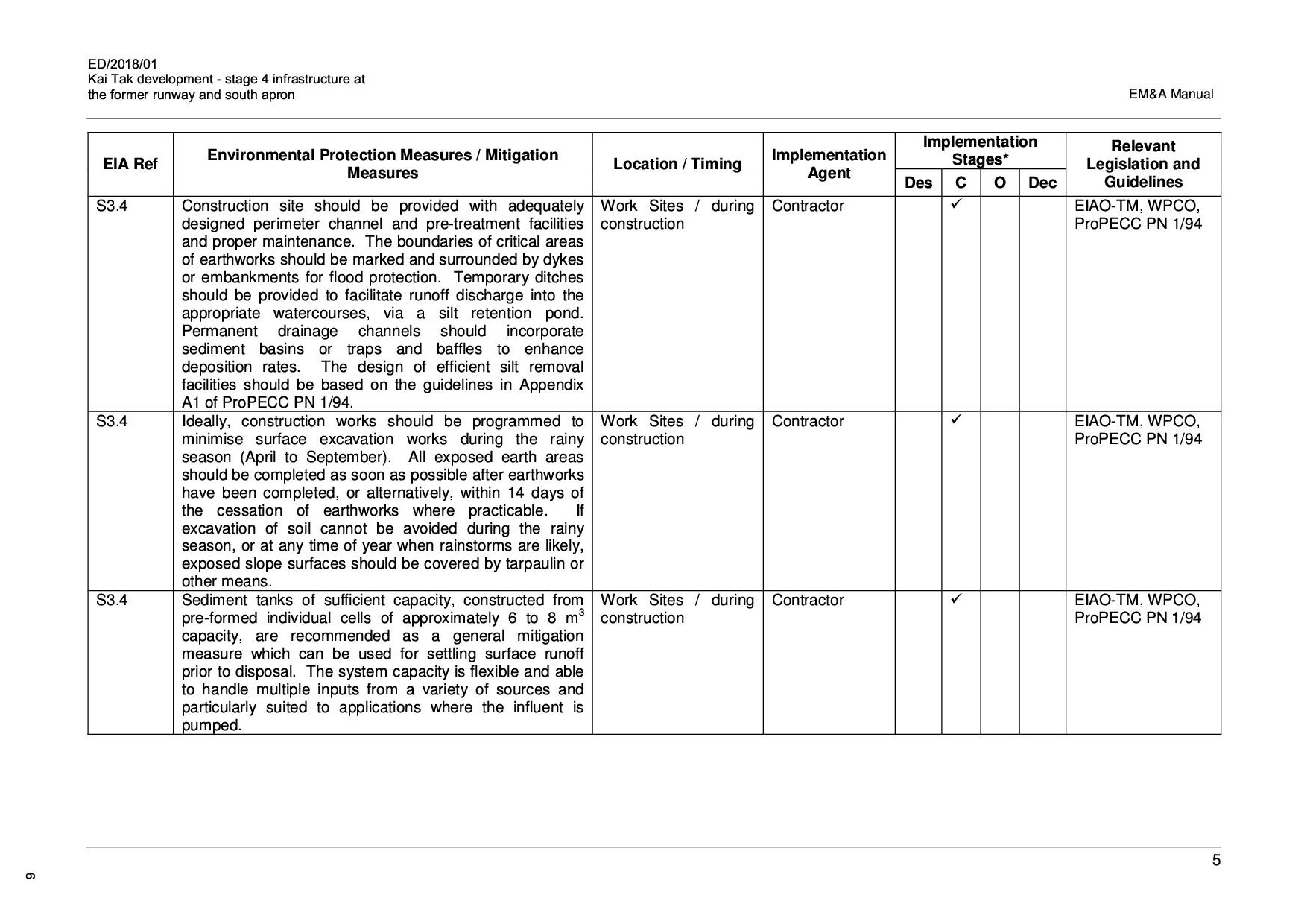

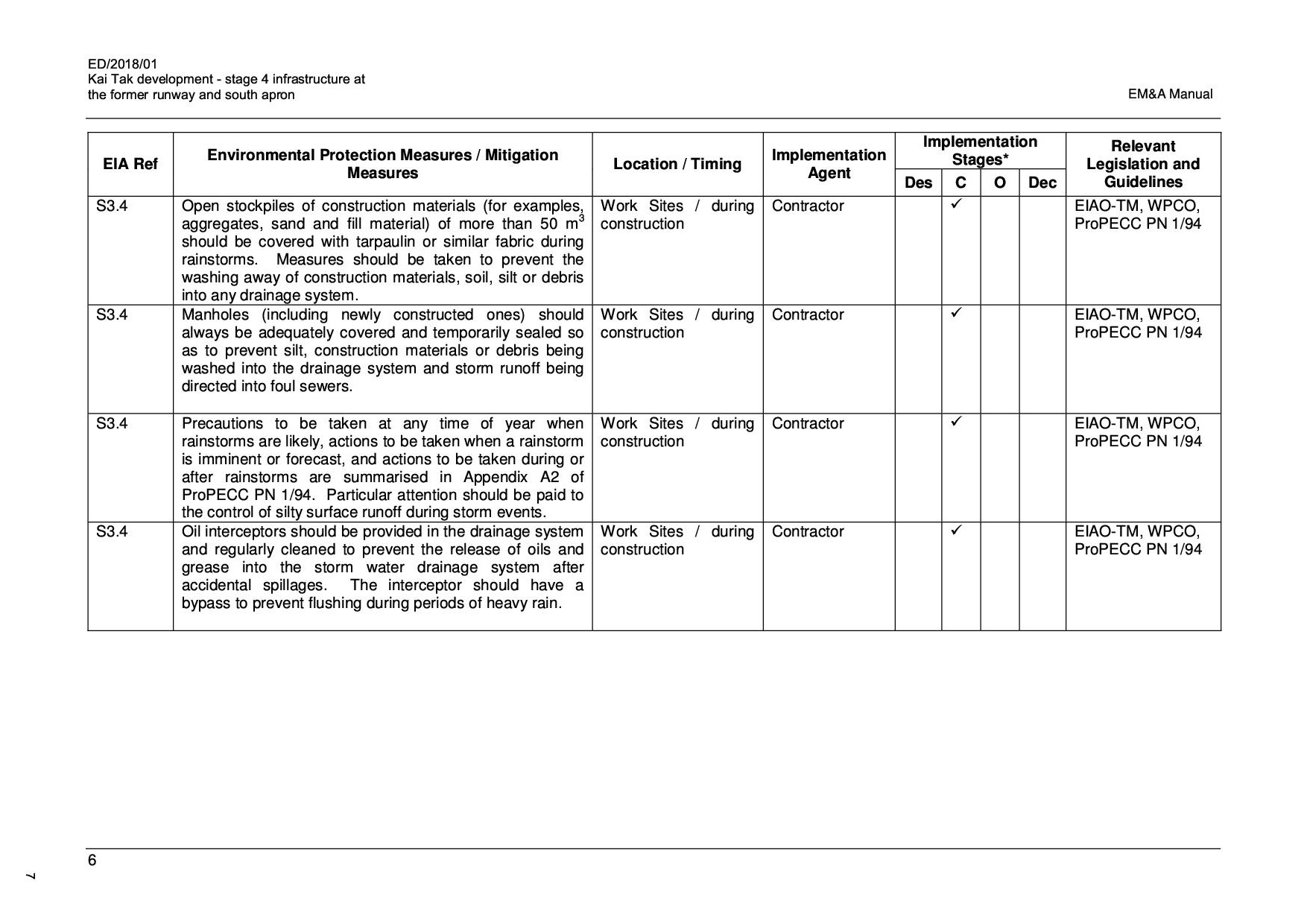

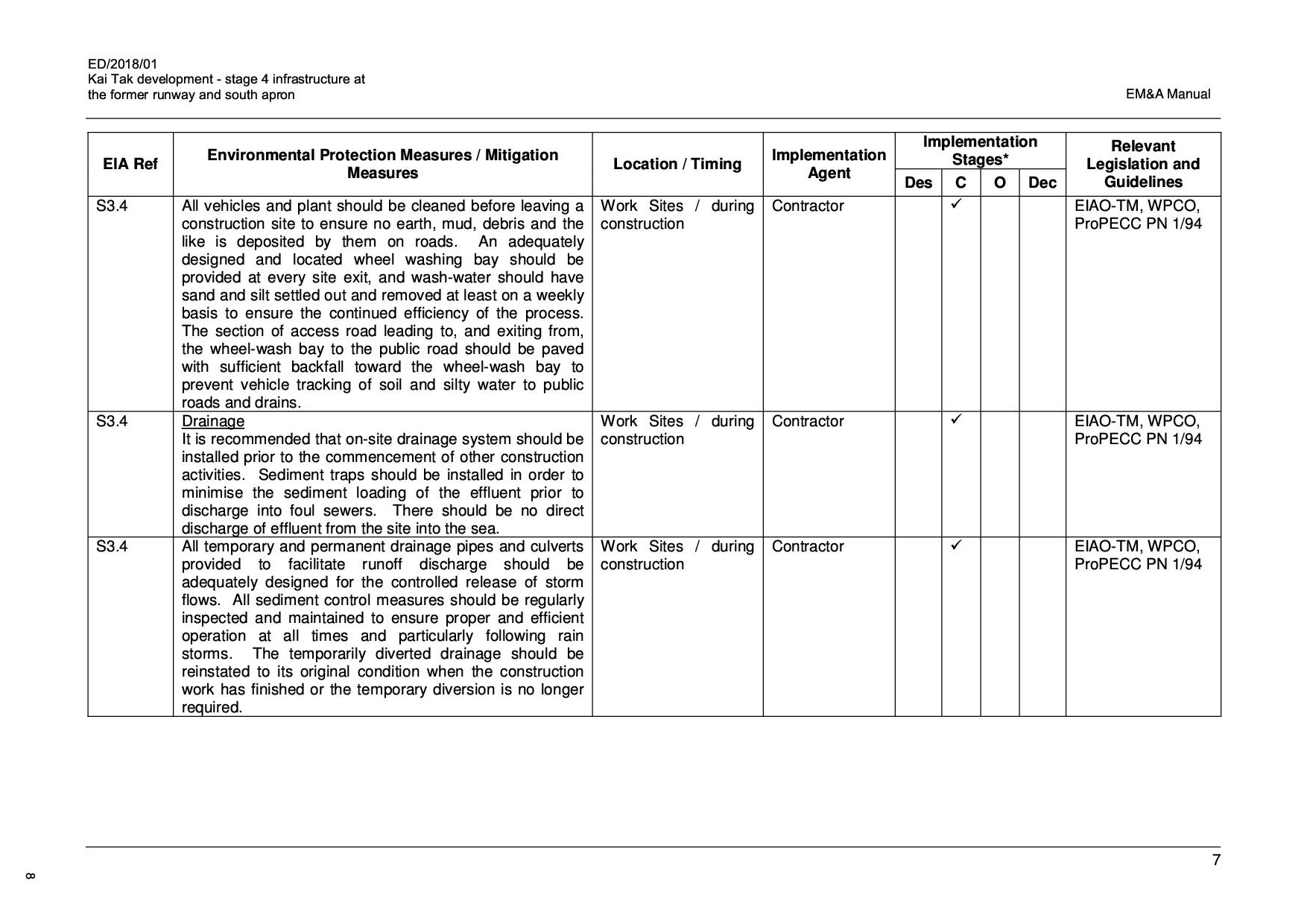

2.4.1

No off-site marine water

quality impact would be expected from the Project and

given that there would not be any marine-based works for the proposed

works, water quality

monitoring is not considered

necessary. However, it is recommended that regular site audits (at

least once

per week) be

undertaken to inspect the

construction activities and works

areas in order to ensure the

recommended mitigation measures are properly implemented. Proposed

mitigation

measures for containing and minimizing water quality impacts are

listed in the

implementation schedule given in Appendices A and A1 respectively.

Site

Audits

2.4.2

Implementation of

regular site audits (at least once per week)

is to ensure that the recommended mitigation measures are

to be properly undertaken. It can also provide an effective control of any malpractices and

therefore achieve

continual improvement of environmental

performance

on site.

2.4.3

Site audits shall

include site inspections and monitoring audits.

Site Inspections

2.4.4

Site inspections shall

be carried out by the ET and

shall be based on

the

mitigation measures for water

pollution

control recommended in the implementation schedule as attached in Appendices A and A1 respectively.

In the

event that the recommended mitigation measures are not

fully or properly implemented, deficiency shall be recorded

and reported to the site management. Suitable actions are to be

carried out to:

·

Investigate the problems and the

causes;

·

Issue action notes to the Contractor which is

responsible for the works;

·

Implement remedial and corrective actions

immediately;

·

Re-inspect the site conditions upon completion of

the remedial and corrective actions; and

·

Record the event and discuss

with the Contractor for preventive

actions.

Monitoring

Audits

2.4.5

Monitoring audits are to be undertaken to

ensure that a valid discharge license has been issued

by EPD prior to the discharge of effluent from the

Project site. Parameters

included in

the WPCO licence, will also

be included in the monitoring programme. The chemical

testing of water samples

collected

in the monitoring programme should be undertaken by a Hong Kong

Laboratory

Accreditation Scheme (HOKLAS) accredited laboratory. The audit results

reflect

whether the effluent quality is in compliance with the discharge

license

requirements and that the recommended water quality mitigation

measures are

properly implemented. In case

of

non-compliance, suitable actions should be undertaken

to:

·

Notify the site management for the

non-compliance;

·

Identify the sources of pollution;

·

Check the implementation status

of the recommended mitigation

measures;

·

Investigate the operating conditions of the

on-site treatment systems;

·

Implement corrective and remedial actions to

improve the effluent quality;

·

Increase monitoring frequency until the

effluent quality is in compliance with the discharge licence

requirements; and

·

Record the non-compliance and propose

preventive measures.

2.5

Waste

Management Implications

Introduction

2.5.1

Waste management will

be the Contractor’s responsibility to ensure that all

wastes produced during the construction works of the Project

are handled, stored and disposed

of

in accordance with good waste

management

practices and EPD’s regulations and

requirements.

2.5.2

Waste materials

generated during the construction works, such

as, general refuse and chemical

wastes, are recommended

to be

audited at regular

intervals (at

least once per week)

to ensure

that proper storage, transportation and disposal

practices are being

implemented. This monitoring of

waste

management practices will ensure

that these solid and liquid wastes

are

not disposed into the

nearby harbour waters. The Contractor

will be responsible

for the implementation of any mitigation measures to minimise

waste or redress problems arising from the waste materials.

Waste Control and Mitigation Measures

2.5.3

Mitigation measures

for waste management

are summarised below. With the

appropriate handling, storage

and removal of

waste arisings

during the construction works

as

defined below, the potential to cause adverse environmental impacts

will be minimised.

Good Site Practices

2.5.4

Adverse impacts

related to waste management

are not

expected to arise, provided

that

good site practices are strictly followed. Recommendations for good

site

practices during the construction works

include:

·

Nomination of an

approved person, such as

a site manager, to be responsible

for good site practices, arrangements for collection and effective disposal to an appropriate

facility, of all wastes

generated at the site;

·

Training of site

personnel in proper waste management

and chemical waste handling

procedures;

·

Provision of sufficient

waste disposal points

and regular collection for disposal;

·

Appropriate measures

to minimise windblown

litter and dust during

transportation

of waste

by either covering trucks or by

transporting wastes in enclosed

containers;

·

Regular cleaning and

maintenance programme for drainage systems, sumps and oil

interceptors;

·

A recording system

for the amount of wastes

generated, recycled and disposed

of

(including the disposal sites).

Waste Reduction

Measures

2.5.5

Good management and control can prevent the

generation of a

significant amount of waste.

Waste reduction is best

achieved

at the planning and design stage, as well

as

by ensuring the implementation of

good

site practices. Recommendations to achieve waste

reduction include:

·

Sorting C&D waste

from construction activities to recover recyclable

portions such as

metals;

·

Segregation and storage of different types of

waste

in different containers, skips or stockpiles to enhance reuse

or

recycling of materials

and their

proper disposal;

·

Encouraging collection of

aluminium cans, PET bottles and

paper by providing

separate labelled bins to enable these wastes

to be segregated from other general refuse generated by the work

force;

·

Recycling any unused

chemicals or those with remaining functional

capacity;

·

Proper storage and site practices to minimise

the potential for damage or contamination of

construction materials;

·

Planning and stocking construction materials

carefully to minimise amount of

waste generated

and

avoid unnecessary generation of waste.

2.5.6

In addition to the above measures, specific

mitigation measures are recommended below for the identified waste

arisings to minimise

environmental impacts during handling, transportation and disposal

of these wastes.

Construction and

Demolition Material

2.5.7

The C&D material

should be sorted on-site into inert C&D material (that is, public

fill) and C&D

waste. The inert C&D material

would require disposal to

the designated public fill reception facility. C&D waste,

such as steel and other metals should be re-used or

recycled and, as a last resort, disposed

of

to landfill. It is recommended that a suitable area be designated to

facilitate

the sorting process and a temporary stockpiling area will be required

for the

separated materials.

2.5.8

In order to monitor the disposal

of public fill and C&D

waste

at public filling facilities and

landfills, respectively, and to control fly tipping, a

trip-ticket system should

be included as one of the

contractual requirements

and

implemented by the ET. The IEC should be responsible for auditing the

results of the

system.

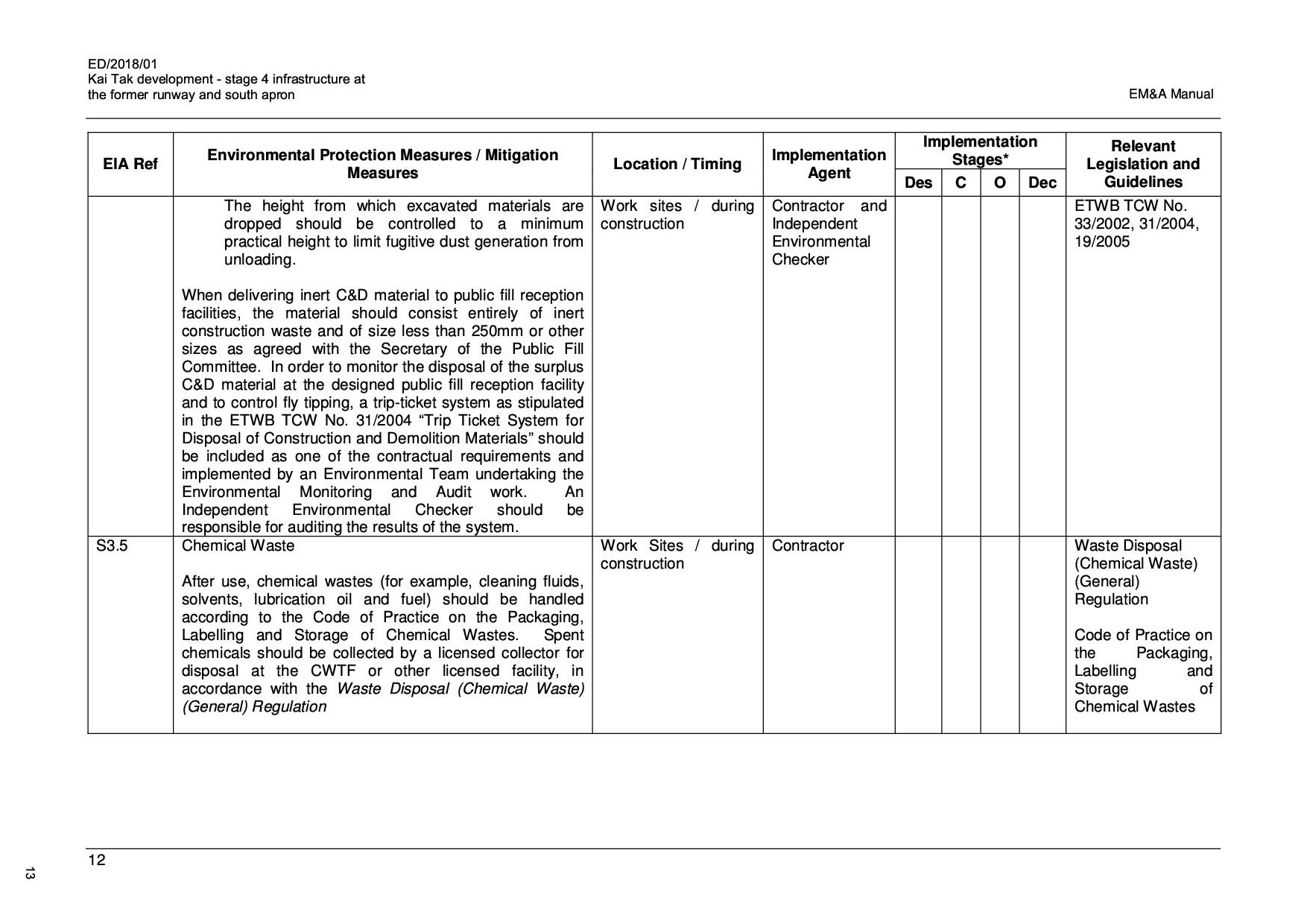

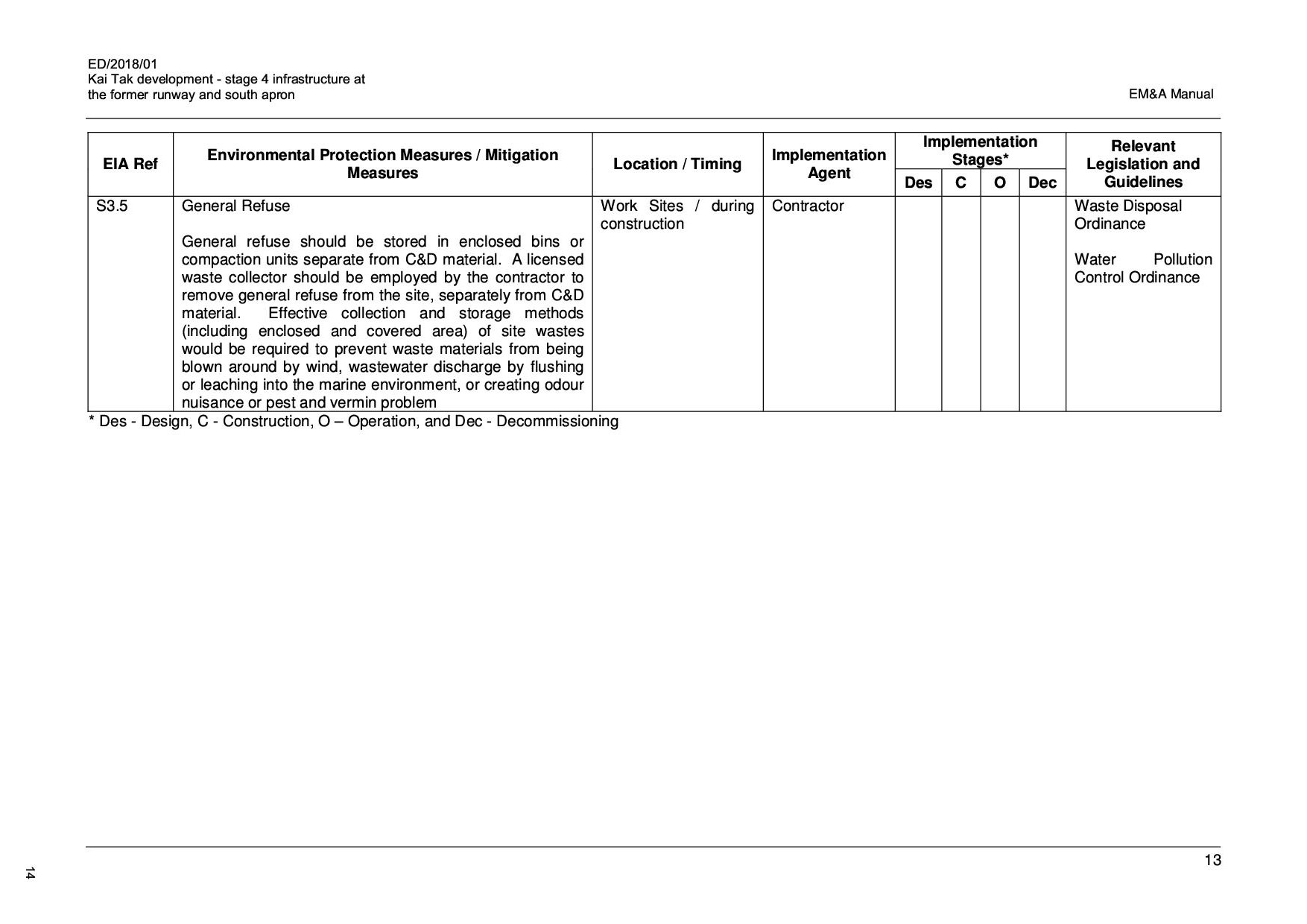

General Refuse

2.5.9

General refuse

should be stored in enclosed bins or compaction units separate

from C&D material.

A licensed waste collector

should be employed by the Contractor to remove general refuse from the

site,

separately from C&D

material.

Effective collection and storage methods (including enclosed

and covered area) of

site wastes would be required to prevent waste

materials from being blown around by wind, wastewater

discharge by flushing or

leaching into the marine environment or creating odour

nuisance or pest and

vermin

problem.

Chemical

Wastes

2.5.10

After use, chemical

wastes (for example,

cleaning

fluids, solvents, lubrication oil

and

fuel) should be handled according to the Code

of Practice on the

Packaging,

Labelling and Storage

of Chemical

Wastes. Spent chemicals should

be

collected by a licensed collector for disposal

at the CWTF or other licensed facility, in accordance with the

Waste Disposal (Chemical

Waste) (General) Regulation.

2.5.11

Table 2.7 provides a

summary of the various

waste types likely to

be generated during

the construction works, together

with

the recommended handling and disposal methods.

Table 2.7

Summary

of Waste Handling Procedures and Disposal Routes

|

Waste

Type

|

Generated

From Works Item

|

Total

Quantity Generated

|

Quantity

to be disposed off-site / re- used

|

Handling

|

Disposal

|

|

C&D Material

|

Distributor roads serving

the planned Kai Tak Development

|

2,217

m3 in total

|

Public fill / on-site

reuse

|

Dust and water Dust

quality mitigation measures

|

Sort on-site into Inert

C&D material to be disposed off-

site to the designated public fill reception facility, C&D

material should be reused as far as practicable

|

|

Chemical Wastes

|

Lubrication oil, fuel

etc. from operation, maintenance, and servicing of

construction plant

|

Few cubic metres

per month (preliminary estimate)

|

Few cubic metres

per month (preliminary estimate)

|

Recycle on-site or by

licensed companies

Stored

on-site within suitably designed containers

|

Chemical Waste Treatment

Facility or other licensed facility

|

|

General

Refuse

|

Waste paper, discarded

containers etc. generated from workforce

|

Few cubic metres

per month (preliminary estimate)

|

Few cubic metres

per month (preliminary estimate)

|

Provide

on-site refuse collection points

|

Refuse station for

compaction and containerisatio n

and then to landfill

|

2.5.12

The implementation schedule of

the recommended mitigation measures is

presented in Appendices

A and A1

respectively

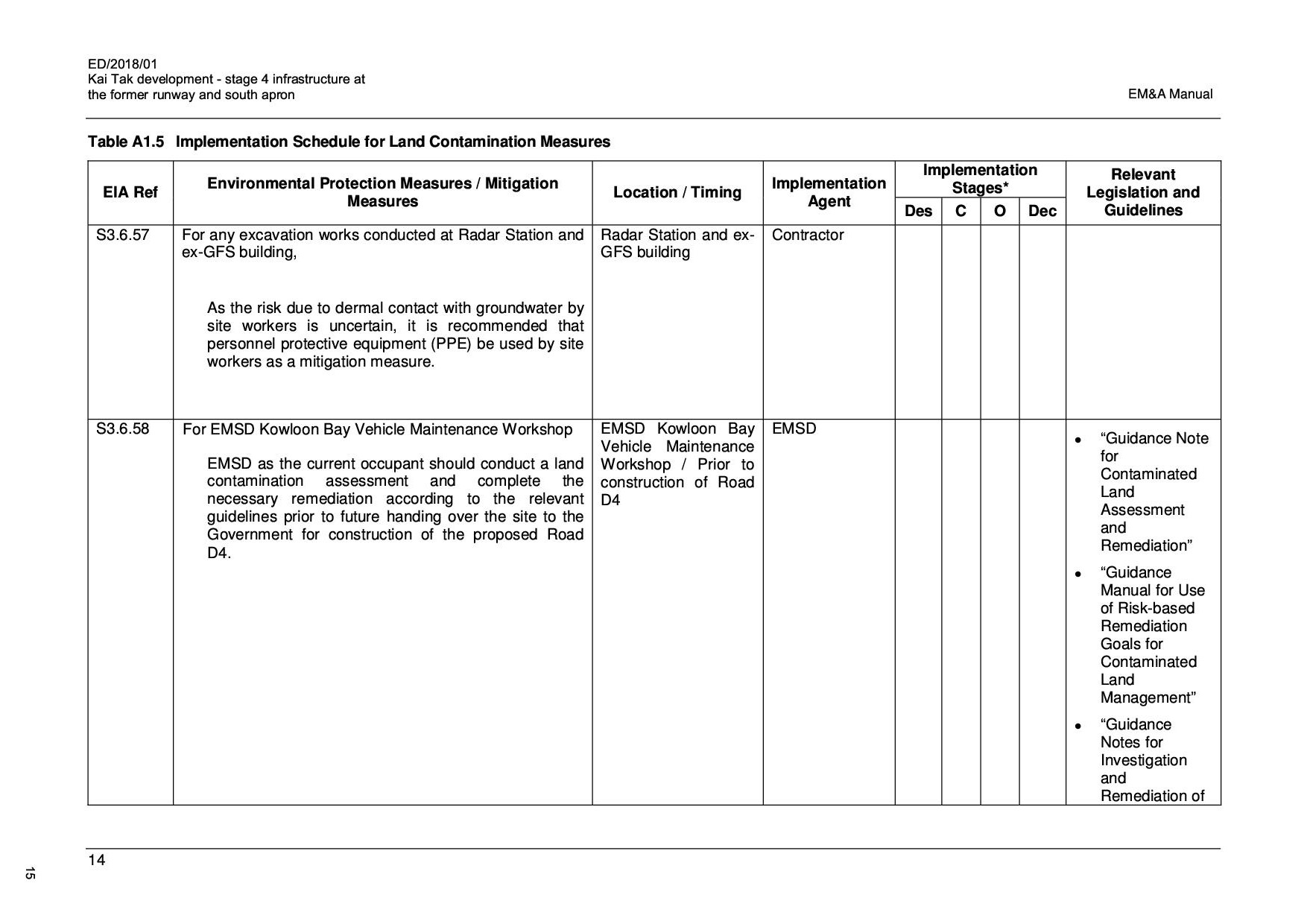

2.6

Land

Contamination Impact

2.6.1

The EIA study has

evaluated the potential land contamination issues that may pose

impacts on the construction of

the new distributor roads.

As indicated in the EIA study, no

potential land contamination associated with Roads D1, D2 & D3 is

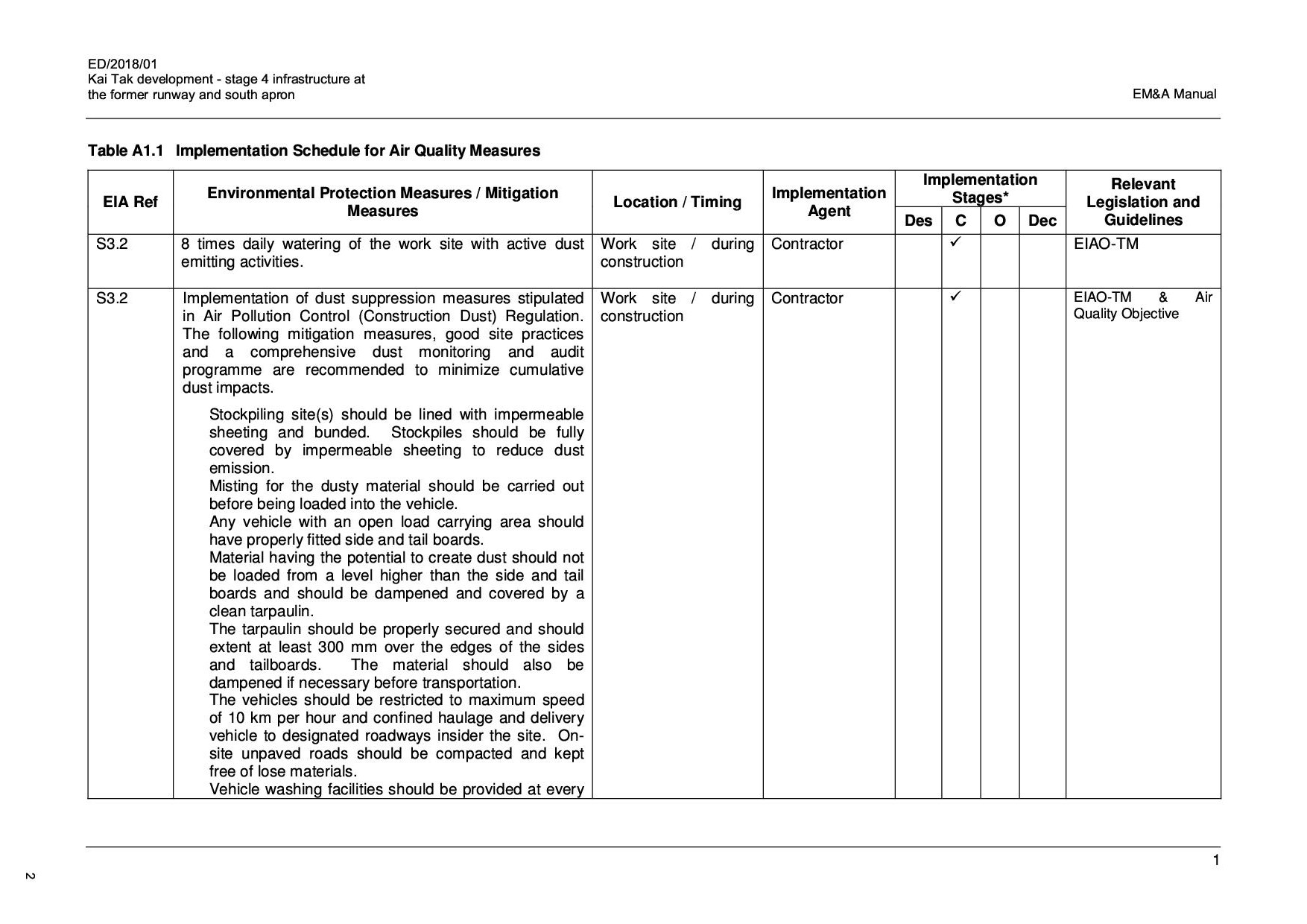

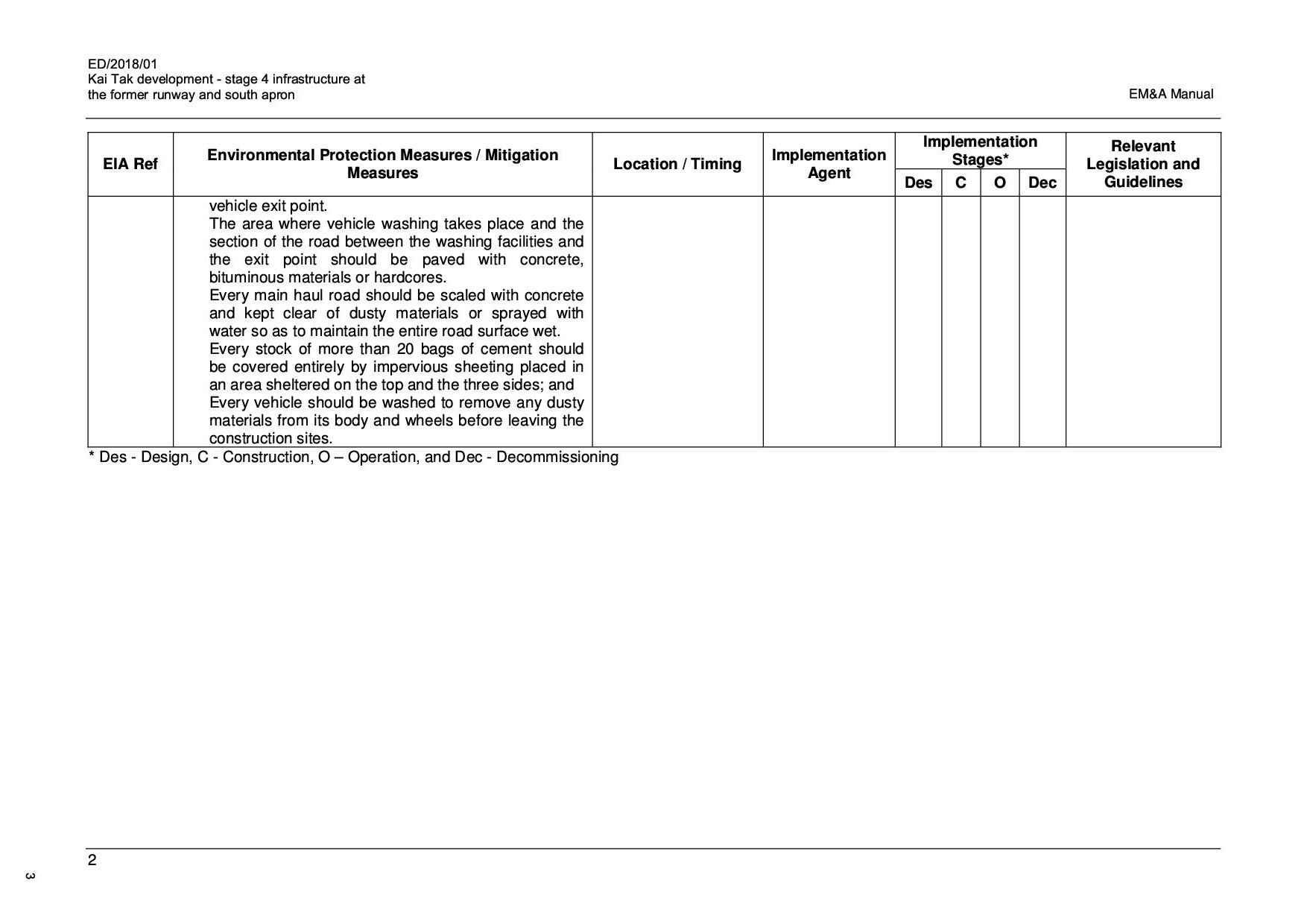

anticipated; however potential land contamination impacts in

association with

the proposed Road D4 alignment were

revealed

from the land contamination investigations.

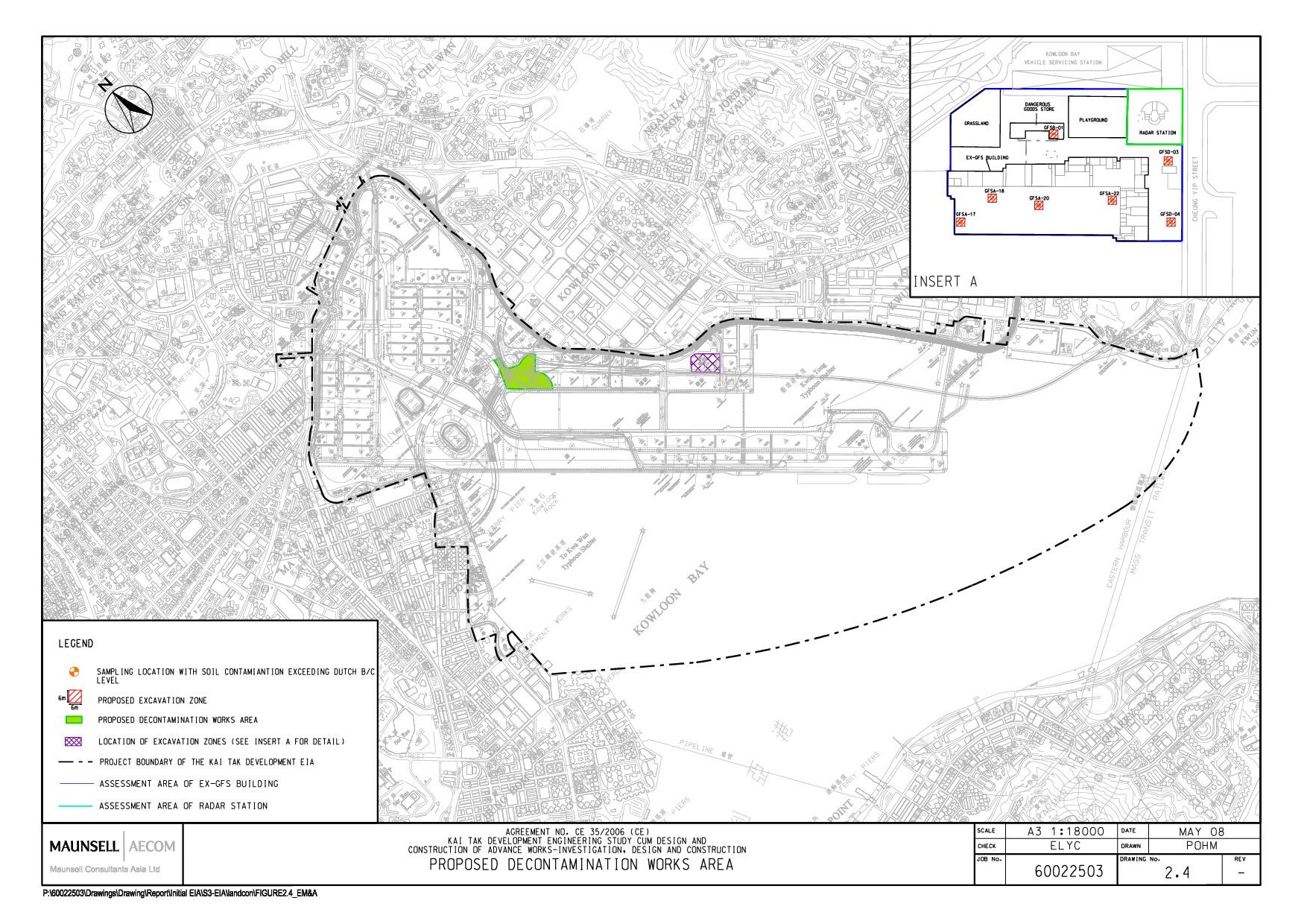

2.6.2

The proposed Road D4

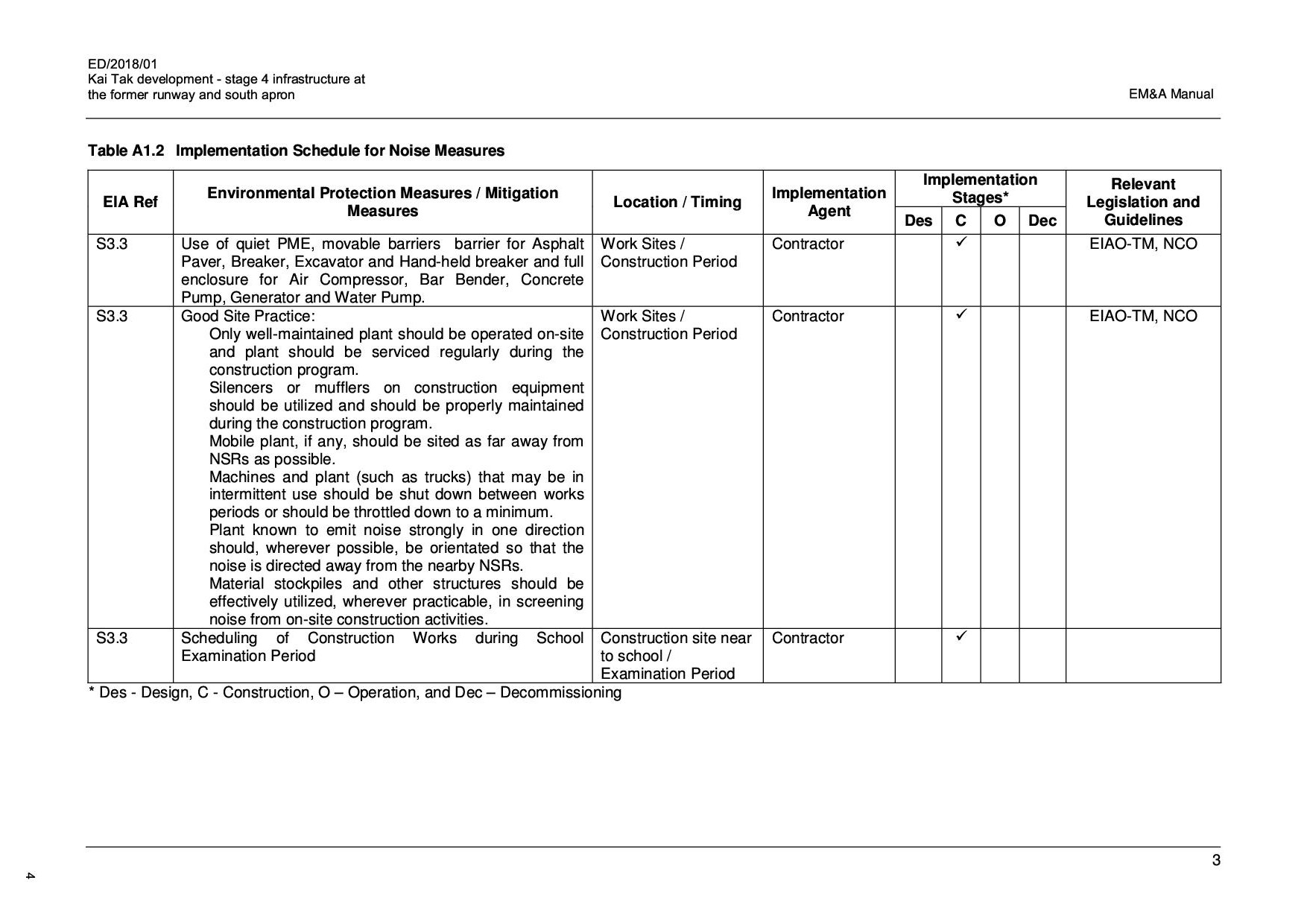

alignment would encroach

upon a small part of the sites of

the

ex- GFS building, the Radar Station and the EMSD Kowloon

Bay Vehicle Repairing and

Maintenance Workshop. Based on the findings of land

contamination

assessment, the extent of identified

contamination

within the ex-GFS building and the Radar Station does not

fall within the alignment of

Road D4, therefore adverse environmental

impact of the ex-GFS

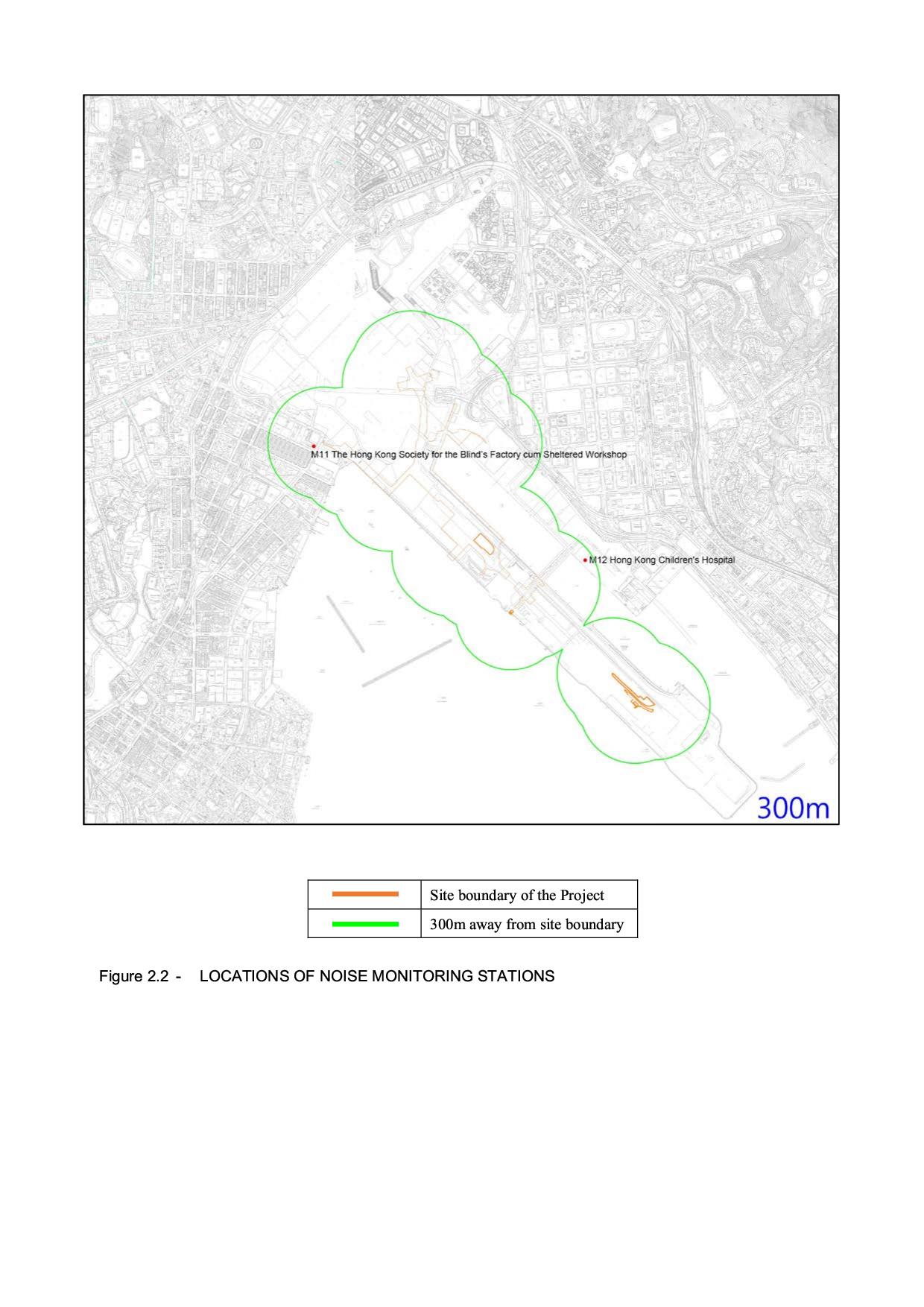

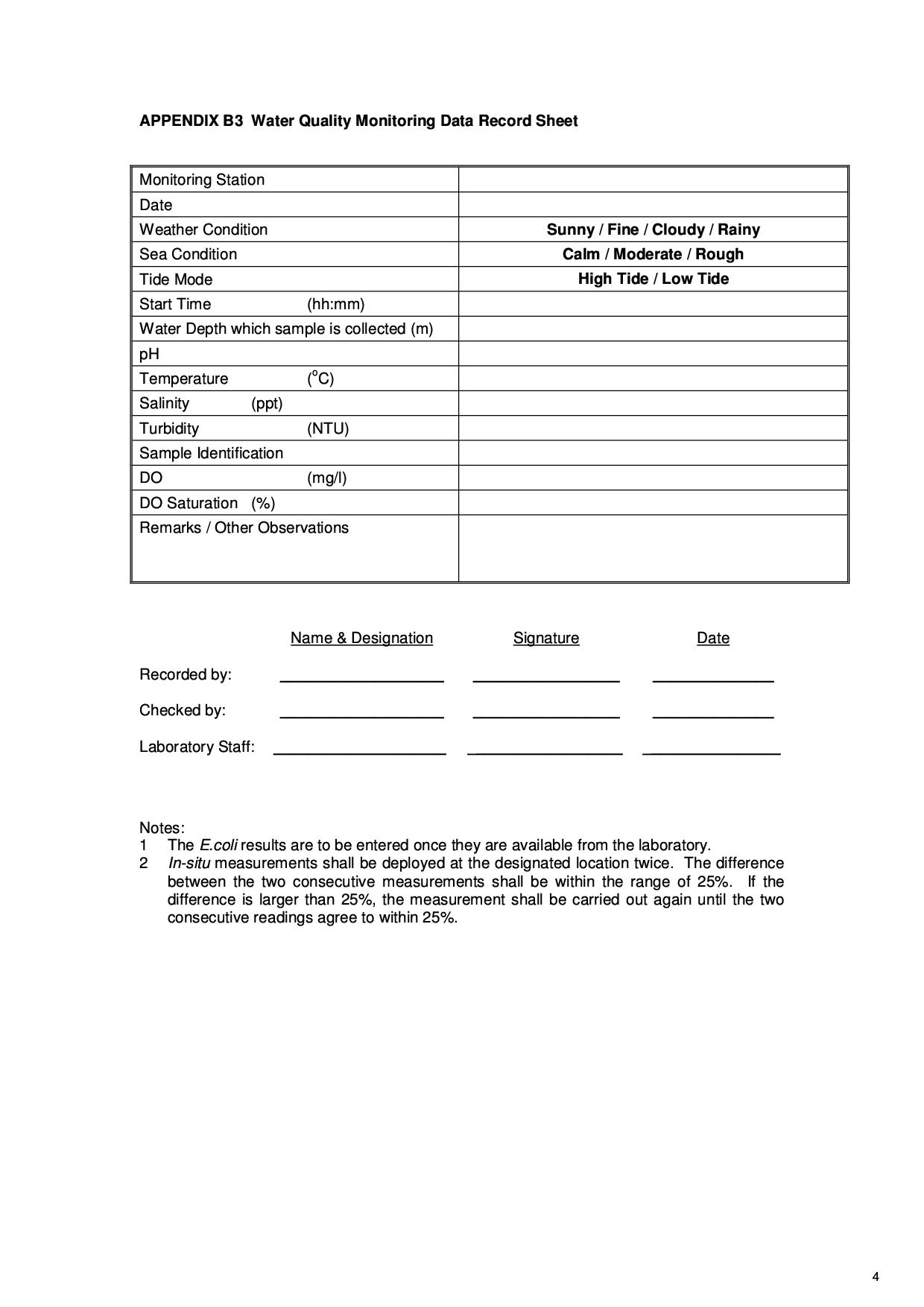

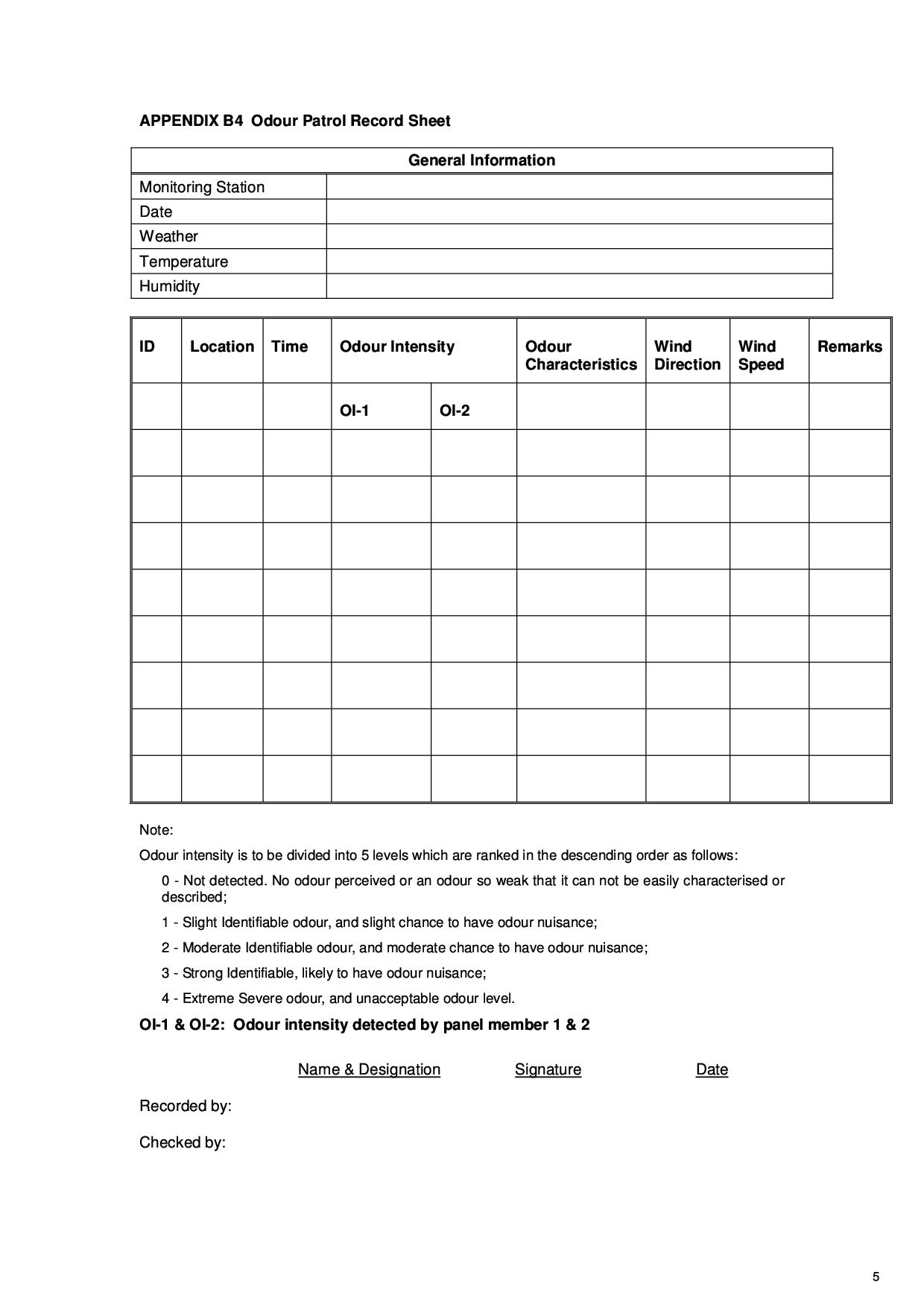

building and