Environmental Monitoring and Audit Report

for

Contract No. ED/2018/01 –

Kai Tak Development – Stage 4 infrastructure at the former runway and south apron

Contract No.: EDO 15/2018

April 2021

(Version 1.0)

Environmental Monitoring and Audit Report

for

Contract No. ED/2018/01 –

Kai Tak Development – Stage 4 infrastructure at the former runway and south apron

Contract No.: EDO 15/2018

April 2021

(Version 1.0)

Breaches of Action and Limit Levels

Notifications of summons and successful prosecutions

Key construction works in the reporting month

Works Area and Construction Programme

Construction works undertaken during reporting month

Submission Status under the Environmental Permits

Monitoring Parameters, Frequency and Duration

Monitoring Methodology and QA/QC Procedure

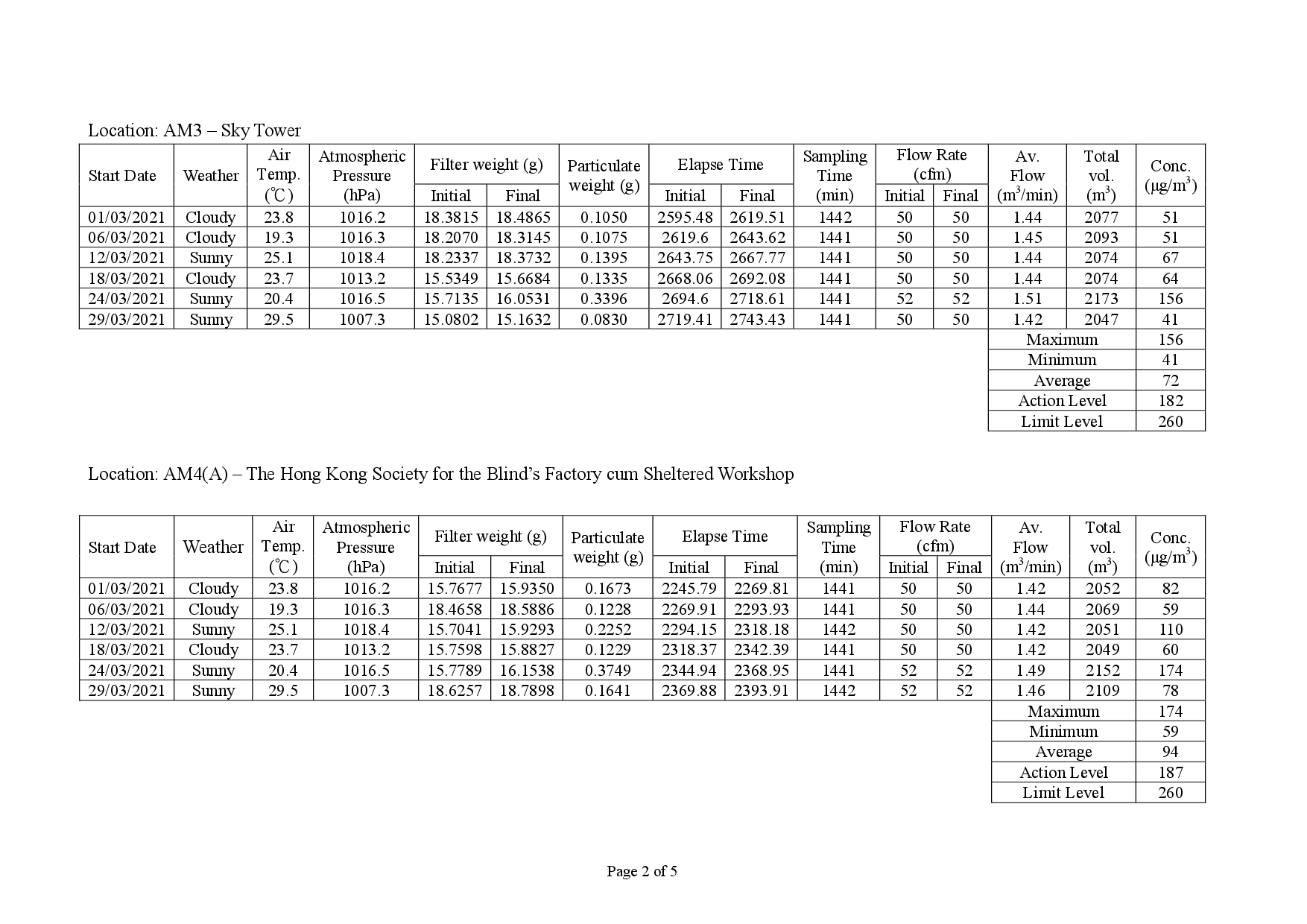

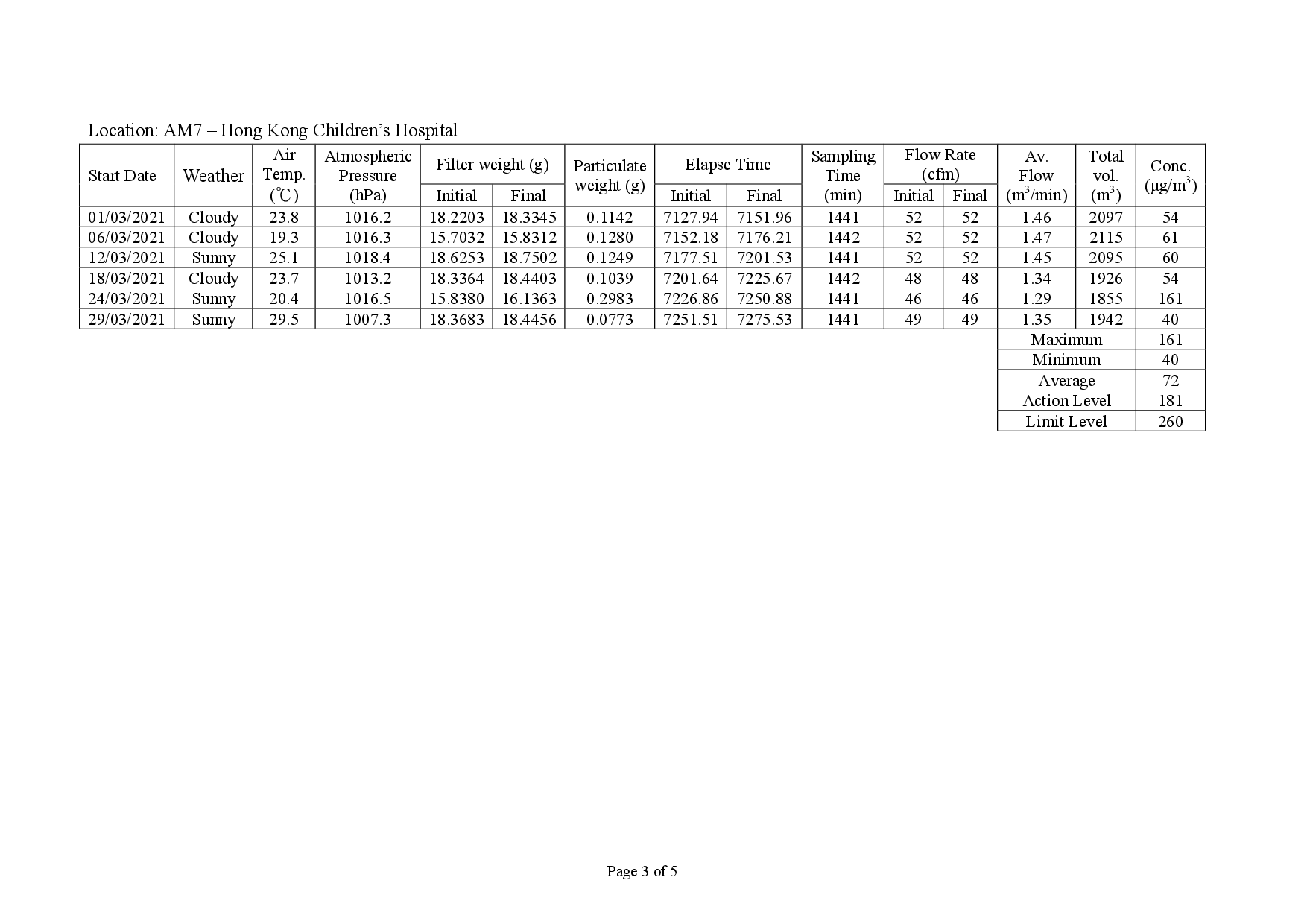

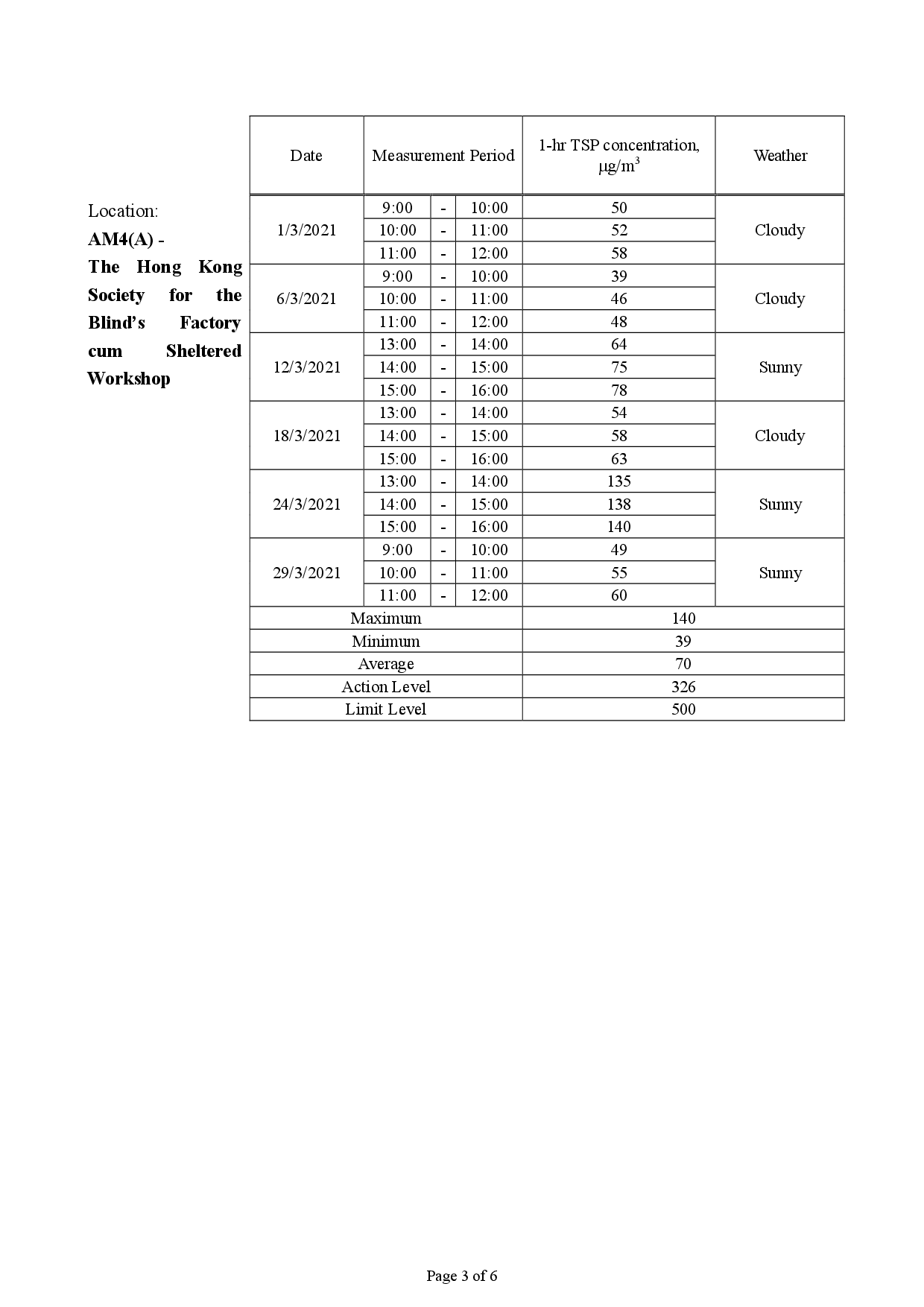

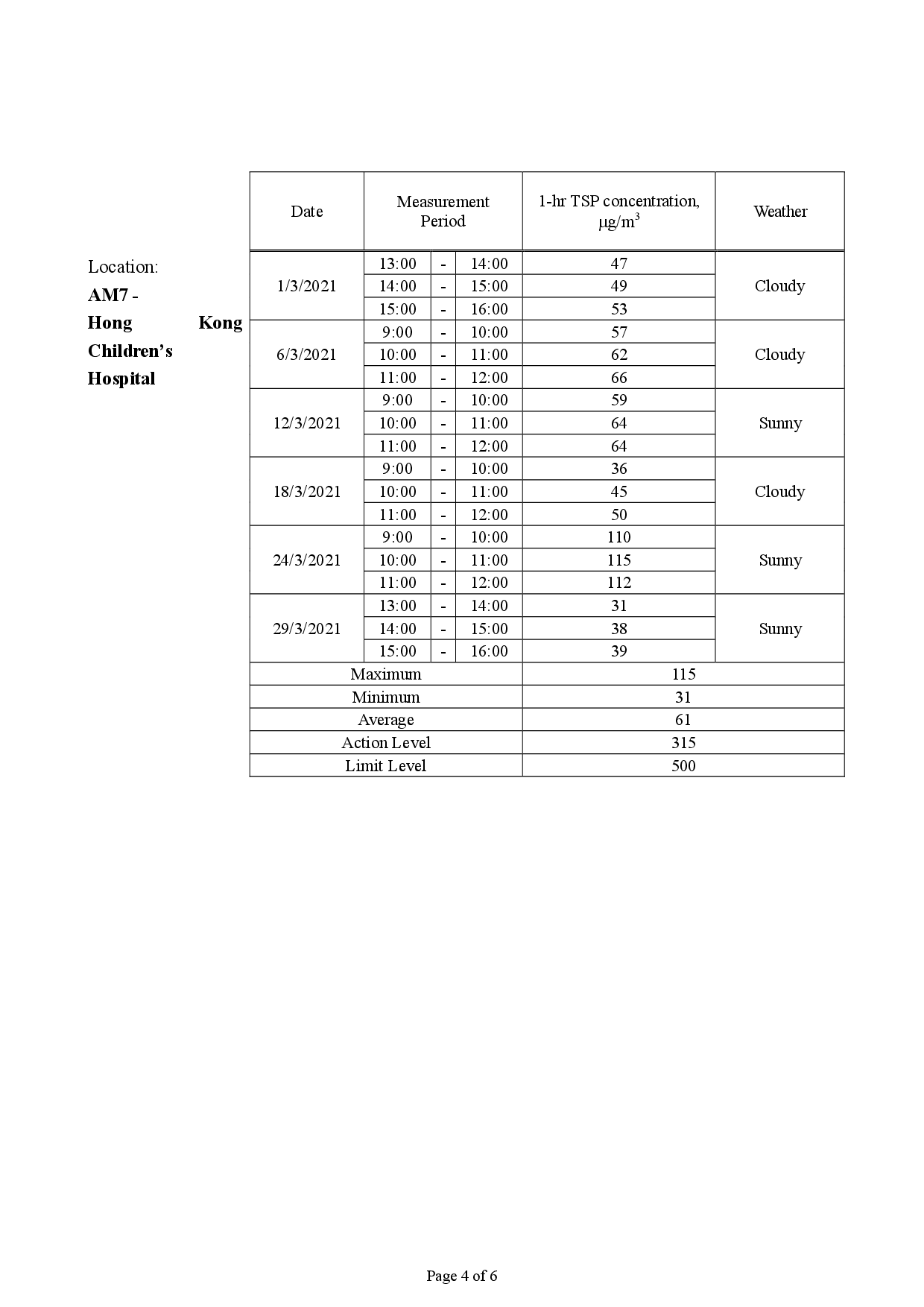

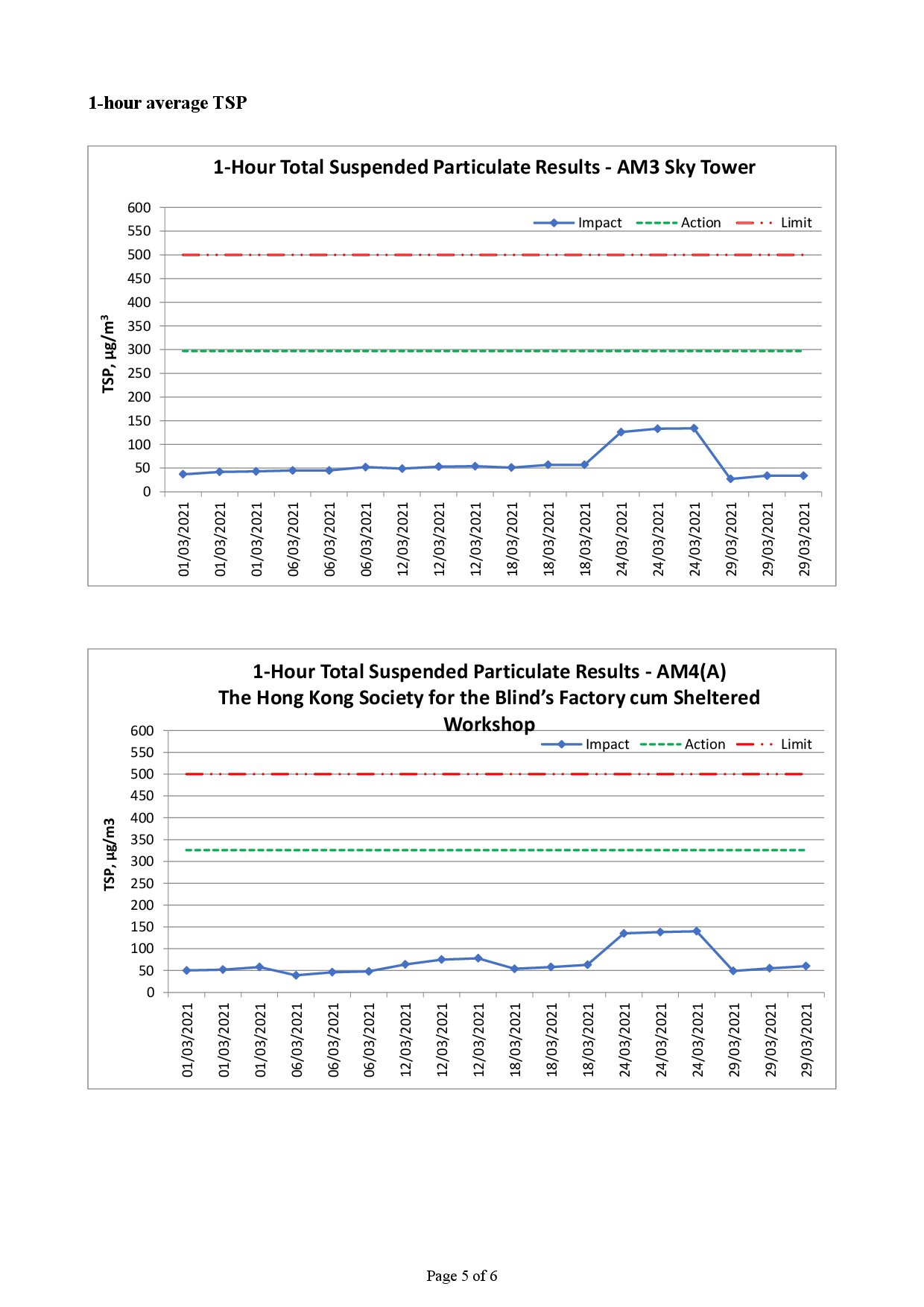

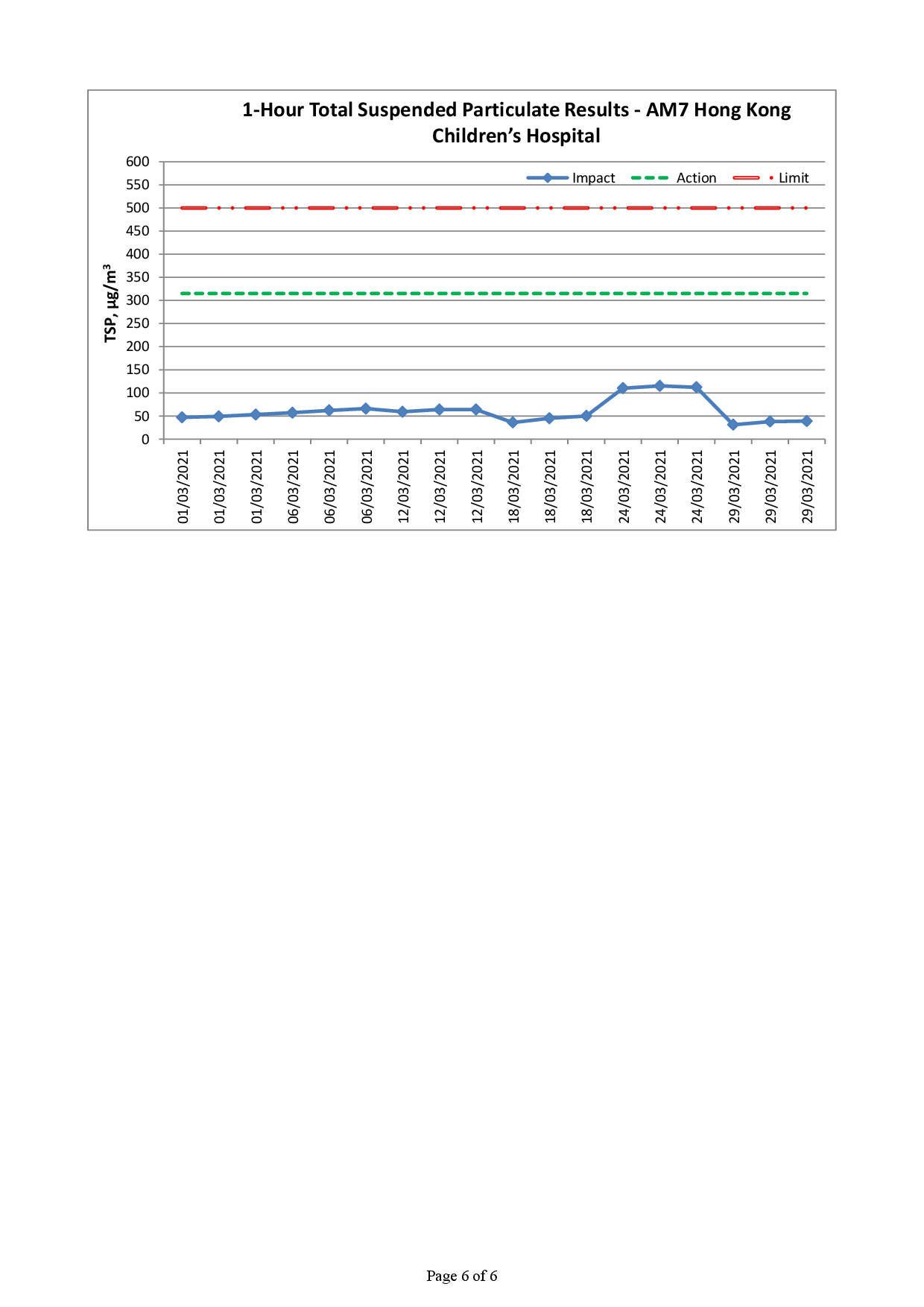

Impact Air Quality Monitoring results

Monitoring Parameters, Frequency and Duration

Monitoring Methodology and QA/QC Procedure

Impact Noise Monitoring results

4. COMPARISON OF EM&A RESULTS WITH EIA PREDICTIONS

5. LANDSCAPE AND VISUAL MONITORING

6. ENVIRONMENTAL SITE INSPECTION AND AUDIT

Status of Environmental Licenses, Notification and Permits

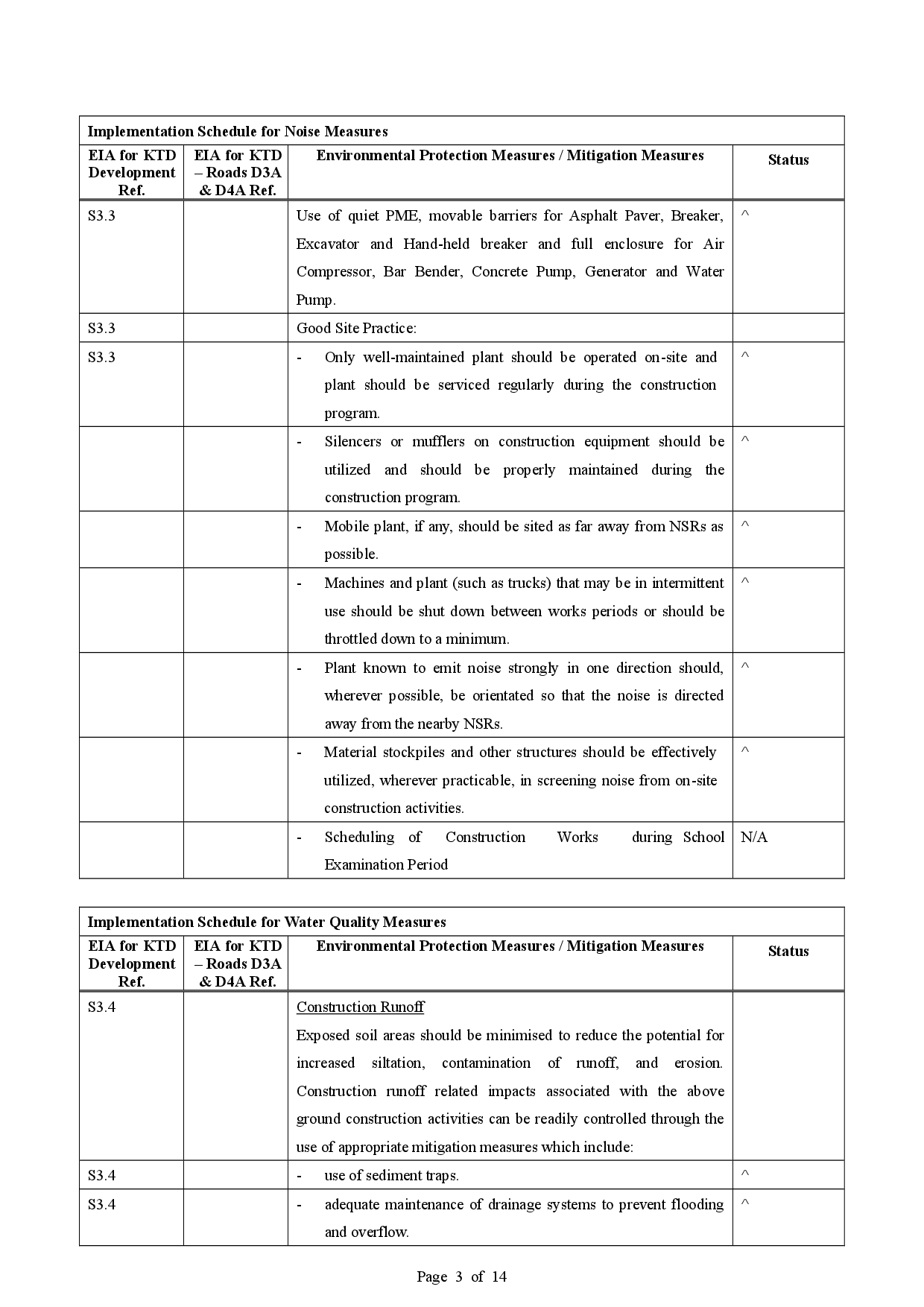

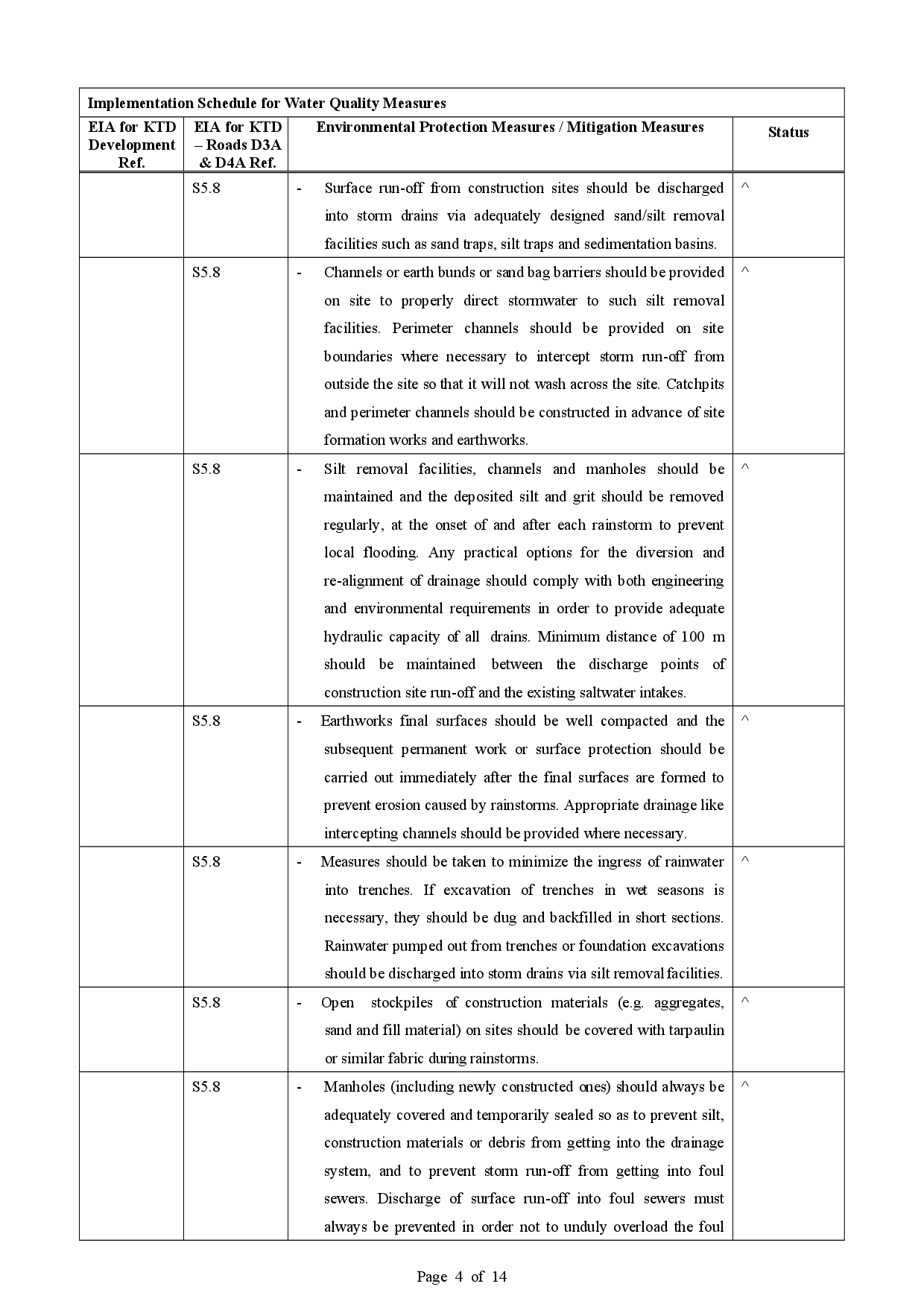

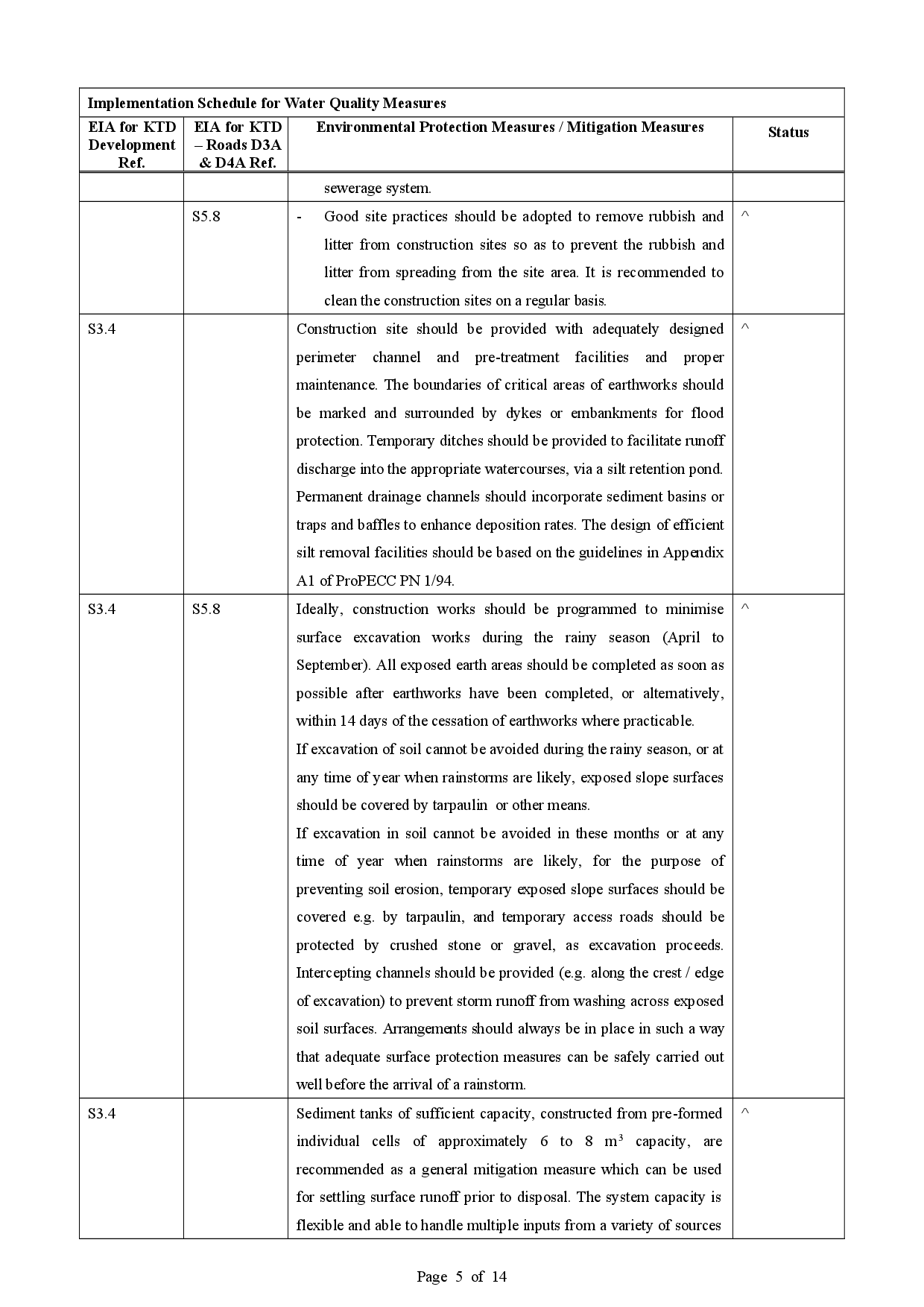

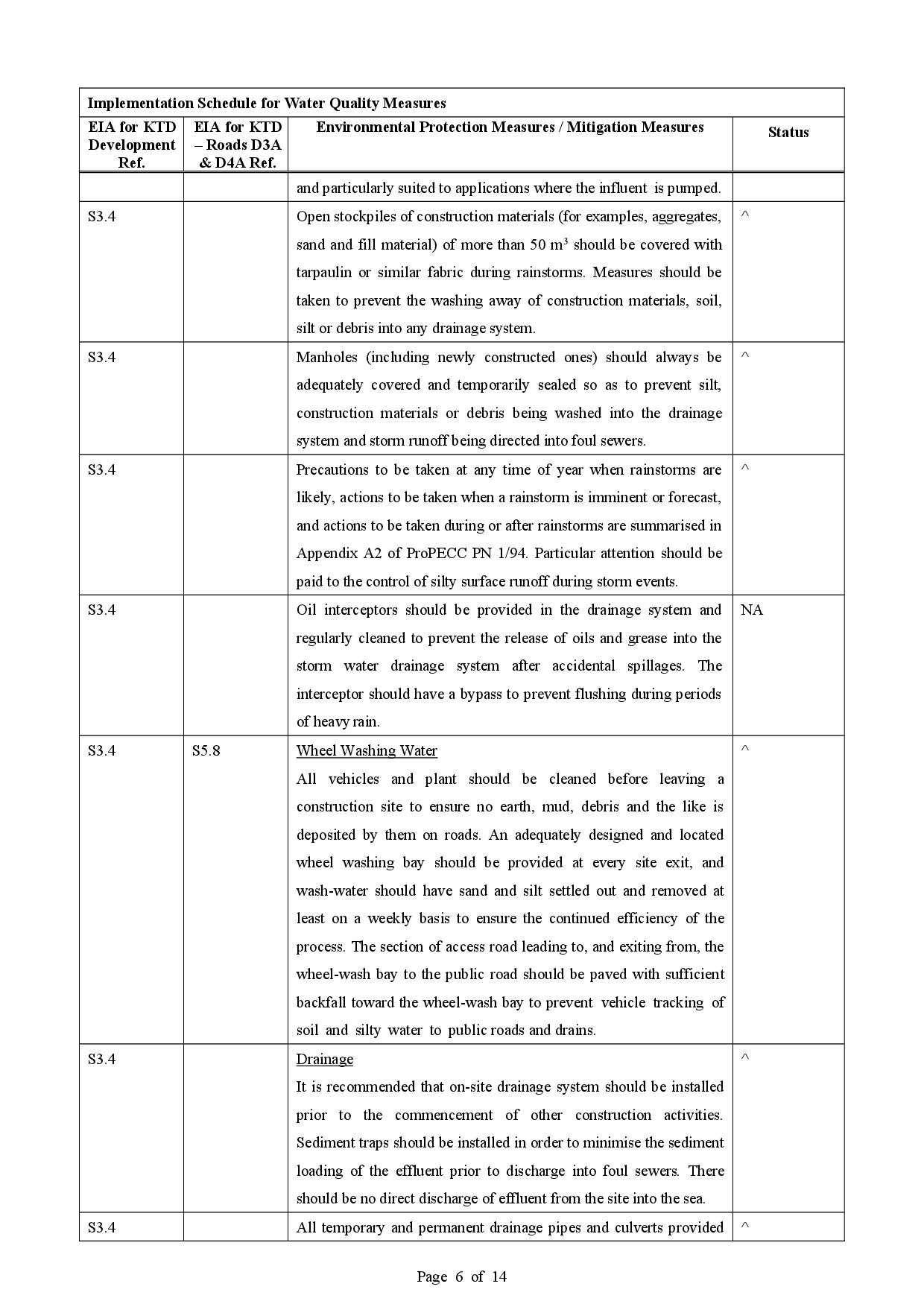

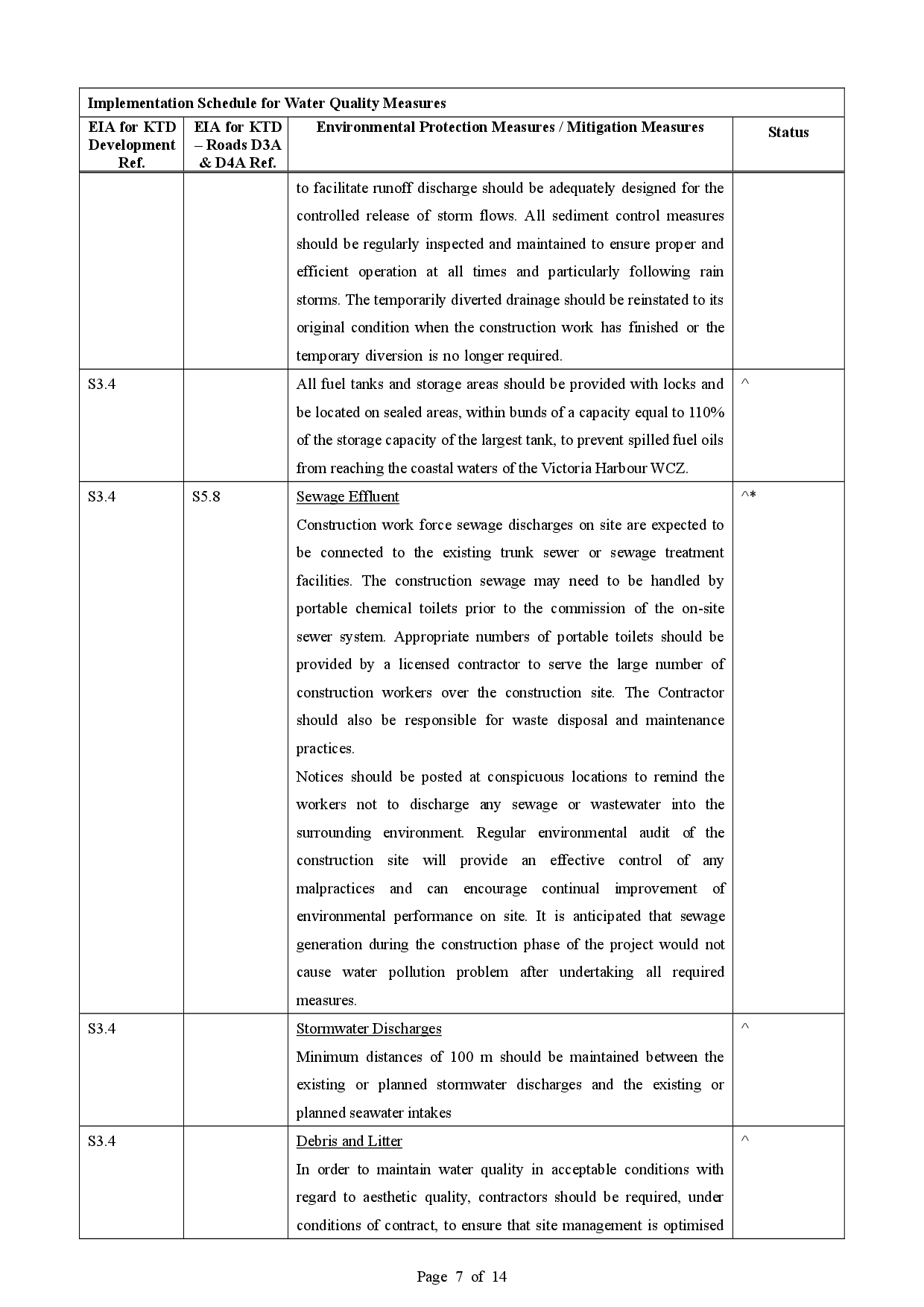

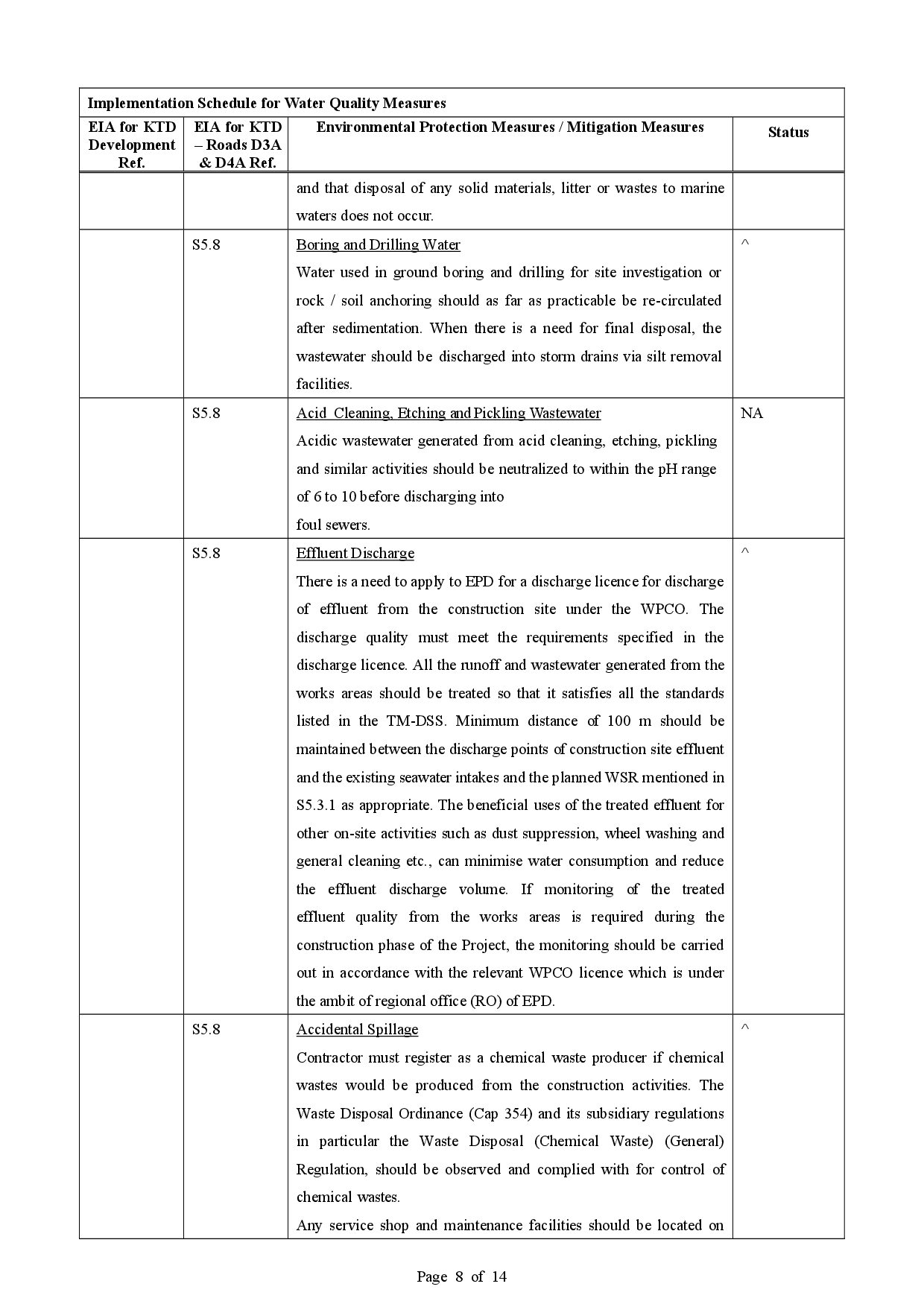

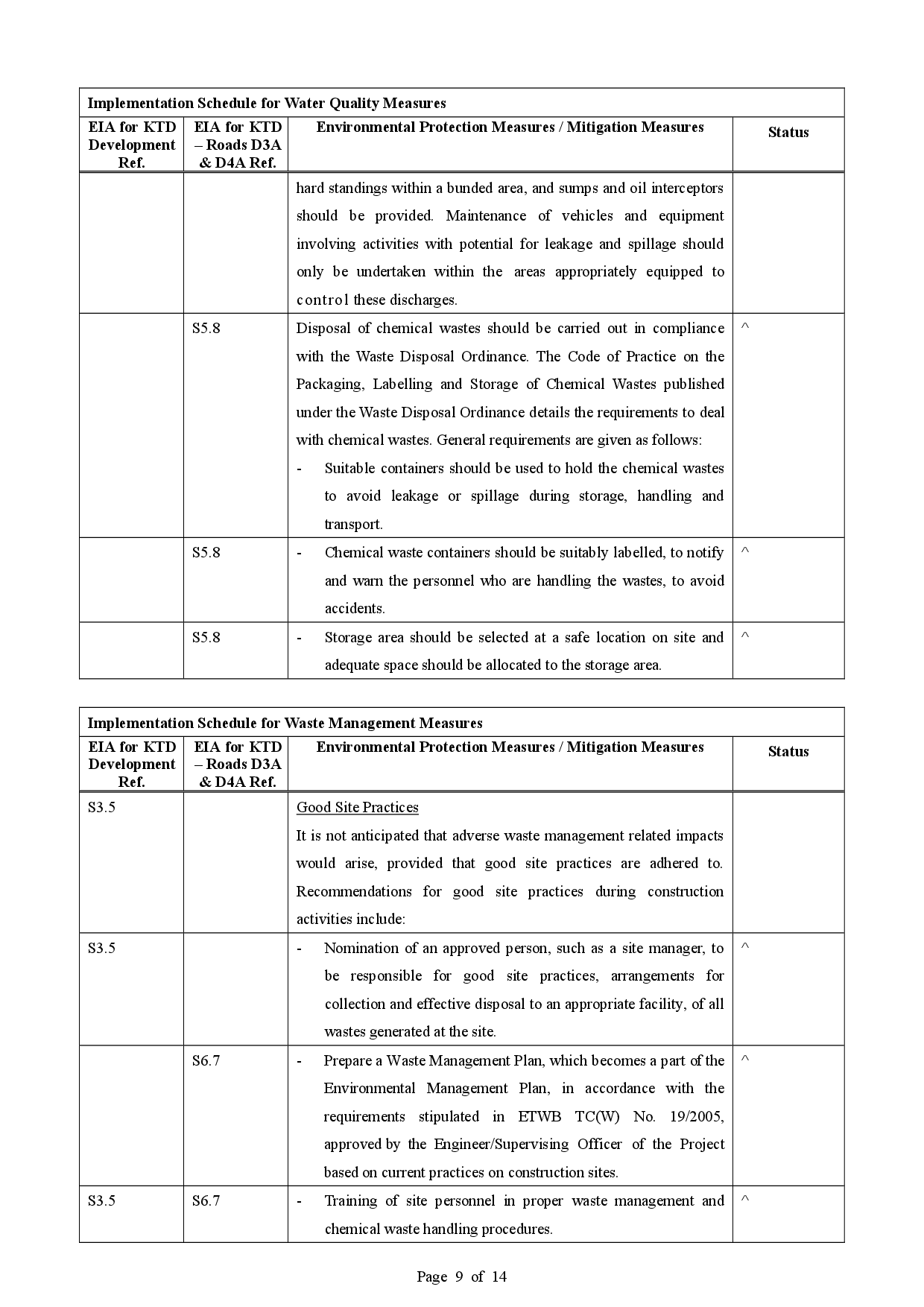

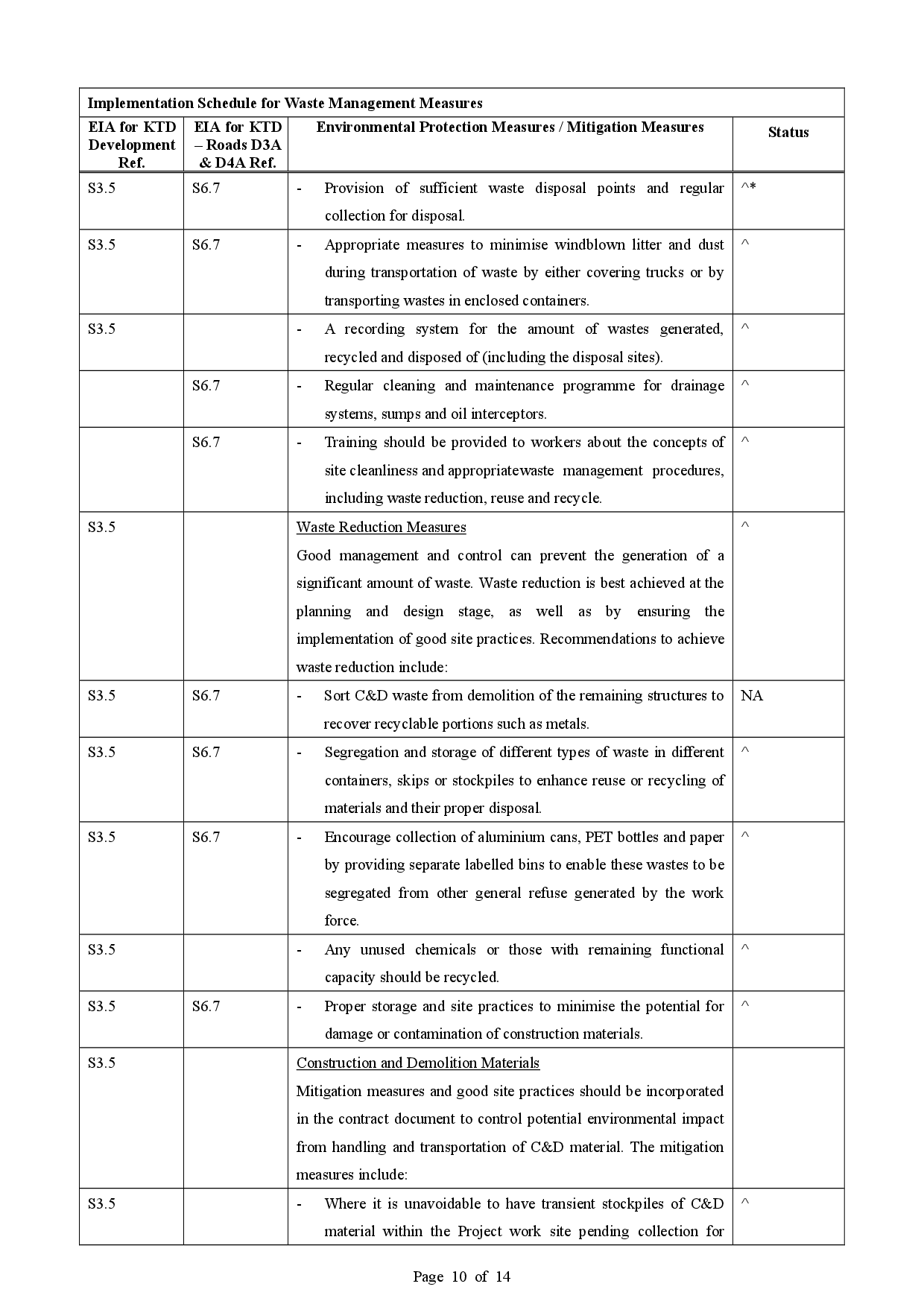

Implementation Status of Environmental Mitigation Measures

Environmental Complaint and Non-compliance

Notifications of summons and successful prosecutions

Construction Programme in the coming month

Environmental Site Inspection and Monitoring Schedule for next month

List of Tables

Table I Non-compliance Record in the Reporting Month

Table II Summary of complaints in the Reporting Month

Table III Summary of summons and successful prosecutions in the Reporting Month

Table IV Summary of future key issues and potential impact in the coming month

Table 1.1 Contact Information of Key Personnel

Table 1.2 Major activities of the Project during reporting month

Table 1.3 Summary of Status of Required Submission of EPs

Table 2.1 Locations of Air Quality Monitoring Stations

Table 2.2 Air Quality Monitoring Parameters, Frequency and Duration

Table 2.3 Air Quality Monitoring Equipment

Table 2.4 Action and Limit Levels of 24-hour average TSP for Construction Dust Monitoring

Table 2.5 Action and Limit Levels of 1-hour average TSP for Construction Dust Monitoring

Table 2.6 Summary of 24-hour average TSP Monitoring Data during the reporting month

Table 2.7 Summary of 1-hour average TSP Monitoring Data during the reporting month

Table 3.1 Locations of Noise Monitoring Stations

Table 3.2 Noise Monitoring Parameters, Frequency and Duration

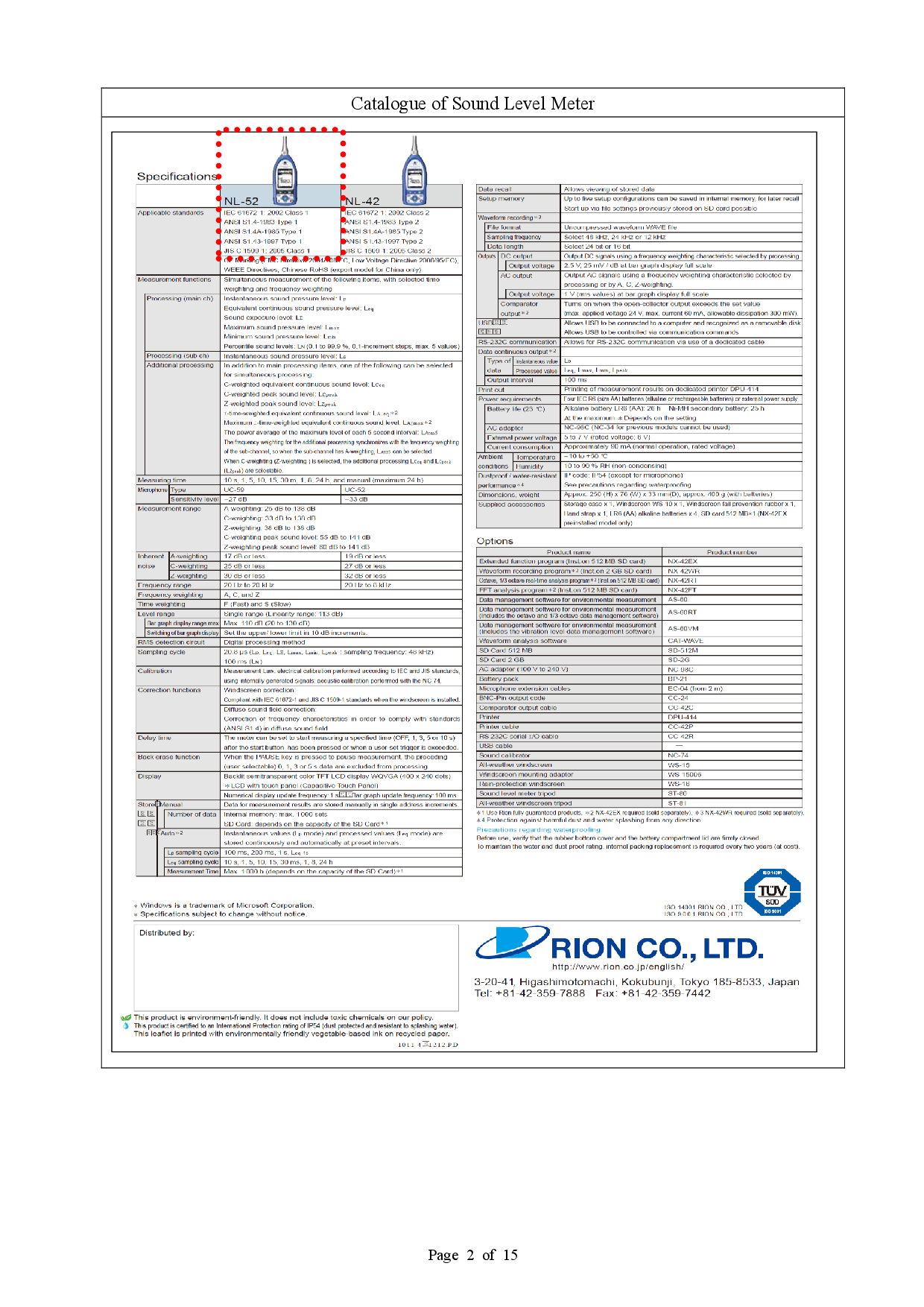

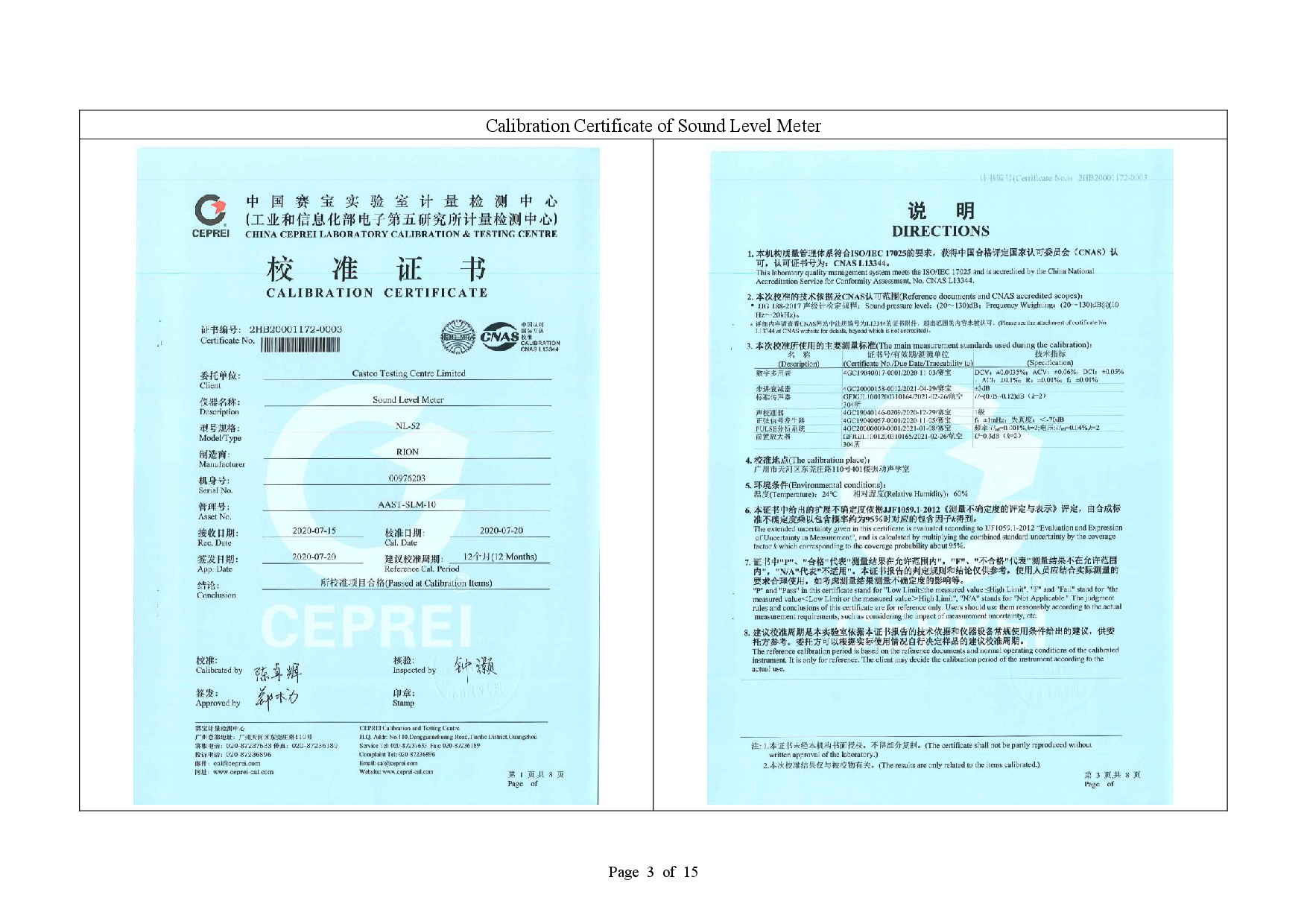

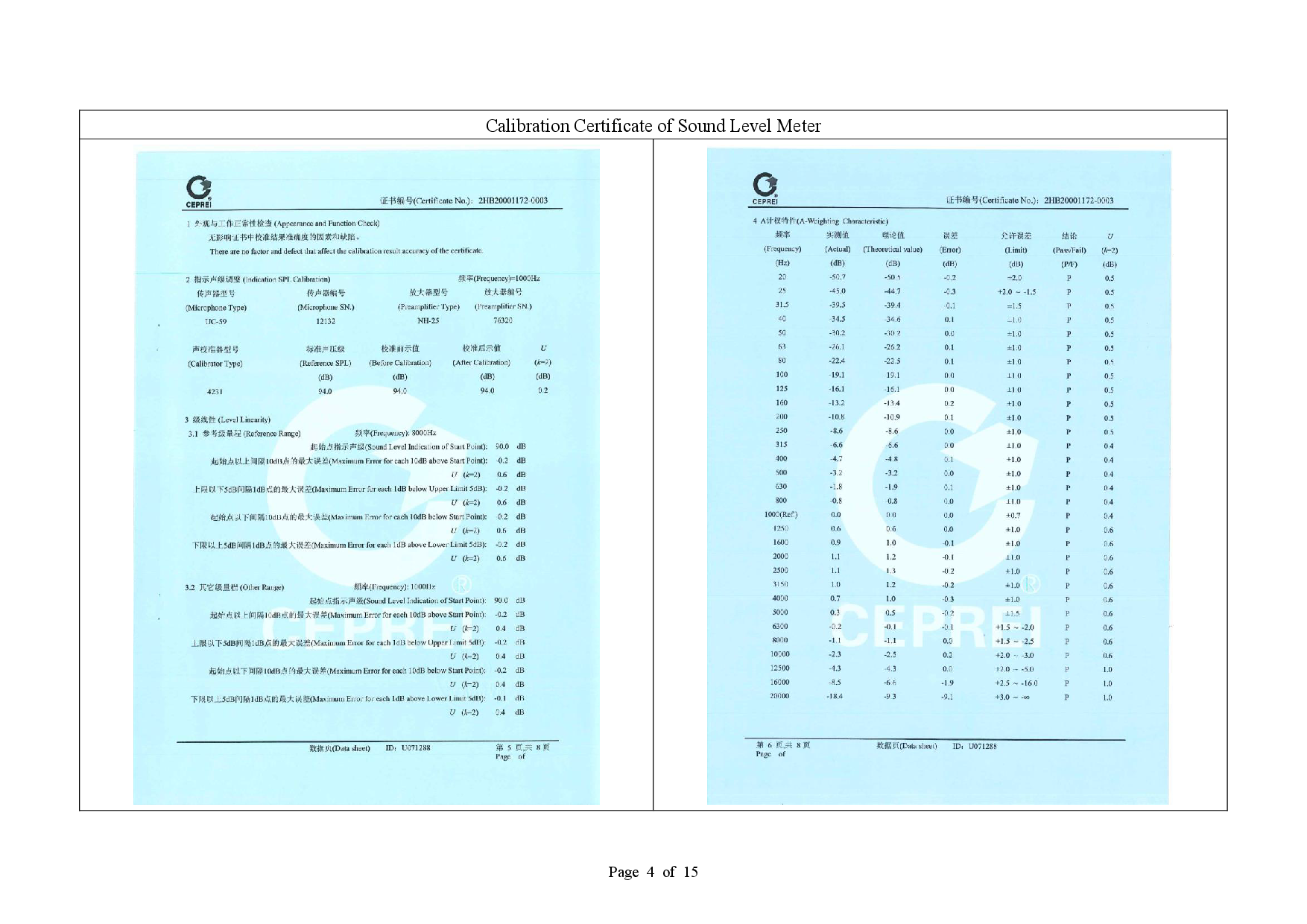

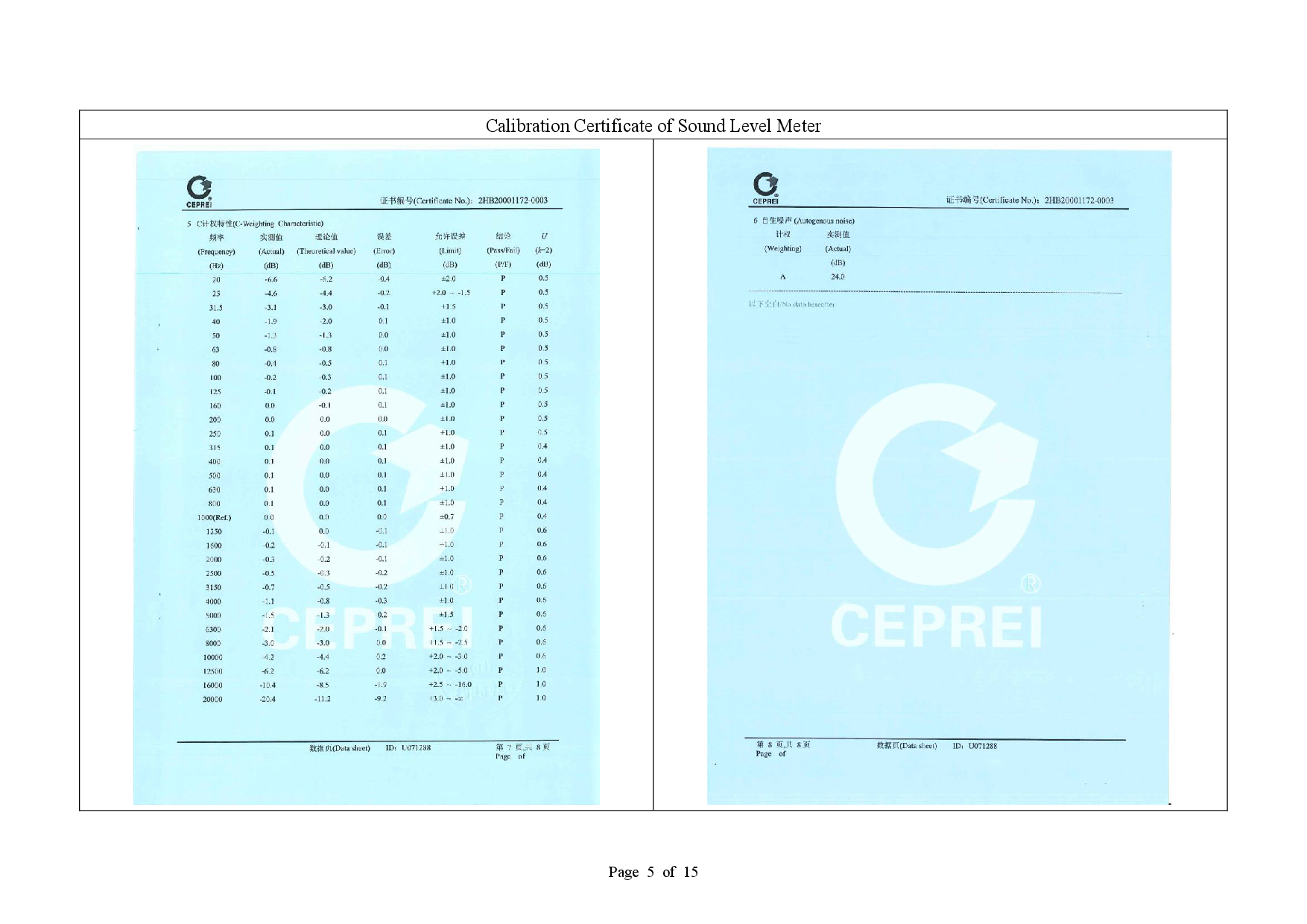

Table 3.3 Noise Monitoring Equipment

Table 3.4 Baseline Noise Level and Action and Limit Levels for Construction Noise Monitoring

Table 3.5 Summary of Noise Monitoring Data during the reporting month

Table 4.1 Comparison of 24-hour average TSP Monitoring Data with EIA predictions

Table 4.2 Comparison of 1-hour average TSP Monitoring Data with EIA predictions

Table 4.3 Comparison of Noise Monitoring Data with EIA predictions

Table 5.1 Summary of observations of Landscape and Visual impact during the reporting month

Table 6.1 Summary of site inspections observations during the reporting month

Table 6.2 Summary of Environmental Licenses, Notifications and Permits

Table 6.3 Summary of complaints in the Reporting Month

Table 6.4 Summary of summons and successful prosecutions in the Reporting Month

Table 7.1 Summary of future key issues and potential impact in the coming month

List of Figure

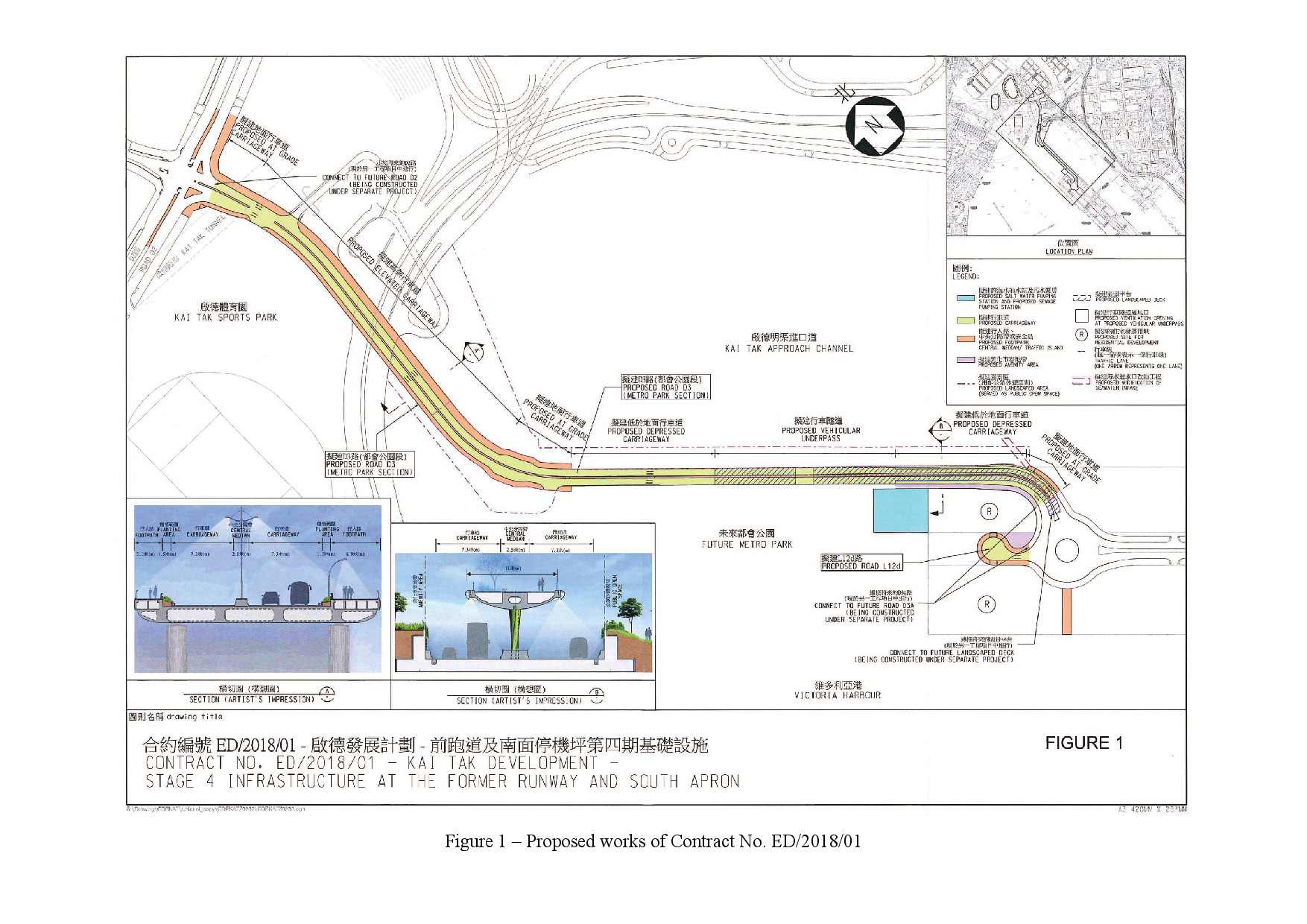

Figure 1 – Proposed works of Contract No. ED/2018/01

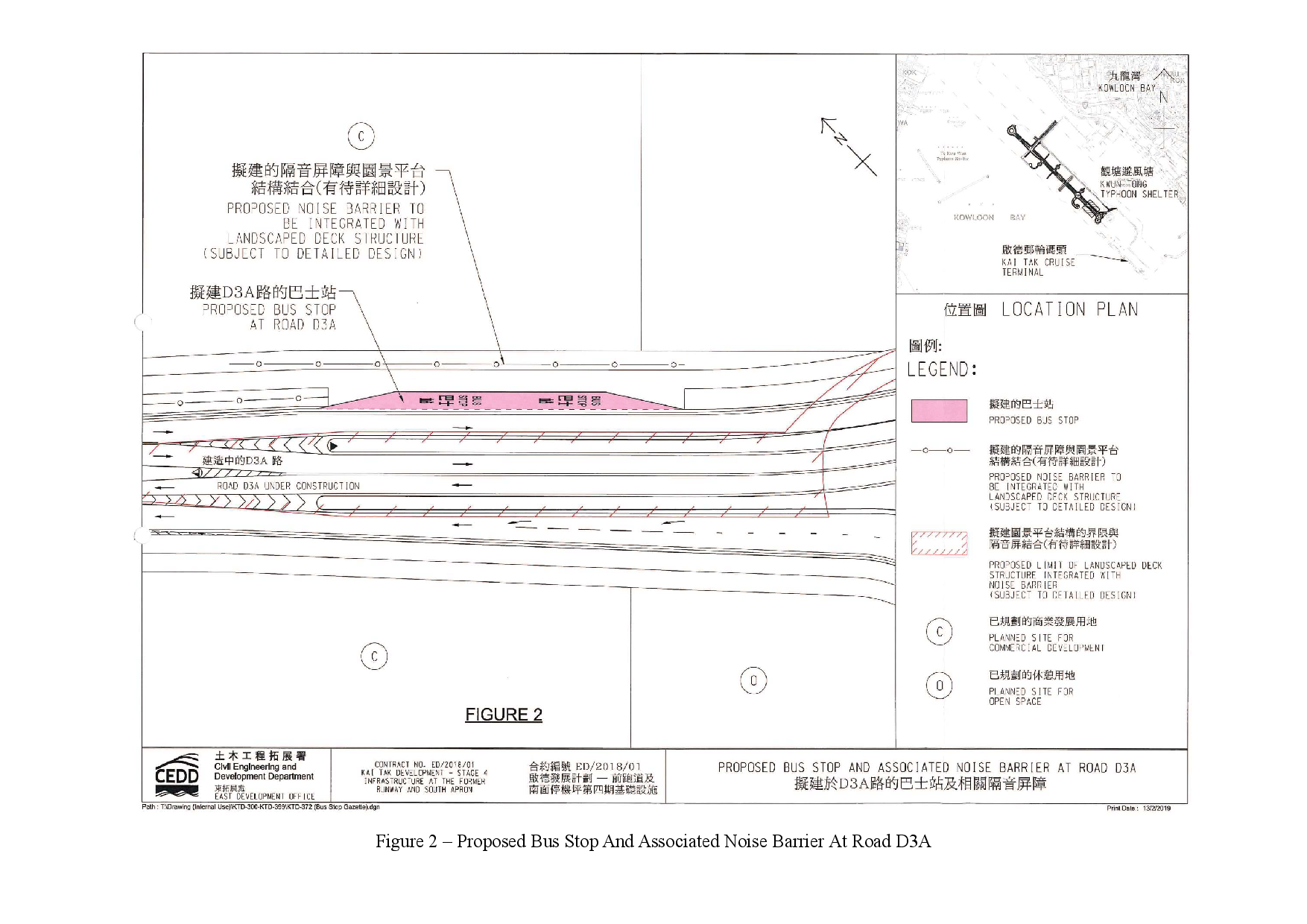

Figure 2 – Proposed Bus Stop And Associated Noise Barrier At Road D3A

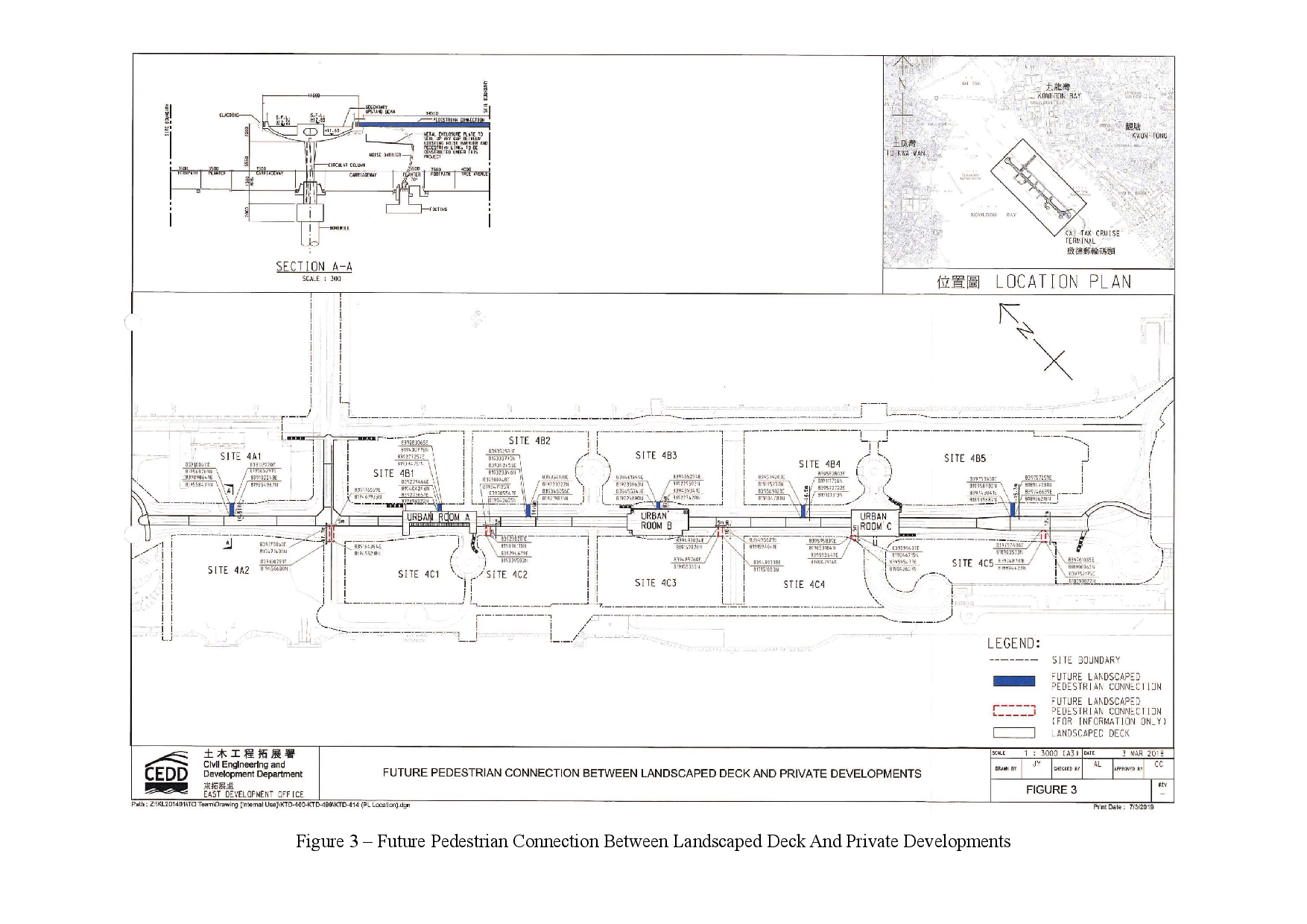

Figure 3 – Future Pedestrian Connection Between Landscaped Deck And Private Developments

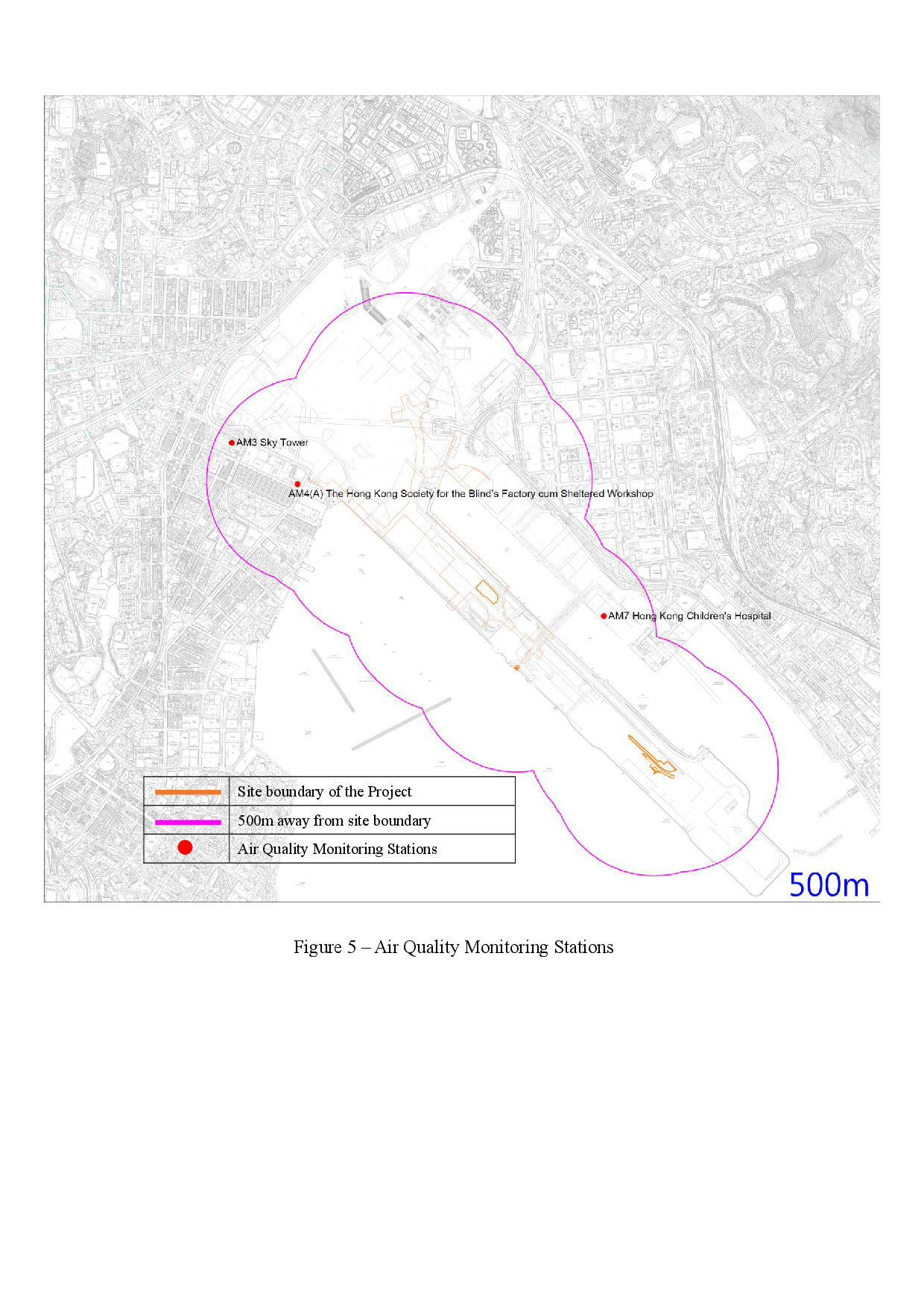

Figure 5 – Air Quality Monitoring Stations

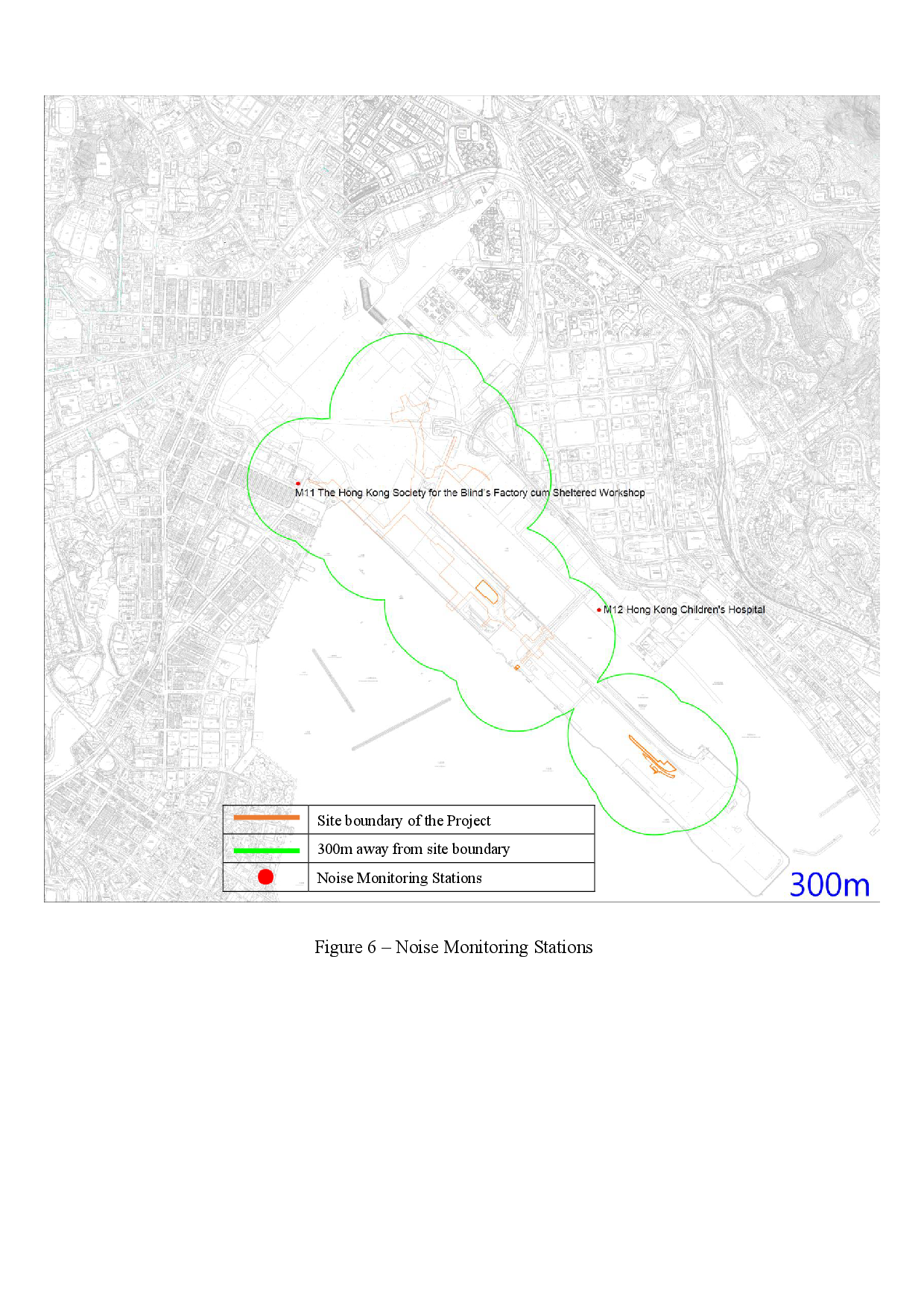

Figure 6 – Noise Monitoring Stations

List of Appendices

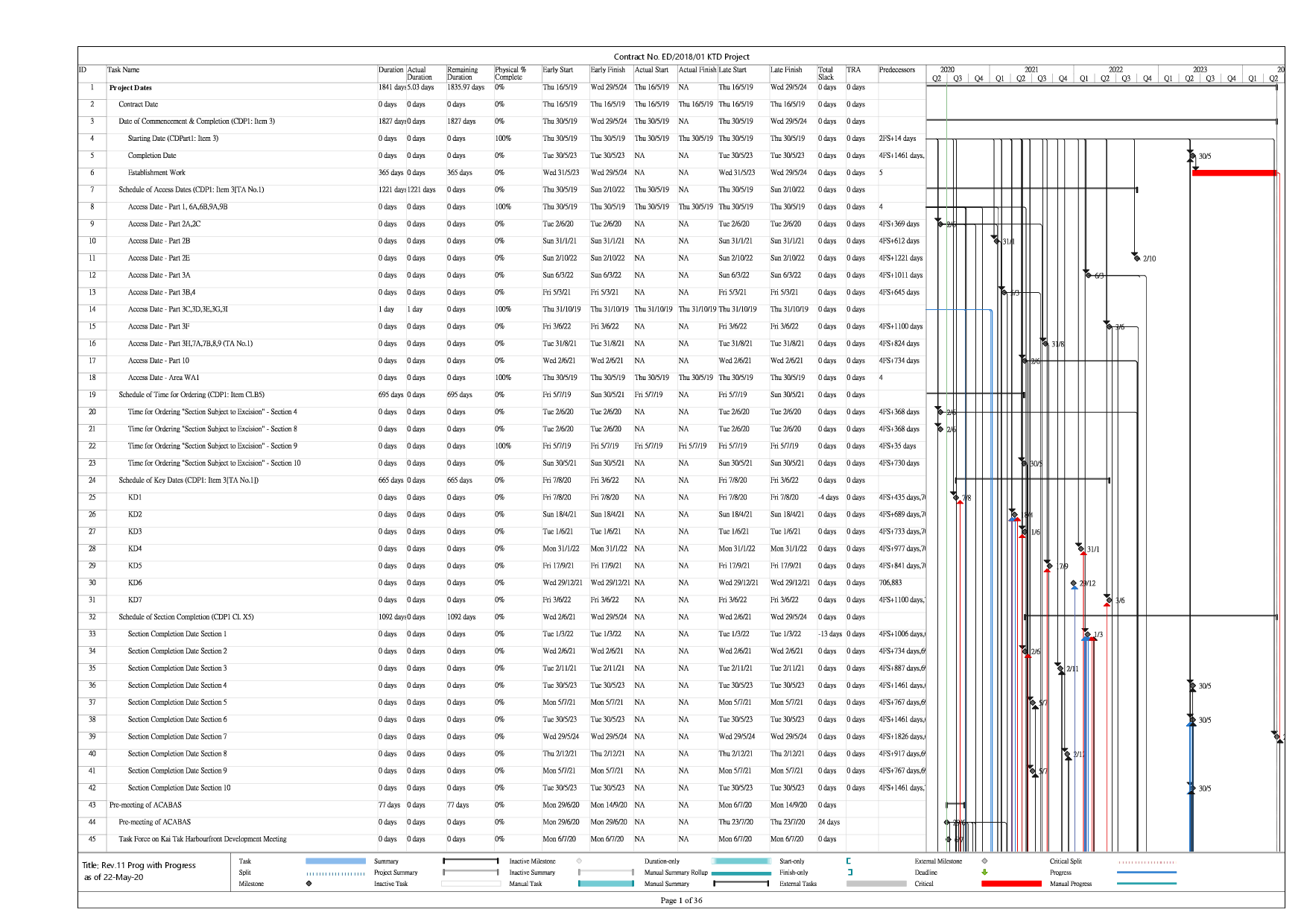

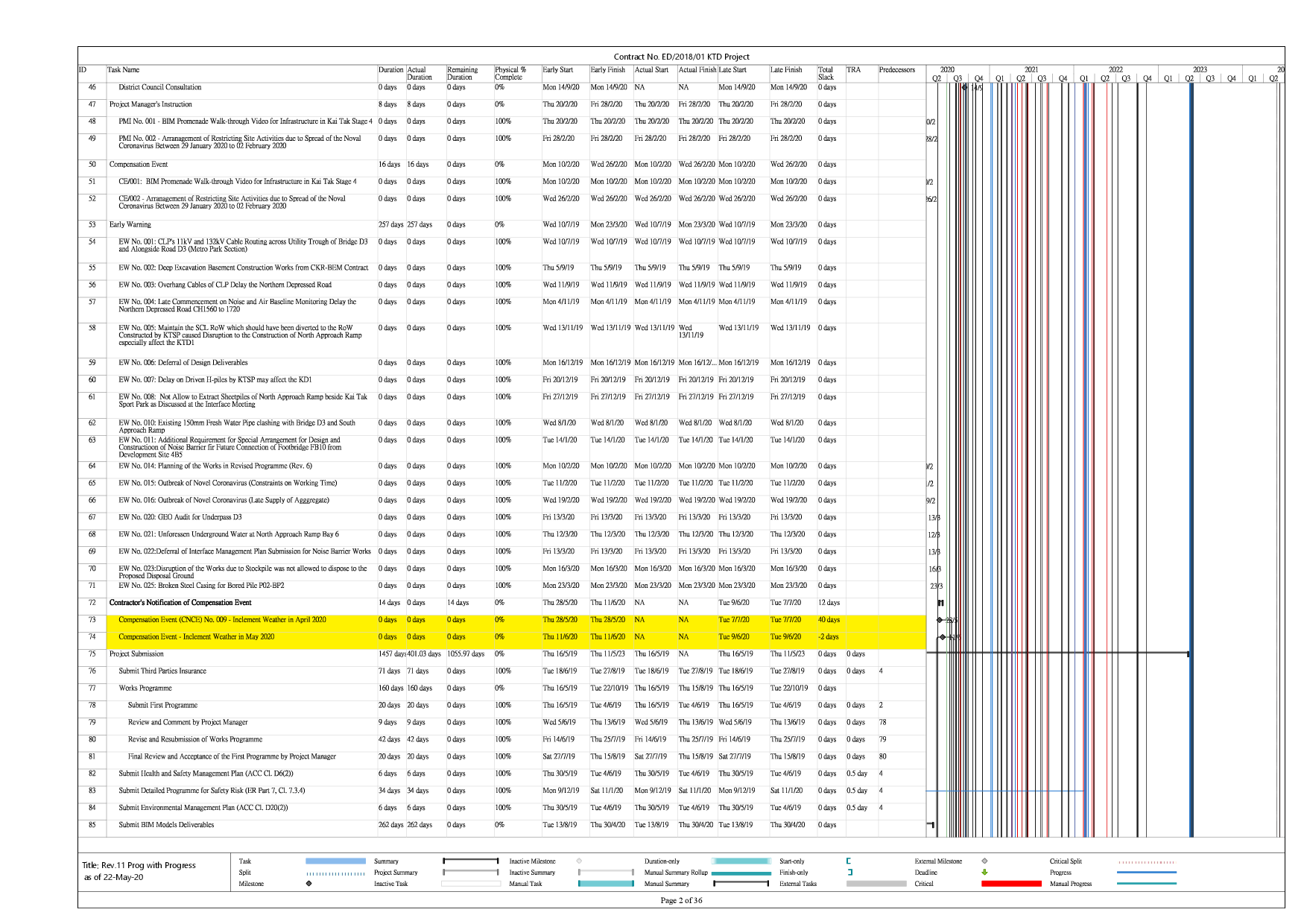

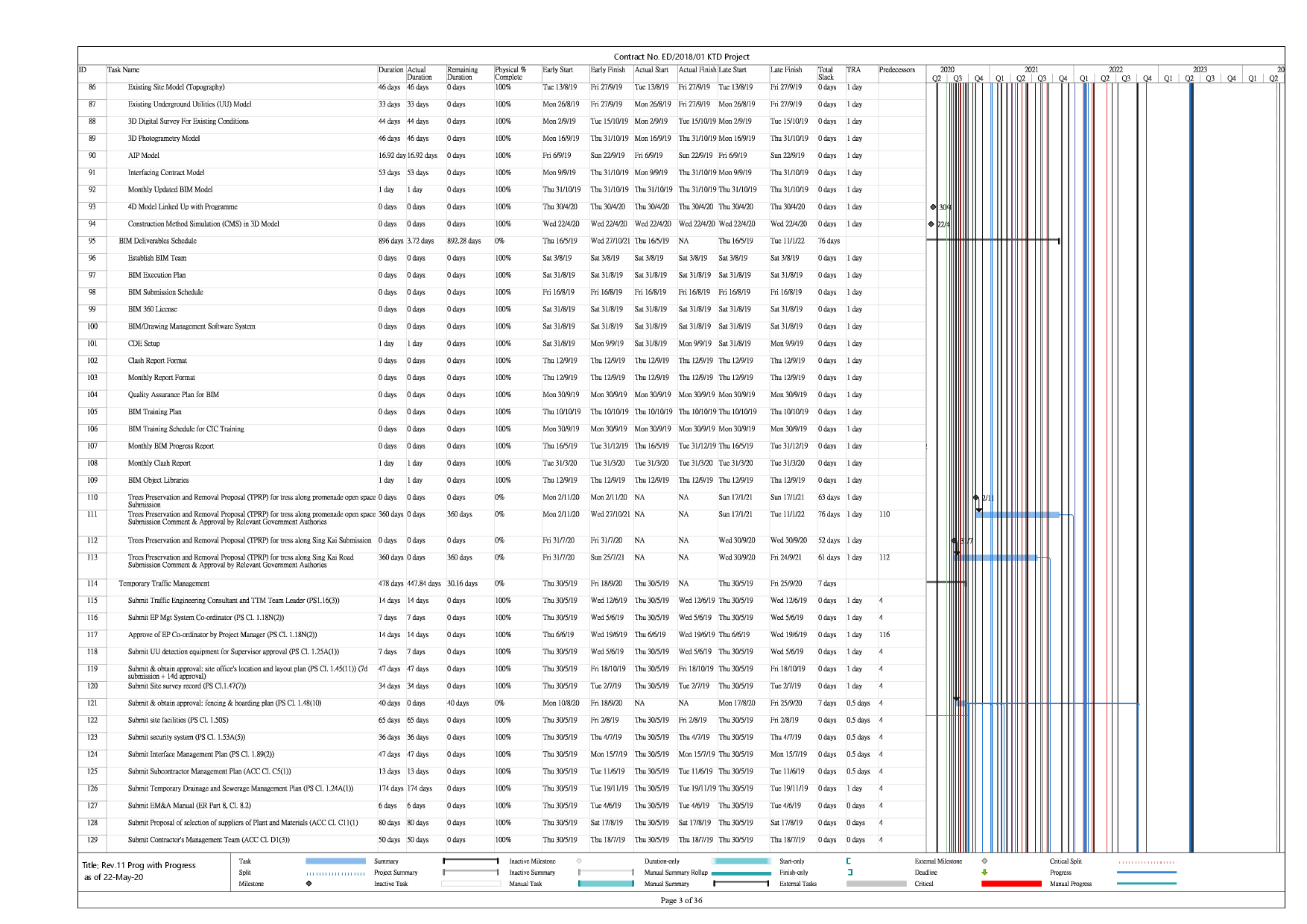

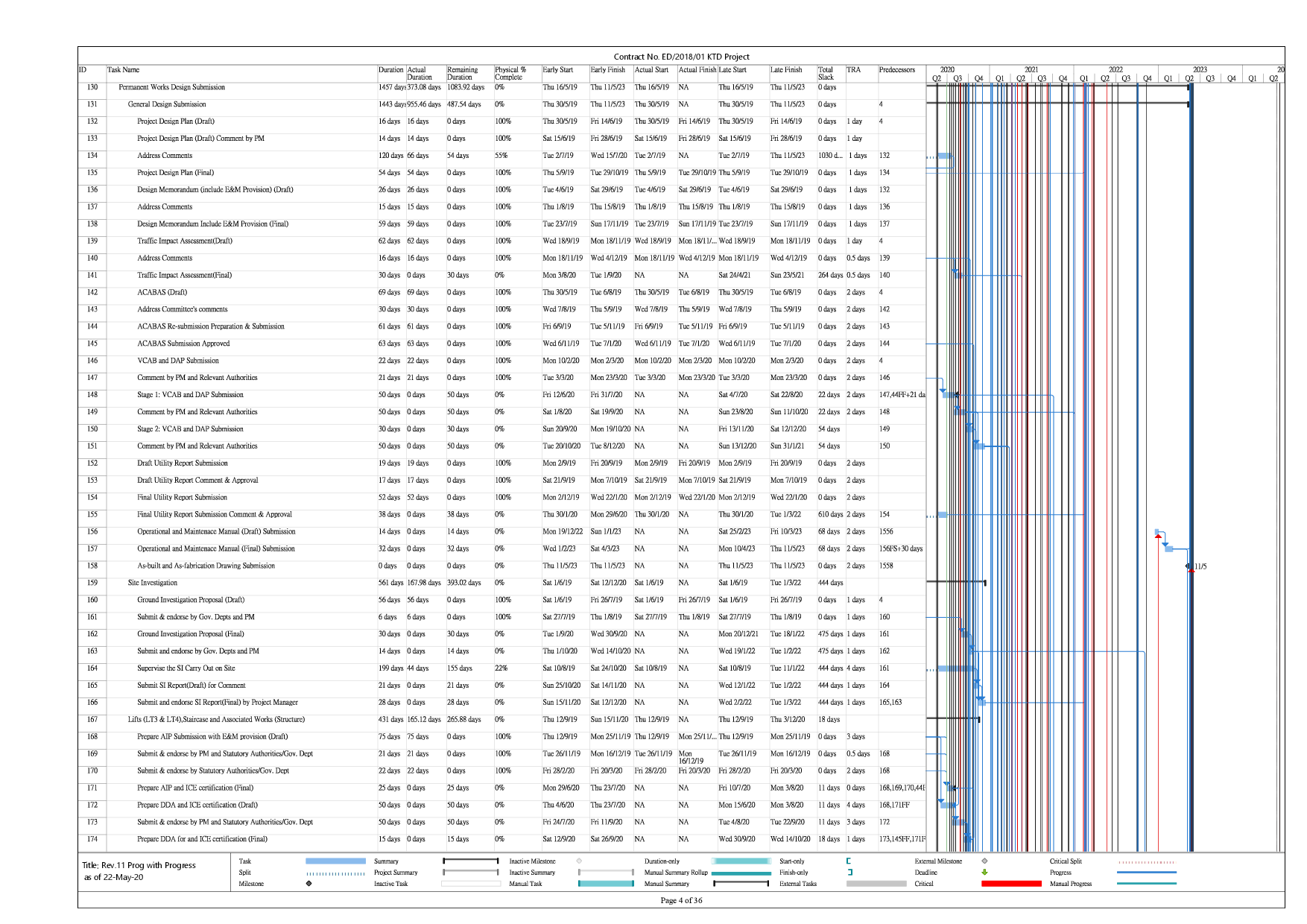

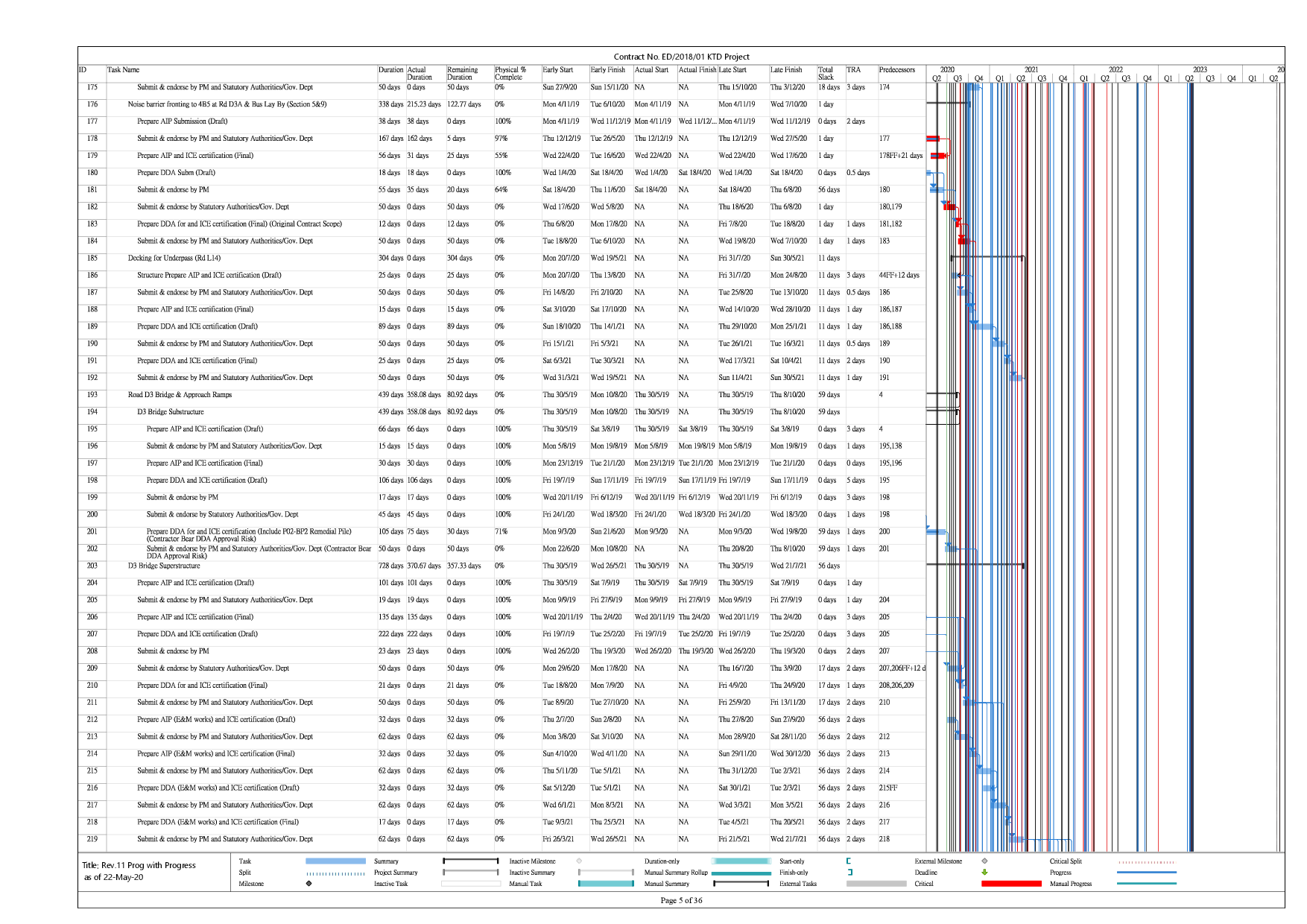

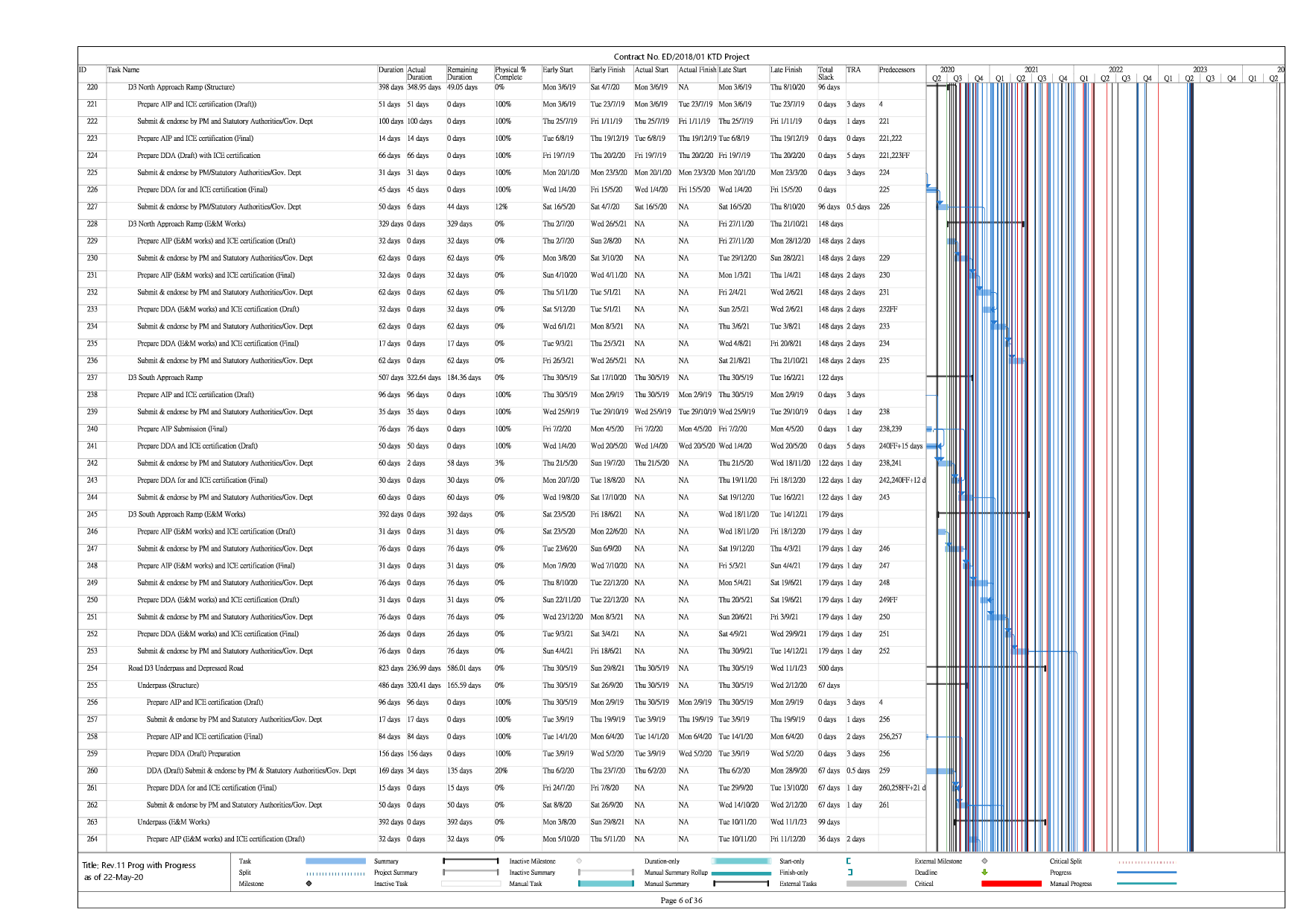

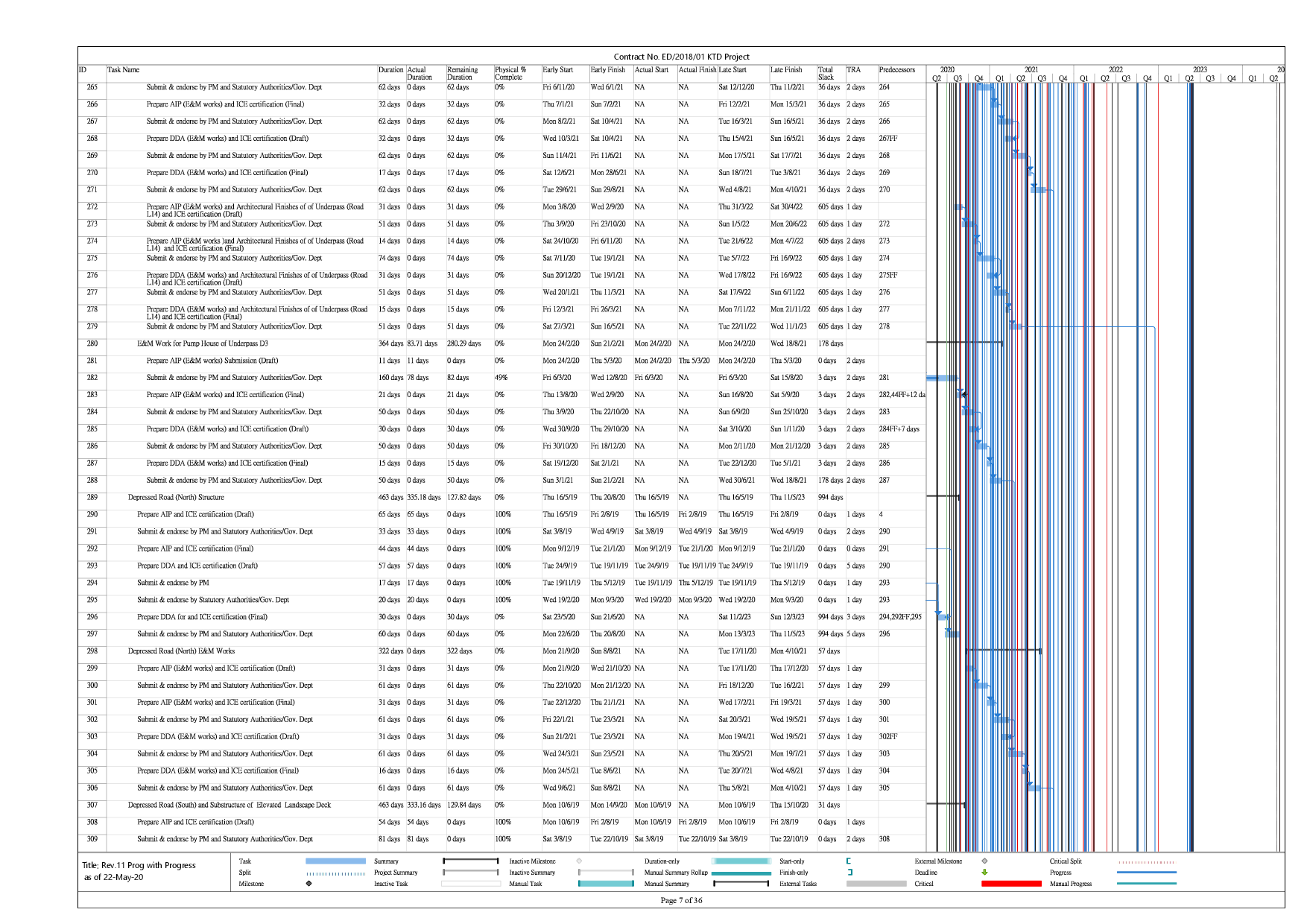

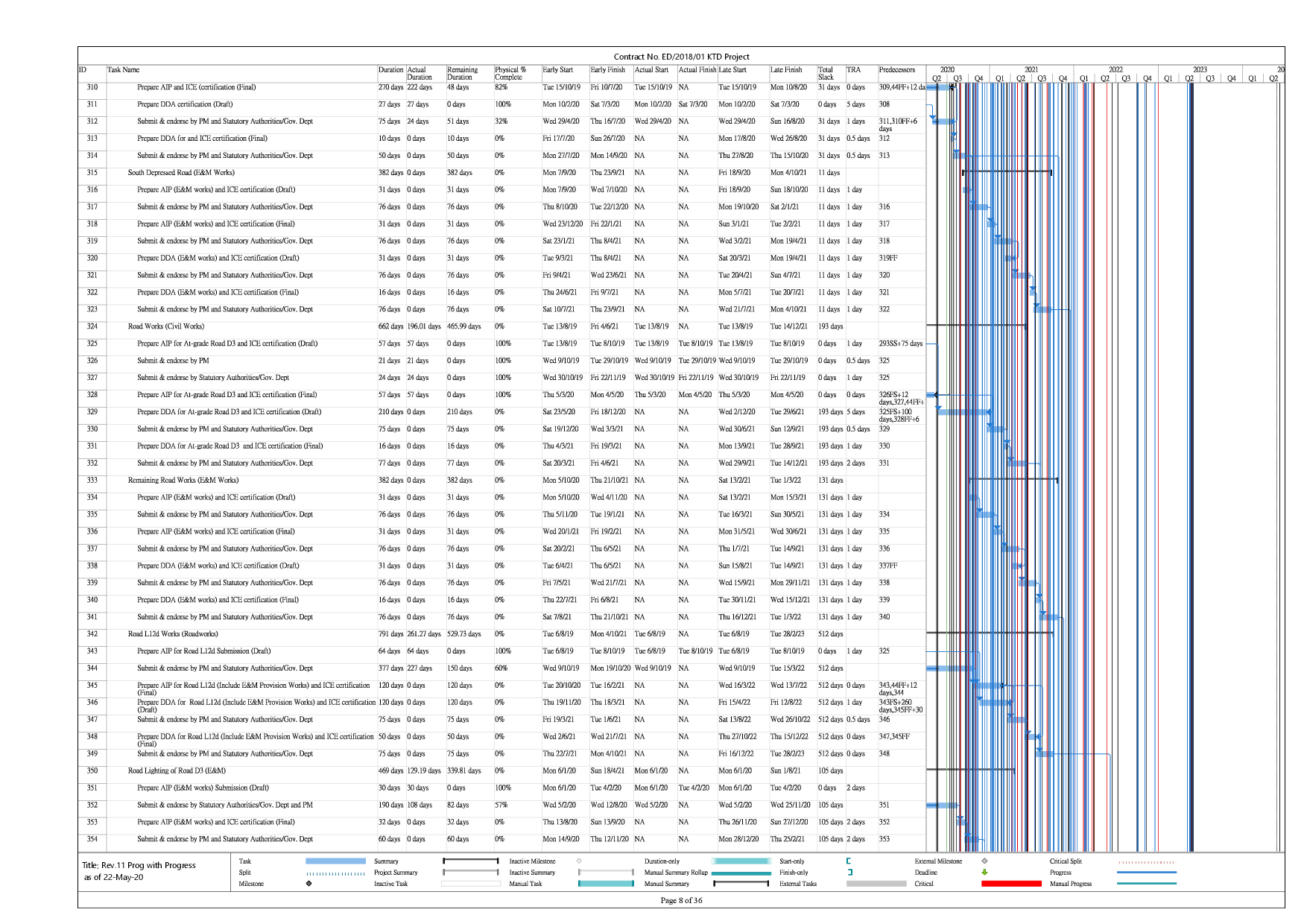

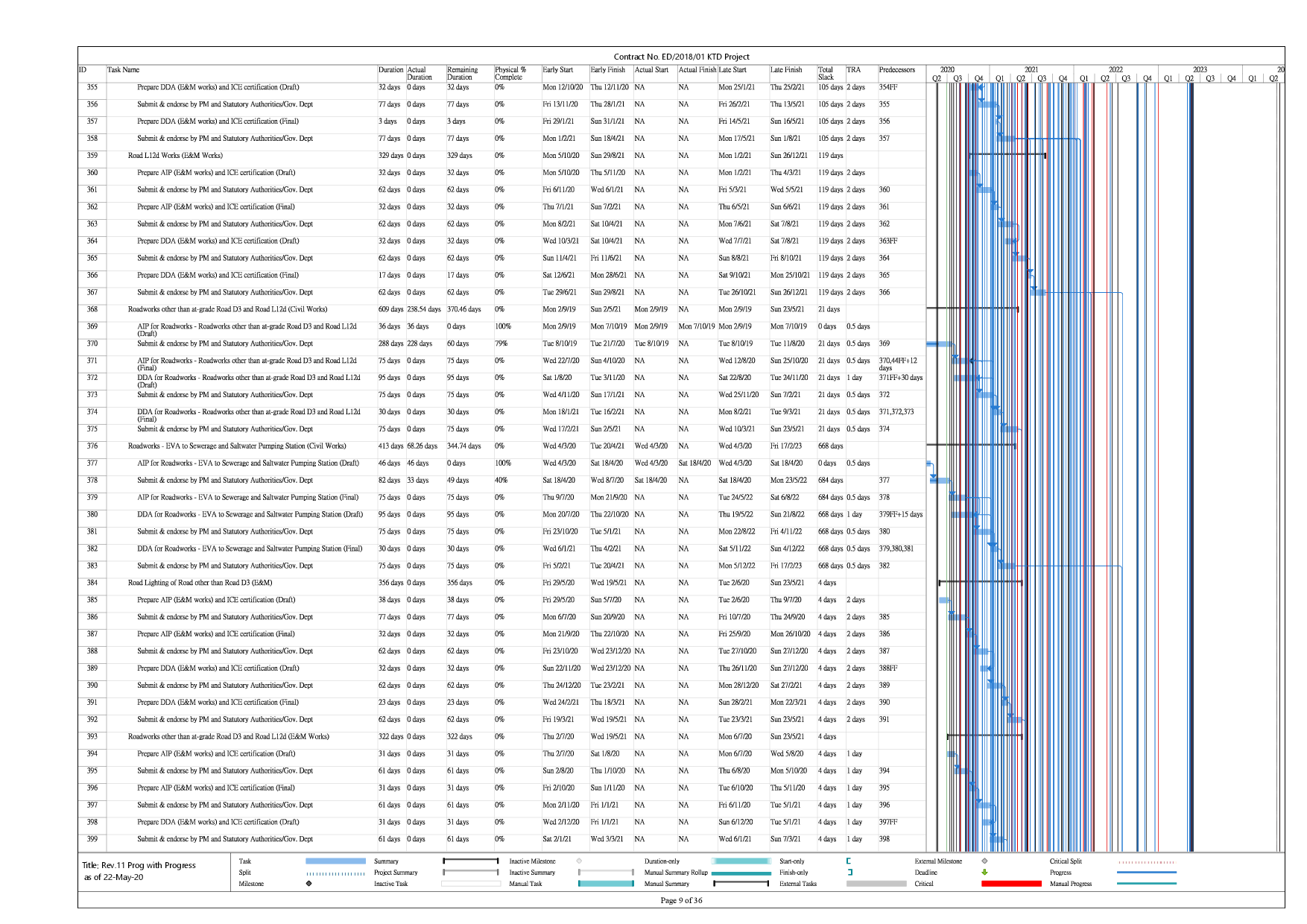

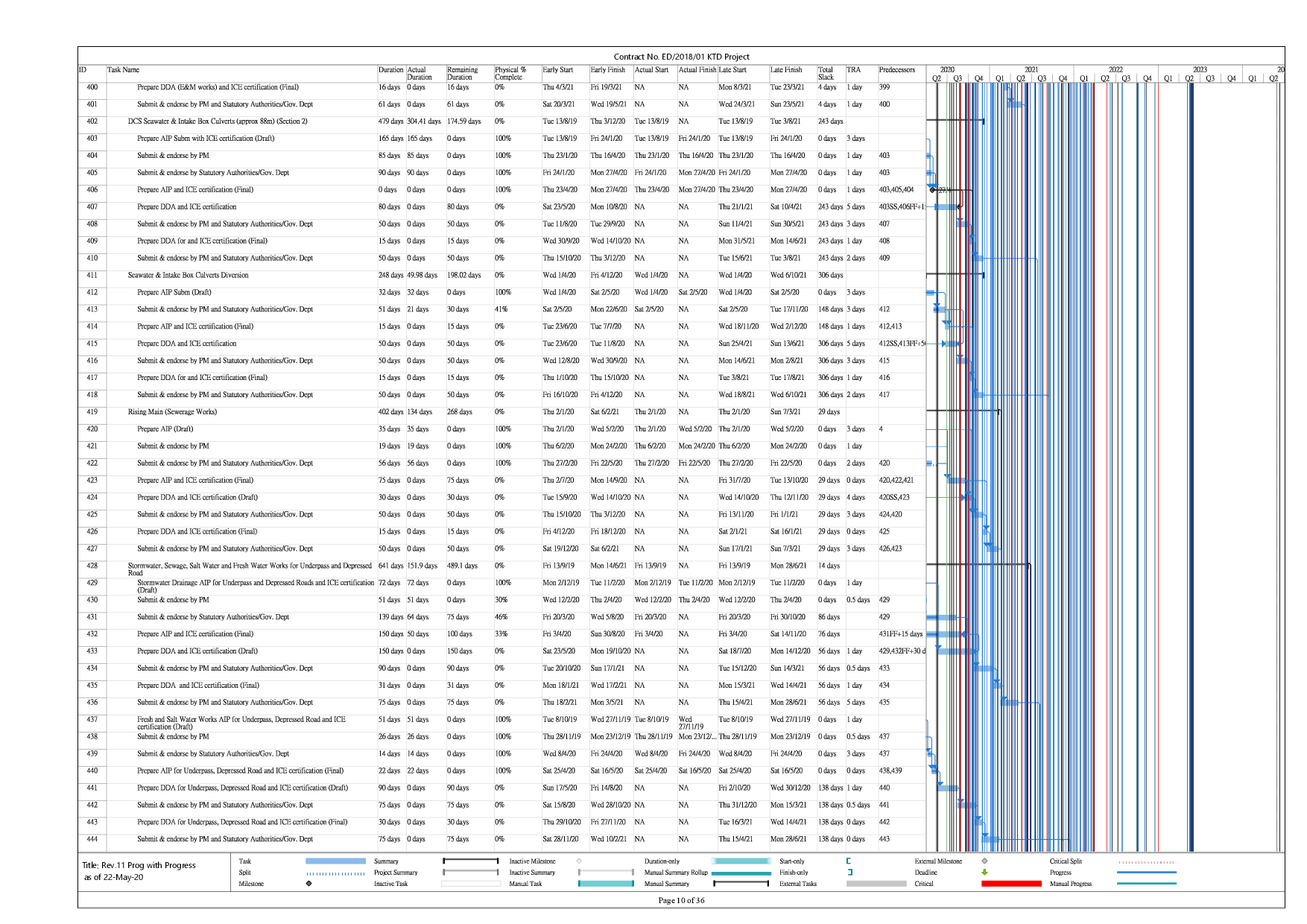

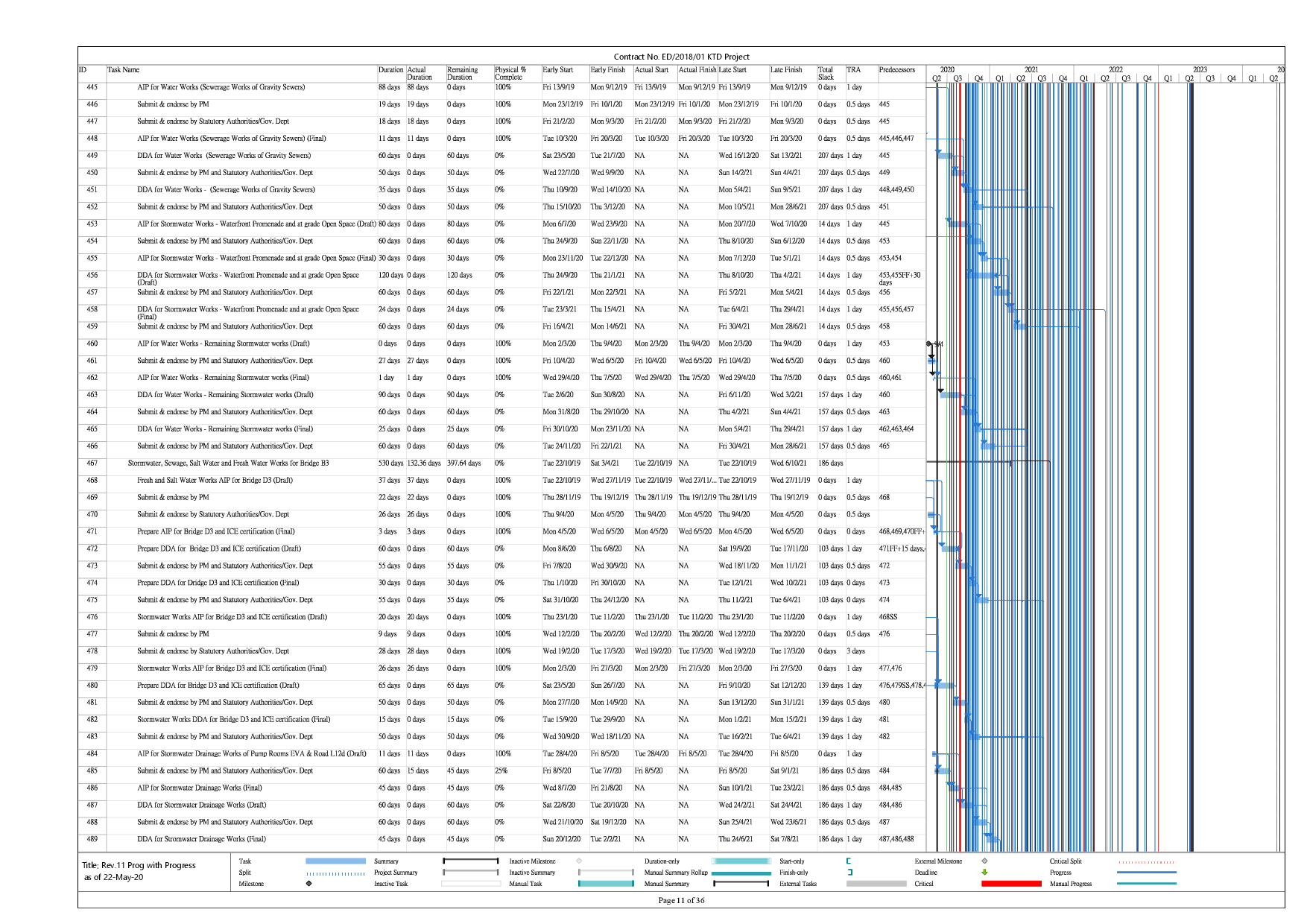

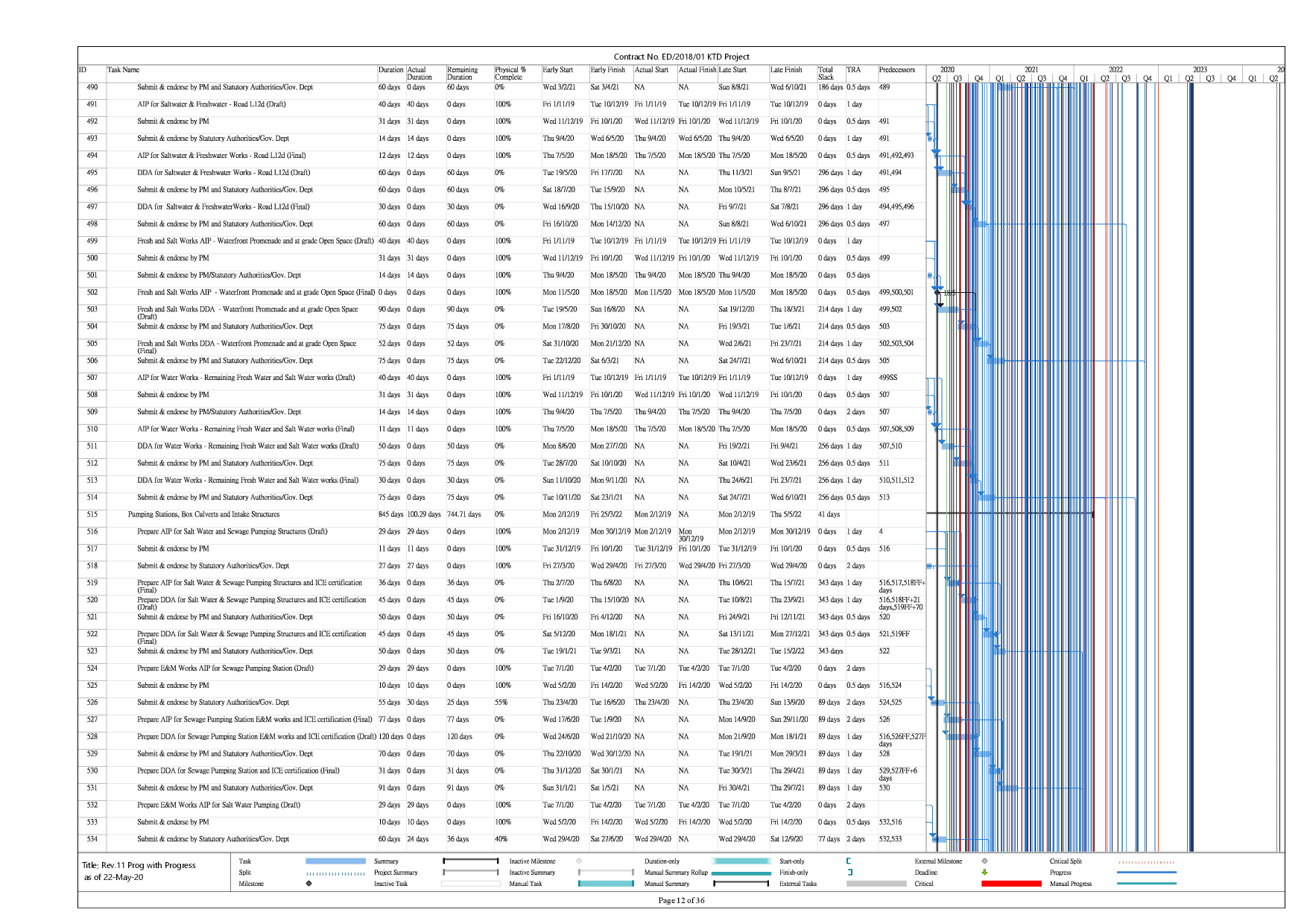

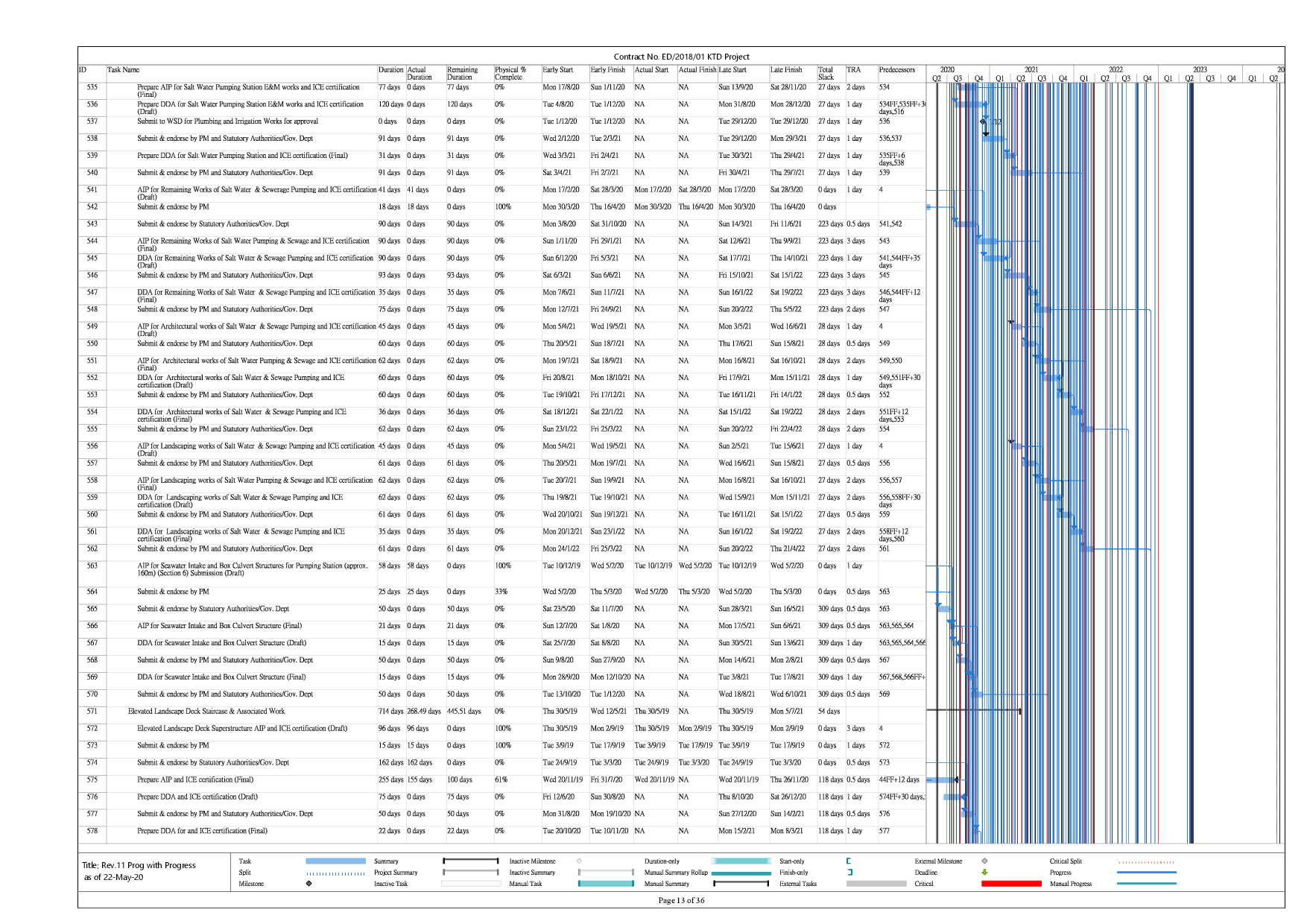

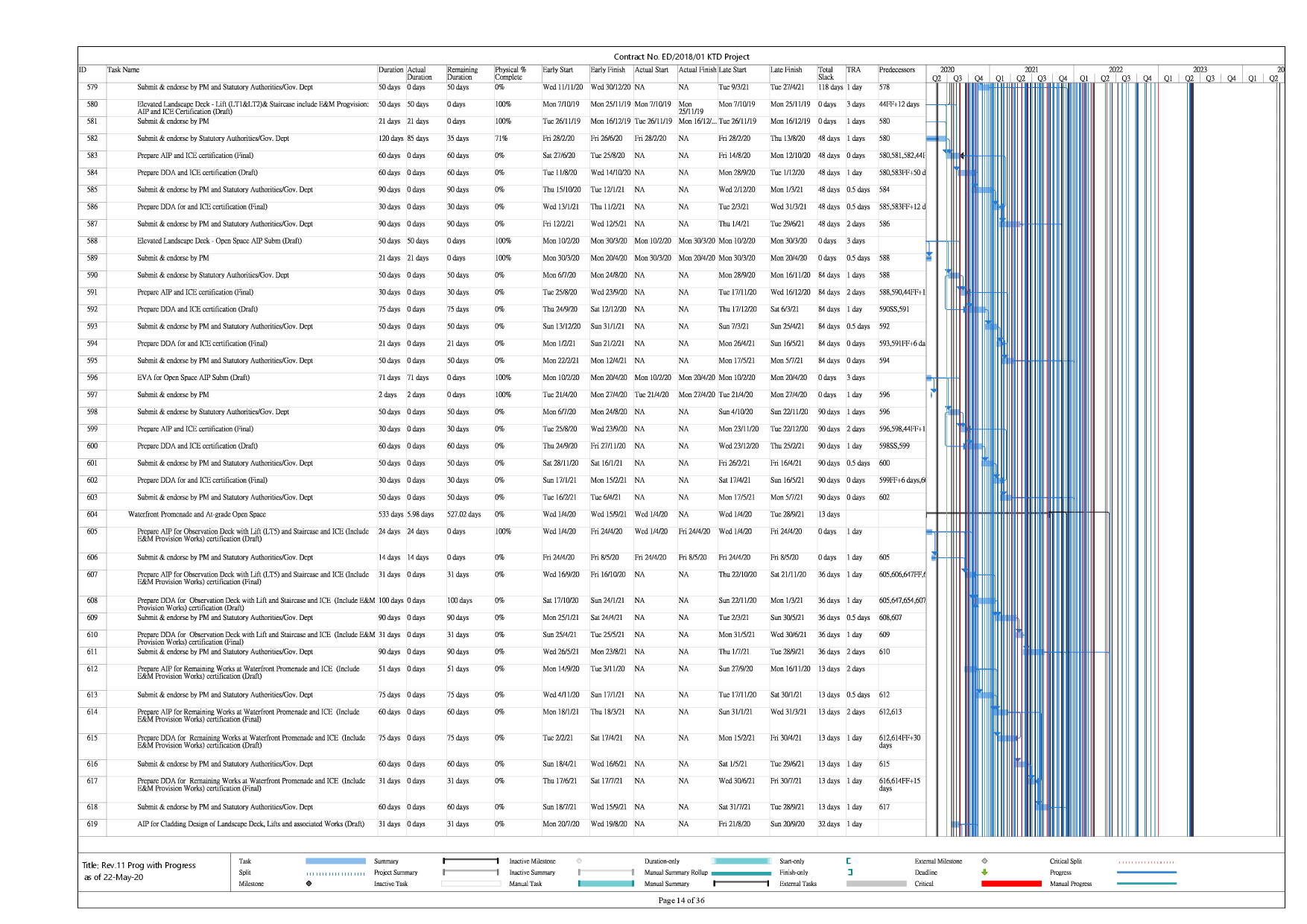

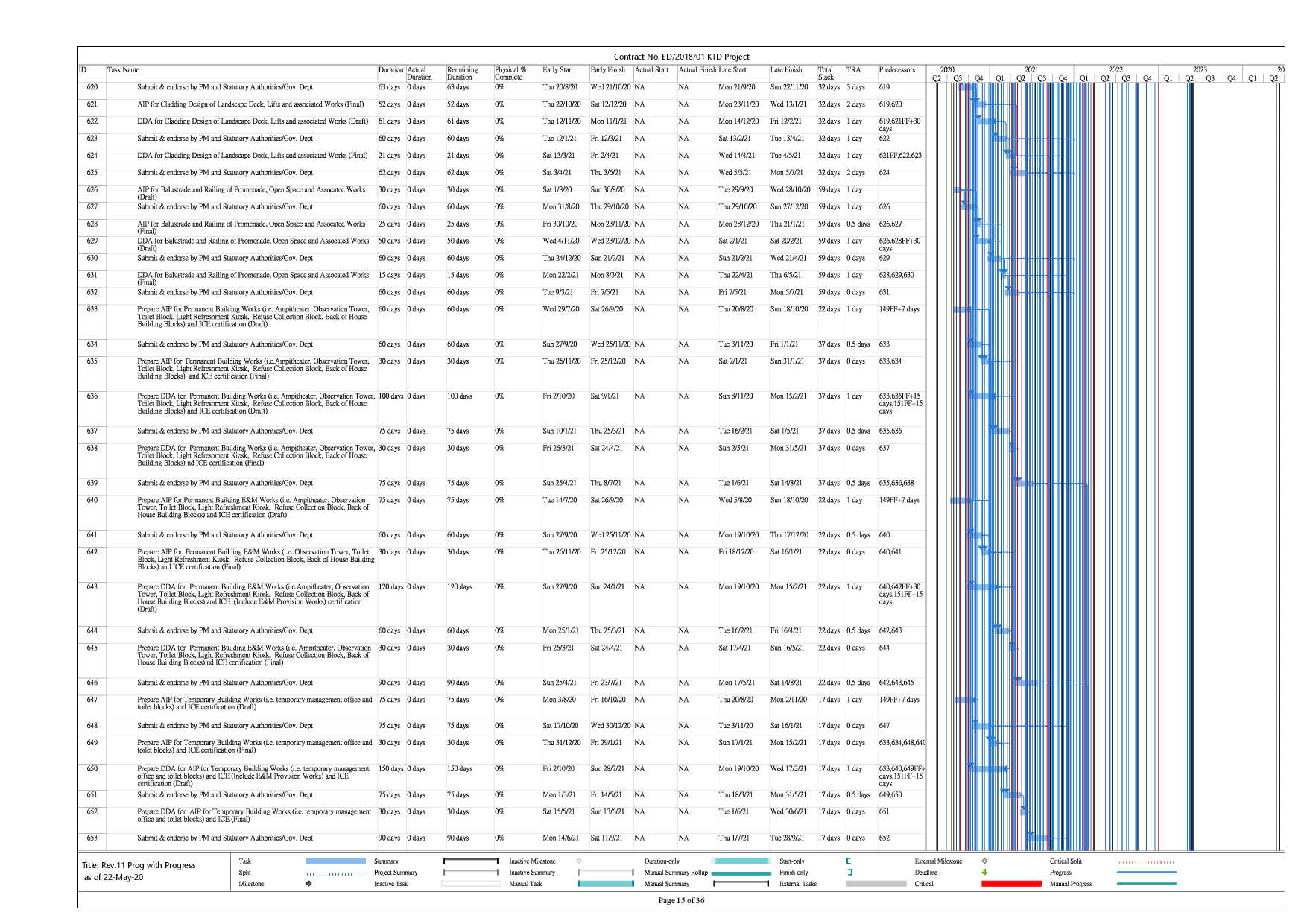

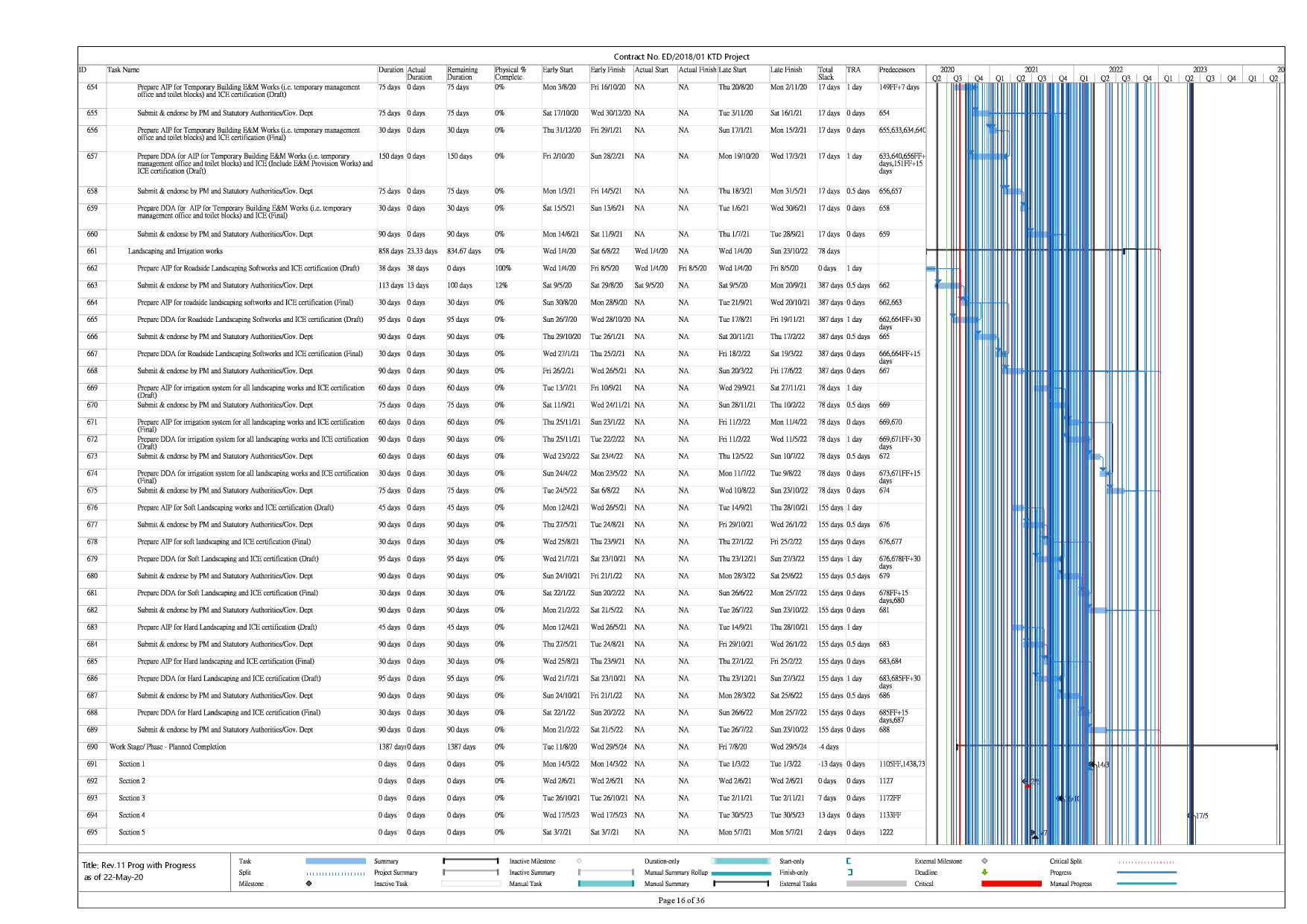

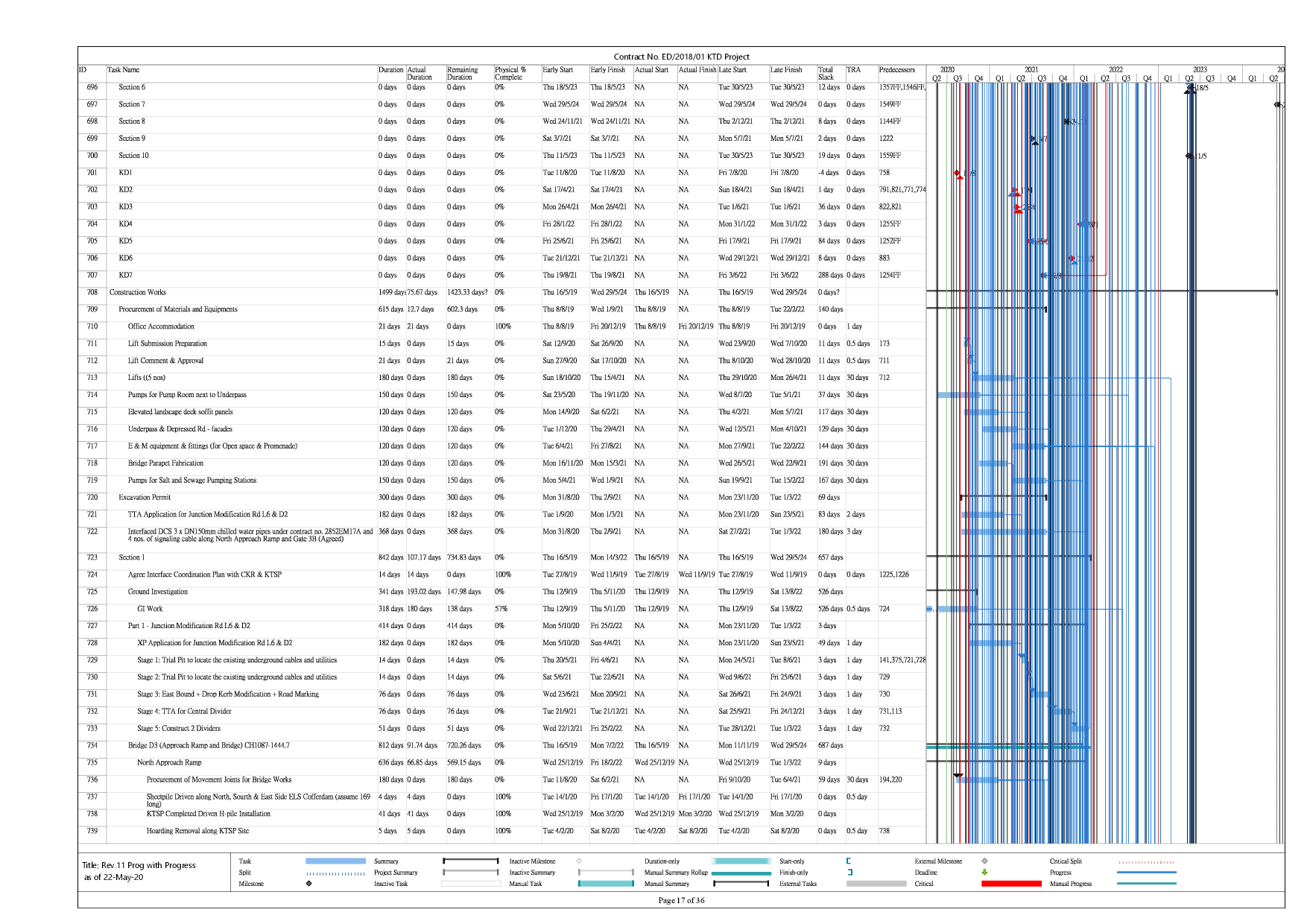

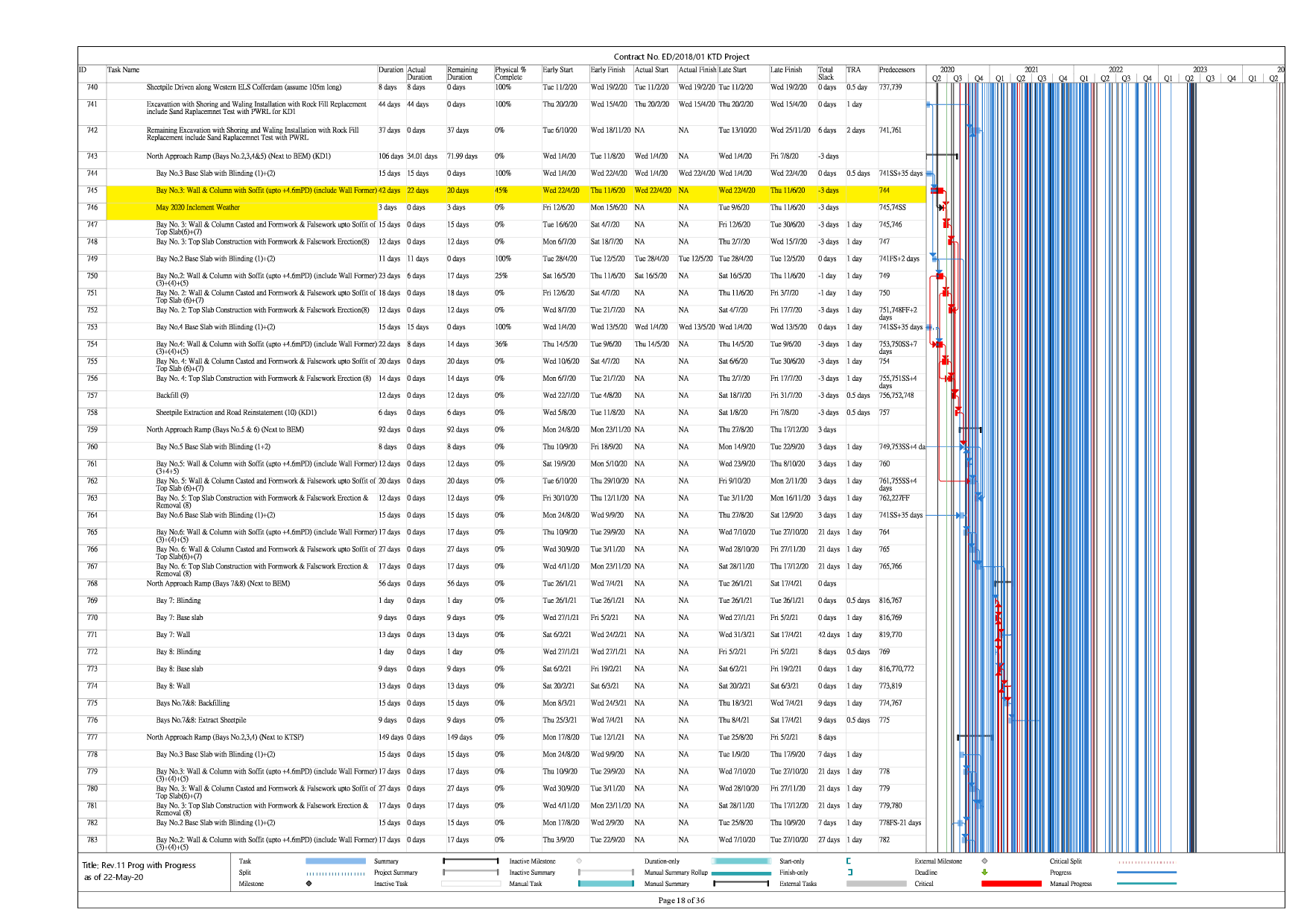

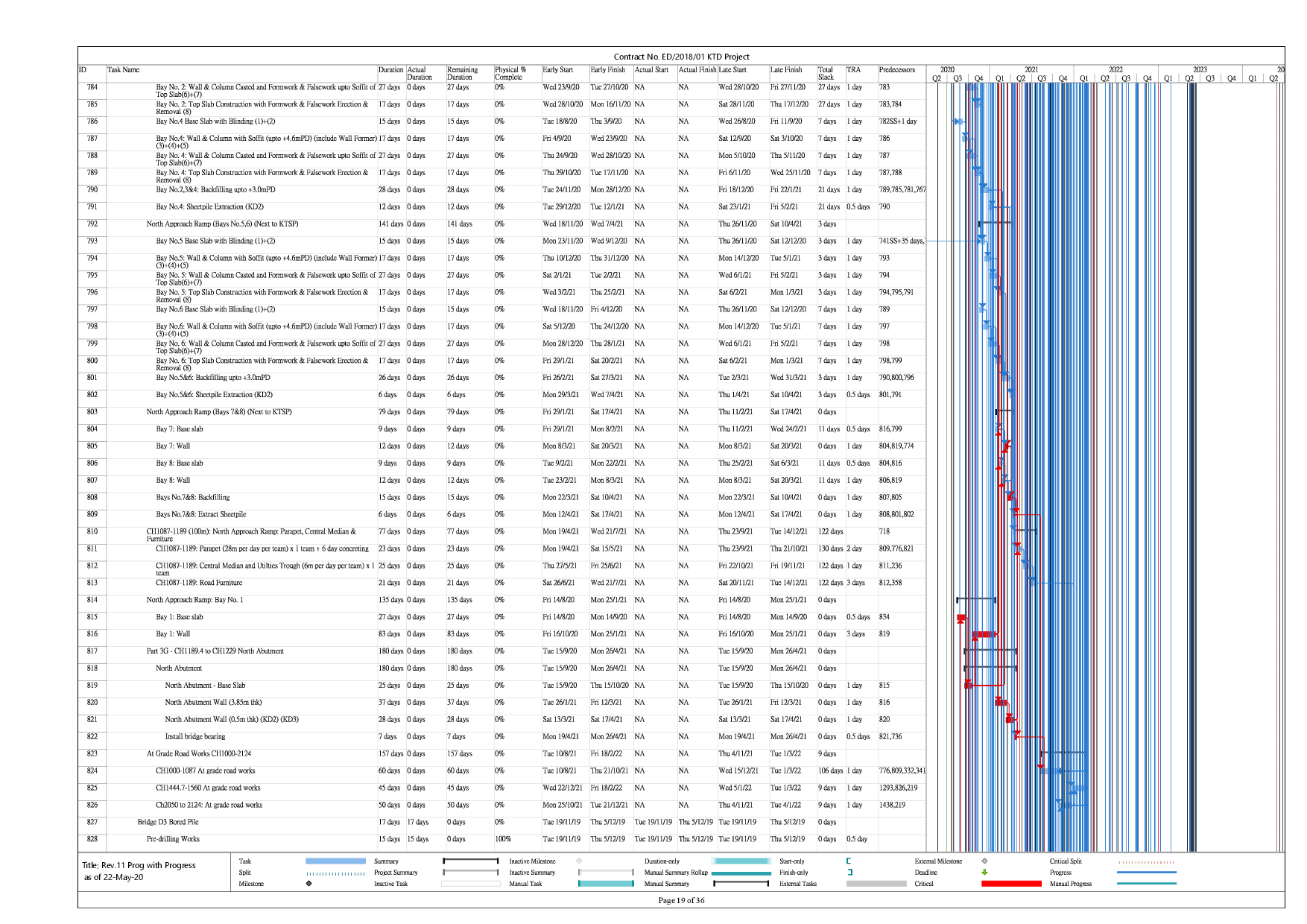

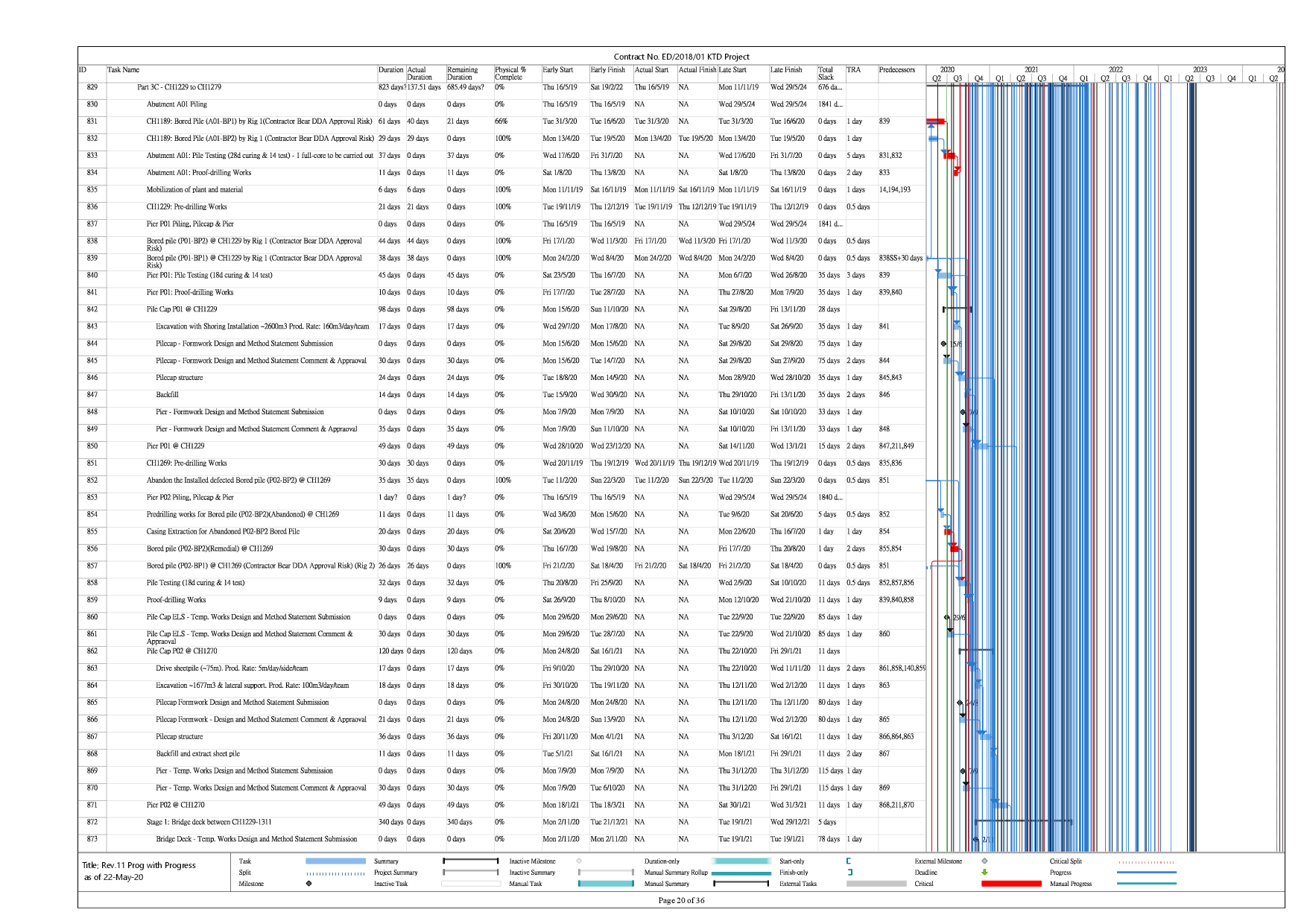

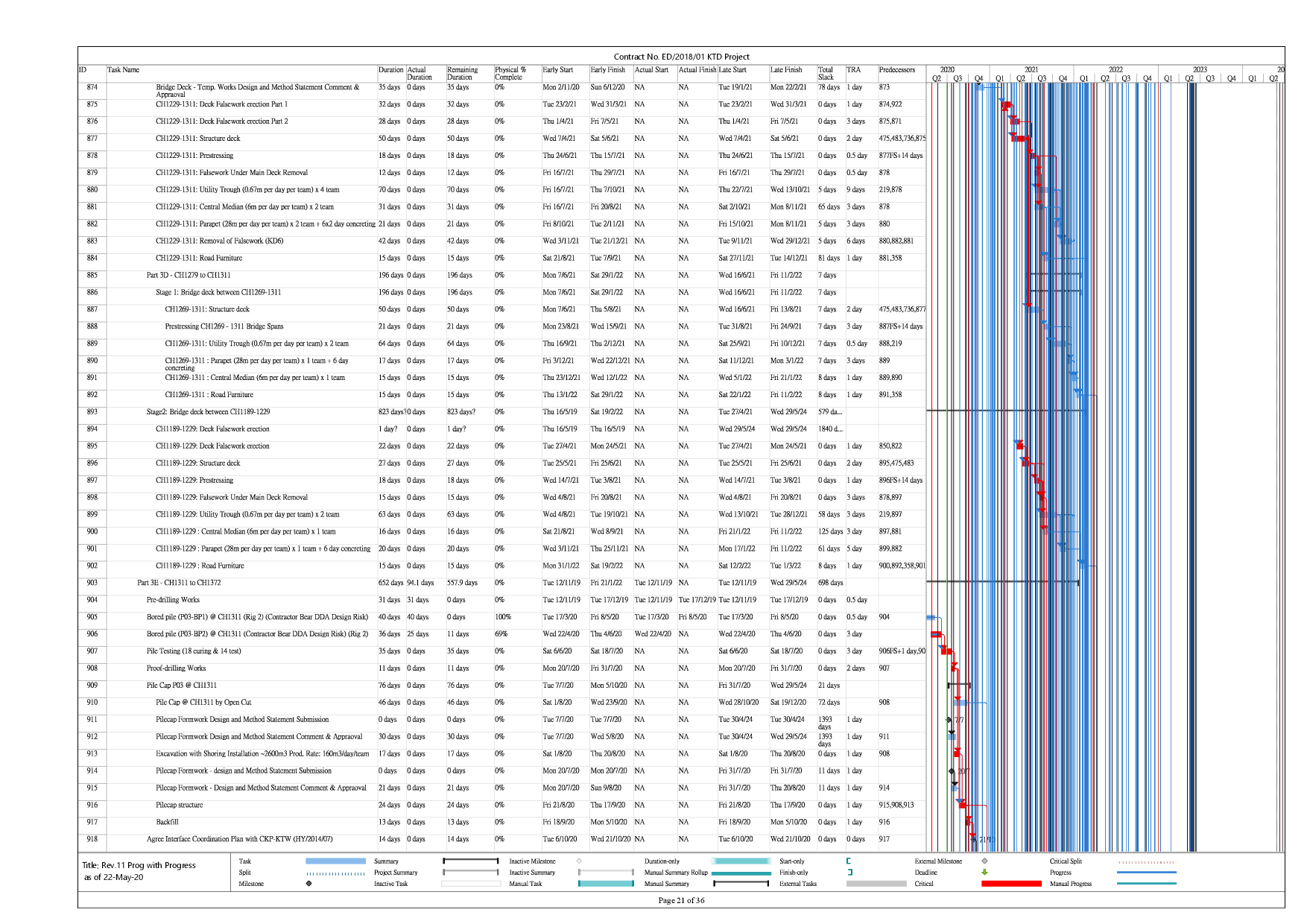

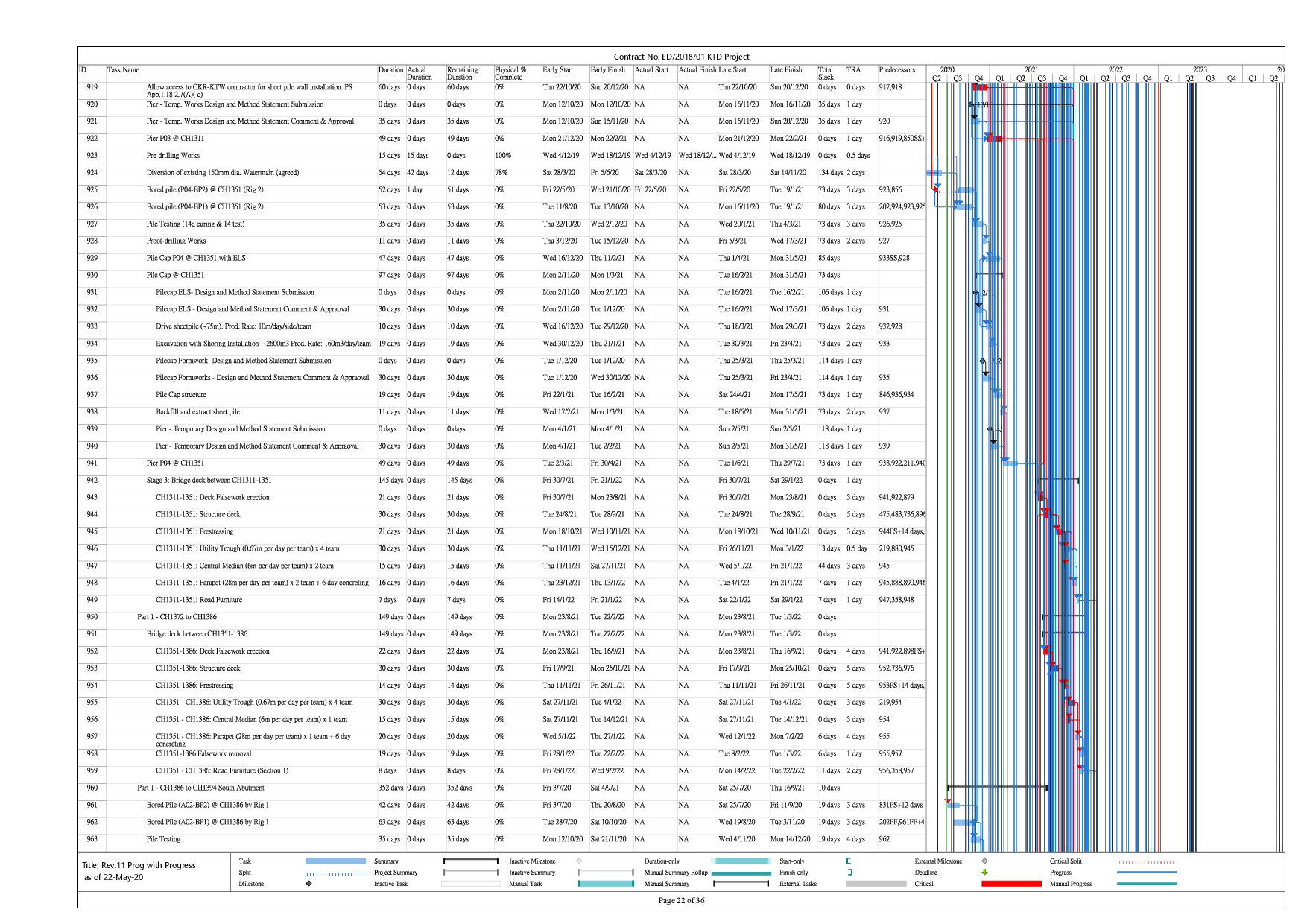

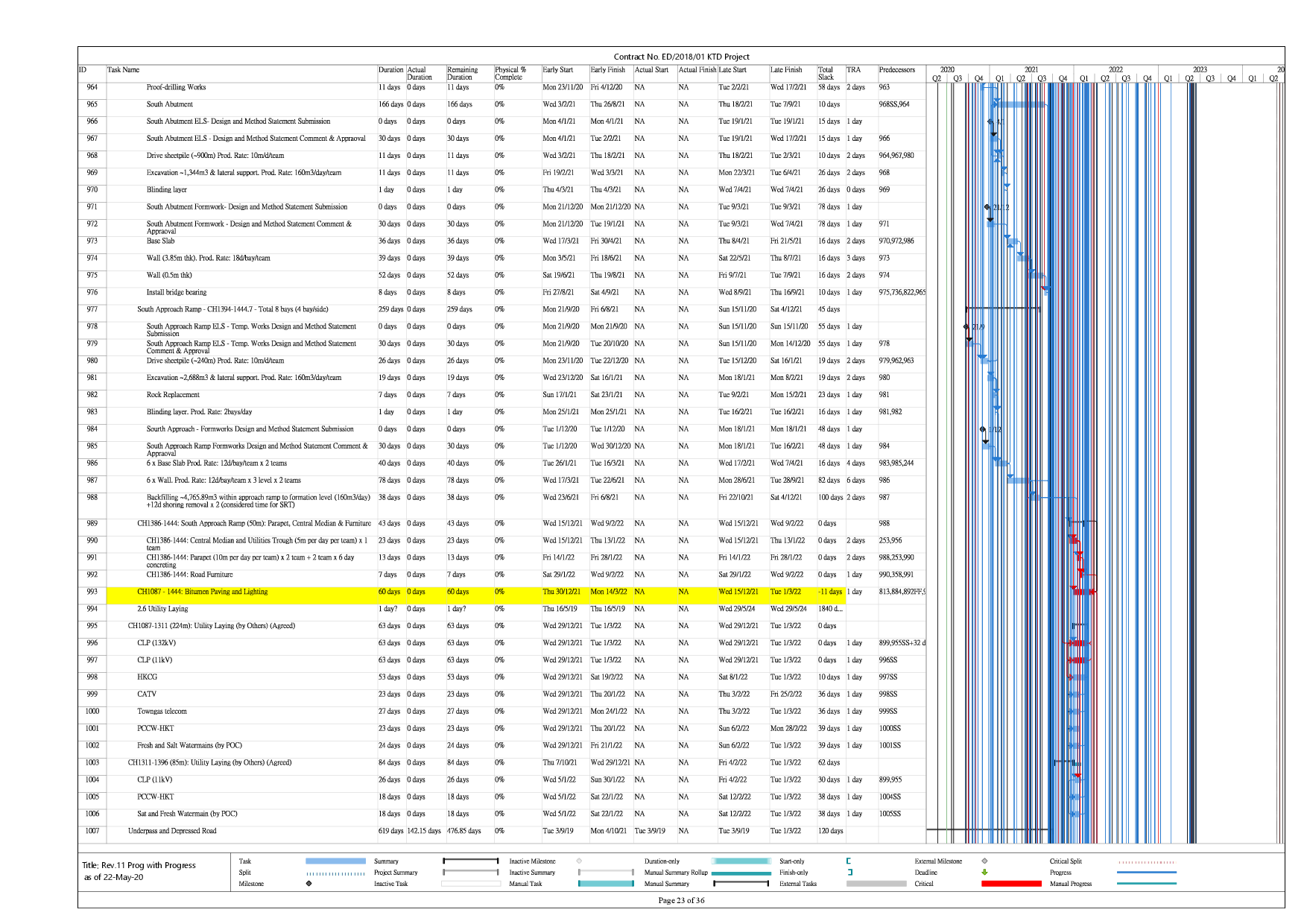

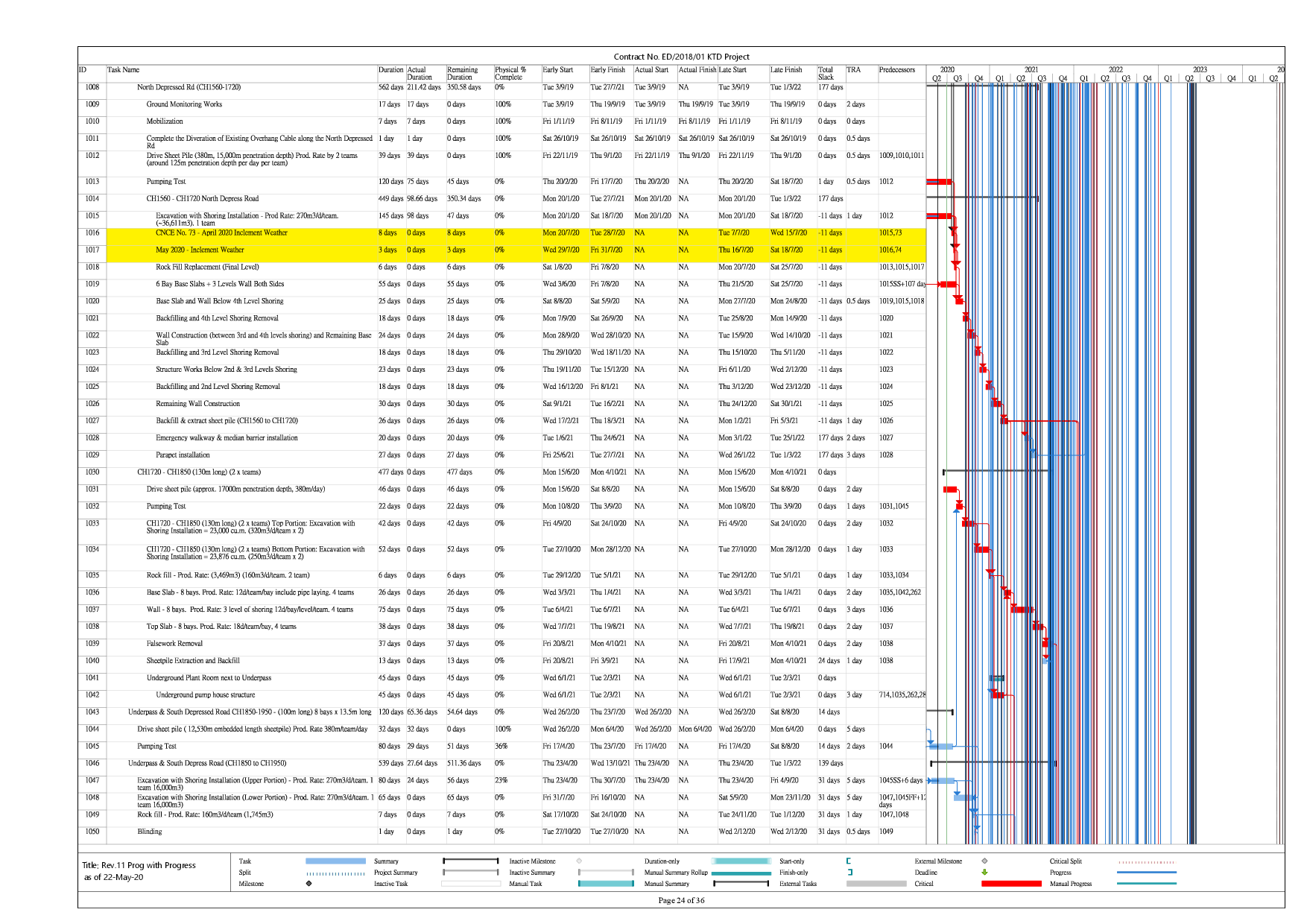

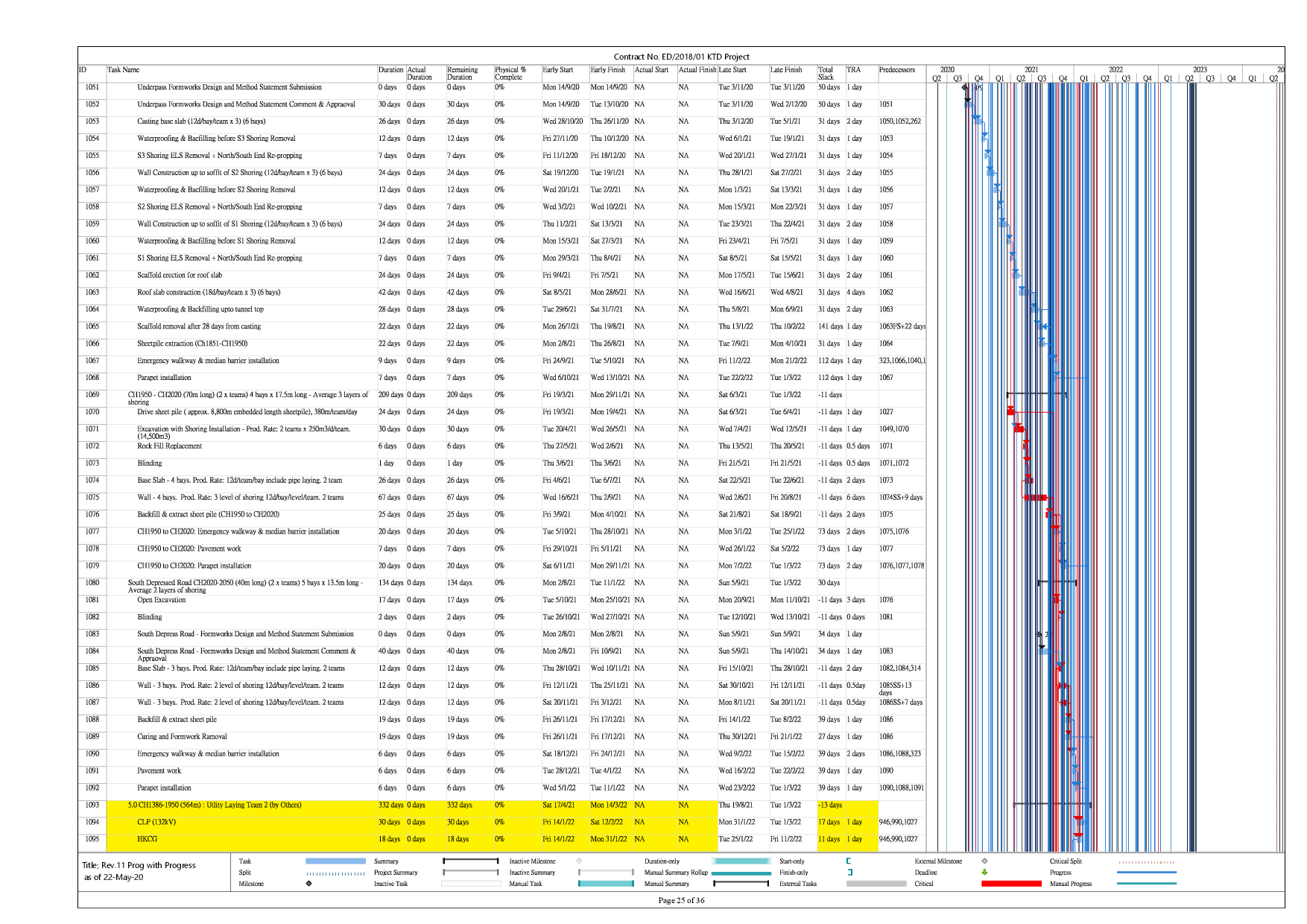

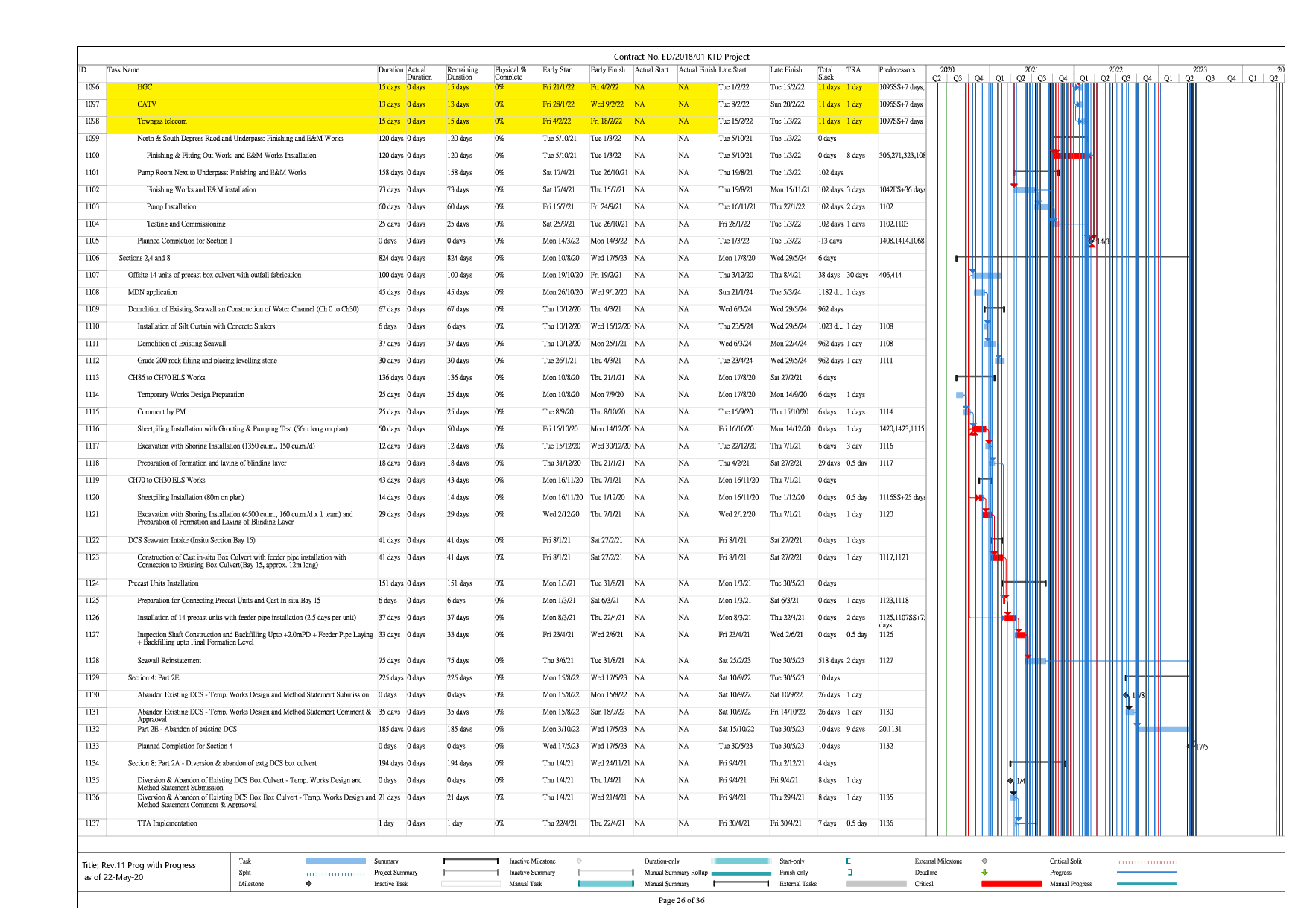

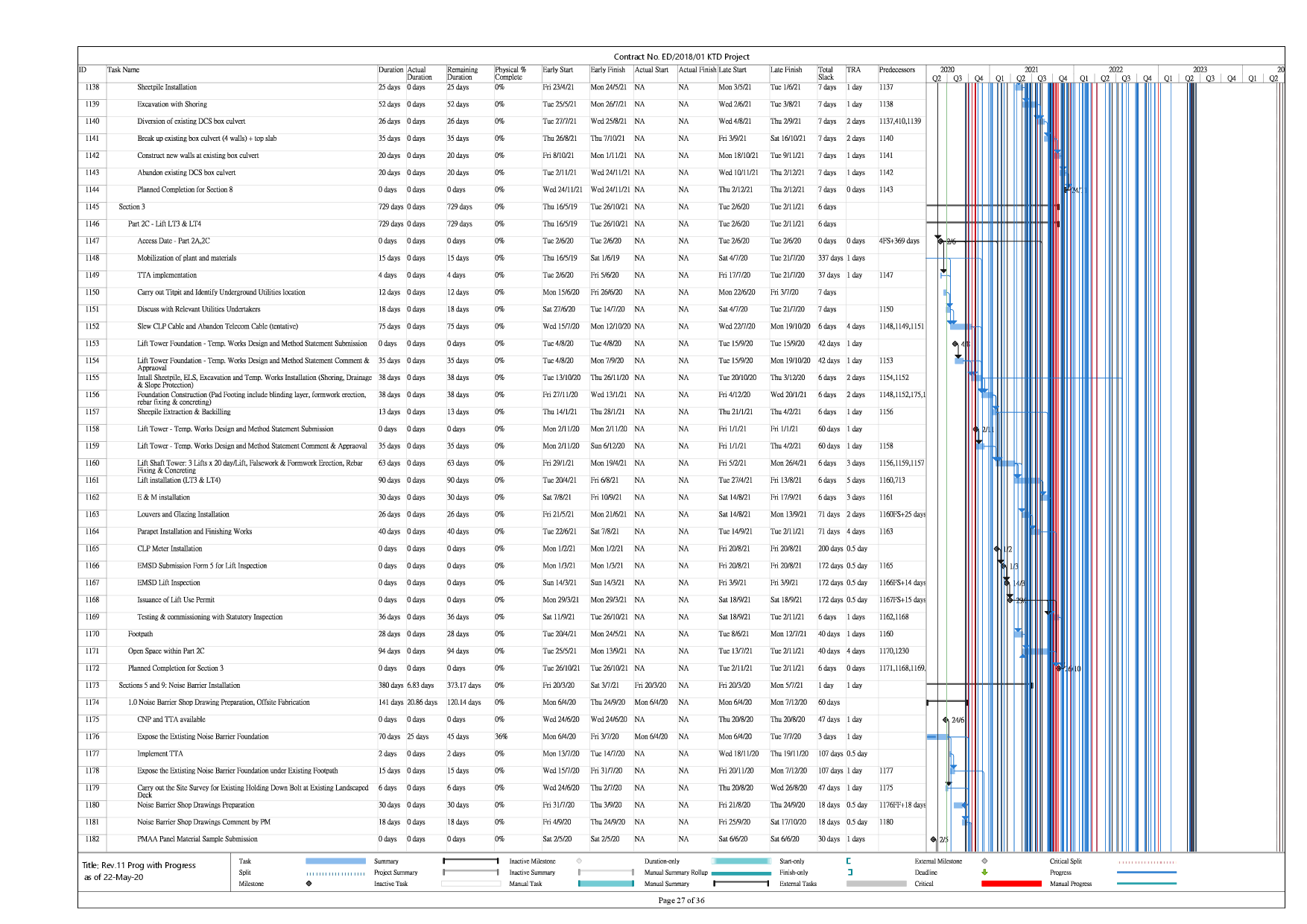

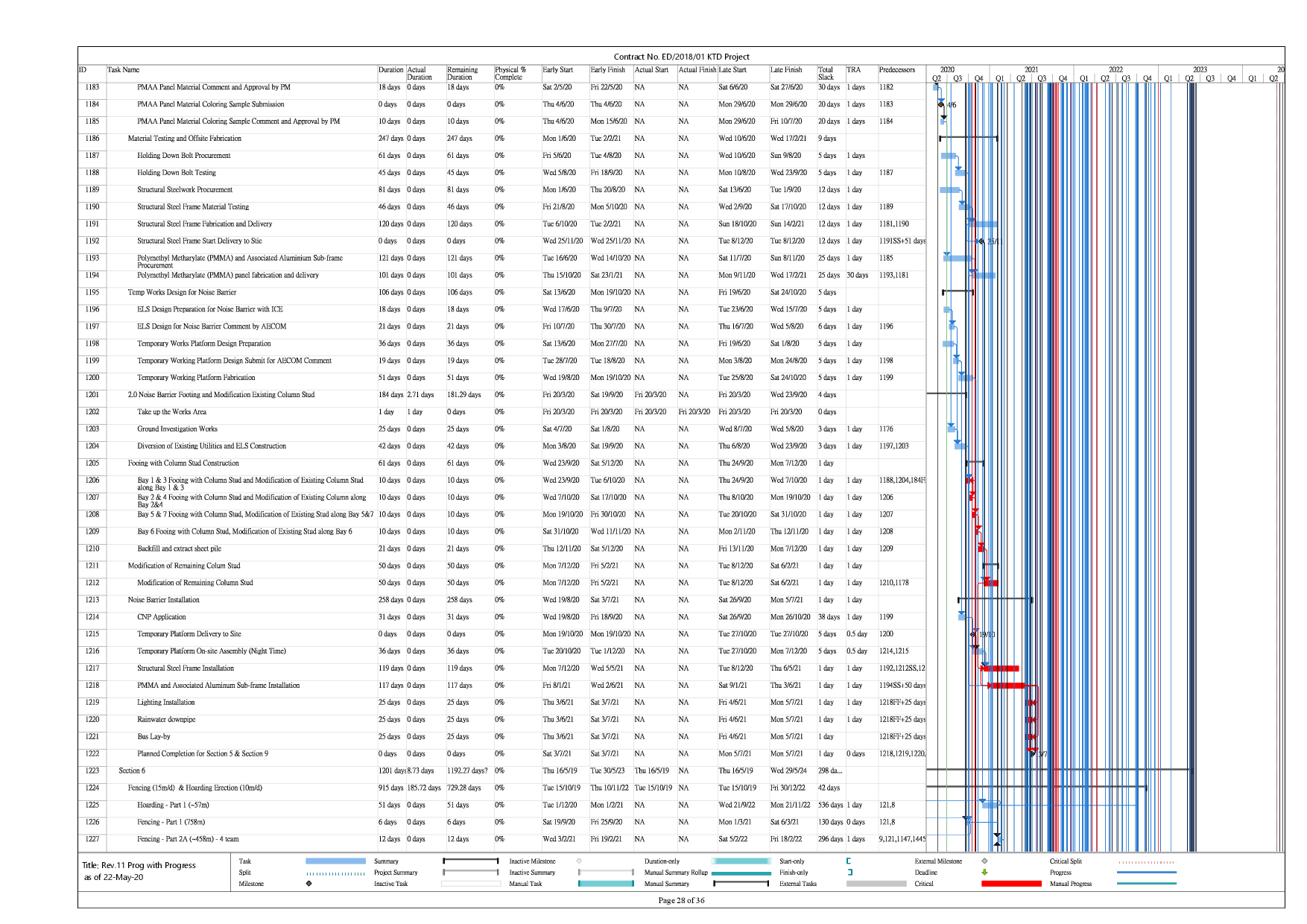

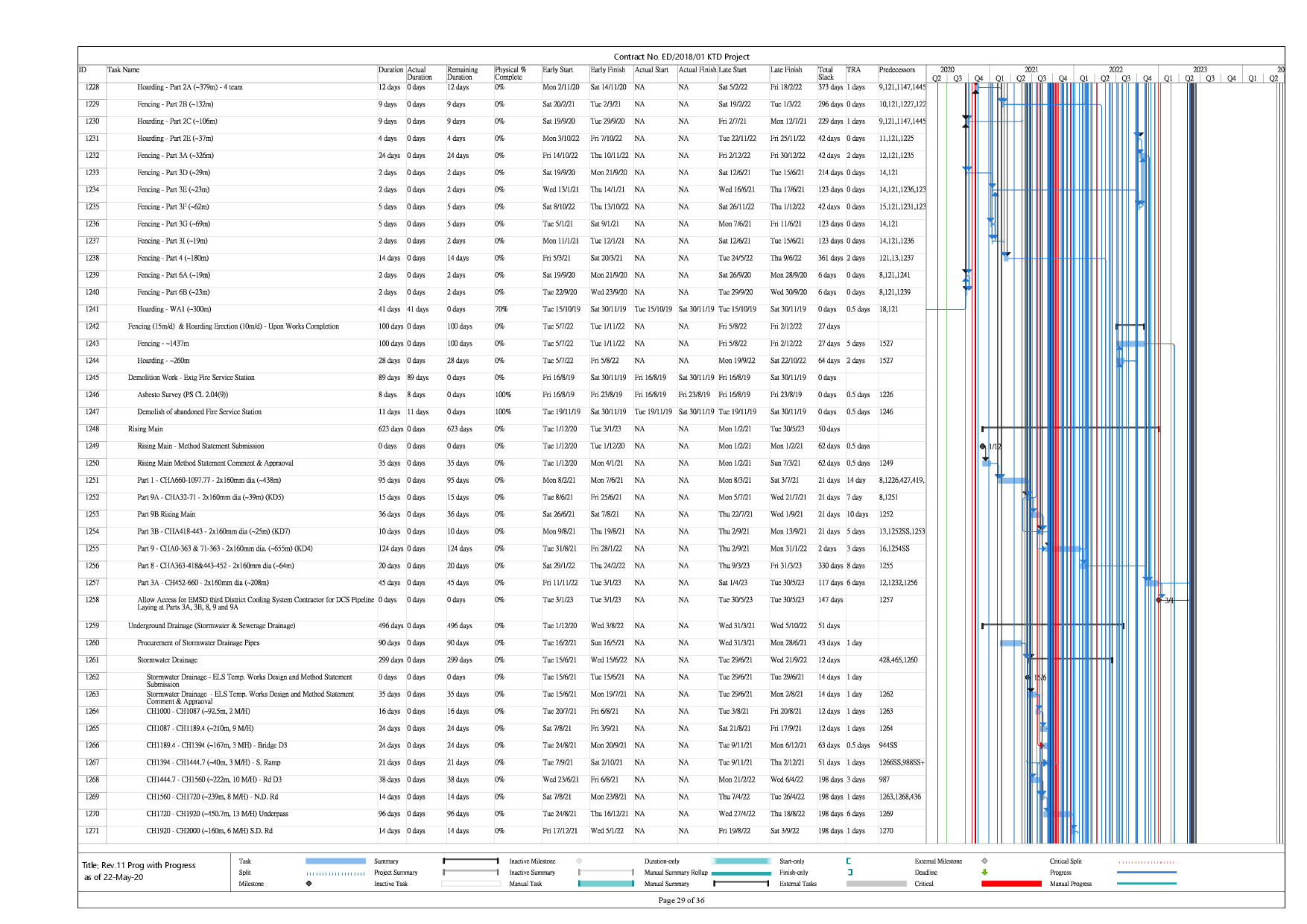

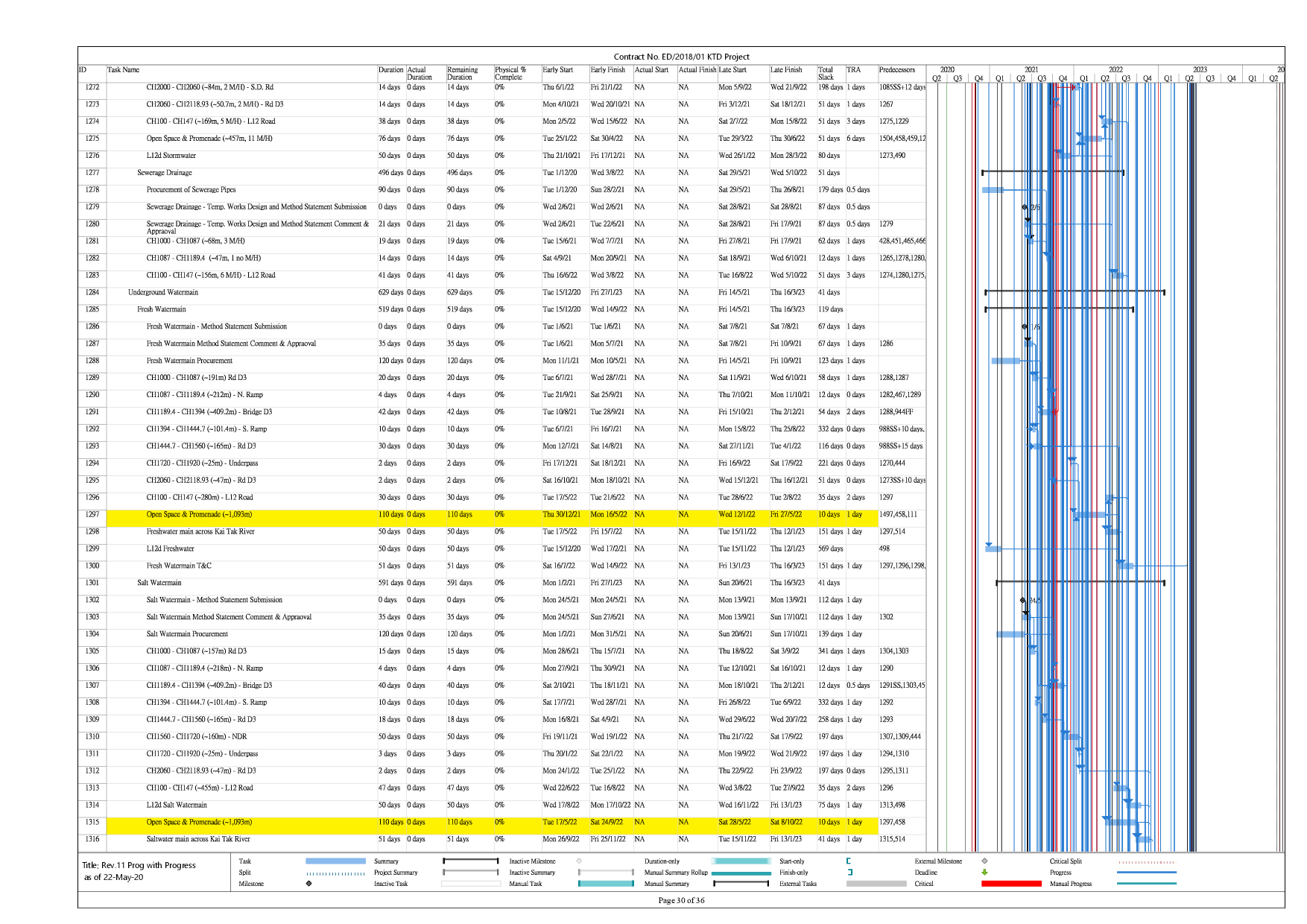

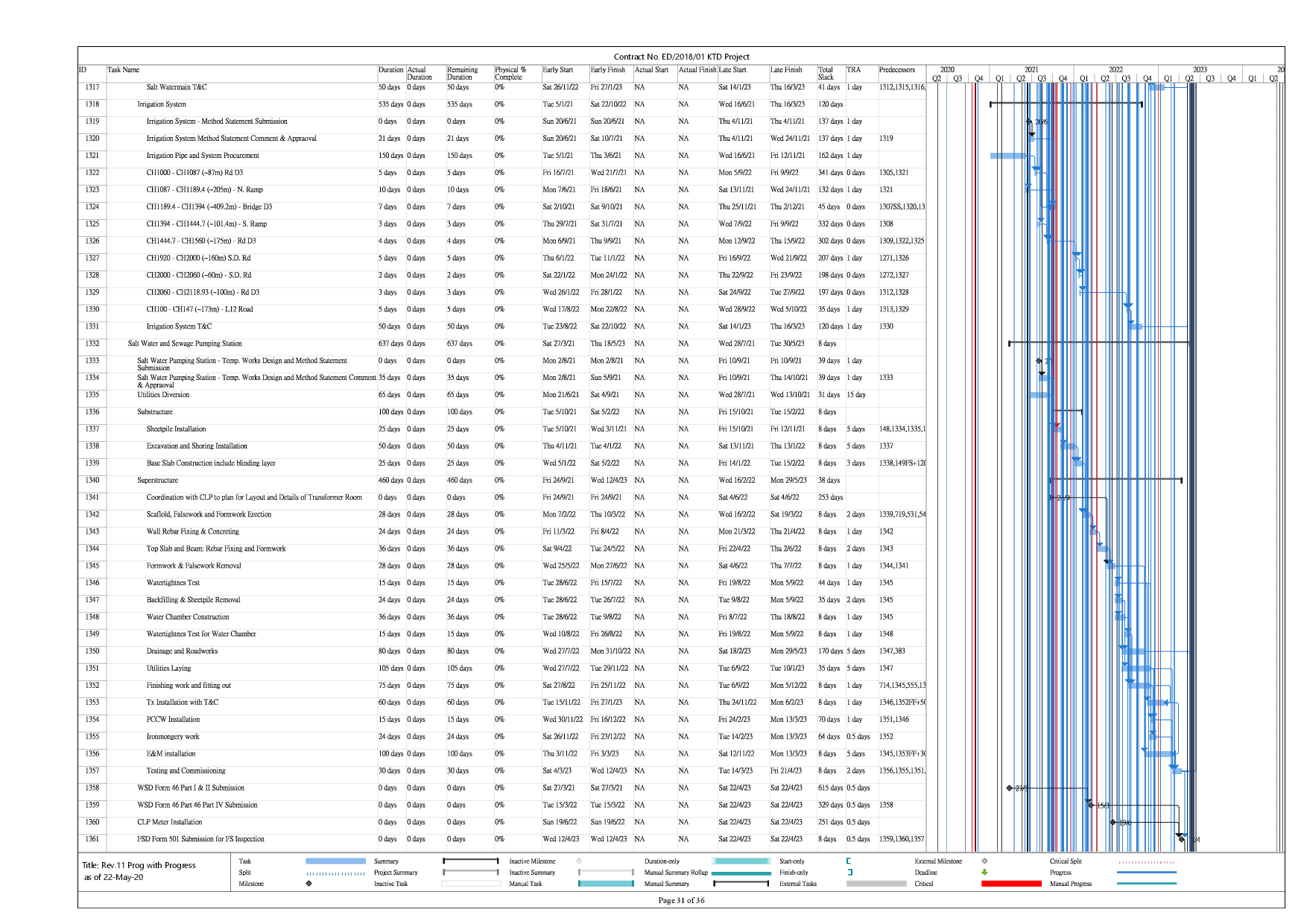

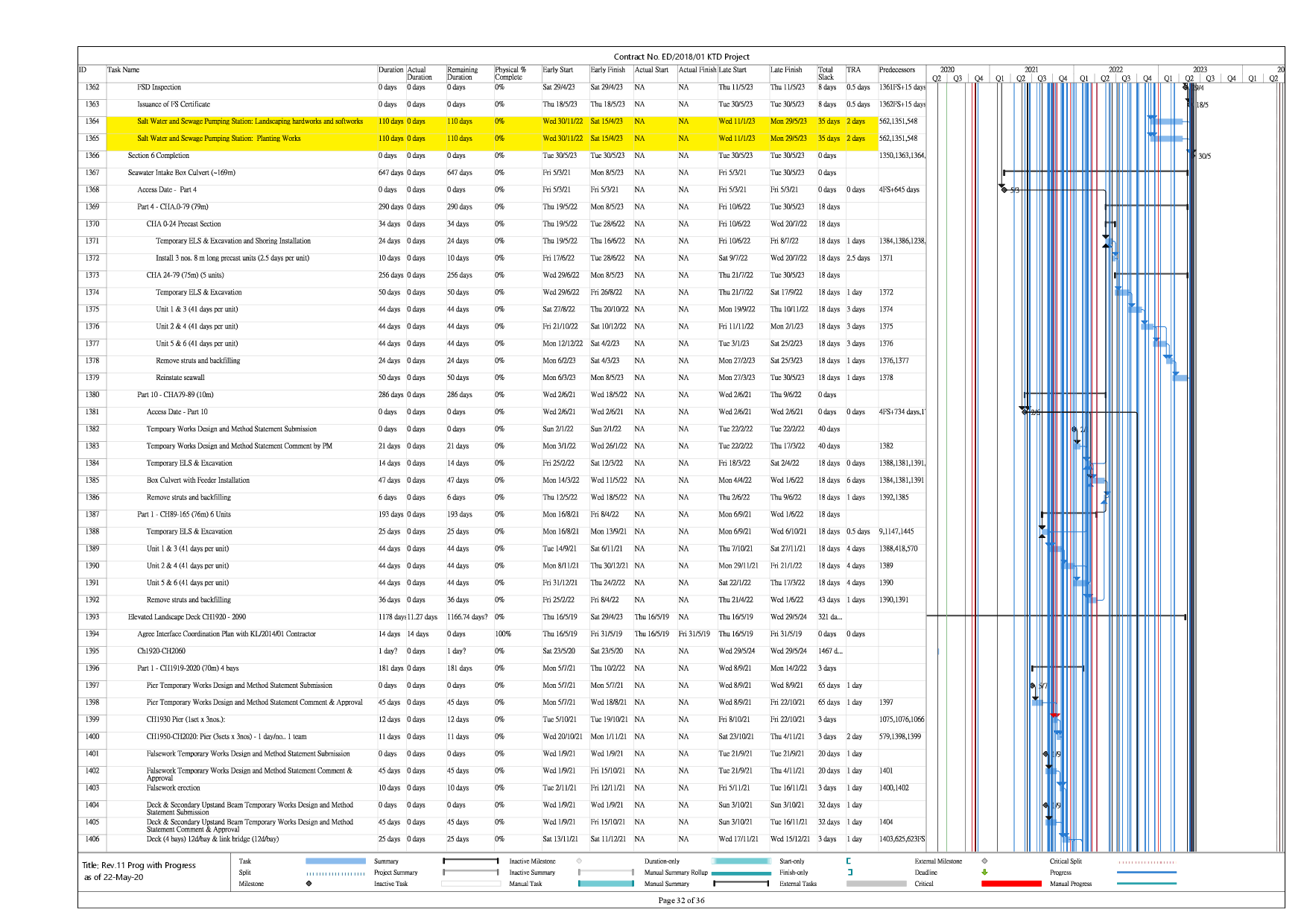

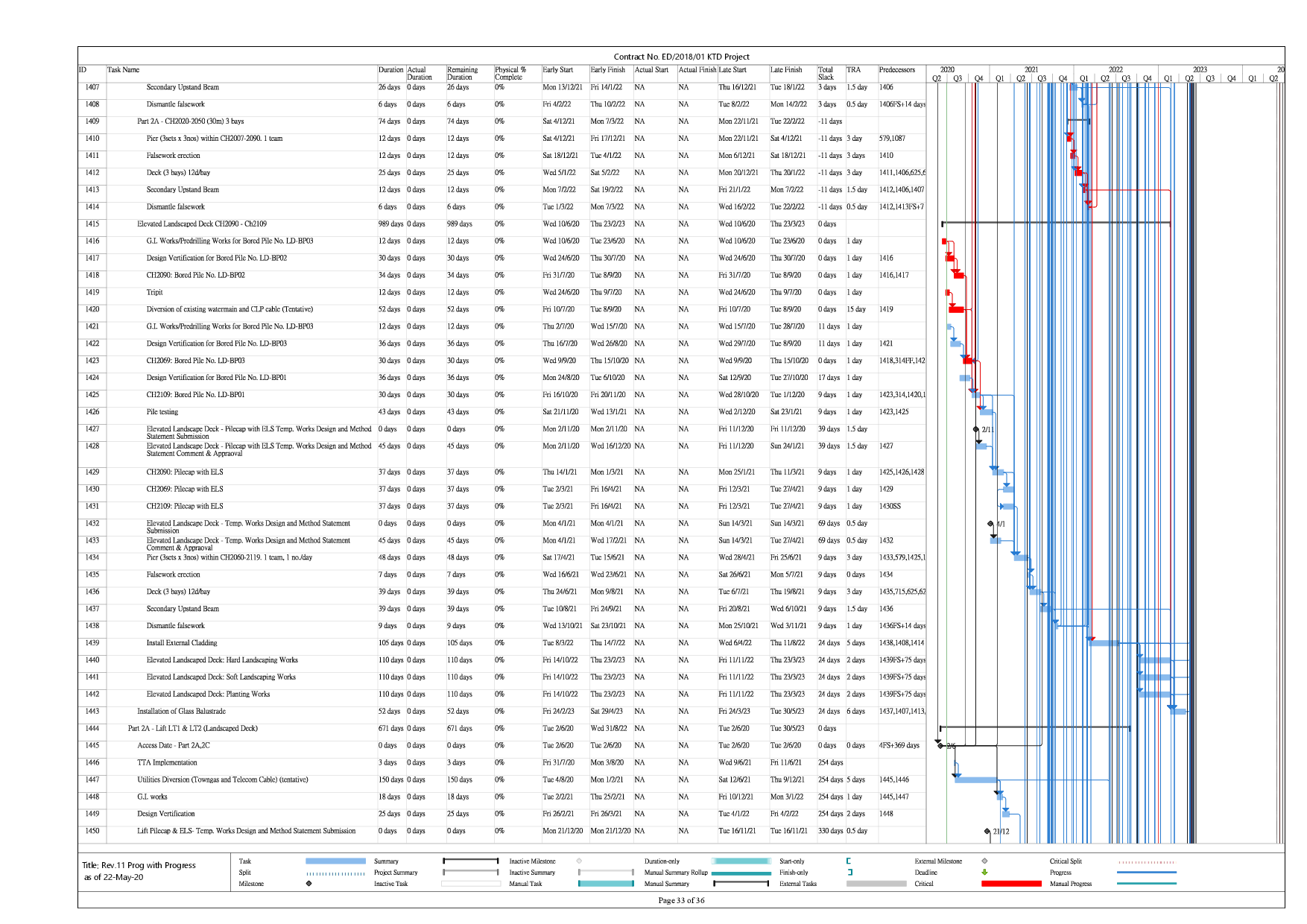

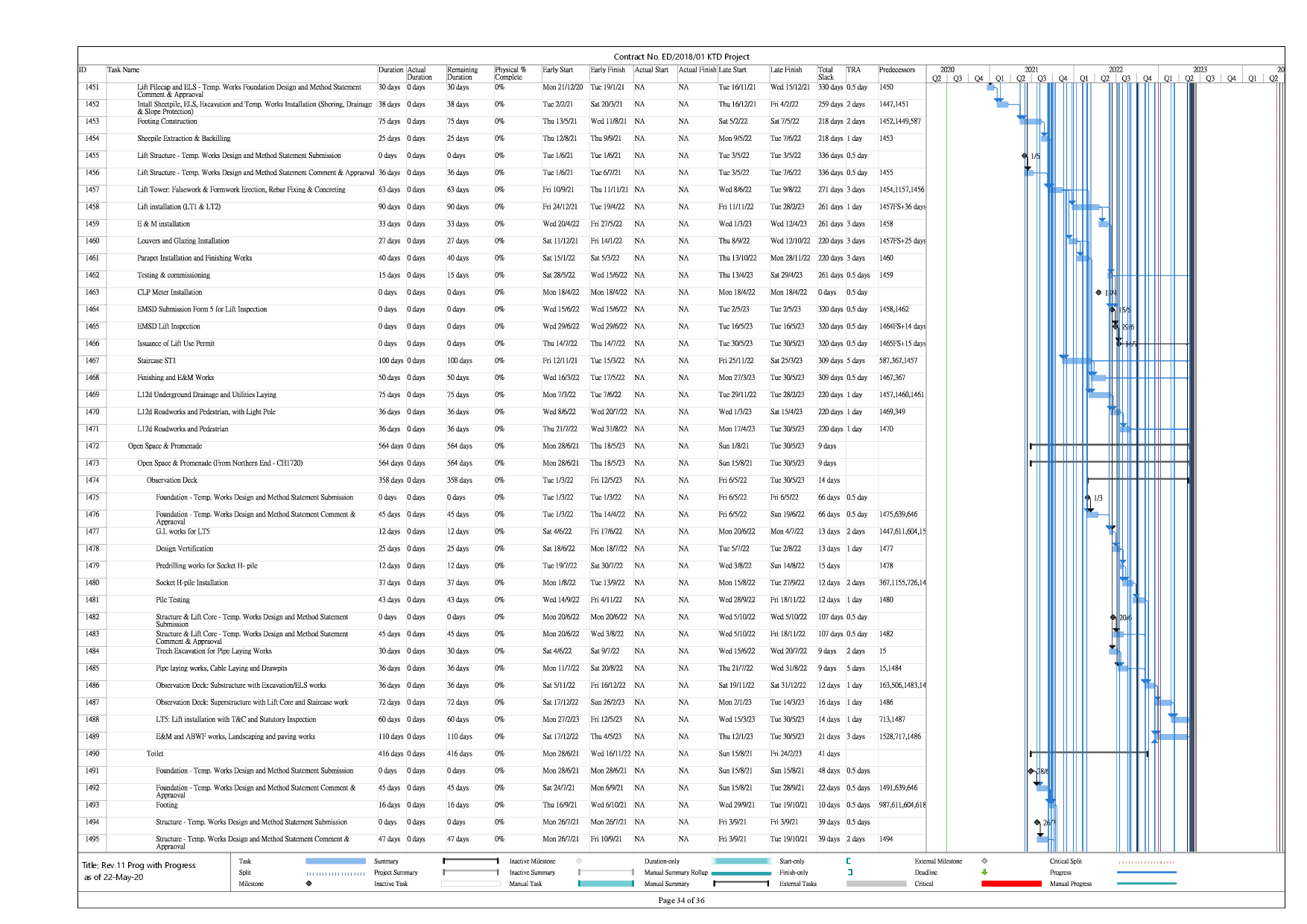

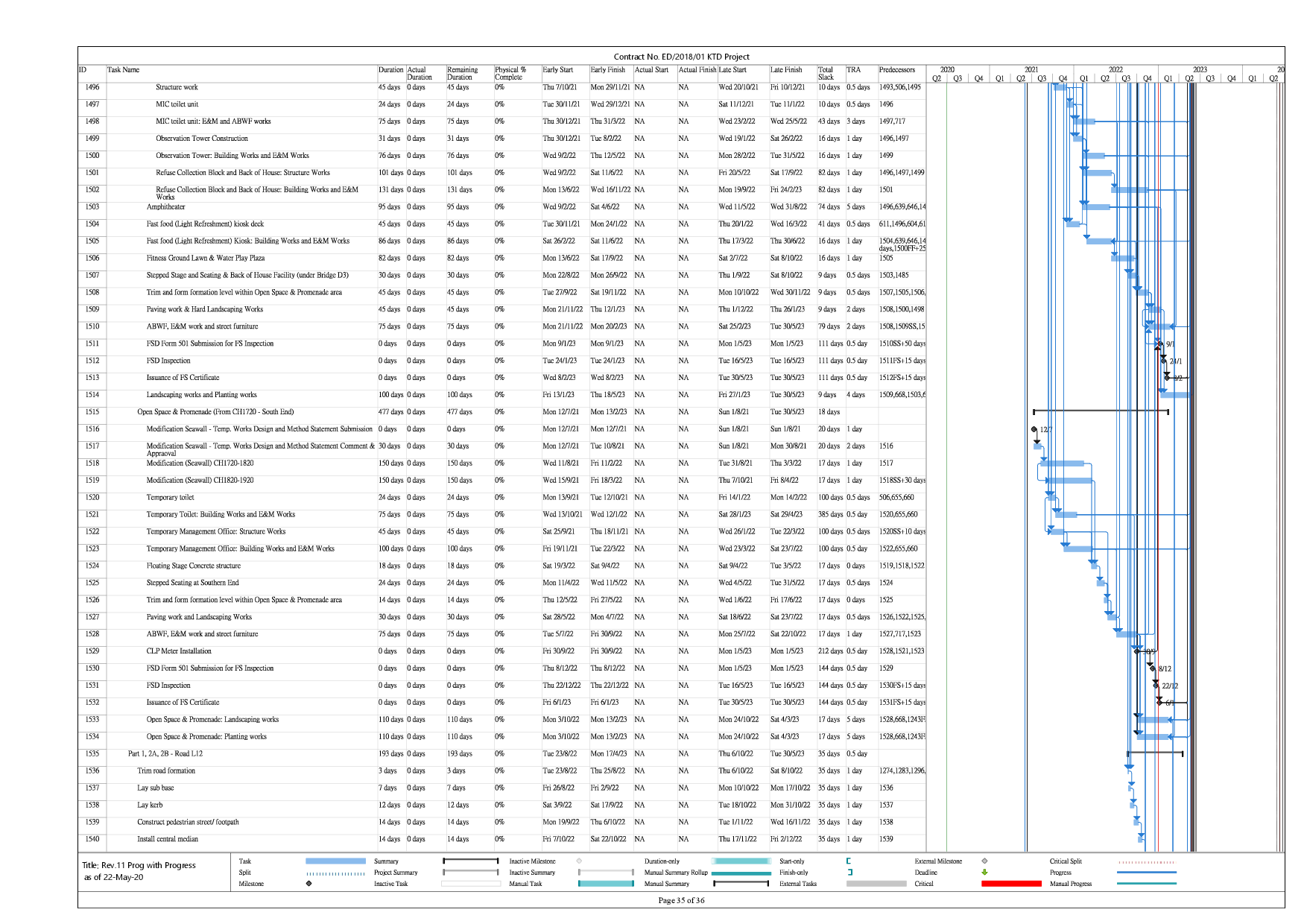

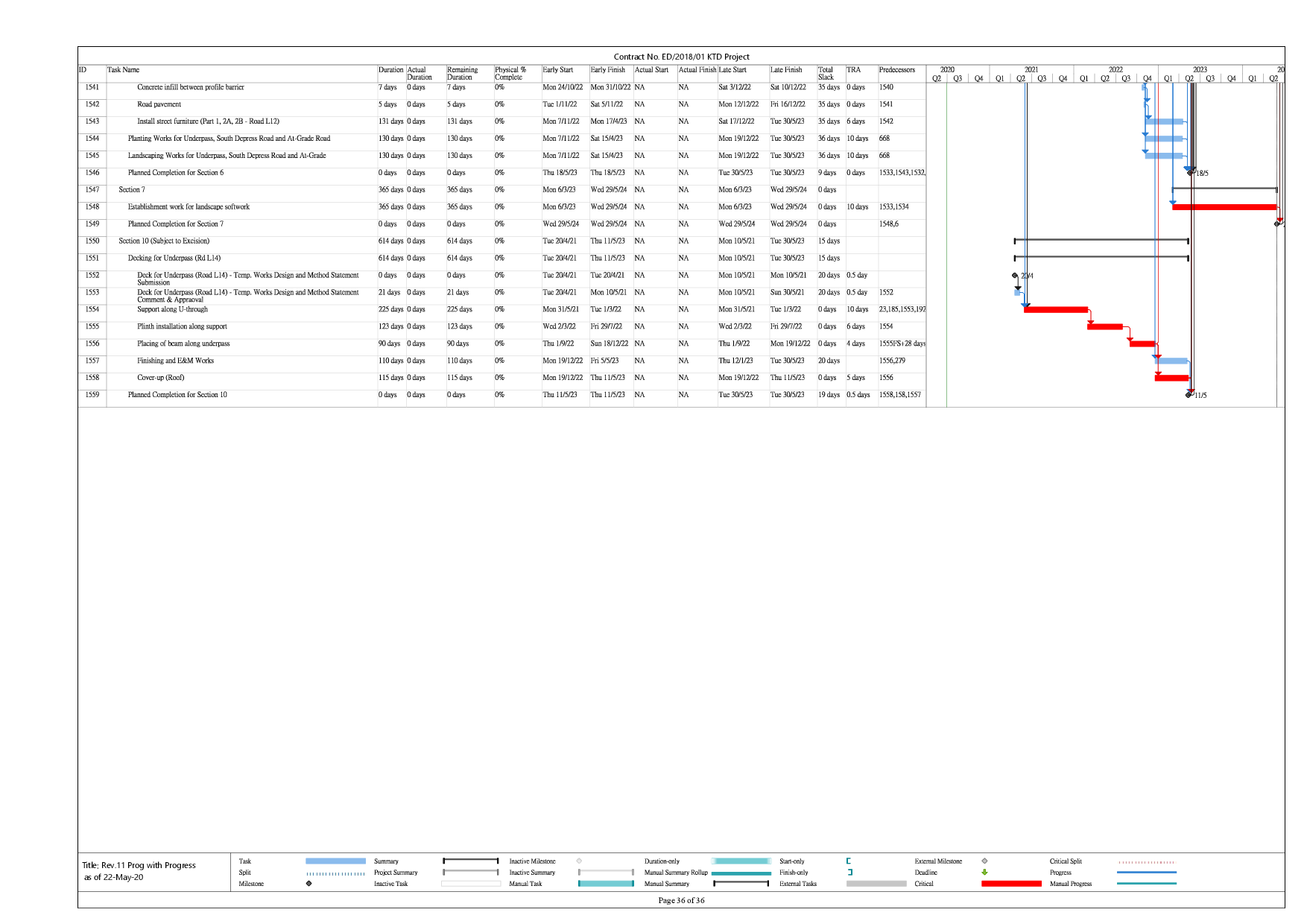

Appendix B – Construction Programme

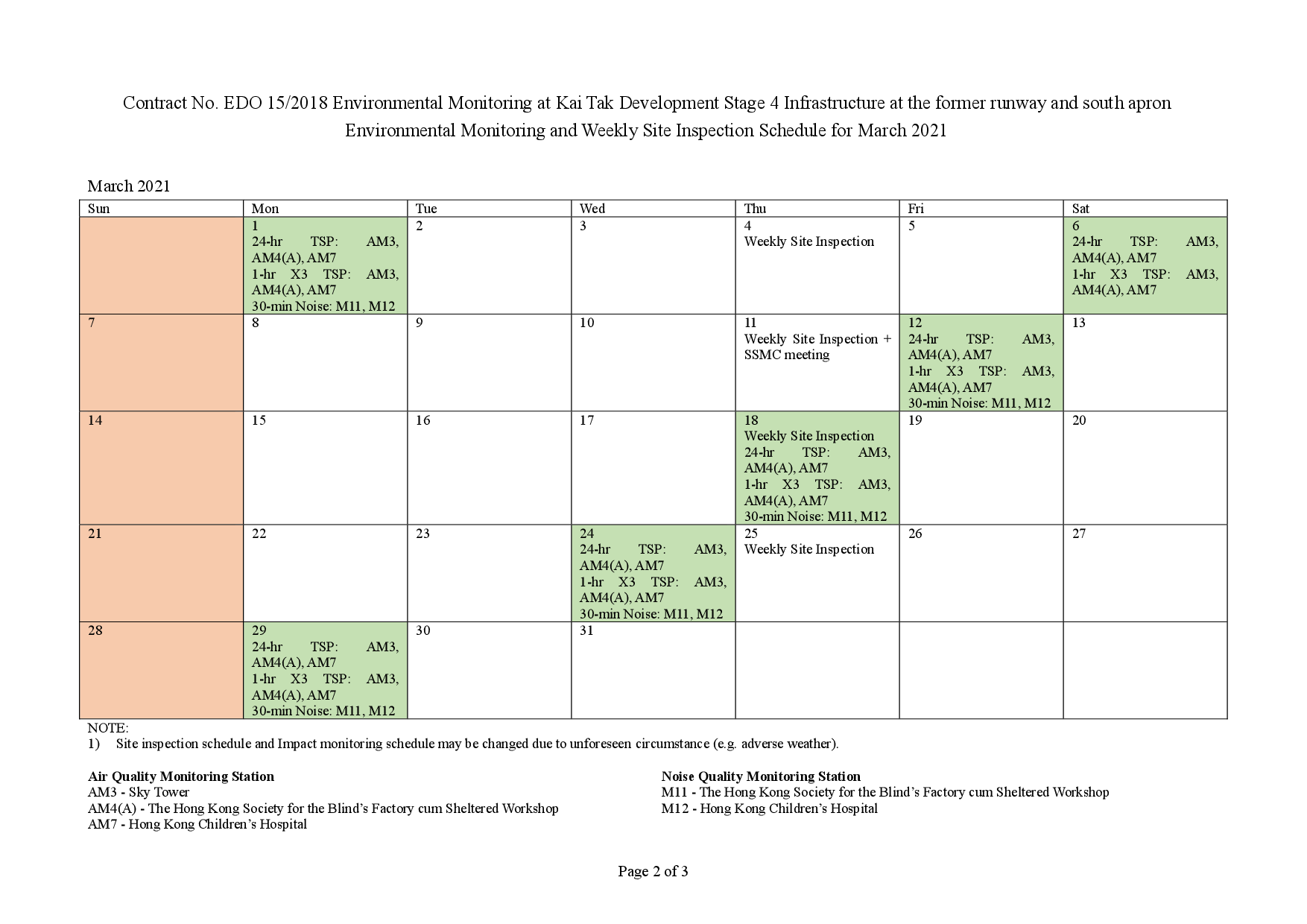

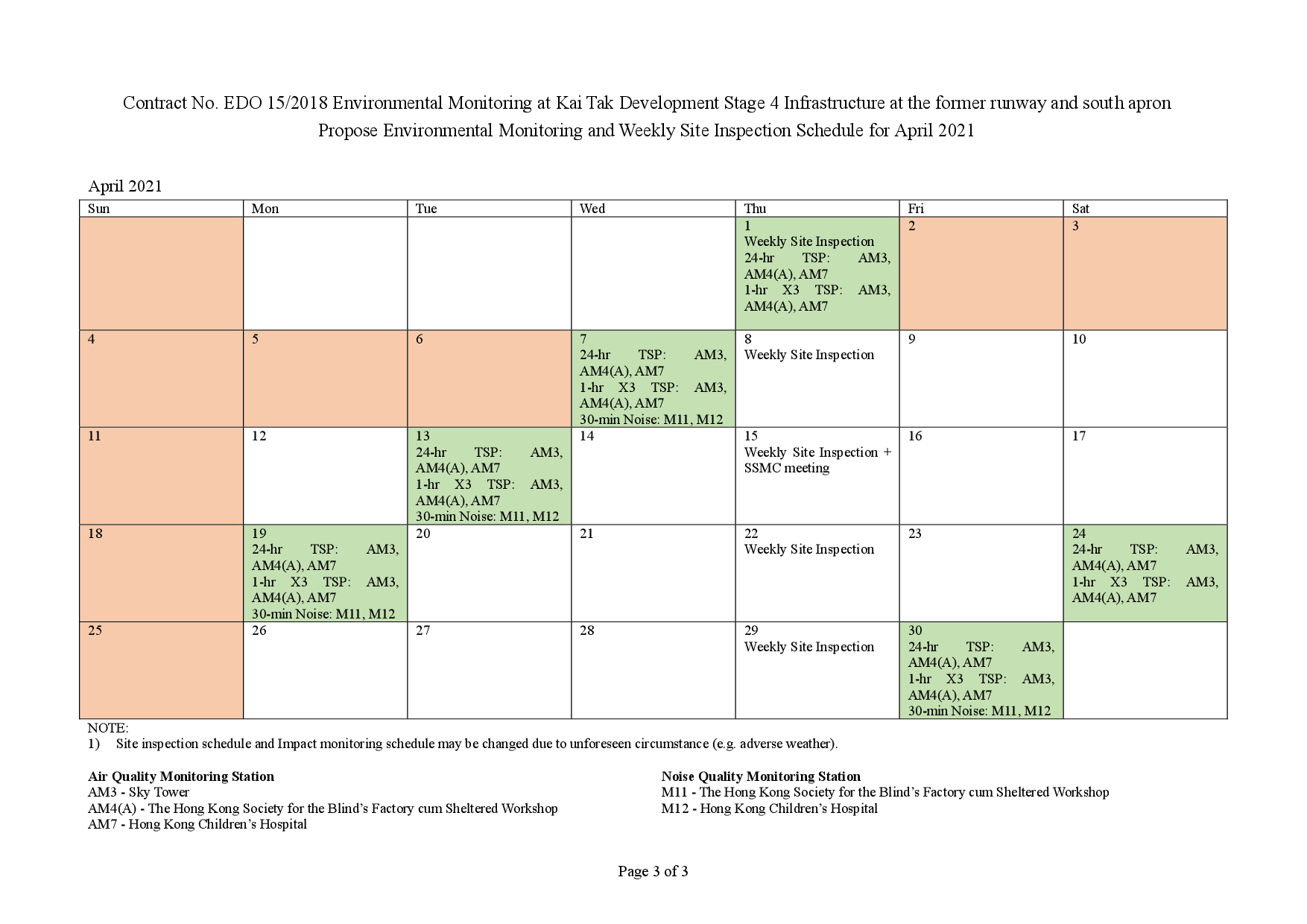

Appendix C – Environmental monitoring schedules

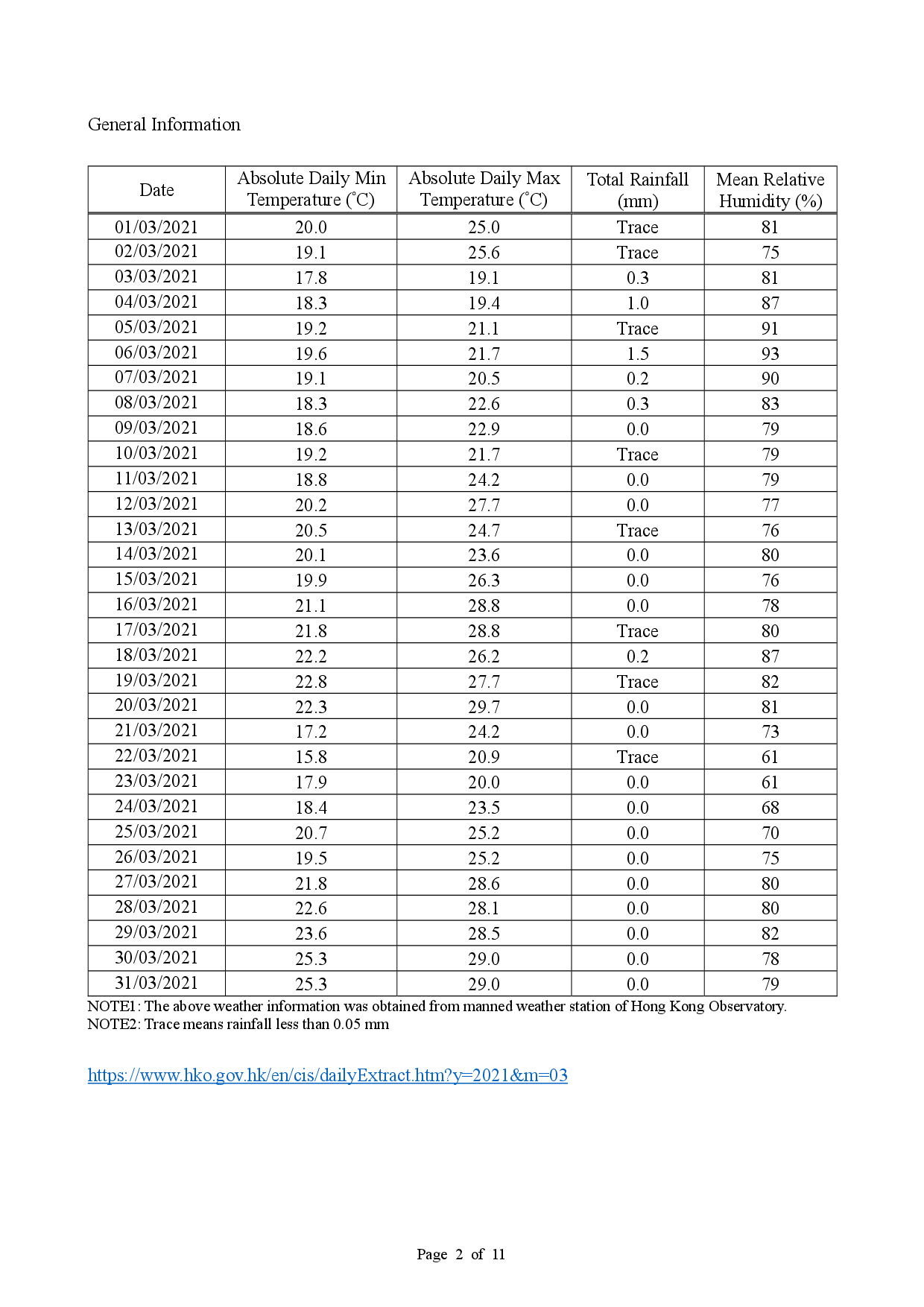

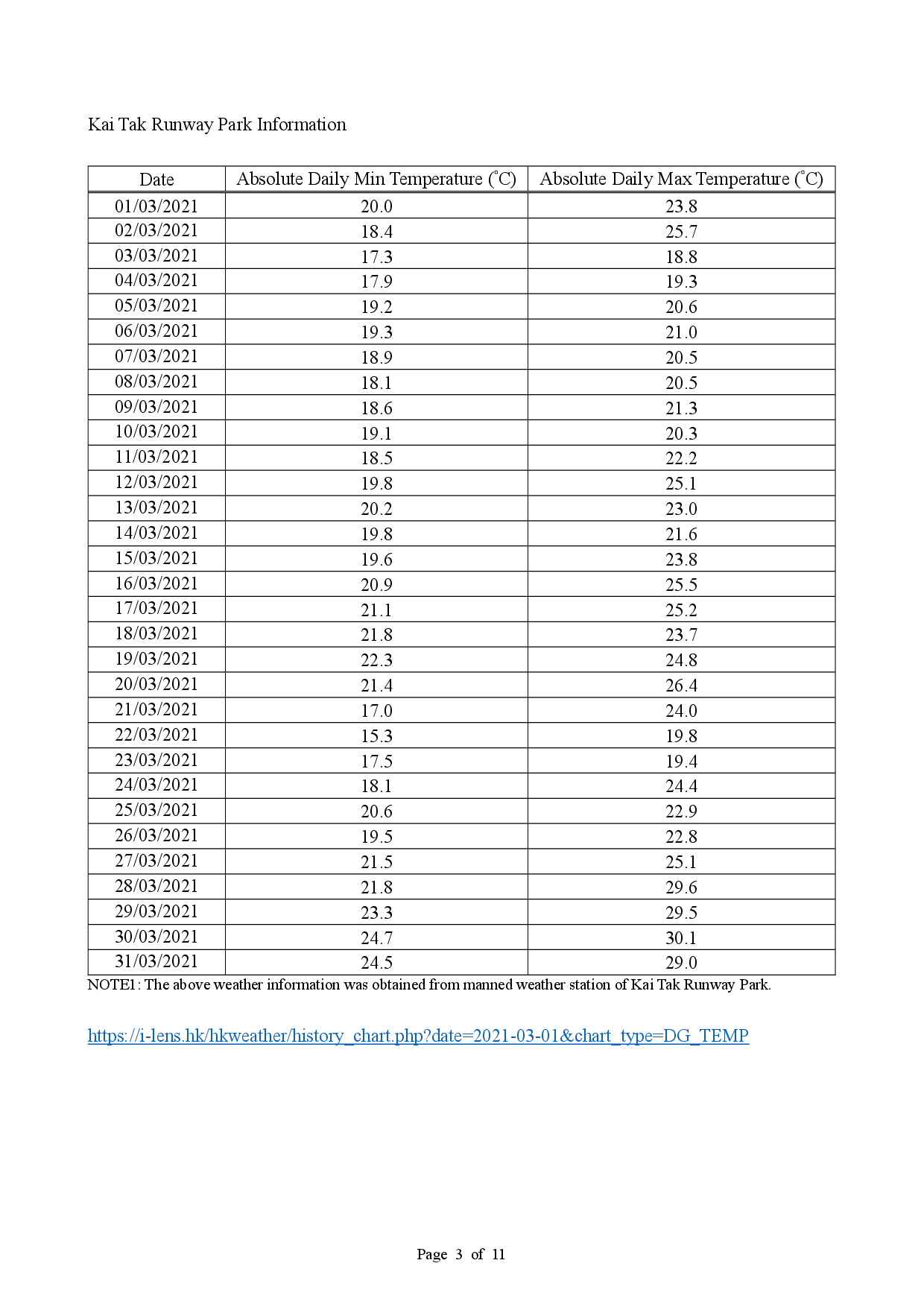

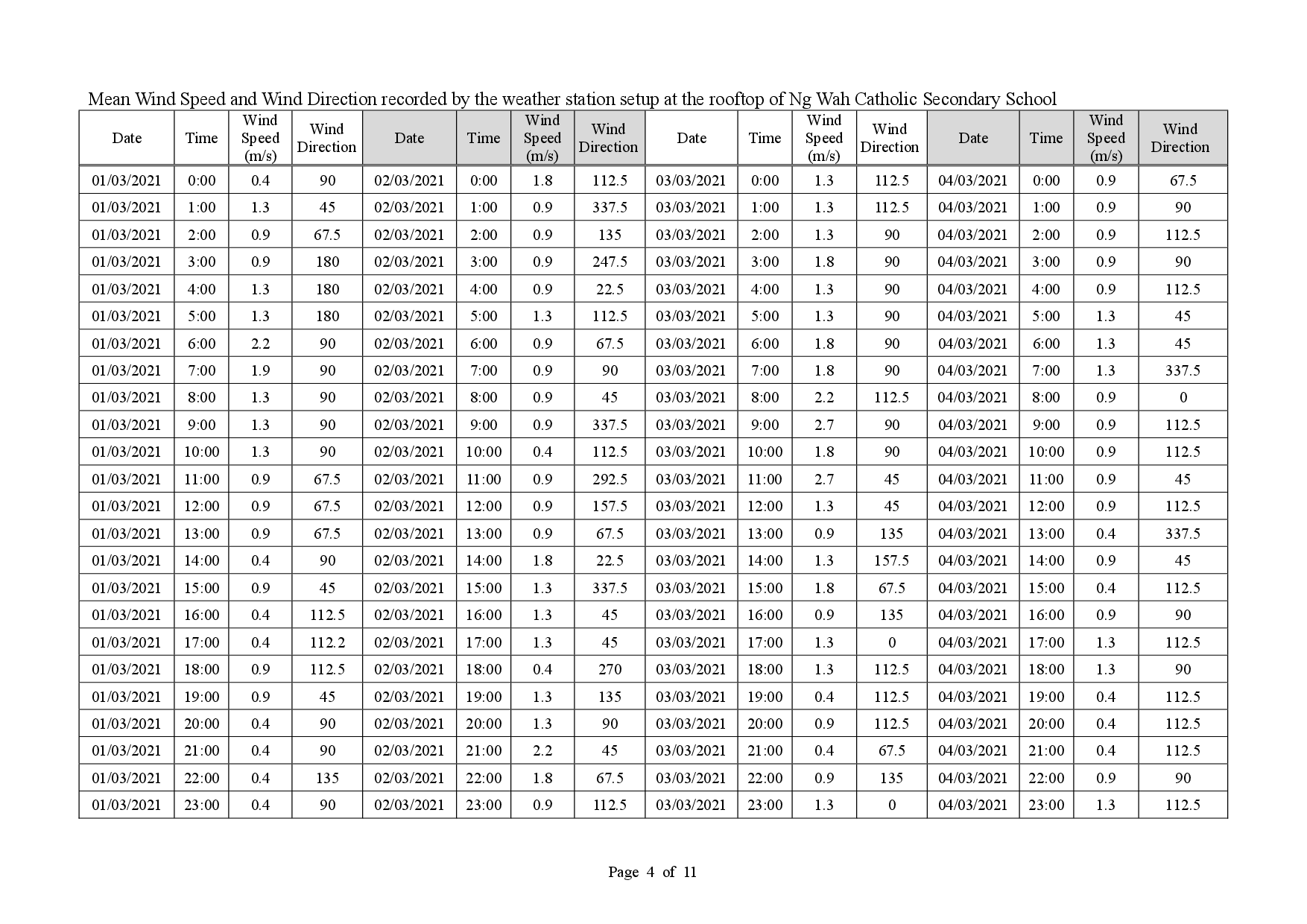

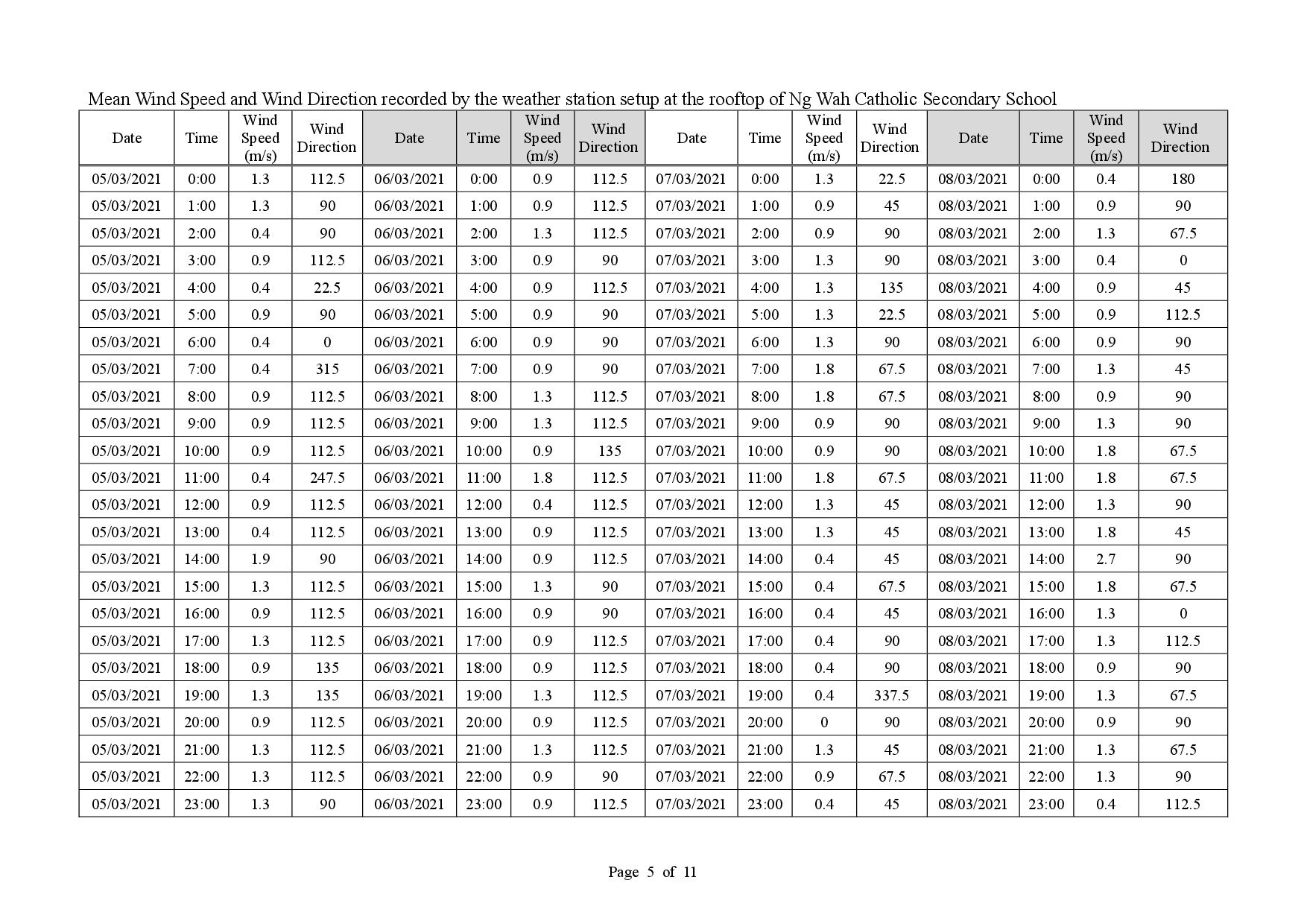

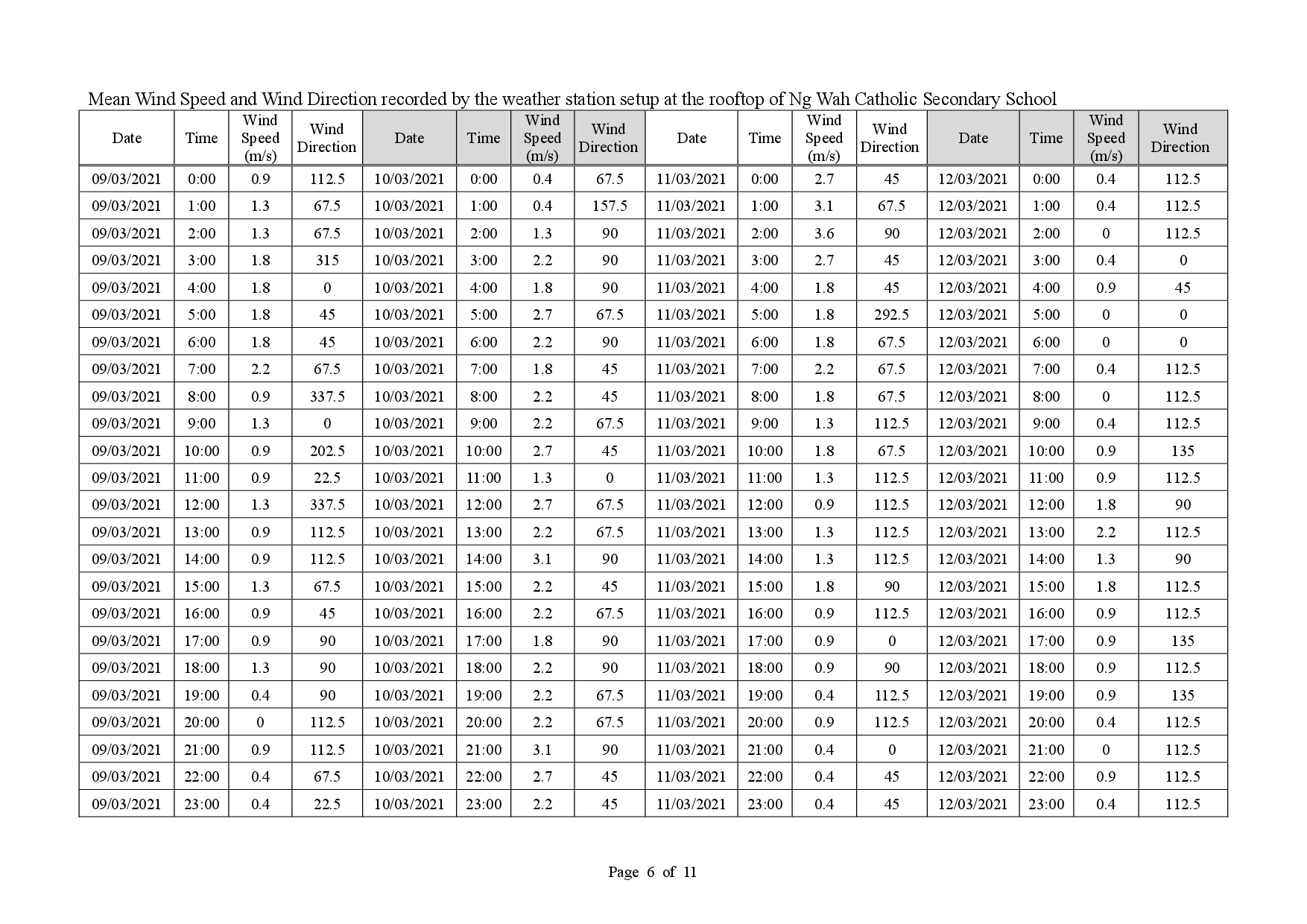

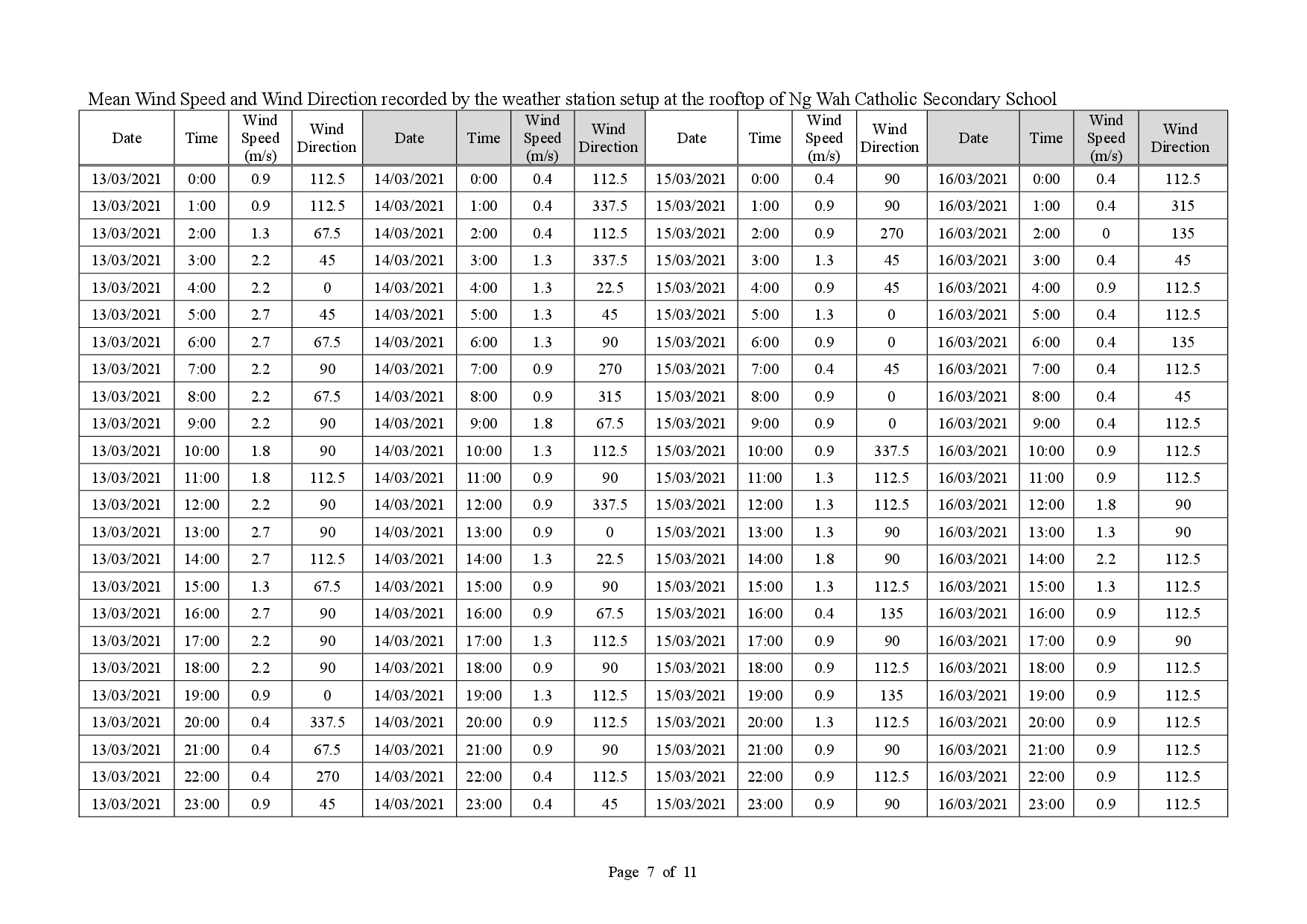

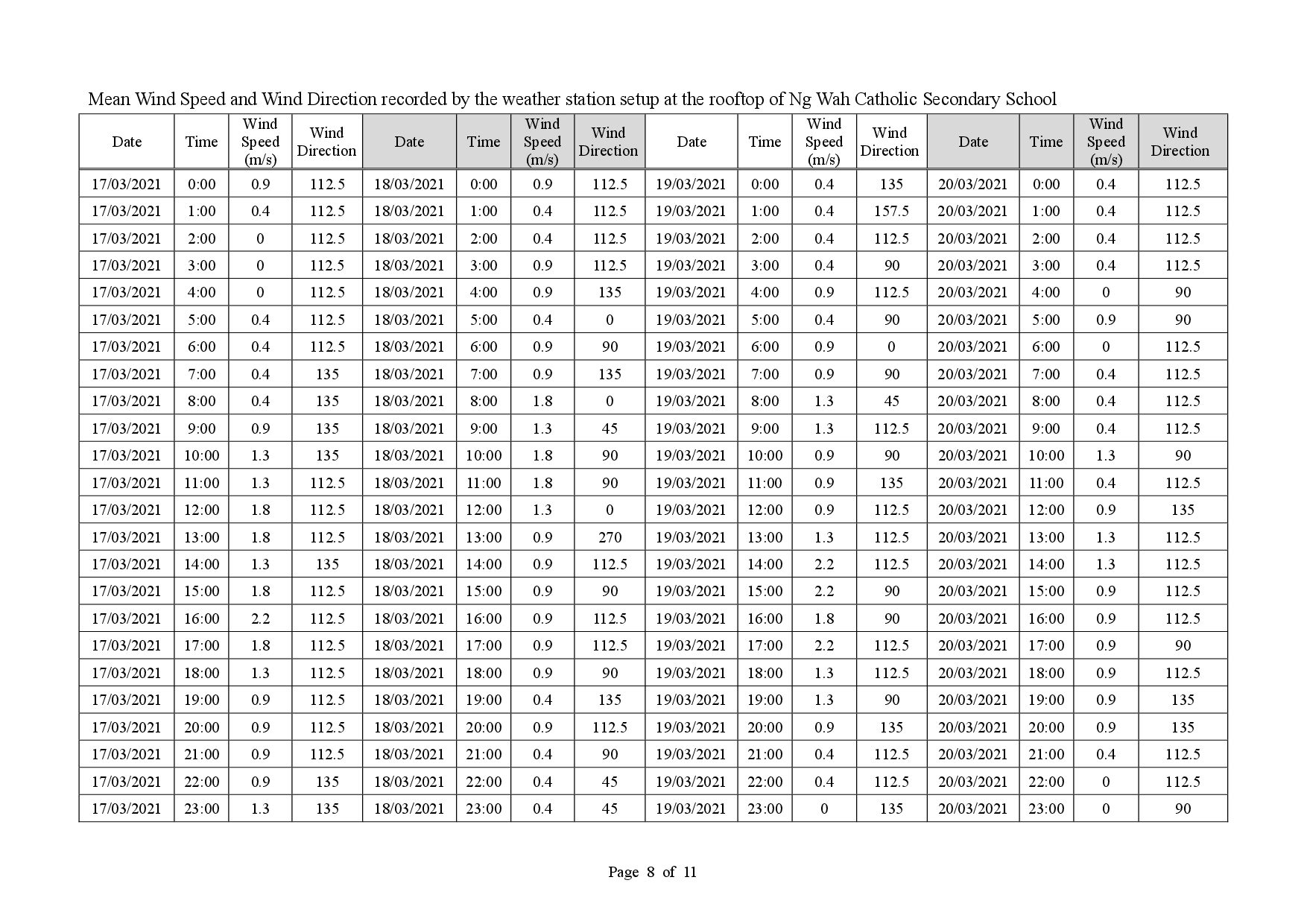

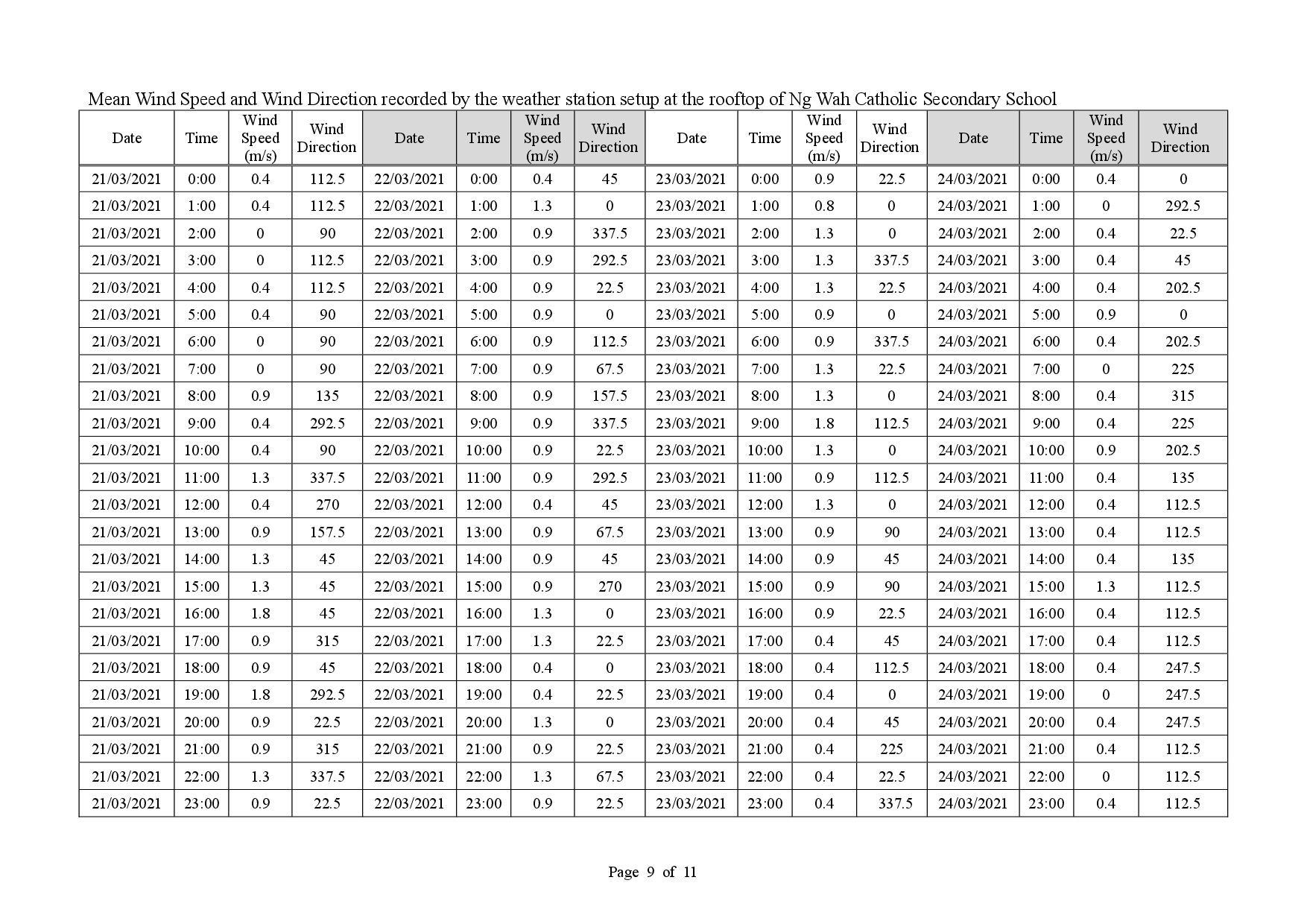

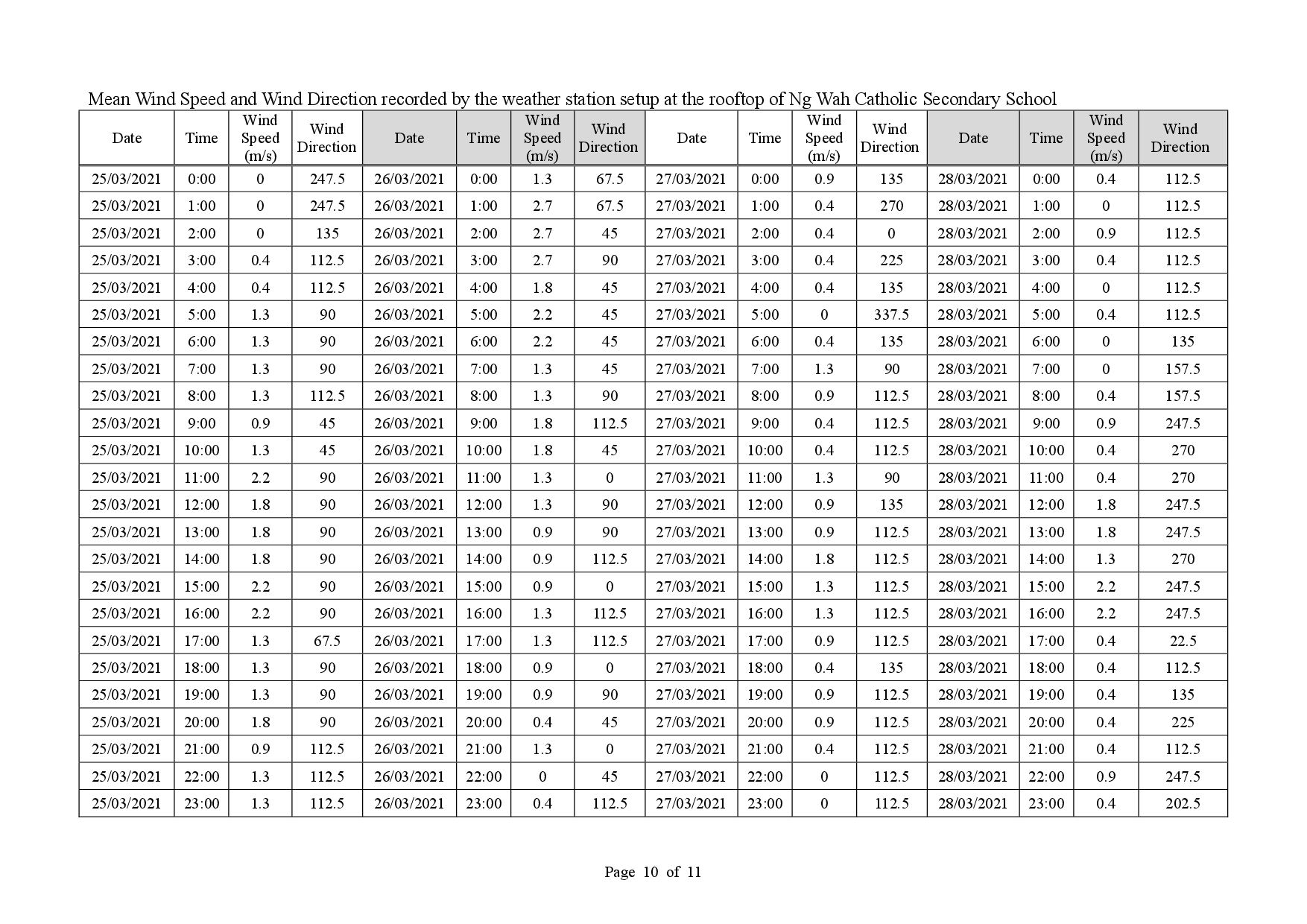

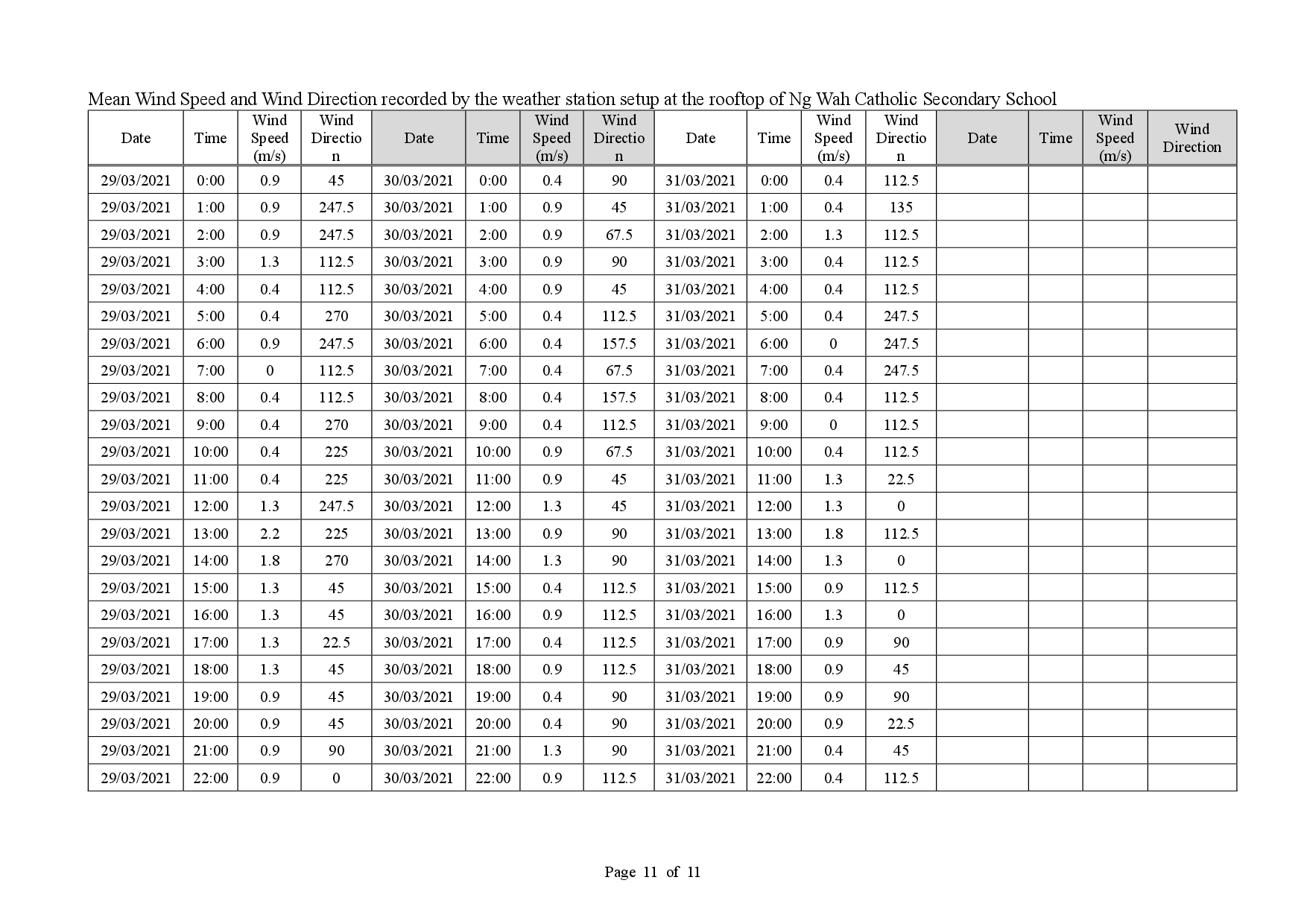

Appendix F – Weather information

Appendix H – 1-hr TSP monitoring results and graphical presentation

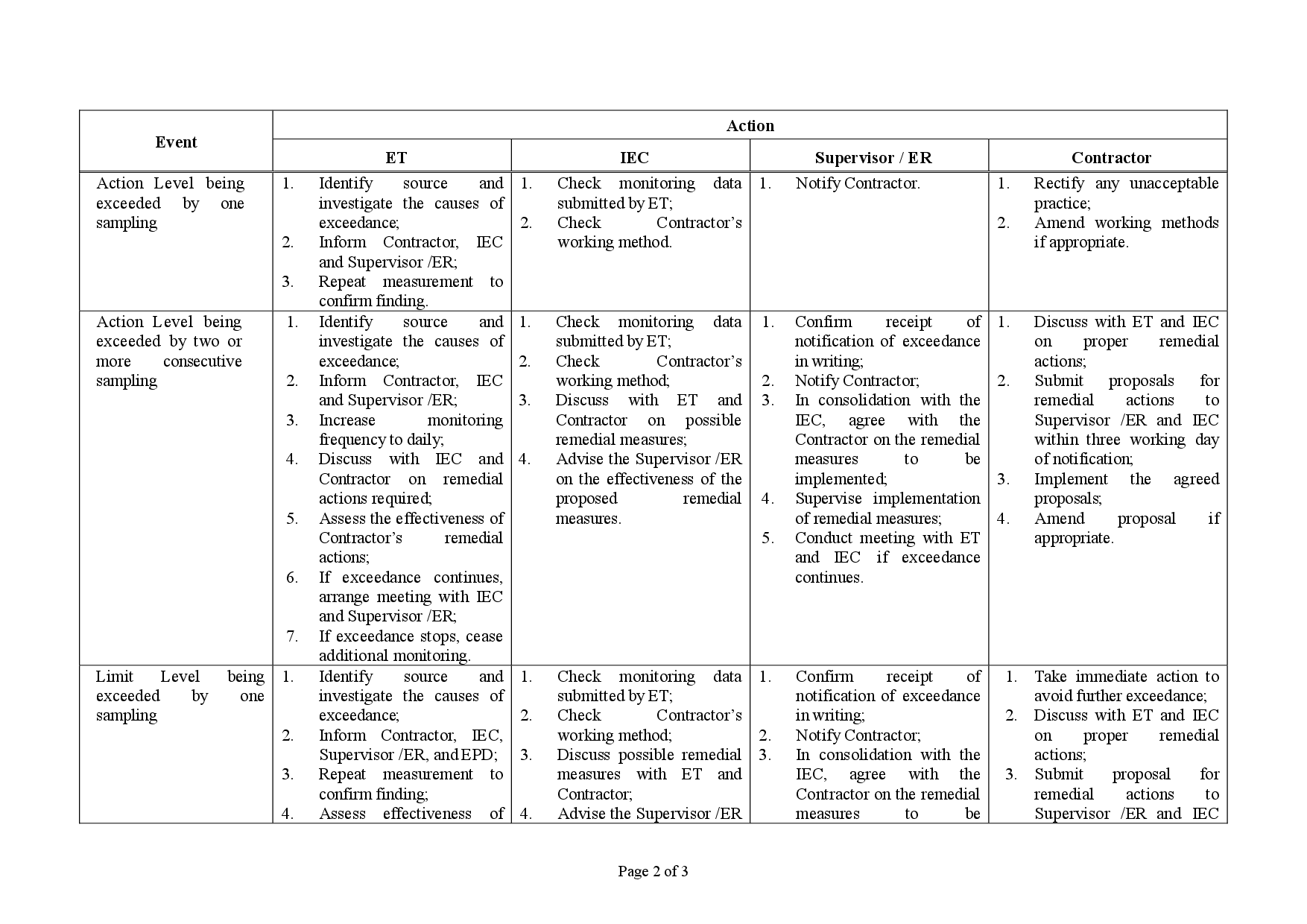

Appendix I – Event and Action Plan for air quality

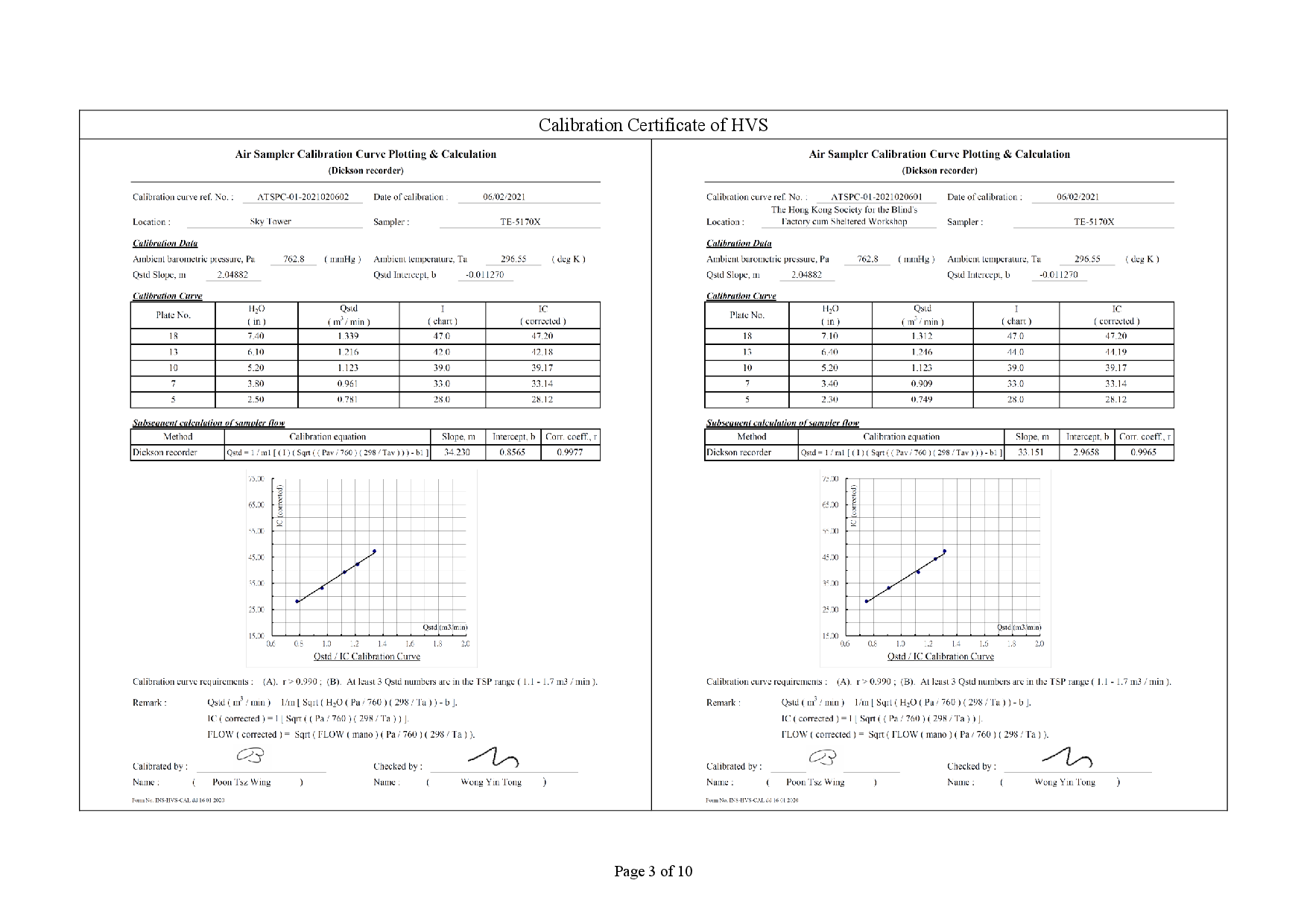

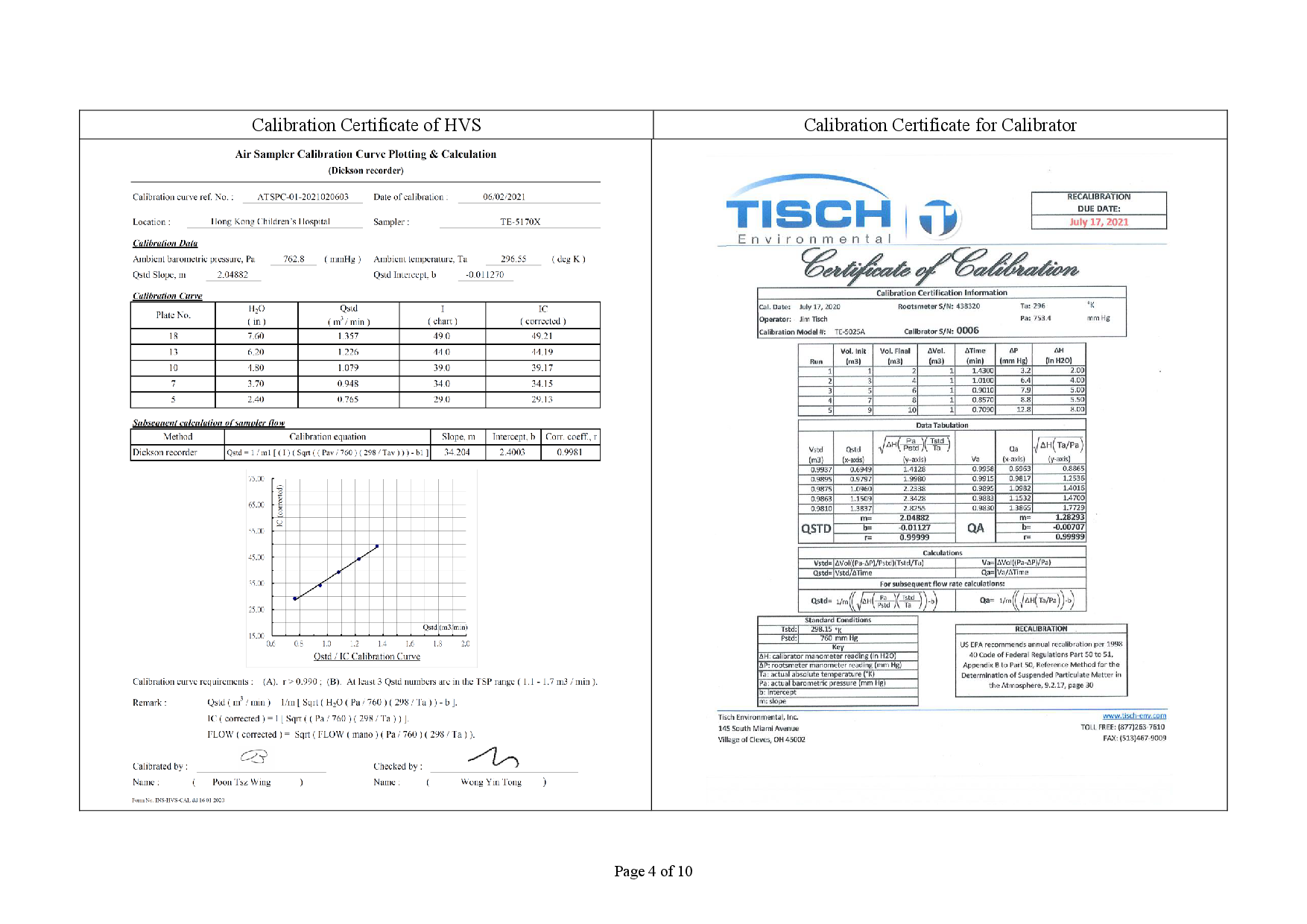

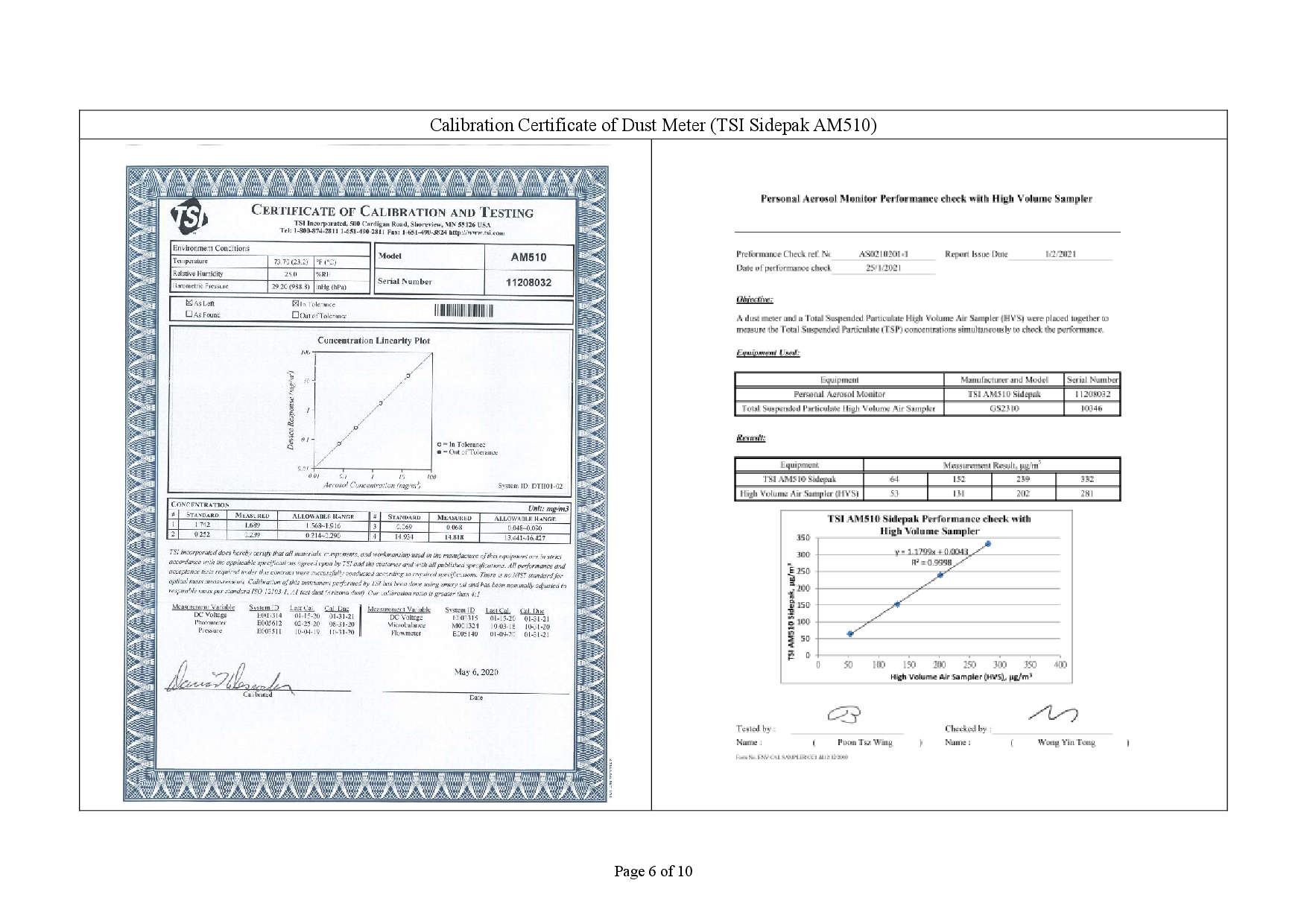

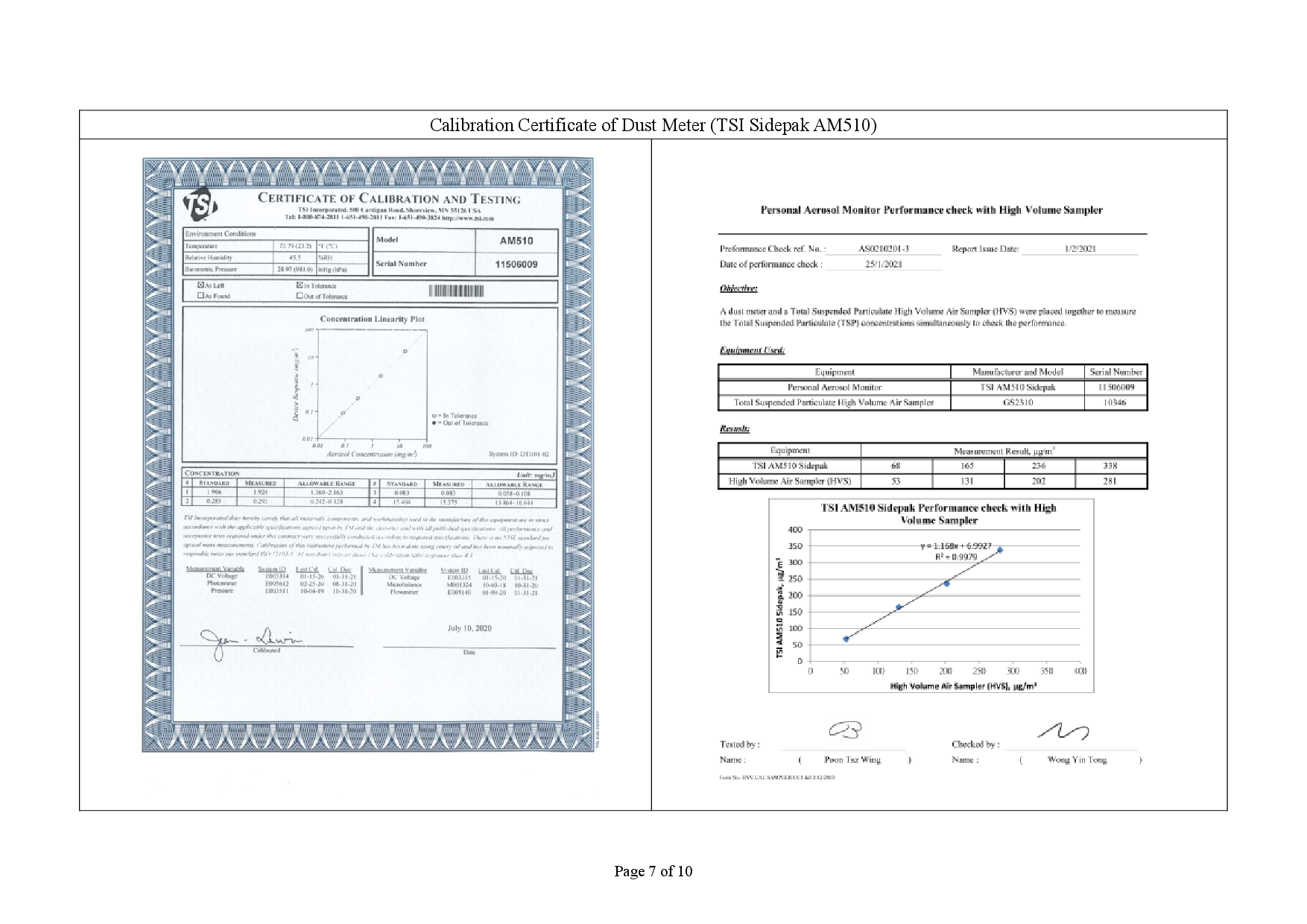

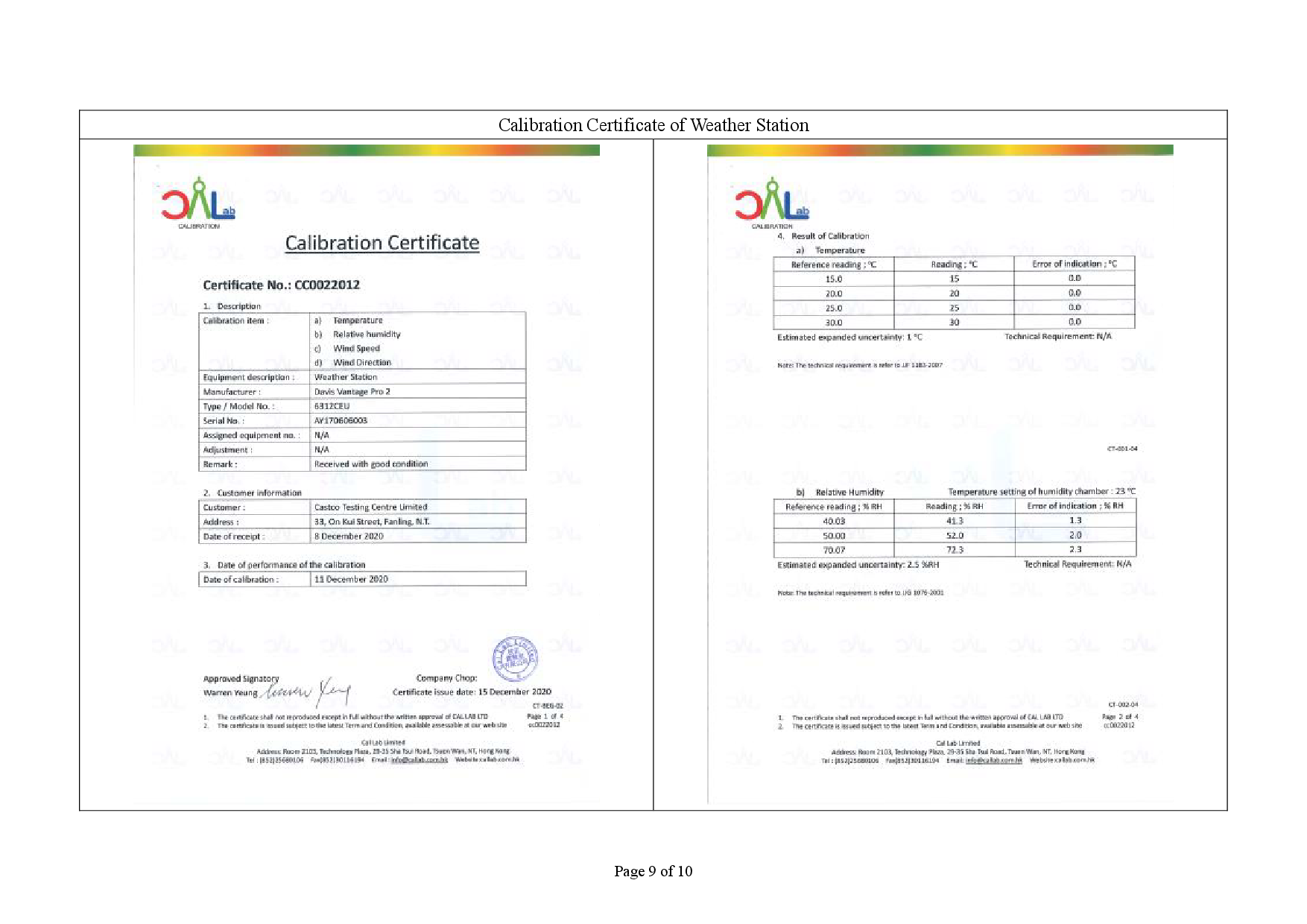

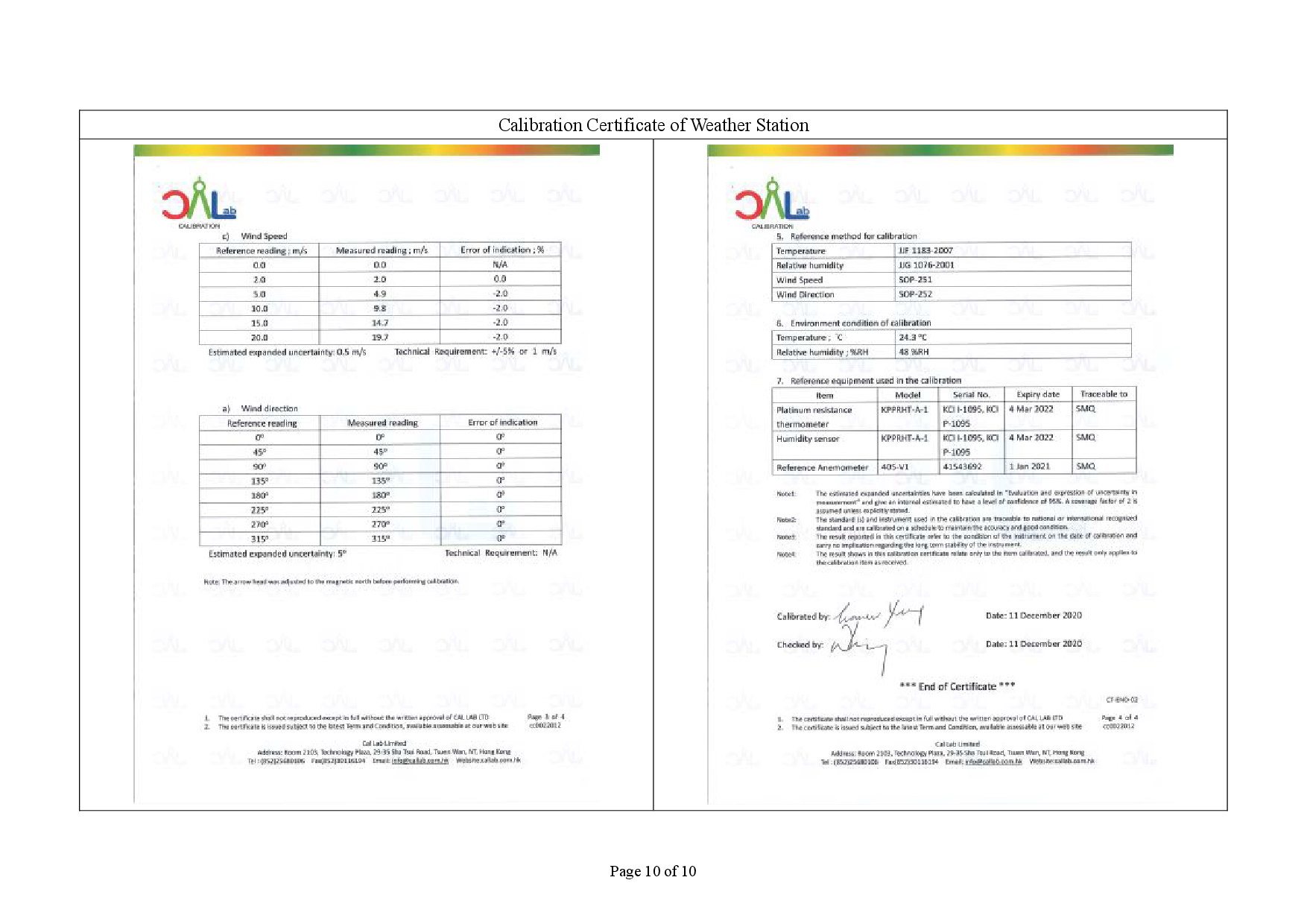

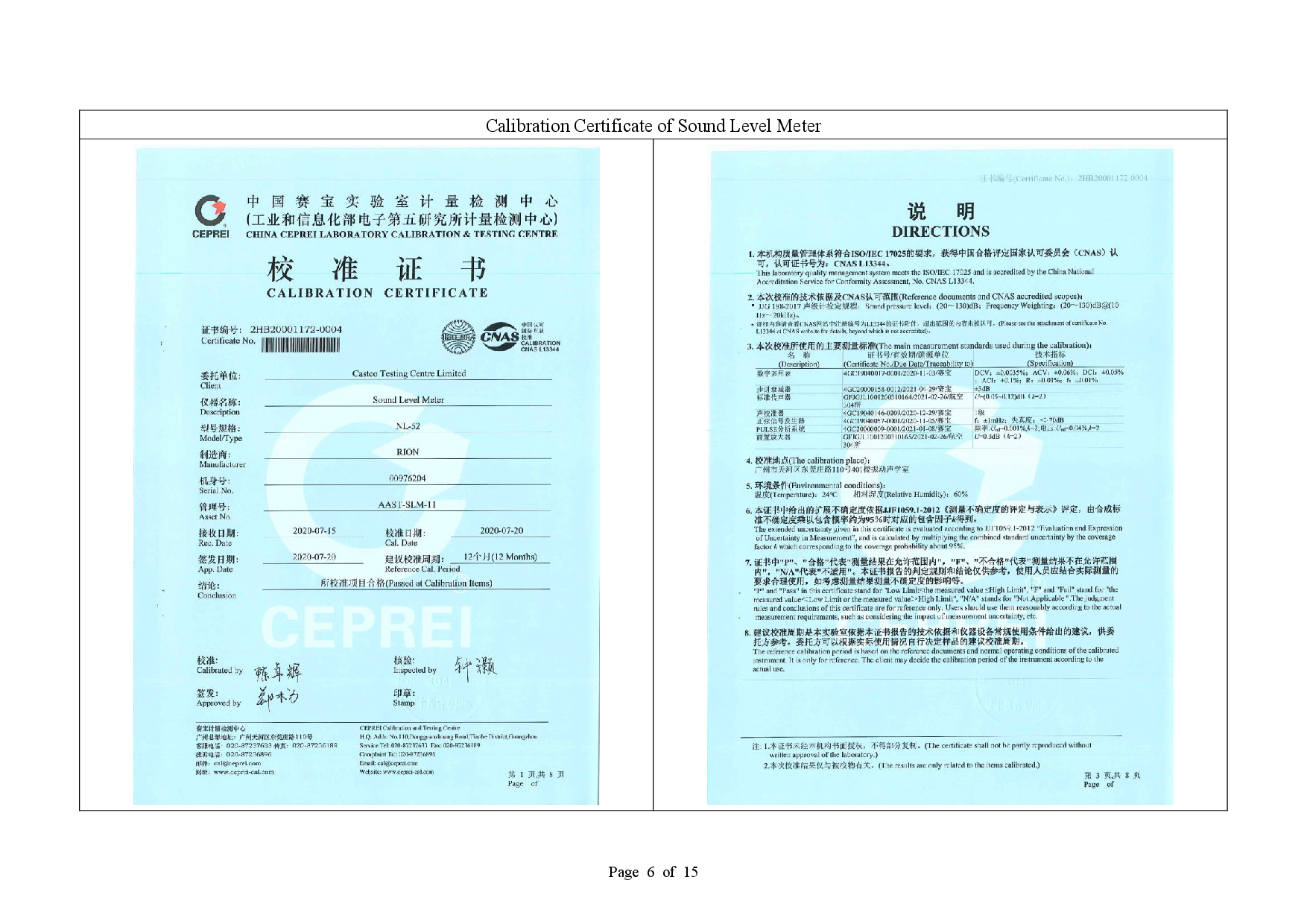

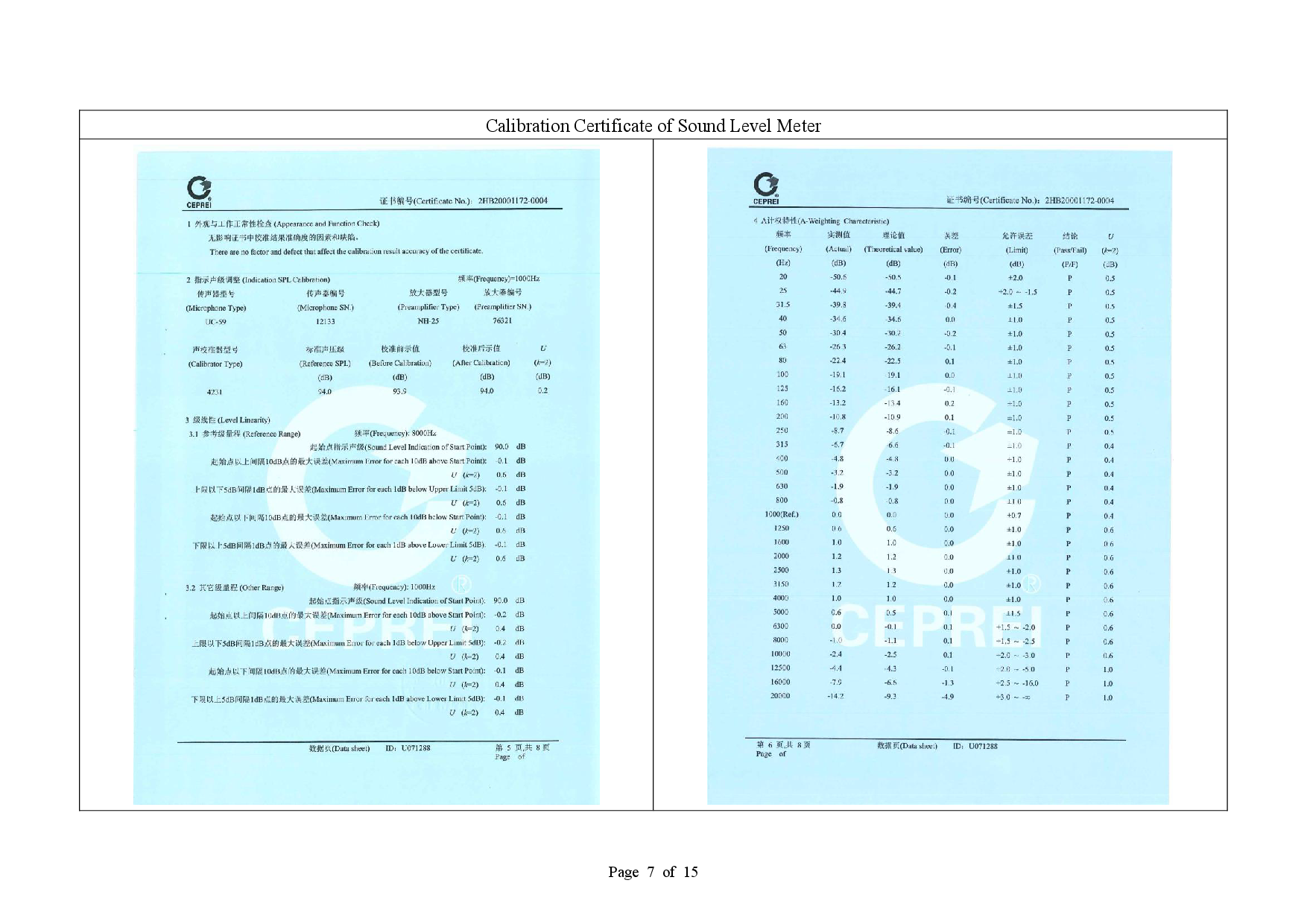

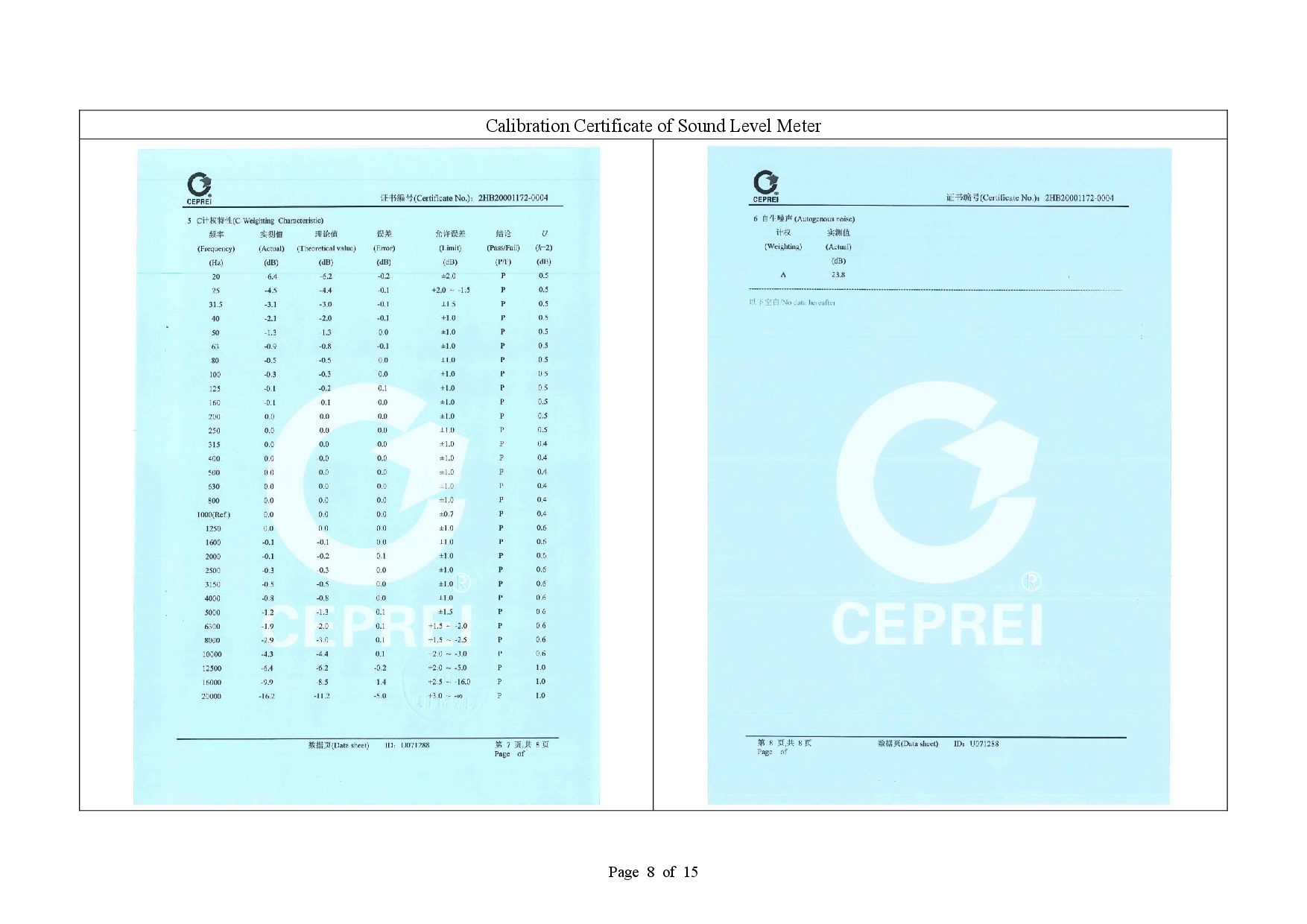

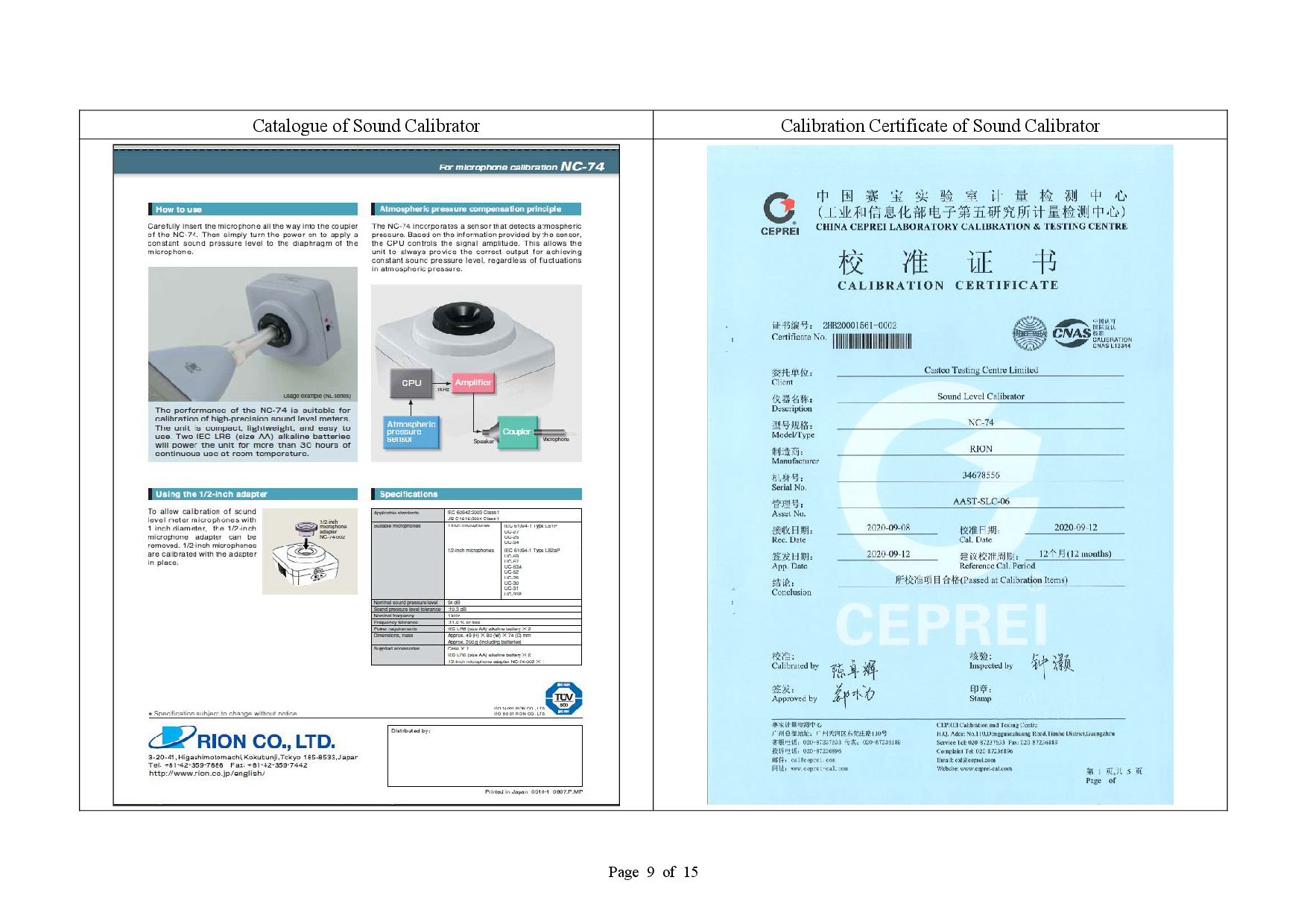

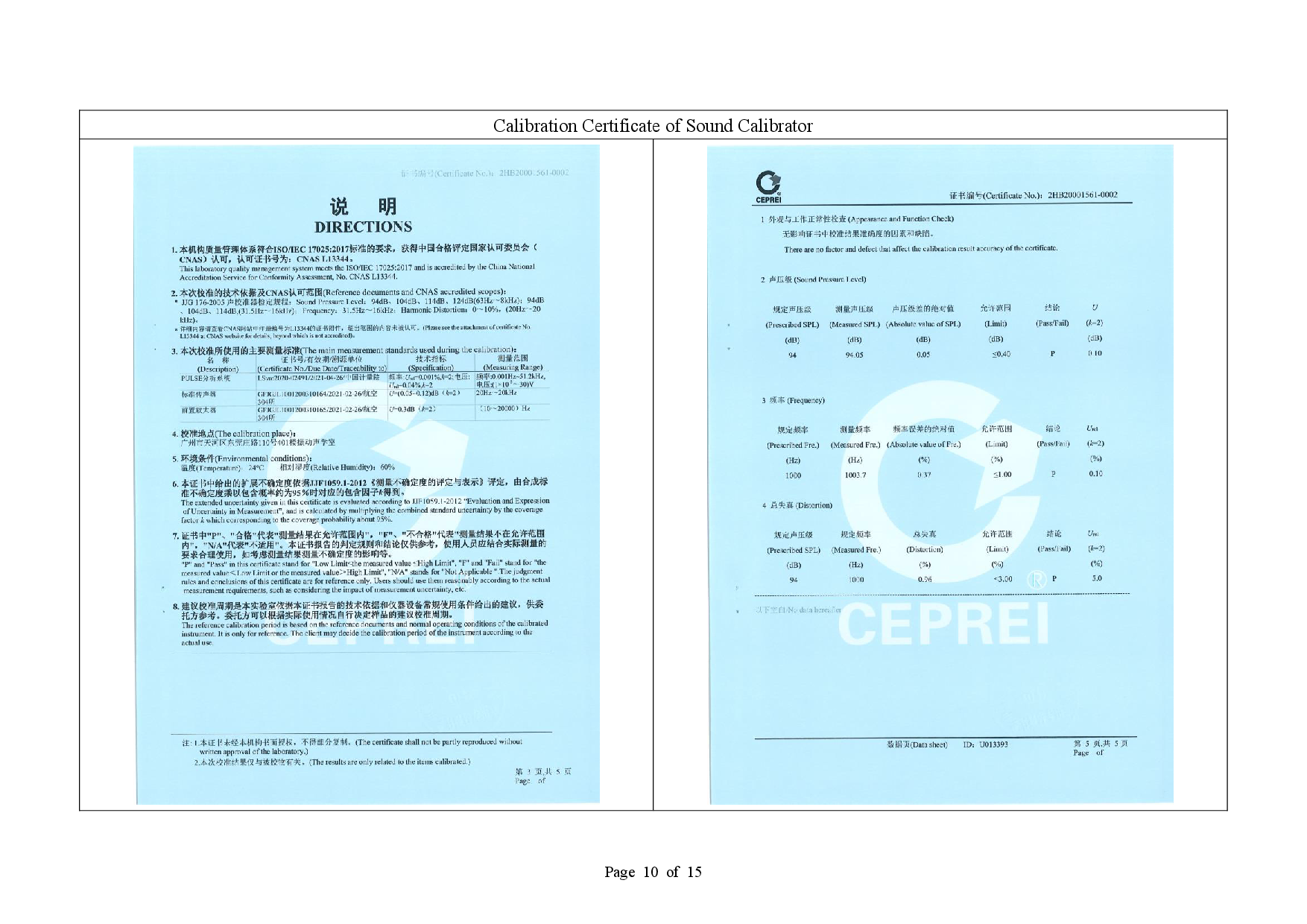

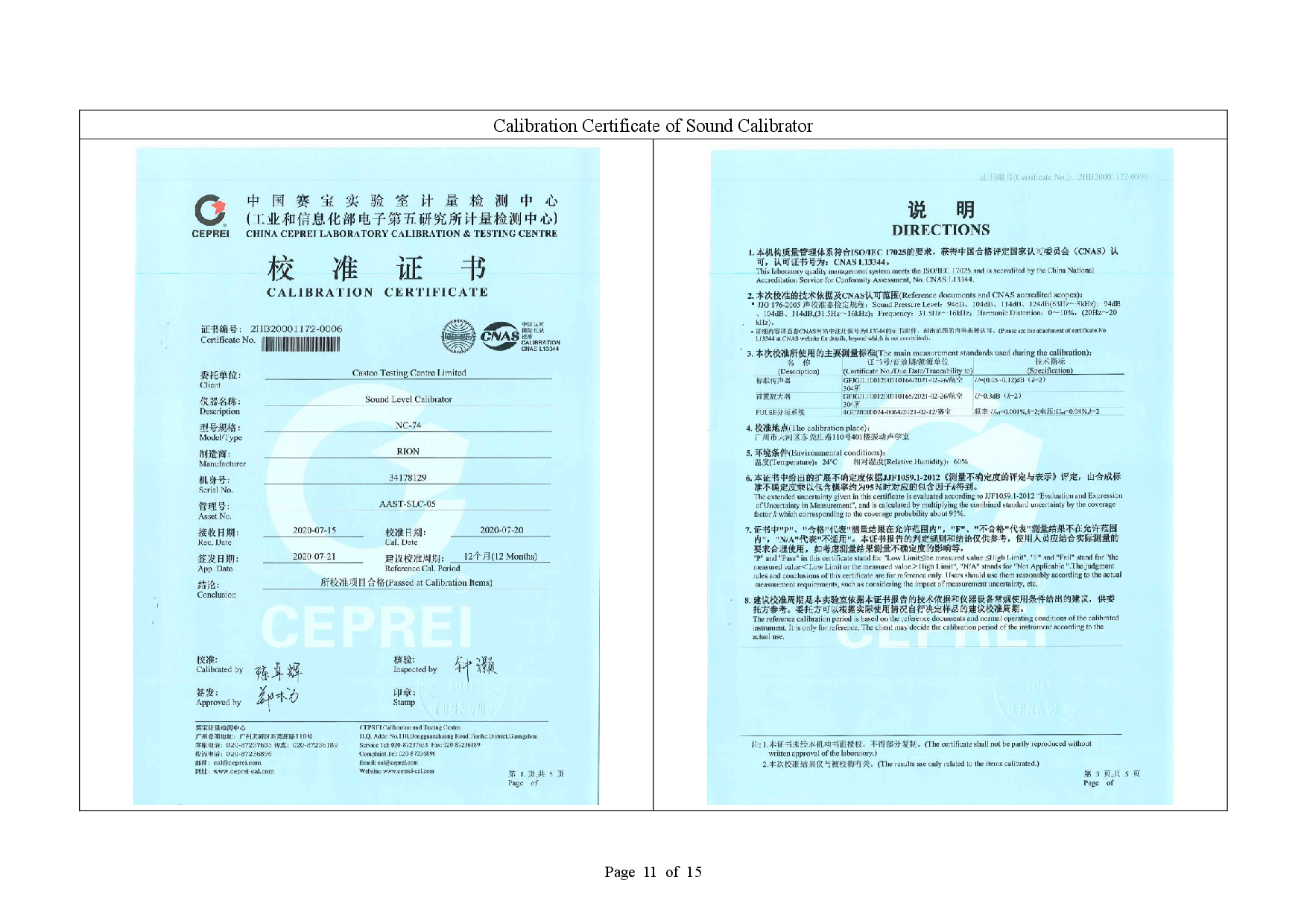

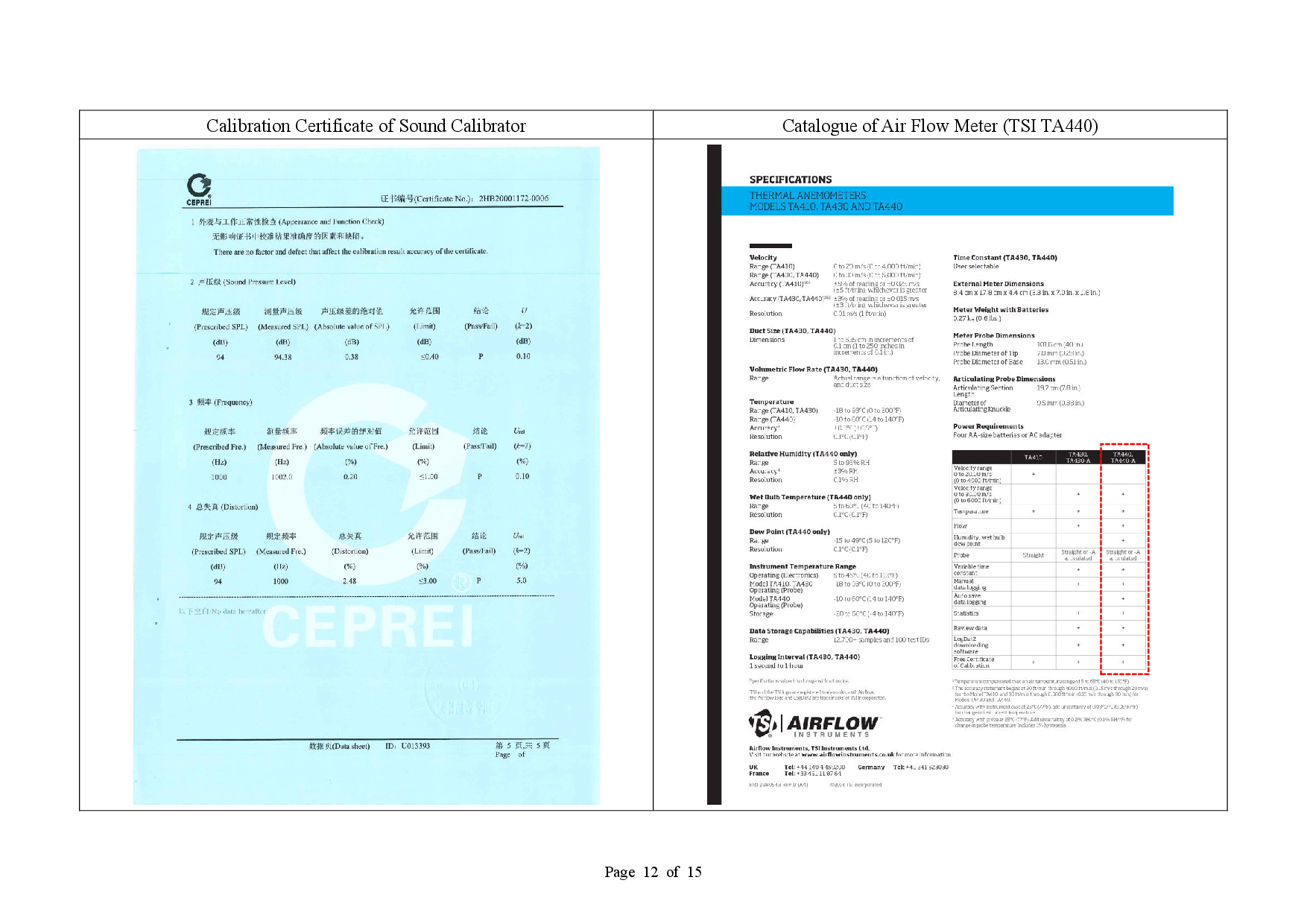

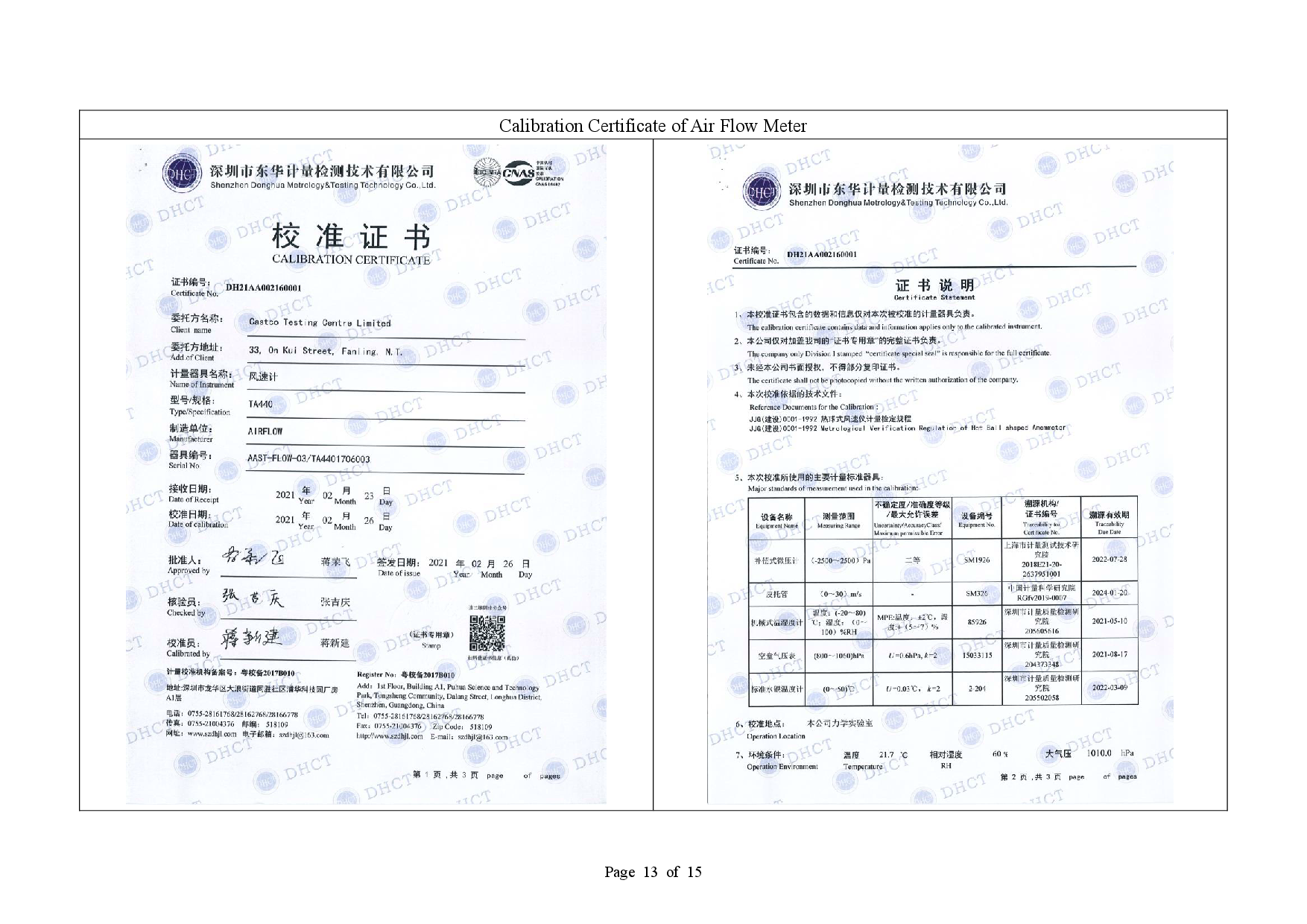

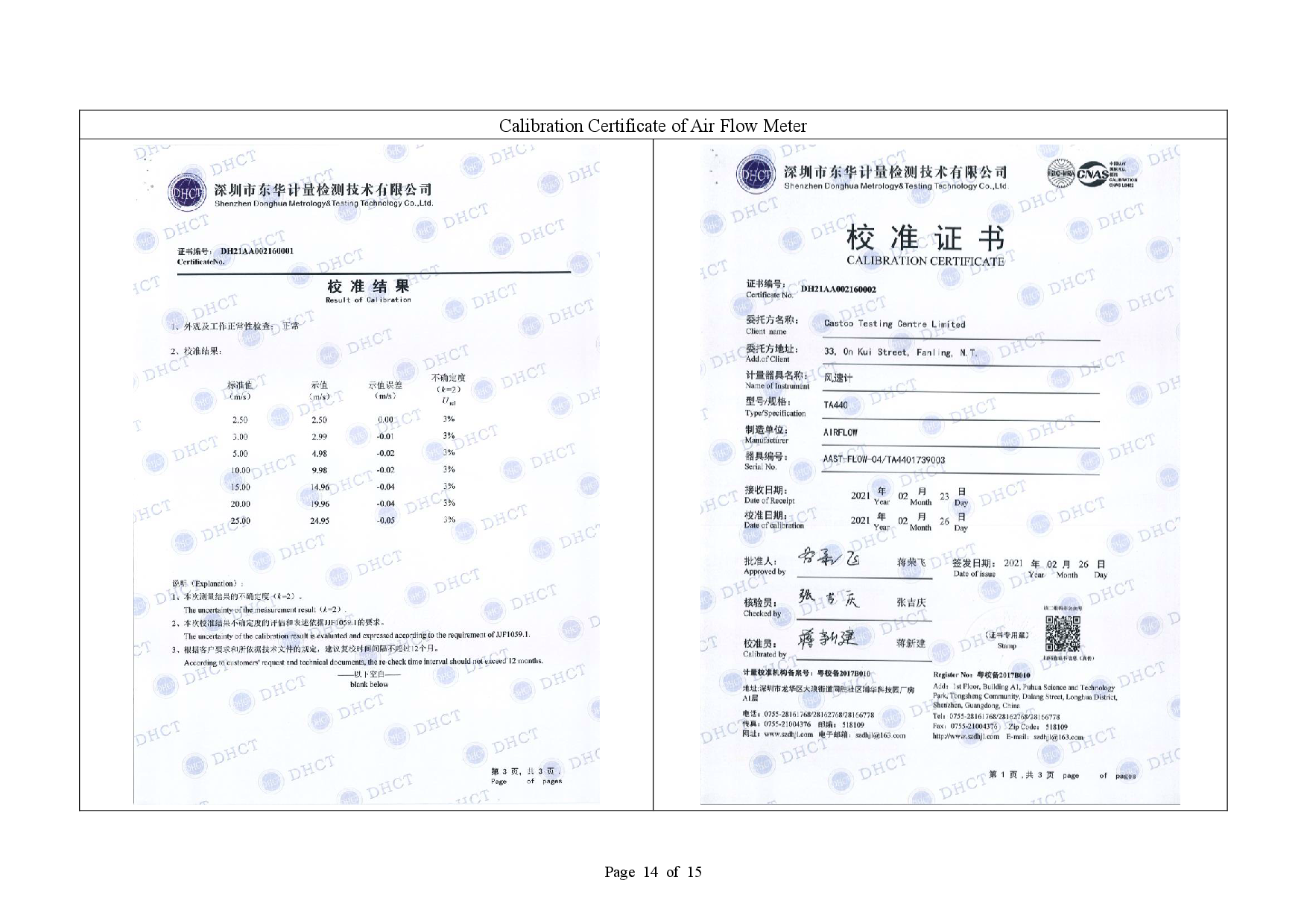

Appendix J – Calibration certificates, catalogue of noise monitoring equipment

Appendix K – Noise monitoring results and graphical presentation

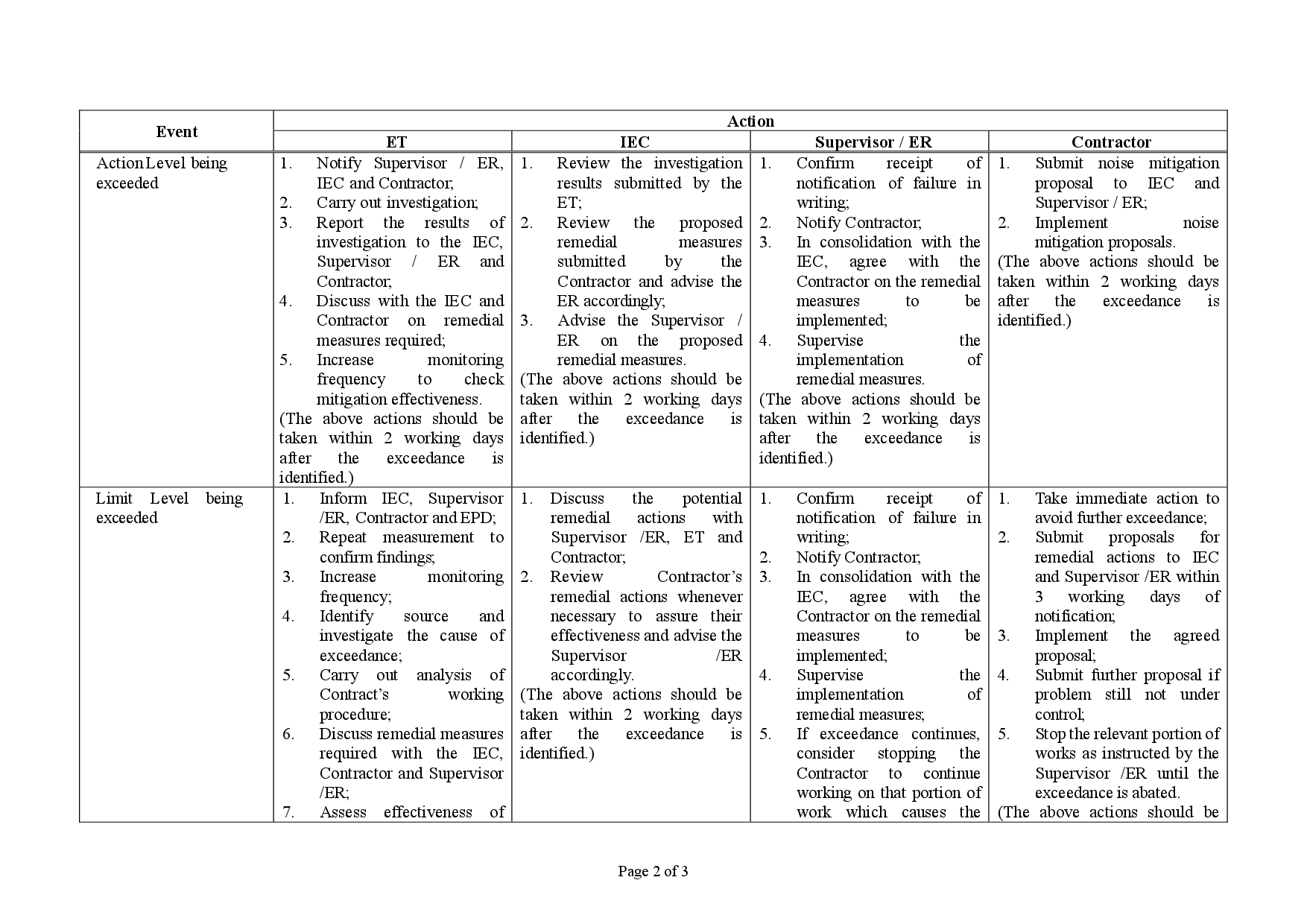

Appendix L – Event and Action Plan for noise

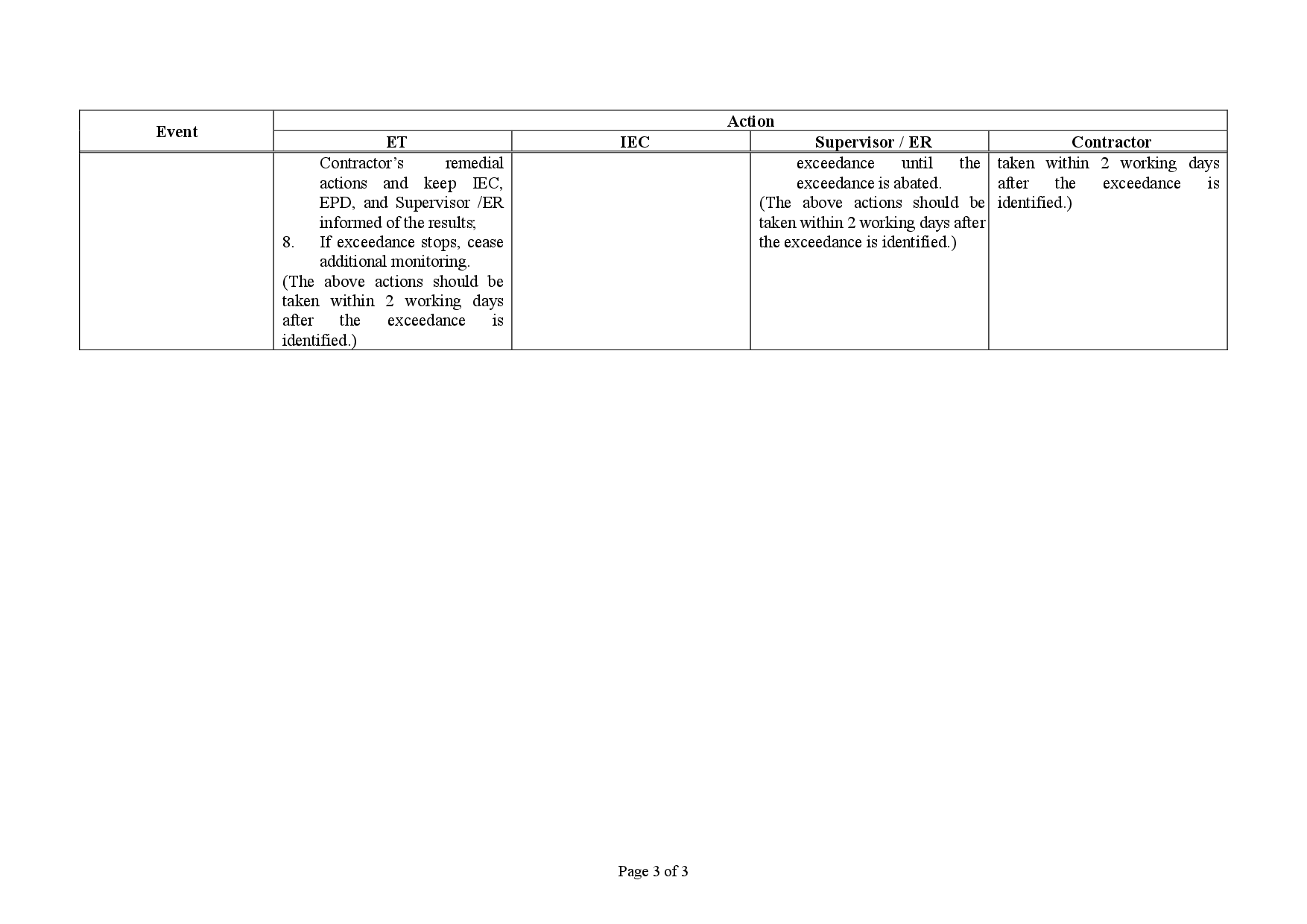

Appendix M – Event and Action Plan for Landscape and Visual Impact

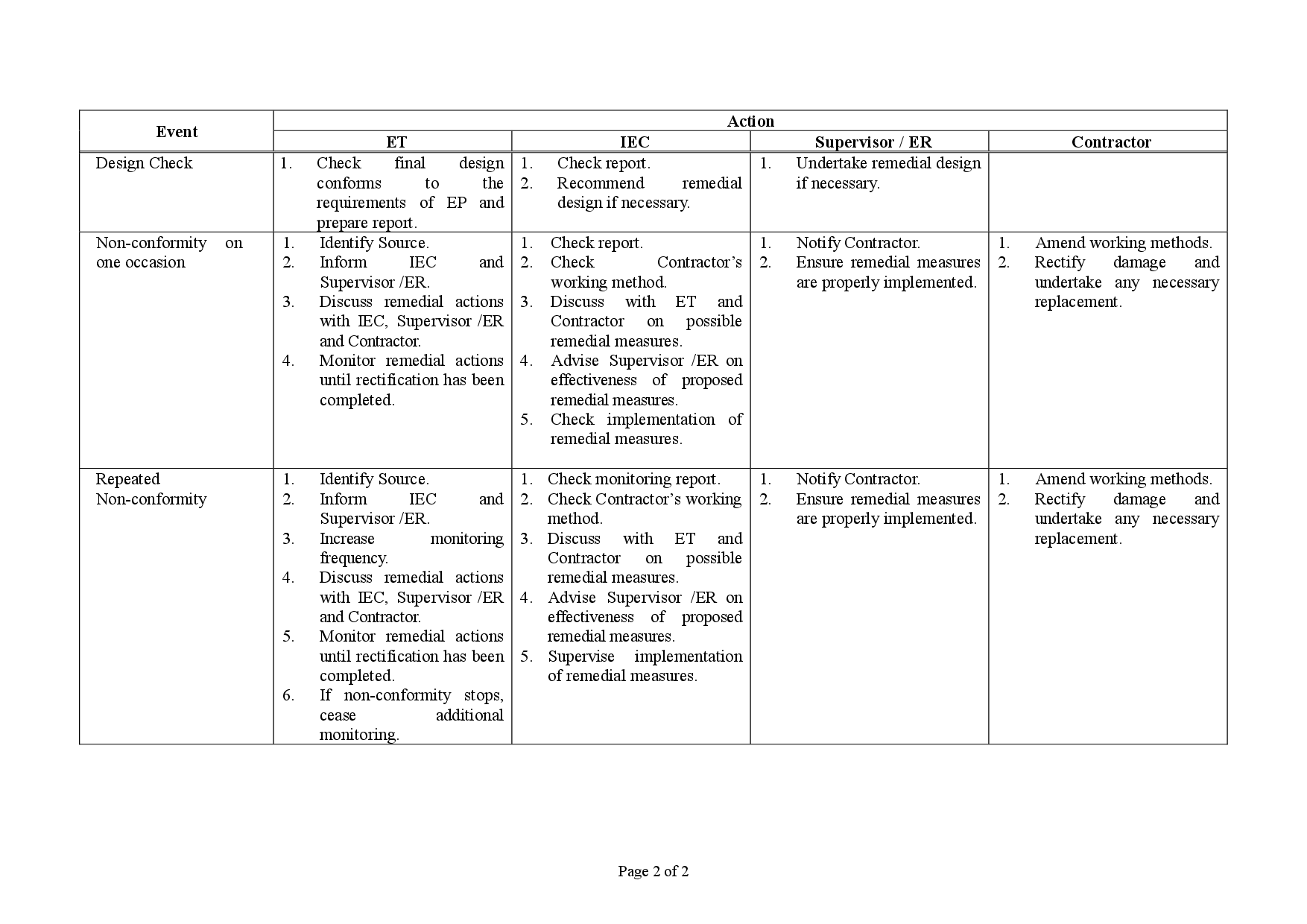

Appendix N – Waste Flow Table

Appendix O – Environmental Licenses and Notification

Appendix P – Environmental Mitigation Implementation Schedule (EMIS)

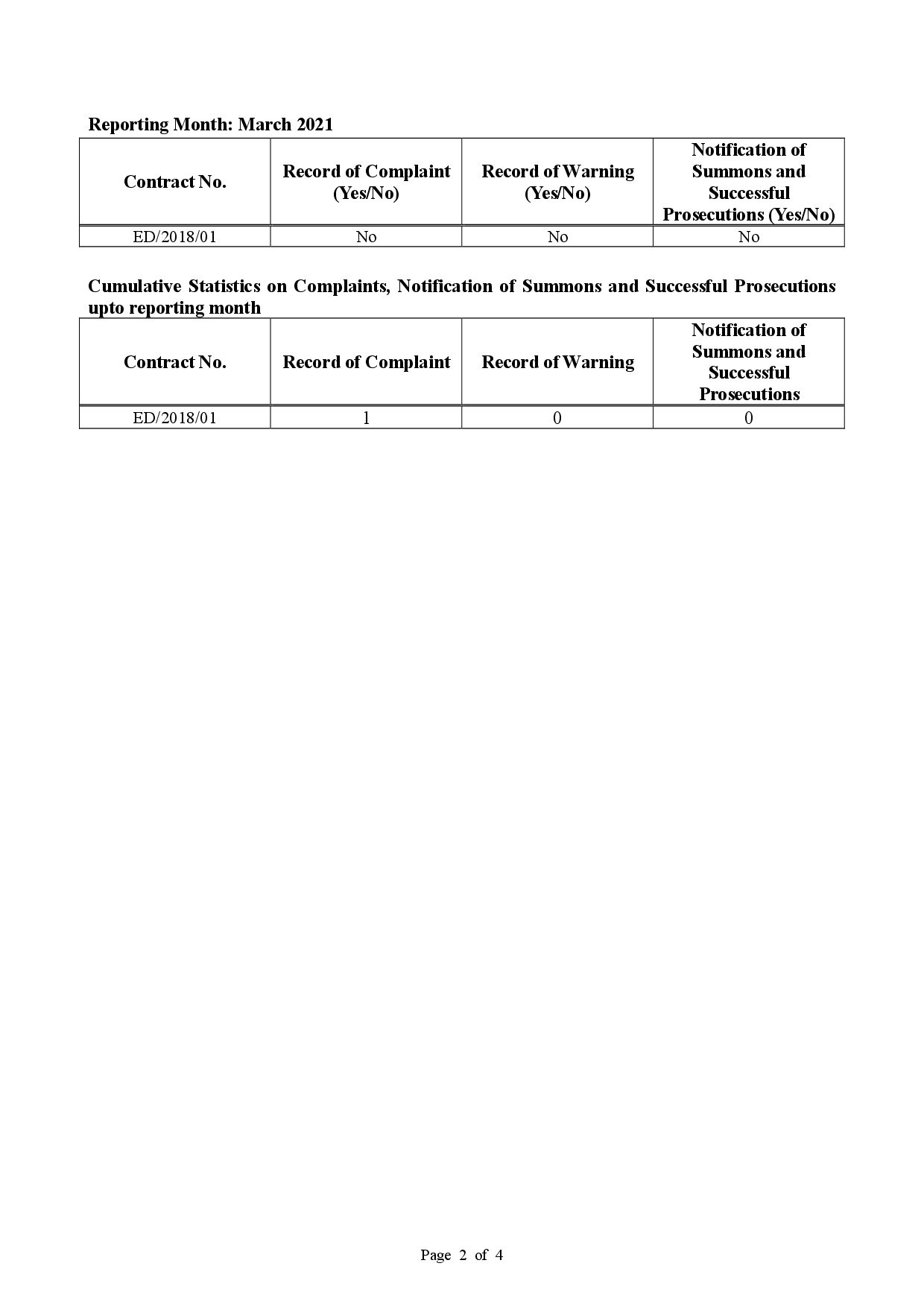

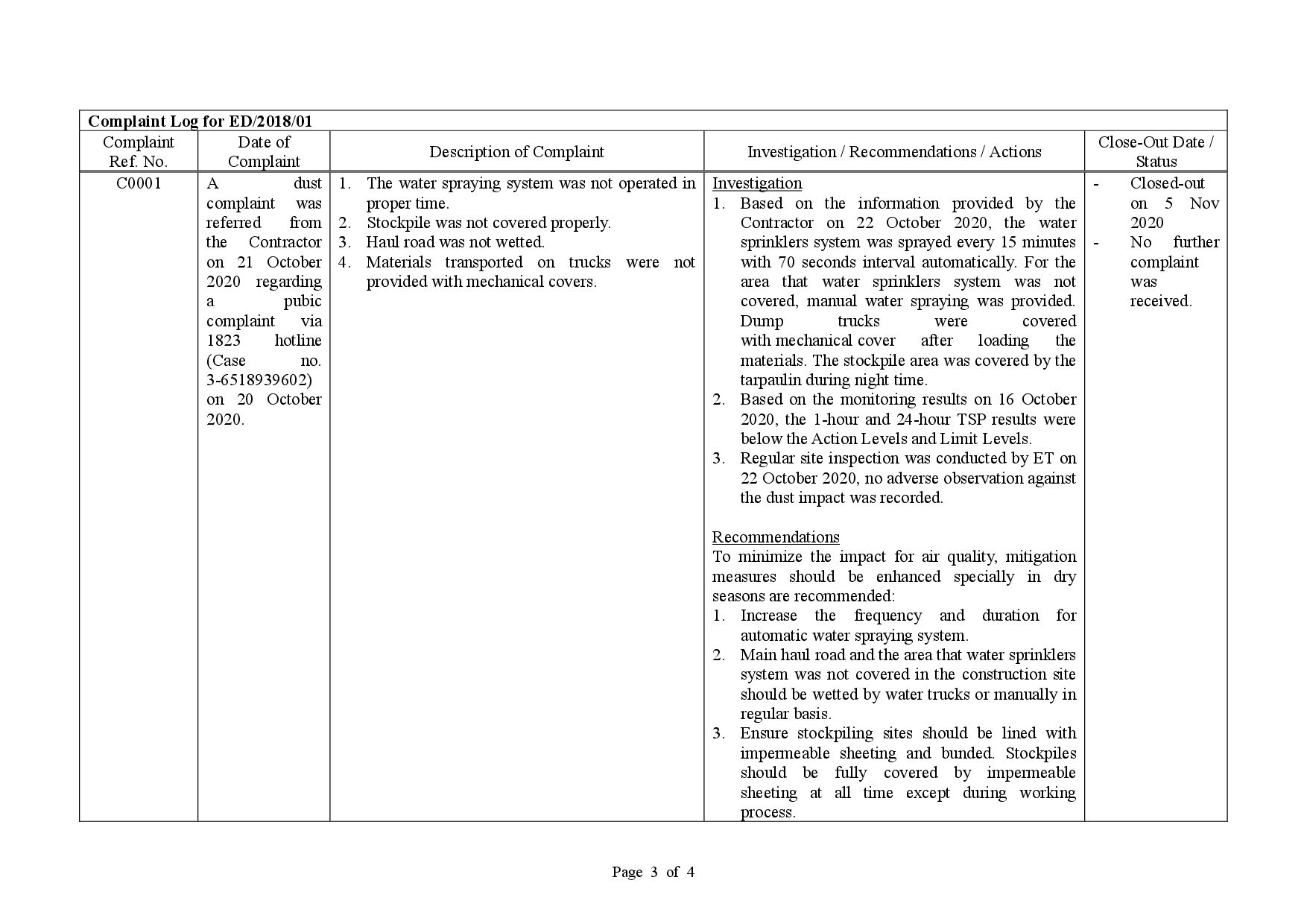

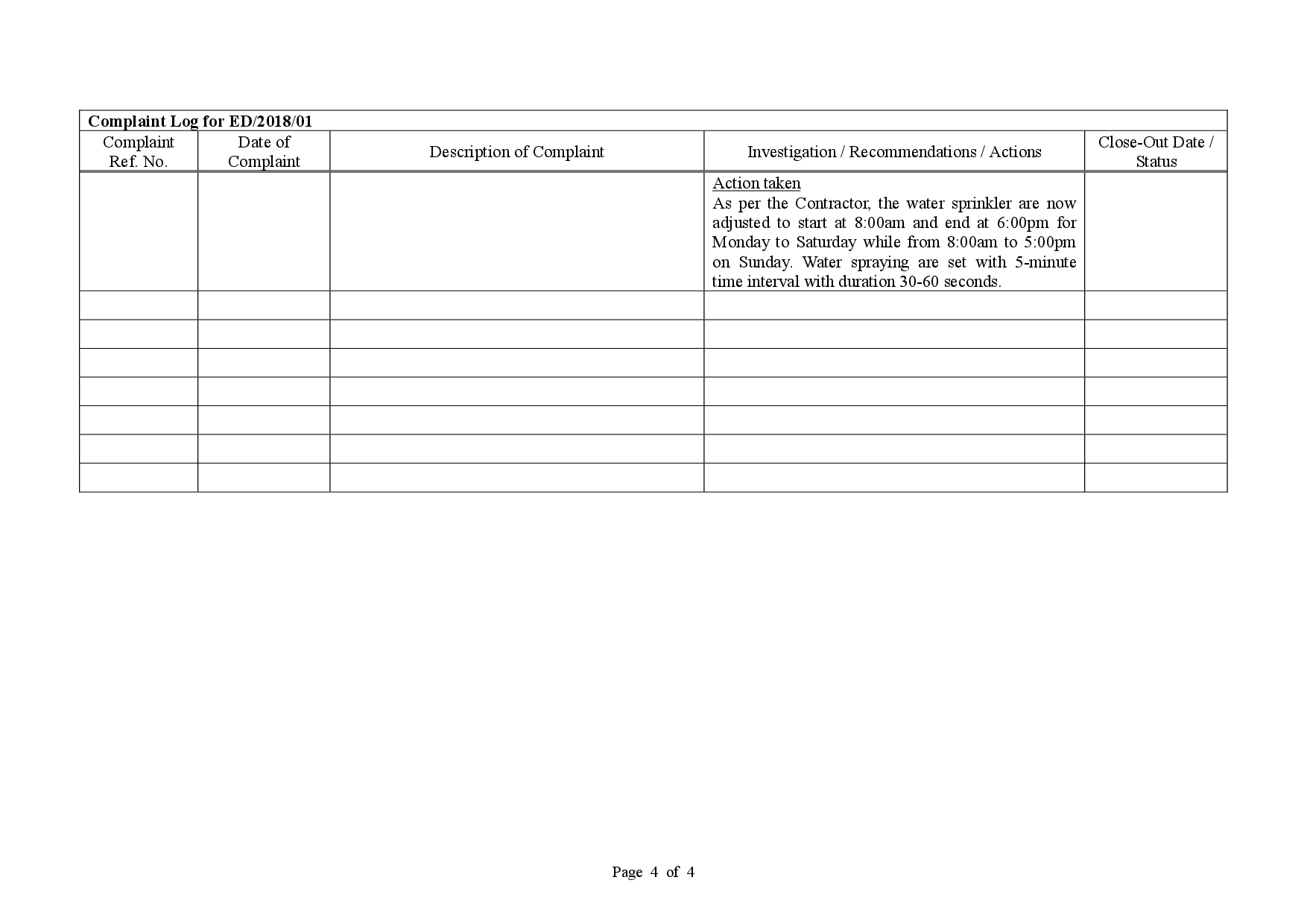

Appendix Q – Summaries of Environmental Complaint, Warning, Summon and Notification of Successful Prosecution

1. This is the 16th Monthly Environmental Monitoring & Audit (EM&A) report which summaries the findings of the EM&A Programme during the reporting period from 1 to 30 April 2021.

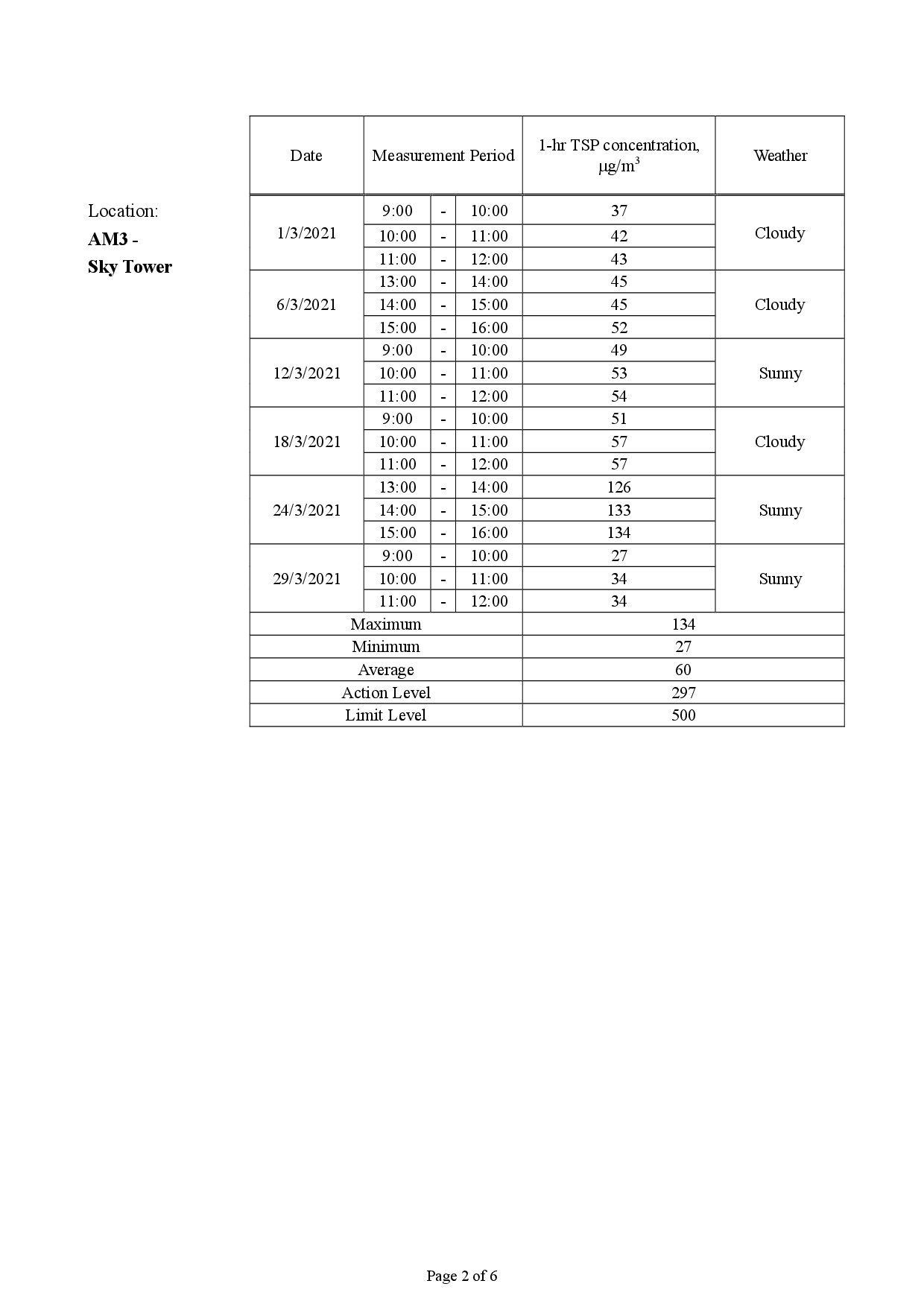

2. 1-hour TSP monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

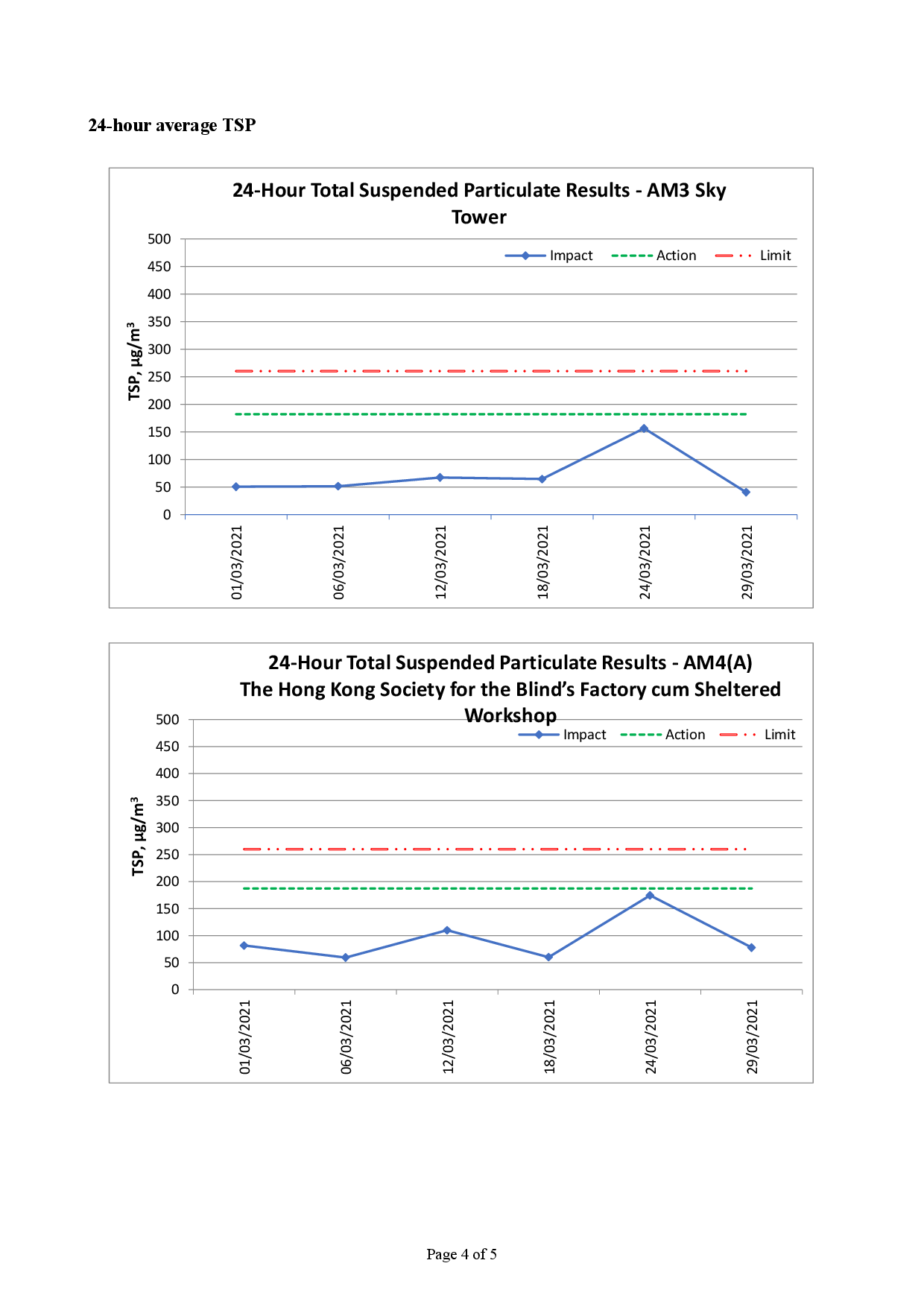

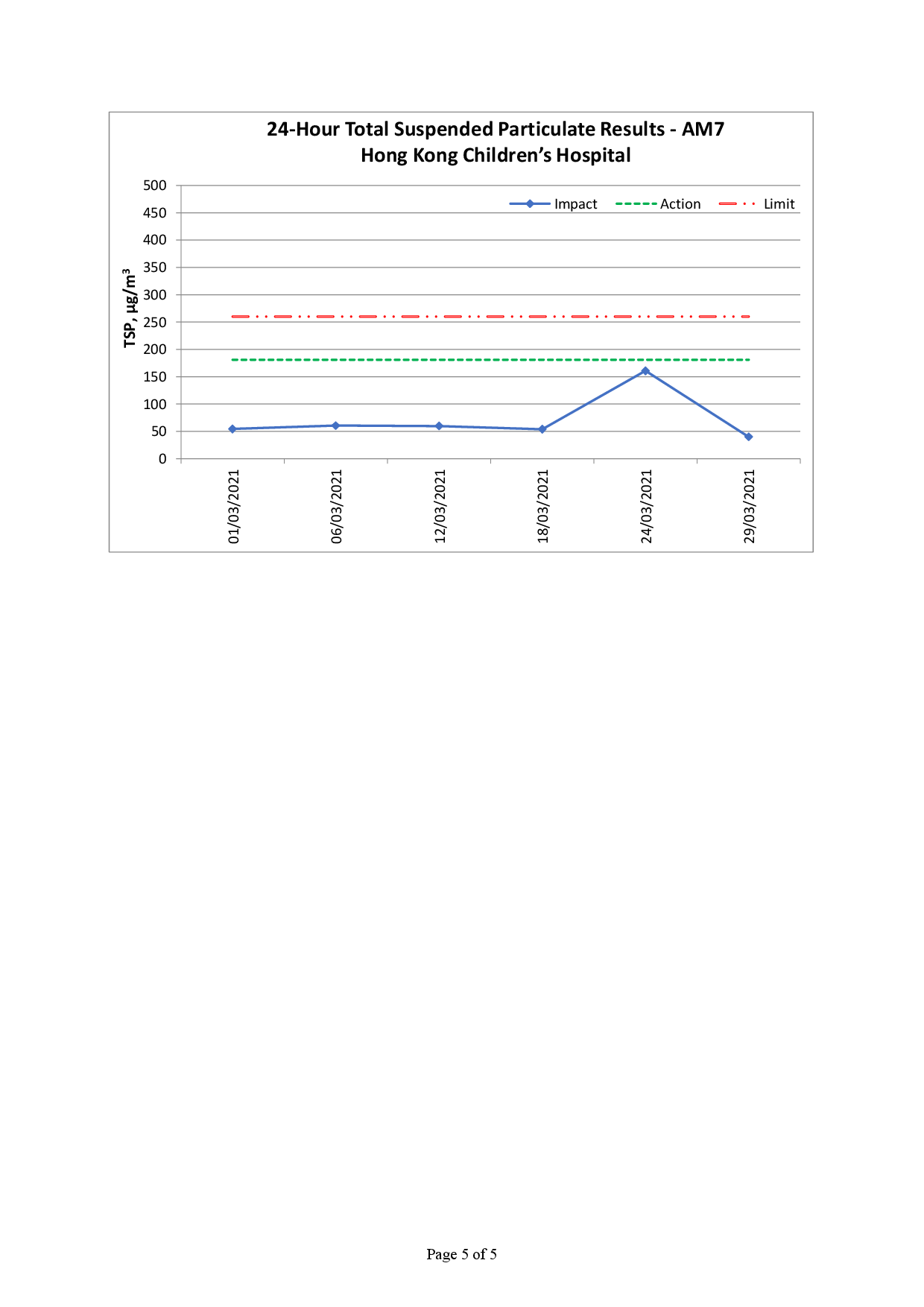

3. 24-hour TSP monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

4. Construction noise monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

5. Summary of the non-compliance in the reporting month for the Project is tabulated in Table I.

|

Parameter |

No. of Exceedance |

Action Taken |

|

|

Action Level |

Limit Level |

||

|

1-hr TSP |

0 |

0 |

N/A |

|

24-hr TSP |

0 |

0 |

N/A |

|

Construction noise |

0 |

0 |

N/A |

6. No complaint was received in the reporting month. Summary of complaints in the reporting month is tabulated in Table II.

|

Date of complaint received |

Date of complaint |

Description of complaint |

Investigation / Recommendations / Action take |

Close-out date / Status |

|

No complaint was received in the reporting month. |

NA |

NA |

NA |

NA |

7. No notification of summons and successful prosecutions was received in the reporting month. Summary of summons and successful prosecutions in the reporting month is tabulated in Table III.

|

Date of receiving notification of summons or prosecutions |

Date of event |

Description of event |

Action take |

Close-out date / Status |

|

No notification of summons and successful prosecutions were received in the reporting month. |

NA |

NA |

NA |

NA |

8. There was no reporting change in the reporting month.

9. Major construction activities undertake during the reporting month included:

- North Approach Ramp – Construction of wall, intermediate slab and column

- Bridge D3 – Construction of pile cap and pier

- North Depressed Road – Construction of wall & top slab / dismantling of wailing & strut of cofferdam

- Underpass – Excavation and construction of base slab

- South Approach Ramp – Installation of sheet pile and excavation

- Landscaped Deck – Construction of bored piles

- District Cooling System seawater intake box culvert - Construction of cofferdam and box structure

- Noise barrier – Installation of steel structure and PMMA panel

- Lift 3 – Construction of cofferdam for footing

- Lift 4 – Excavation for footing

- South Depressed Road – Excavation and Installation of Lateral Support works

10. The future key issues and potential impact in the coming month are given in Table IV.

|

Future key issues in the coming month |

Potential impact |

|

North Approach Ramp – Construction of wall, intermediate slab and column |

Noise and Air Quality |

|

Bridge D3 – Construction of pile cap and pier |

Noise and Air Quality |

|

North Depressed Road – Construction of wall & top slab / dismantling of wailing & strut of cofferdam |

Noise and Air Quality |

|

Underpass – Excavation and construction of base slab |

Noise and Air Quality |

|

South Approach Ramp – Installation of sheet pile and excavation |

Noise and Air Quality |

|

Landscaped Deck – Construction of bored piles |

Noise and Air Quality |

|

District Cooling System seawater intake box culvert - Construction of cofferdam and box structure |

Noise and Air Quality |

|

Noise barrier – Installation of steel structure and PMMA panel |

Noise and Air Quality |

|

Lift 3 – Construction of cofferdam for footing |

Noise and Air Quality |

|

Lift 4 – Excavation for footing |

Noise and Air Quality |

|

South Depressed Road – Excavation and Installation of Lateral Support works |

Noise and Air Quality |

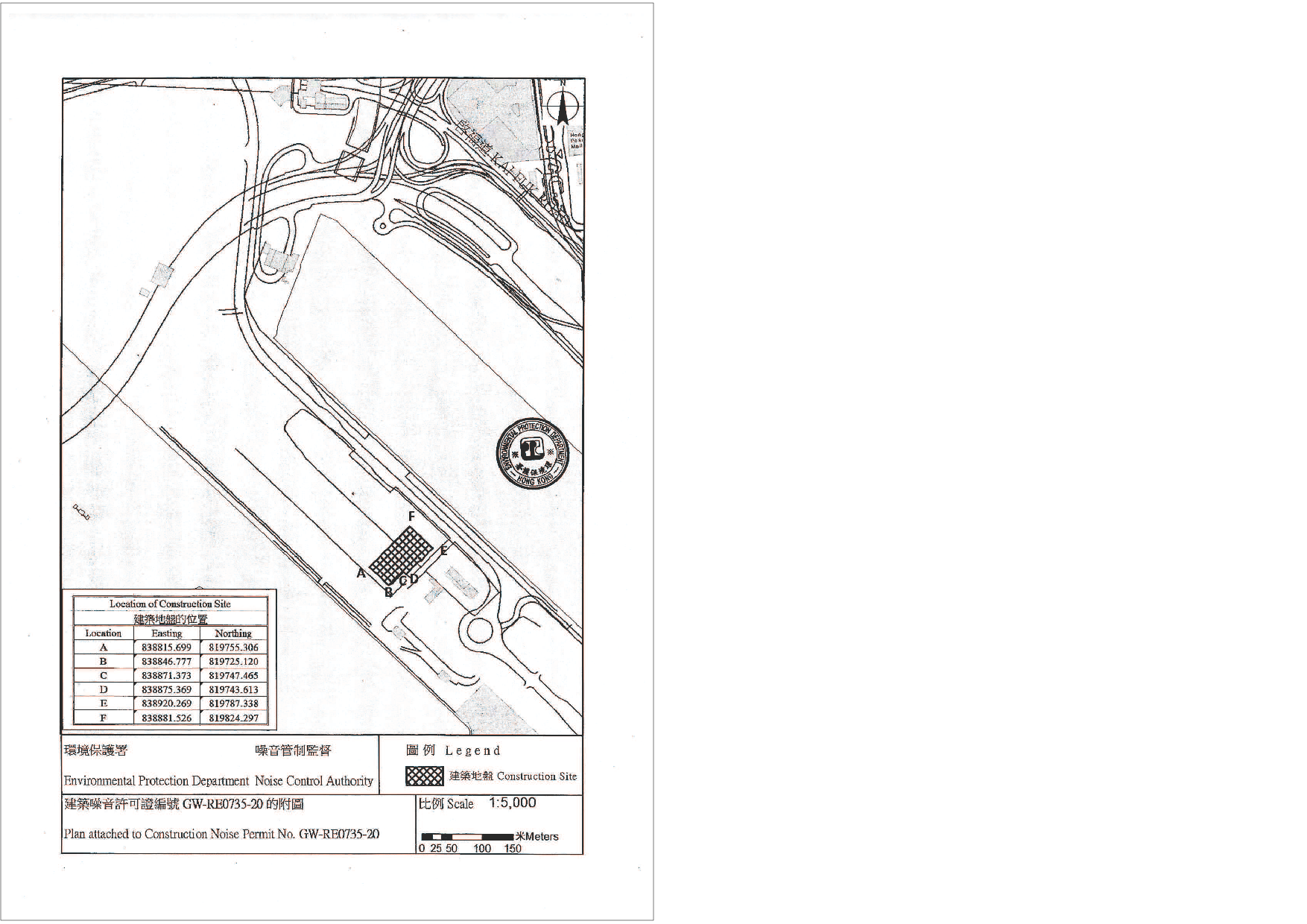

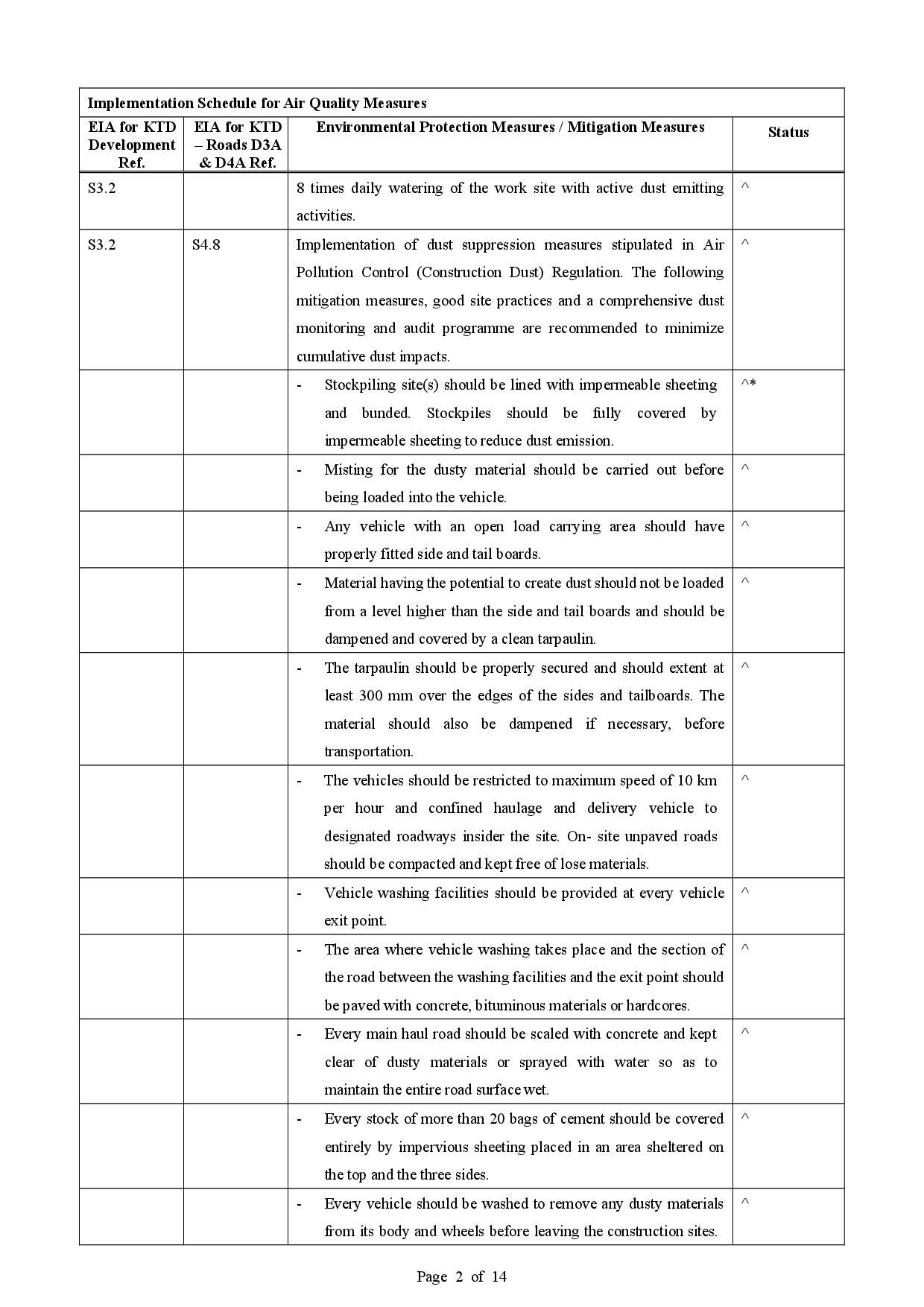

1.1 The Kai Tak Development (KTD) is located in the south-eastern part of Kowloon Peninsula of the HKSAR, comprising the apron and runway areas of the former Kai Tak Airport and existing waterfront areas at To Kwa Wan, Ma Tau Kok, Kowloon Bay, Kwun Tong and Cha Kwo Ling.

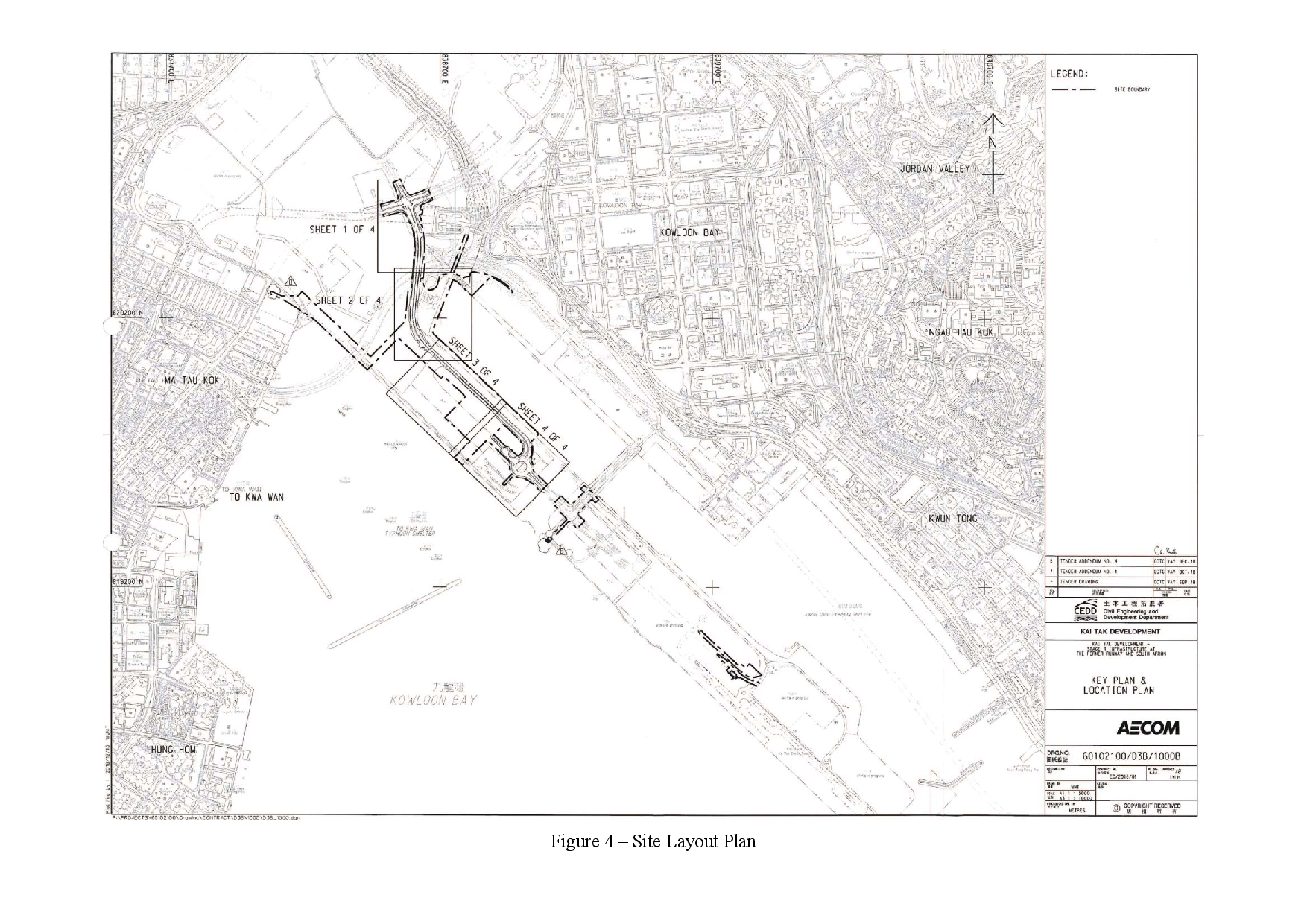

1.2 Contract No. ED/2018/01 - Kai Tak Development – stage 4 infrastructure at the former runway and south apron (The Project), comprises mainly the design and construction of a dual two- lane Road D3 (Metro Park Section), a single 2-lane Road L12d, a salt water pumping station, a sewage pumping station, landscaped deck and promenade above and adjoining Road D3 (Metro Park Section) respectively, some remaining road works at Road L14, noise barrier at Road D3A, and other associated works at the former runway and south apron. The proposed works are shown in Figure 1 and Figure 2. During the course of the Contract No. ED/2018/01, there may be modification of noise barriers in association with the construction of footbridges connecting to the landscaped deck of Road D3A by developers of adjacent lands (Figure 3). The proposed works and site boundary are shown in Figure 4.

1.3 Civil Engineering and Development Department (CEDD) had completed an Environmental Impact Assessment (EIA) and is the Permit Holder.

1.4 The construction work under ED/2018/01 comprises the EM&A Manuals (EIA Register Nos. AEIAR-130/2009 for Kai Tak Development and EIA Register Nos. AEIAR-170/2013 for Roads D3A and D4A) and Environmental Permit (EP) Nos. EP-337/2009, EP-445/2013 and Variation to the EP (VEP) No. EP-445/2013/A.

1.5 Air quality and noise monitoring has been proposed in the EM&A Manual with EIA Register Nos. AEIAR-130/2009 for Kai Tak Development while no air quality and noise monitoring are proposed in EM&A Manual with EIA Register Nos. AEIAR-170/2013 for Roads D3A and D4A.

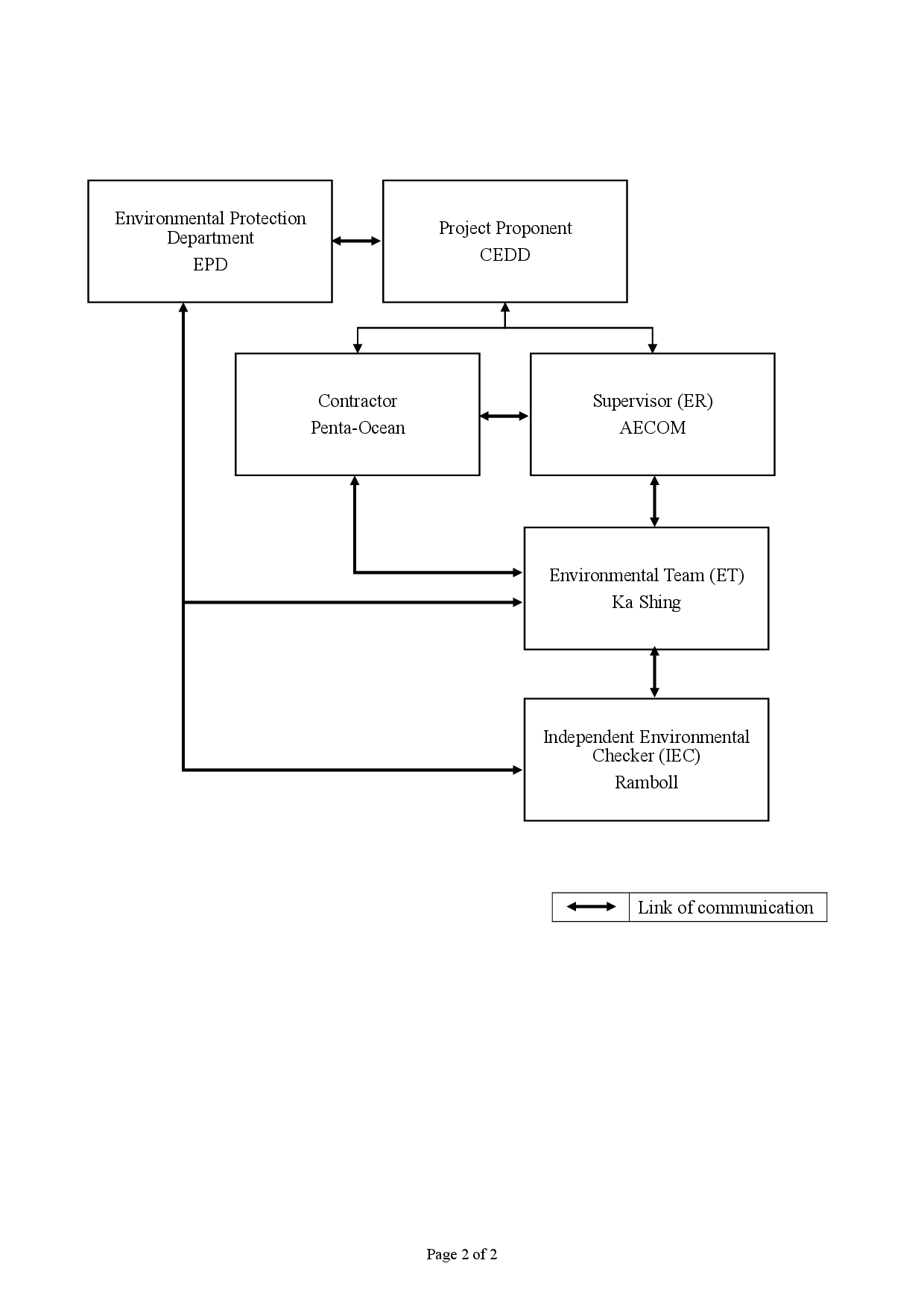

1.6 The project organization chart and with respect to the EM&A programme is shown in Appendix A. Information of key personnel contact names and telephone numbers are summarized in Table 1.1.

|

Party |

Role |

Contact Person |

Position |

Phone No. |

Fax No. |

|

Civil Engineering and Development Department (CEDD) |

Project Proponent |

Mr. Ronald Siu |

Senior Engineer |

3579 2452 |

2739 0076 |

|

Ms. Chan Ka Yan |

Engineer |

3579 2458 |

2739 0076 |

||

|

AECOM Asia Co. Ltd. (AECOM) |

Supervisor (act as Engineers’ Representative (ER) listed in EM&A Manual) |

Mr. Clive Cheng |

CRE |

3911 4201 |

3911 4288 |

|

Ramboll Hong Kong Limited (Ramboll) |

Independent Environmental Checker (IEC) |

Mr. Manson Yeung |

IEC (until 11 Apr 2021) |

9700 6767 |

3465 2899 |

|

Independent Environmental Checker (Deputy IEC) |

Mr. Y H Hui |

Deputy IEC |

3465 2850 |

3465 2899 |

|

|

Ka Shing Management Consultant Limited (Ka Shing) |

Environmental Team (ET) |

Mr. Chan Pang |

ET Leader |

6082 2973 |

2120 7752 |

|

Penta-Ocean Construction Co., Ltd. (Penta-Ocean) |

Contractor |

Mr. Lulu Mar |

Environmental Officer |

6845 0626 |

3465 8898 |

1.7 The construction works commenced on 20 January 2020.The construction programme of the Project is given in Appendix B.

1.8 Major construction works of the Project in the reporting month are summarized in Table 1.2:

|

North Approach Ramp – Construction of wall, intermediate slab and column |

Bridge D3 – Construction of pile cap and pier |

|

North Depressed Road – Construction of wall & top slab / dismantling of wailing & strut of cofferdam |

Underpass – Excavation and construction of base slab |

|

South Approach Ramp – Installation of sheet pile and excavation |

Landscaped Deck – Construction of bored piles |

|

District Cooling System seawater intake box culvert - Construction of cofferdam and box structure |

Noise barrier – Installation of steel structure and PMMA panel |

|

Lift 3 – Construction of cofferdam for footing |

Lift 4 – Excavation for footing |

|

South Depressed Road – Excavation and Installation of Lateral Support works |

|

1.9 The status of required submission under Environmental Permit (EP) conditions under EP-337/2009, EP-445/2013 and Variation to the EP (VEP) No. EP-445/2013/A are summarized in Table 1.3.

|

EP Condition EP-337/2009 |

EP Condition EP-445/2013 |

EP Condition EP-445/2013/A |

Submission |

Submission Date |

|

Condition 1.11 |

Condition 1.12 |

Condition 1.12 |

Notification of Commencement Date of Construction of the Project |

6 Jan 2020 |

|

Condition 2.3 |

Condition 2.3 |

Condition 2.3 |

Management Organization of Main Construction Companies |

9 Sep 2019 |

|

Condition 2.3 |

Condition 2.3 |

Condition 2.3 |

Updated Management Organization of Main Construction Companies |

28 May 2020 |

|

Condition 2.4 |

Condition 2.4 |

Condition 2.4 |

Design Drawings |

6 Jan 2020 |

|

Condition 2.11 |

Condition 2.5 |

Condition 2.5 |

Landscape Mitigation Plans |

13 Nov 2020 |

|

Condition 3.2 |

NA |

NA |

Baseline Monitoring Report |

2 Jan 2020 |

|

Condition 3.2 |

NA |

NA |

Revised Baseline Monitoring Report |

28 Mar 2020 |

|

Condition 3.3 |

Condition 3.2 |

Condition 3.2 |

Monthly EM&A Report (March 2021) |

14 Apr 2021 |

2.1 In accordance with EM&A Manuals (EIA Register Nos. AEIAR-130/2009), impact air quality monitoring shall be carried out during the construction phase of the Project. For regular impact monitoring, a sampling frequency of at least once in every six says will be strictly observed at all of the monitoring stations for 24-hour TSP. For 1-hour TSP monitoring, the sampling frequency of at least three times in every six days will be undertaken when the highest dust impact occurs.

2.2 Three designated monitoring stations were selected for air quality monitoring programme. Impact air quality monitoring was conducted at three air quality monitoring stations in the reporting month. Table 2.1 describes the air quality monitoring locations, which are also depicted in Figure 5.

|

Air Quality Monitoring Locations for the Project |

Location of Measurement |

|

AM3 - Sky Tower |

Podium floor near T7 |

|

AM4(A) - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

Rooftop |

|

AM7 – Hong Kong Children’s Hospital |

Rooftop |

2.3 The air quality monitoring locations and monitoring frequency are listed in Table 2.2.

|

Air Monitoring Station |

Location for Measurement |

Parameter |

Duration |

Frequency |

|

AM3 - Sky Tower |

Podium floor near T7 |

- 24-hour average TSP

- 1-hour average TSP |

- 24 hours

- 1 hour |

- Once every 6 days

- Three times every 6 days |

|

AM4(A) - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

Rooftop |

|||

|

AM7 - Hong Kong Children’s Hospital |

Rooftop |

2.4 The monitoring schedule for reporting month and next month is presented in Appendix C.

2.5 Photographic records of the impact monitoring setup are shown in Appendix D.

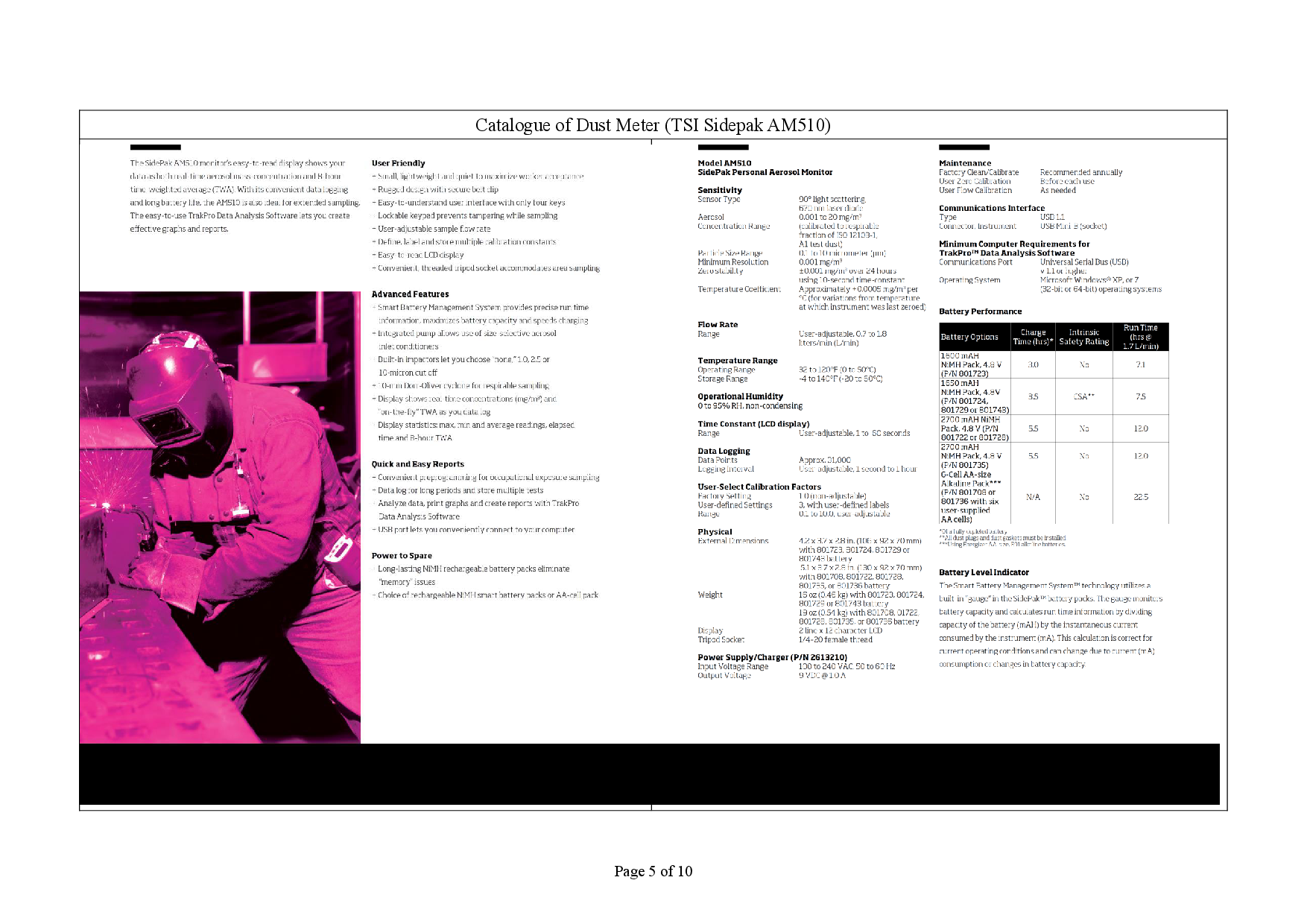

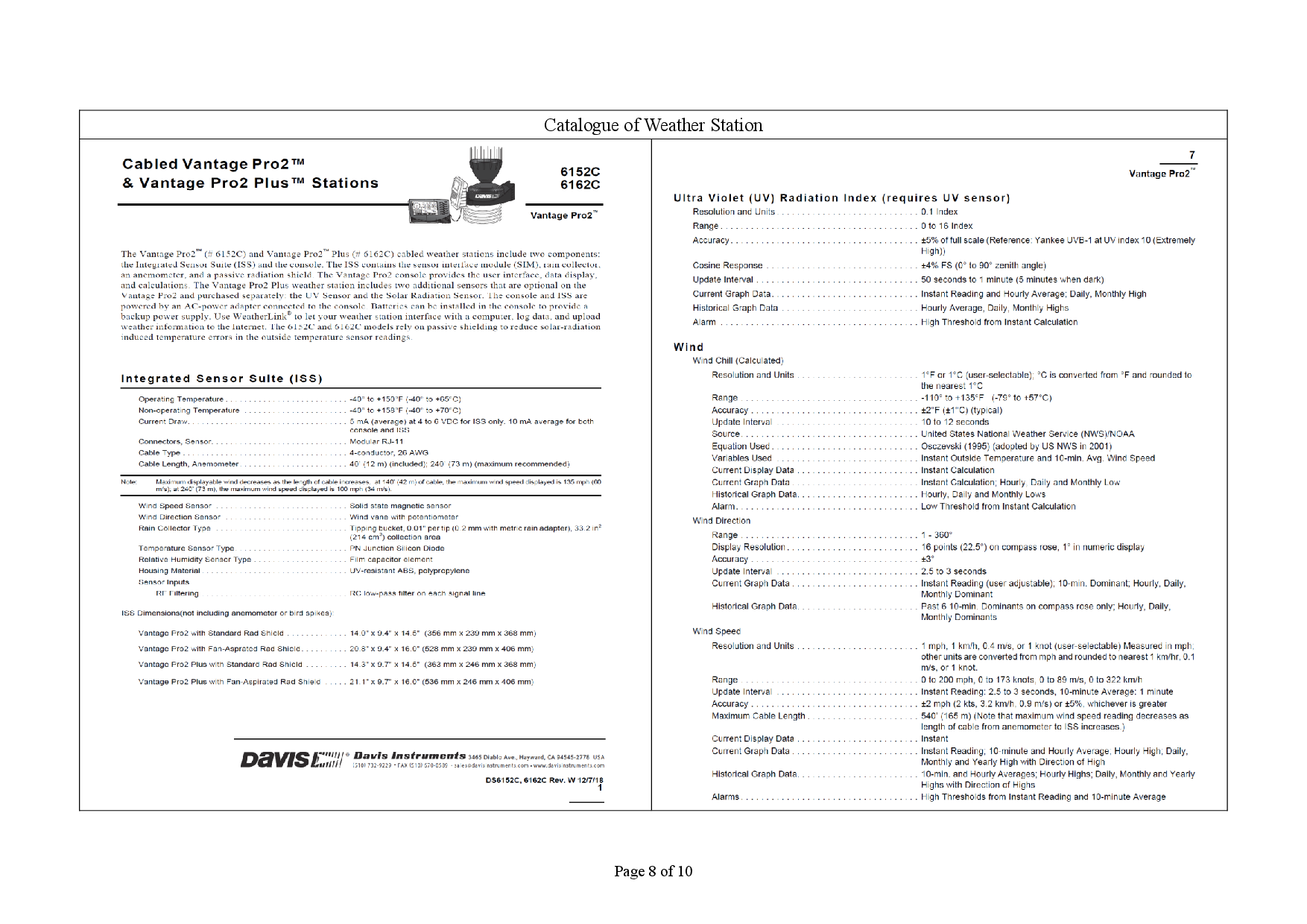

2.6 24-hour average TSP and 1-hour average TSP levels were measured for impact monitoring. 24-hour average TSP levels were measured by the High Volume Samplers (HVS) and 1-hour average TSP levels were measured by direct reading method to indicate short-term impacts. Wind data monitoring equipment was set up at conspicuous locations for logging wind speed and wind direction near to the dust monitoring locations. Table 2.3 summarizes the equipment to be used in the air quality monitoring.

|

Equipment |

Model |

Quantity |

|

HVS Sampler |

TE-5170 X c/w of TSP sampling inlet |

3 |

|

Calibrator |

TISCH TE-5025A |

1 |

|

1-hour TSP Dust Meter |

TSI Model AM510 SidePak Personal Aerosol Monitor |

2 |

|

Wind Anemometer |

Davis Vantage Pro2 Weather Station |

1 |

2.7 High volume samplers (HVS) (TE-5170 X c/w of TSP sampling inlet) comprising with appropriate sampling inlets were employed for 24-hour TSP monitoring. The sampler was composed of a motor, a filter holder, a flow controller and a sampling inlet and its performance specification complied with that required by USEPA Standard Title 40, Code of Federation Regulations Chapter 1 (Part 50).

2.8 Calibration certificates, catalogue of equipment are given in Appendix E.

24-hour TSP Monitoring

Operating/Analytical Procedures

2.9 Setup criteria of HVS are shown as follows:

l A horizontal platform with appropriate support to secure the samplers against gusty wind was provided.

l No two samplers were placed less than 2m apart.

l The distance between the sampler and an obstacle, such as buildings, was at least twice the height that the obstacle protrudes above the sampler.

l A minimum of 2m of separation from walls, parapets and penthouses was set for the rooftop samples.

l A minimum of 2m separation from any supporting structure, measured horizontally was set.

l No furnaces or incineration flues was nearby.

l Airflow around the sampler was unrestricted.

l Any wire fence and gate, to protect the samplers, was not caused any obstruction during monitoring.

l Permission were obtained to setup the samplers and to obtain access to the monitoring stations.

l A secured supply of electricity was provided to operate the samplers.

2.10 Prior to the commencement of the dust sampling, the flow rate of the HVS was properly set (between 1.1 m3/min. and 1.7 m3/min.) in accordance with the manufacturer's instruction to within the range recommended in USEPA Standard Title 40, CFR Part 50.

2.11 For TSP sampling, Glass Fiber Filter Media 8" x 10" have a collection efficiency of > 99 % for particles of 0.3 μm diameter were used.

2.12 The power supply was checked to ensure the sampler worked properly and then placed any filter media at the designated air monitoring station.

2.13 The filter holding frame was removed by loosening the four nuts and a weighted and conditioned filter was carefully centered with the stamped number upwards, on a supporting screen.

2.14 The filter was aligned on the screen so that the gasket formed an airtight seal on the outer edges of the filter. Then the filter holding frame was tightened to the filter holder with swing bolts. The applied pressure was sufficient to avoid air leakage at the edges.

2.15 The shelter lid was closed and secured with the aluminium strip.

2.16 The timer was programmed. Information was recorded on the record sheet, which included the starting time, the weather condition and the filter number (the initial weight of the filter paper can be found out by using the filter number).

2.17 After sampling, the filter was removed from the HVS and put into a clean and labeled seal plastic bag to avoid cross contamination. The elapsed time was also be recorded. The sampled filters were sent to the HOKLAS accredited or other internationally accredited laboratory for weighting.

Maintenance/Calibration

2.18 The following maintenance/calibration are required for the HVS:

l The HVS and their accessories were properly maintained. Appropriate maintenance such as routine motor brushes replacement and electrical wiring checking were made to ensure that the equipment and necessary power supply are in good working condition.

l High volume samplers were calibrated with at bi-monthly intervals using TE-5025A Calibration Kit throughout all stages of the air quality monitoring.

1-hour TSP Monitoring

Measurement Procedures

2.19 The measurement procedures of the 1-hour TSP were conducted in accordance with the Manufacturer’s Instruction Manual as follows:

l Set up the dust meter on a tripod at 1.2m level.

l Turned on the dust meter and check the battery, if too low, change new ones. Pointed the meter to the source area or the planned measurement area.

l The zero calibration of the instrument was conducted before and after each sampling.

l TSP levels were recorded for 1-hour with 5-minute data logging interval.

l Recorded down the general meteorological conditions, Test ID no., start/end time, spot checking reading at each sampling location for data processing.

l Recorded any activities that may generate dust during measurement period.

Maintenance/Calibration

2.20 The following maintenance/calibration are required for the direct dust meters:

l To validity the accuracy of dust meter, compare the results measured by dust meter and HVS by direct reading method every 12 months throughout all stages of the air quality monitoring.

2.21 Wind Anemometer was installed at the roof-top of AM7 - Hong Kong Children’s Hospital with 10m above ground and clear of constructions or turbulence caused by the buildings.

2.22 The wind data was captured by a data logger and the data was downloaded at least once per month for analysis.

2.23 The wind data monitoring equipment will be re-calibrated at least once every six months.

2.24 Wind direction is divided into 16 sectors of 22.5 degrees each.

2.25 Details of weather information during the monitoring period are shown in Appendix F.

2.26 The Action and Limit Levels of 24-hour average TSP and 1-hour average TSP are summarized in Table 2.4 and Table 2.5 respectively.

|

Parameter |

Air Monitoring Station |

Action Level, mg/m3 |

Limit Level, mg/m3 |

|

24-hour average TSP |

AM3 |

182 |

260 |

|

AM4(A) |

187 |

260 |

|

|

AM7 |

181 |

260 |

|

Parameter |

Air Monitoring Station |

Action Level, mg/m3 |

Limit Level, mg/m3 |

|

1-hour average TSP |

AM3 |

297 |

500 |

|

AM4(A) |

326 |

500 |

|

|

AM7 |

315 |

500 |

2.27 Impact monitoring results for 24-hour average TSP and 1-hour average TSP levels at the designed air quality monitoring stations are summarized in Table 2.6 and Table 2.7 respectively.

|

Air Monitoring Station |

Average TSP Concentration, mg/m3 |

Range, mg/m3 |

Action Level, mg/m3 |

Limit Level, mg/m3 |

|

AM3 |

87 |

42 – 116 |

182 |

260 |

|

AM4(A) |

108 |

58 – 180 |

187 |

260 |

|

AM7 |

81 |

52 – 109 |

181 |

260 |

|

Air Monitoring Station |

Average TSP Concentration, mg/m3 |

Range, mg/m3 |

Action Level, mg/m3 |

Limit Level, mg/m3 |

|

AM3 |

62 |

31 – 102 |

297 |

500 |

|

AM4(A) |

65 |

43 – 108 |

326 |

500 |

|

AM7 |

57 |

30 – 94 |

315 |

500 |

2.28 There was no Action and Limit Level exceedance of 24-hour average TSP and 1-hour average TSP levels recorded during the reporting month.

2.29 Graphical presentation and detailed monitoring results of 24-hour average TSP and 1-hour average TSP levels are shown in Appendix G and Appendix H respectively.

2.30 The Event and Action Plan is provided in Appendix I.

2.31 Non-project related construction activities in the adjacent construction sites were observed during the reporting period and may affect the monitoring results.

3.1 In accordance with EM&A Manuals (EIA Register Nos. AEIAR-130/2009), impact noise monitoring shall be carried out during the construction phase of the Project.

3.2 Regular monitoring, LAeq, 30-minute, for each station will be on a weekly basis and conduct one set of measurements between 0700 – 1900 on normal weekdays.

3.3 If construction works are extended to include works during 1900 – 0700 as well as public holidays and Sundays, additional weekly impact monitoring will be carried out during the respective restricted hours periods.

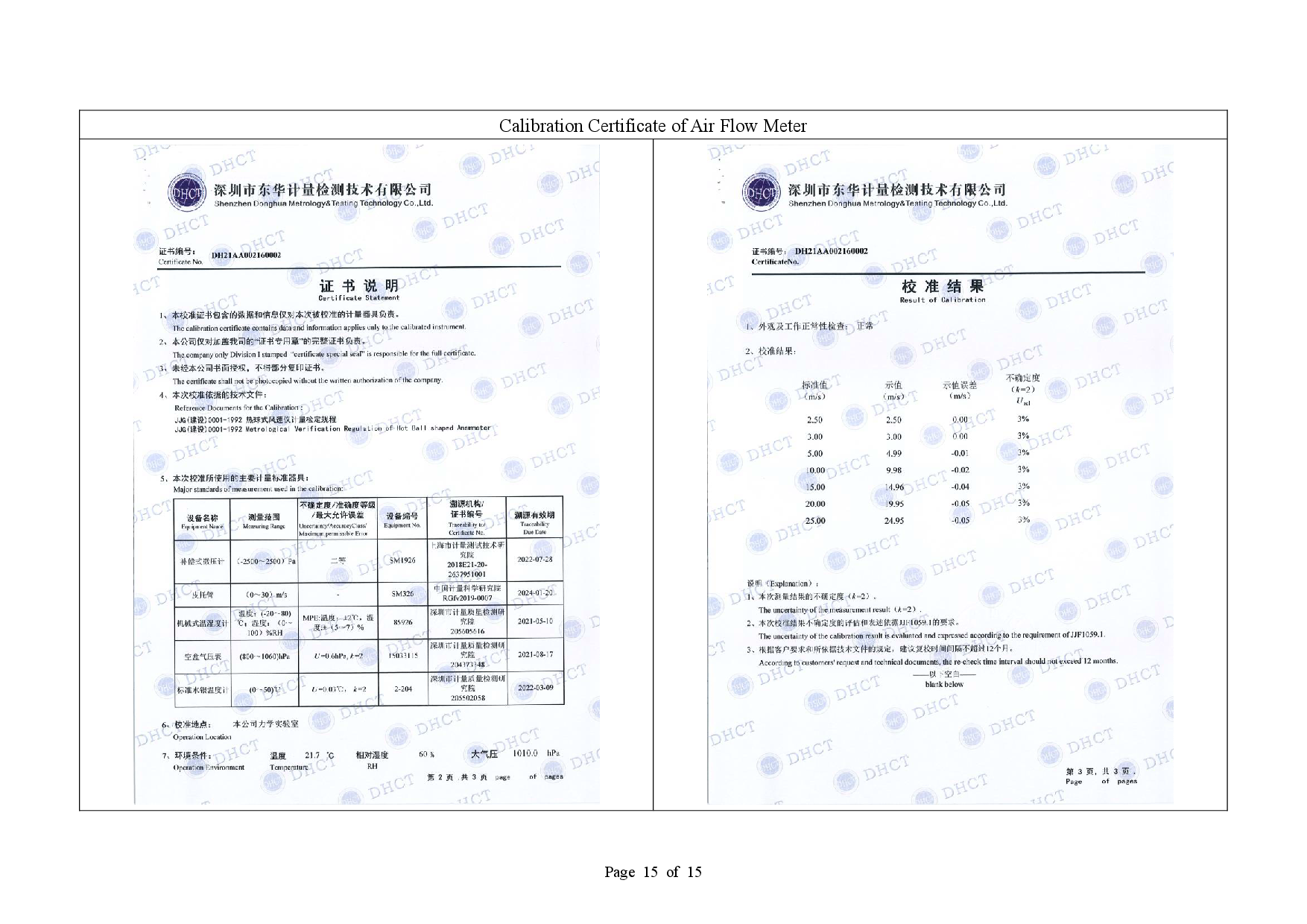

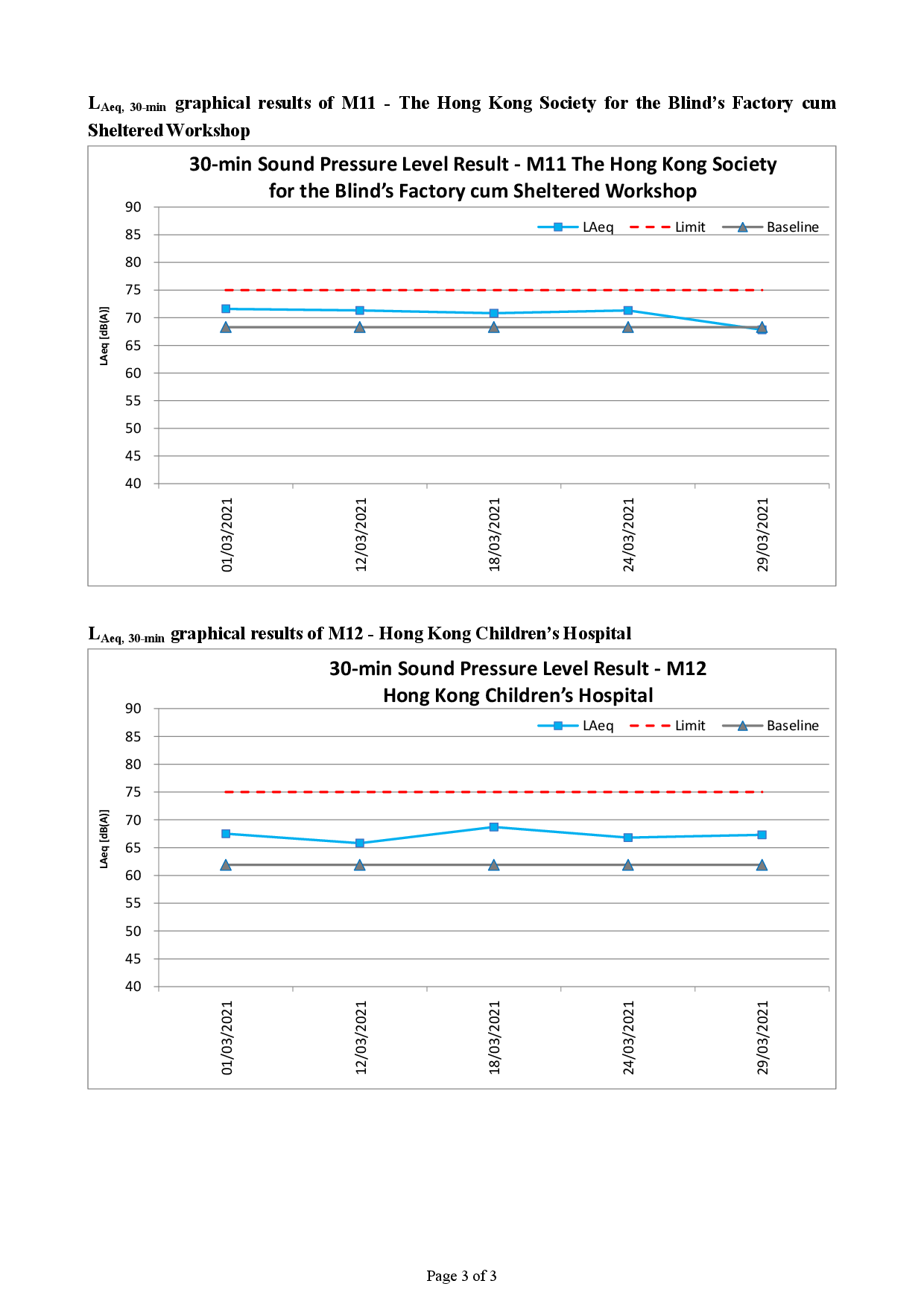

3.4 Two designated monitoring stations were selected for noise monitoring programme. Impact noise monitoring was conducted at two noise monitoring stations in the reporting month. Table 3.1 describes the noise monitoring locations, which are also depicted in Figure 6.

|

Noise Monitoring Locations for the Project |

Location of Measurement |

|

M11 - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

Rooftop (Façade) |

|

M12 - Hong Kong Children’s Hospital |

Rooftop (Façade) |

3.5 The noise monitoring locations and monitoring frequency are listed in Table 3.2.

|

Noise Monitoring Station |

Location for Measurement |

Parameter |

Frequency and Duration |

|

M11 - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

Rooftop (Façade) |

LAeq, LA10 and LA90 |

30 - minutes measurement at each monitoring station between 0700 – 1900 hrs on normal weekdays (Monday to Saturday) at frequency of once per week. |

|

M12 - Hong Kong Children’s Hospital |

Rooftop (Façade) |

3.6 The monitoring schedule for reporting month and next month is presented in Appendix C.

3.7 Photographic records of the monitoring setup are shown in Appendix D.

3.8 As referred to in the Technical Memorandum (TM) issued under the Noise Control Ordinance (NCO), sound level meters in compliance with the IEC 61672-1 (Type 1) standard [this standard replaced the International Electrotechnical Commission Publications 60651:1979 (Type 1) and 60804:1985 (Type 1)] were used for noise monitoring. Table 3.3 summarizes the equipment to be used in the noise monitoring.

|

Equipment |

Model |

Quantity |

|

Sound Level Meter |

RION NL52 |

2 |

|

Sound Level Calibrator |

RION NC 74 |

2 |

|

Air Flowmeter |

TSI TA440 Air Velocity |

2 |

3.9 Calibration certificates, catalogue of equipment are given in Appendix J.

3.10 The noise level measurement was conducted at 1m from the exterior of the nearby noise sensitive receivers building façade and at 1.2m above the ground and facing to the source area or the planned measurement area.

3.11 No noise measurement was conducted in the presence of fog, rain, wind with a steady speed exceeding 5 m/s or wind with gusts exceeding 10 m/s. Air flow was measured by air flow meter.

3.12 Turned on the sound level meter and check the battery, if too low, change new ones.

3.13 Calibration was conducted immediately prior to and after each noise measurement, the accuracy of the sound level meters was checked by using sound calibrator generating 1,000 Hz with 94dB. Measurement data was found to be valid only if the calibration levels from before and after the noise measurement agreed to within 1.0 dB.

3.14 Noise level was recorded.

3.15 Recorded any activities that may generate noise during measurement period.

3.16 The microphone head of the sound level meter and calibrator was cleaned with a soft cloth at quarterly intervals.

3.17 The sound level meter and sound calibrator were calibrated annually.

3.18 Calibration for sound level meter was conducted immediately prior to and following each noise measurement by using sound calibrator generating a known sound pressure level at a known frequency (1,000 Hz with 94dB). Measurements may be accepted as valid only if the calibration levels from before and after the noise measurement agree to within 1.0 dB.

3.19 The Baseline Noise Levels and Action and Limit Levels for construction noise is presented in Table 3.4.

|

Time Period |

Noise Monitoring Station |

Baseline Noise Levels, dB (A) |

Action Level |

Limit Level ^ |

|

0700 – 1900 on normal weekdays |

M11 |

68.3 |

When one documented complaint is received. |

75 dB(A) |

|

M12 |

61.9 |

Note: ^ If works are to be carried out during restricted hours, the conditions stipulated in the Construction Noise Permit (CNP) issued by the Noise Control Authority have to be followed.

3.20 Impact noise monitoring results at the designed noise monitoring stations are summarized in Table 3.5 respectively.

|

Noise Monitoring Station |

Measured LAeq, 30-min, Average, dB(A) |

Measured LAeq, 30-min, Range, dB(A) |

Action Level |

Limit Level ^ |

|

M11 |

68.2 |

62.1 – 69.6 |

When one documented complaint is received |

75 dB(A) |

|

M12 |

66.6 |

63.8 – 68.2 |

Note: ^ If works are to be carried out during restricted hours, the conditions stipulated in the Construction Noise Permit (CNP) issued by the Noise Control Authority have to be followed.

3.21 There were no action level exceedance of noise monitoring and limit level exceedance of LAeq, 30min recorded during the reporting month.

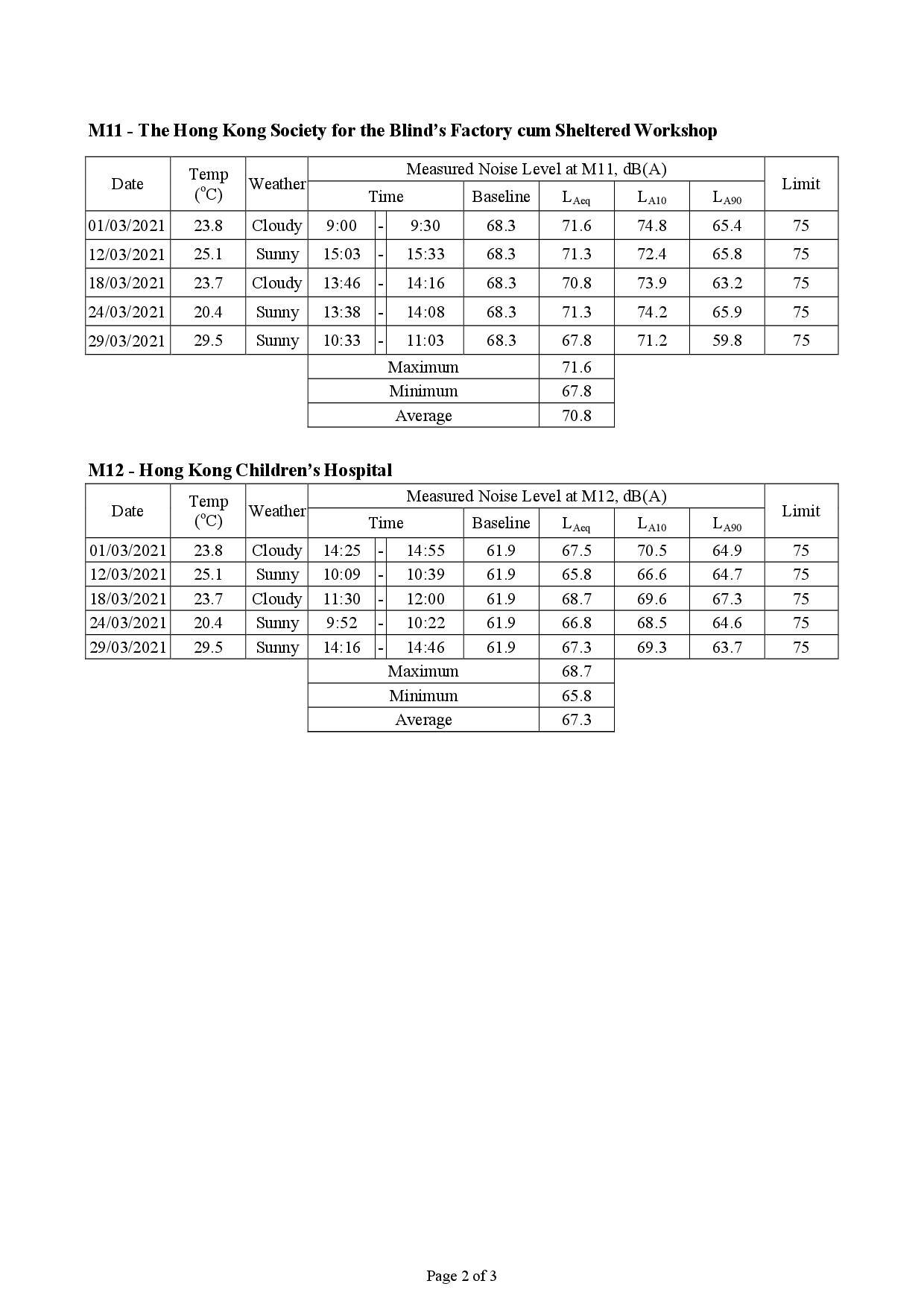

3.22 Graphical presentation and detailed monitoring results are shown in Appendix K.

3.23 The Event and Action Plan is provided in Appendix L.

3.24 Non-project related construction activities in the adjacent construction sites were observed during the reporting period and may affect the monitoring results.

4.1 The environmental impacts predictions were given in Agreement No. CE 35/2006(CE) Kai Tak Development Engineering Study cum Design and Construction of Advance Works - Investigation, Design and Construction - Kai Tak Development Environmental Impact Assessment Report, EIA Register Nos. AEIAR-130/2009 for Kai Tak Development (The EIA Report). The EM&A data was compared with the EIA predictions as summarized in Table 4.1 to Table 4.3.

|

Air Monitoring Station |

ASR No. in EIA report |

Predicted Cumulative Maximum 24-hour average TSP concentration |

Measured 24-hr average TSP in Reporting Month (April 2021) mg/m3 |

|

|

Scenario 1 (Mid 2009 to Mid 2013), µg/m3 |

Scenario 2 (Mid 2013 to Late 2016), µg/m3 |

|||

|

AM3 - Sky Tower |

A40^ |

106 |

138 |

42 – 116 |

|

AM4(A) - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

A43^ |

123 |

195 |

58 – 180 |

|

AM7 – Hong Kong Children’s Hospital |

PA60 |

NA |

NA |

52 – 109 |

Note:

^ Prediction results are given in the Table 3.13 of the EIA report EIA Register Nos. AEIAR-130/2009 for Kai Tak Development.

|

Air Monitoring Station |

ASR No. in EIA report |

Predicted Cumulative Maximum 1-hour average TSP concentration |

Measured 1-hr average TSP in Reporting Month (April 2021) mg/m3 |

|

|

Scenario 1 (Mid 2009 to Mid 2013), µg/m3 |

Scenario 2 (Mid 2013 to Late 2016), µg/m3 |

|||

|

AM3 - Sky Tower |

A40 |

217^ |

247^ |

31 – 102 |

|

AM4(A) - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

A43 |

283^ |

409^ |

43 – 108 |

|

AM7 – Hong Kong Children’s Hospital |

PA60 |

NA |

NA |

30 – 94 |

Note:

^ Prediction results are given in the Table 3.13 of the EIA report EIA Register Nos. AEIAR-130/2009 for Kai Tak Development.

|

Noise Monitoring Station |

NSR No. in EIA report |

Predicted Mitigated Construction Noise Levels during Normal Daytime Working Hour LAeq, 30min, dB(A) |

Measured Noise Level in Reporting Month (April 2021) LAeq, 30min, dB(A) |

|

M11 - The Hong Kong Society for the Blind’s Factory cum Sheltered Workshop |

N18 |

50 – 76* |

62.1 – 69.6 |

|

M12 - Hong Kong Children’s Hospital |

PN83, PN84, PN84A |

NA |

63.8 – 68.2 |

Note:

* Prediction results are given in the Table 3.20 of the EIA report EIA Register Nos. AEIAR-130/2009 for Kai Tak Development.

4.2 24-hour TSP monitoring results at AM3 and AM4(A) were recorded higher than the Scenario 1 (Mid 2009 to Mid 2013) prediction but lower than the Scenario 2 (Mid 2013 to Late 2016) in the EIA Report. Non-project related construction activities in the adjacent construction sites were observed during the reporting period and may affect the monitoring results.

4.3 No prediction in the EIA Report for 24-hour TSP monitoring results at AM7.

4.4 1-hour TSP monitoring results at AM3 and AM4(A) were recorded lower than the prediction in the EIA Report.

4.5 No prediction in the EIA Report for 1-hour TSP monitoring results at AM7.

4.6 Noise monitoring results at M11 were recorded lower than the prediction in the EIA Report.

4.7 No prediction in the EIA Report for noise monitoring results at M12.

5.1 In accordance with EM&A Manuals (EIA Register Nos. AEIAR-130/2009 and AEIAR-170/2013), Landscape and Visual Monitoring shall be carried out during the construction phase of the Project. Regular impact monitoring will be conducted at least once per week.

5.2 Site inspections were carried out on a weekly basis to monitor the timely implementation of proper environmental management practices and mitigation measures in the Project site.

5.3 Site inspections were conducted on 1, 8, 15, 22 and 29 April 2021 in the reporting month.

5.4 The summaries of site audits are attached in Table 5.1.

|

Inspection Date |

Key Observations |

Recommendations / Actions |

Close-out Date / Status |

|

1 April 2021 |

No |

NA |

NA |

|

8 April 2021 |

No |

NA |

NA |

|

15 April 2021 |

No |

NA |

NA |

|

22 April 2021 |

No |

NA |

NA |

|

29 April 2021 |

No |

NA |

NA |

5.5 No non-compliance of the landscape and visual impact was recorded in the reporting month.

5.6 Should non-compliance of the landscape and visual impact occur, action in accordance with the action plan presented in Appendix M shall be performed.

6.1 Site inspections were carried out on a weekly basis to monitor the timely implementation of proper environmental management practices and mitigation measures in the Project site.

6.2 Site inspections were conducted on 1, 8, 15, 22 and 29 April 2021 in the reporting month.

6.3 The summaries of site audits are attached in Table 6.1.

|

Inspection Date |

Key Observations |

Recommendations / Actions |

Close-out Date / Status |

|

1 April 2021 |

NA |

NA |

NA |

|

8 April 2021 |

Observation:

The accumulated waste should be removed. |

Action Taken:

Waste was removed. |

Closed-out 15 April 2021 |

|

Observation:

The drip tray was missing under the diesel container. |

Action Taken:

The diesel container was removed. |

Closed-out 15 April 2021 |

|

|

15 April 2021 |

Observation:

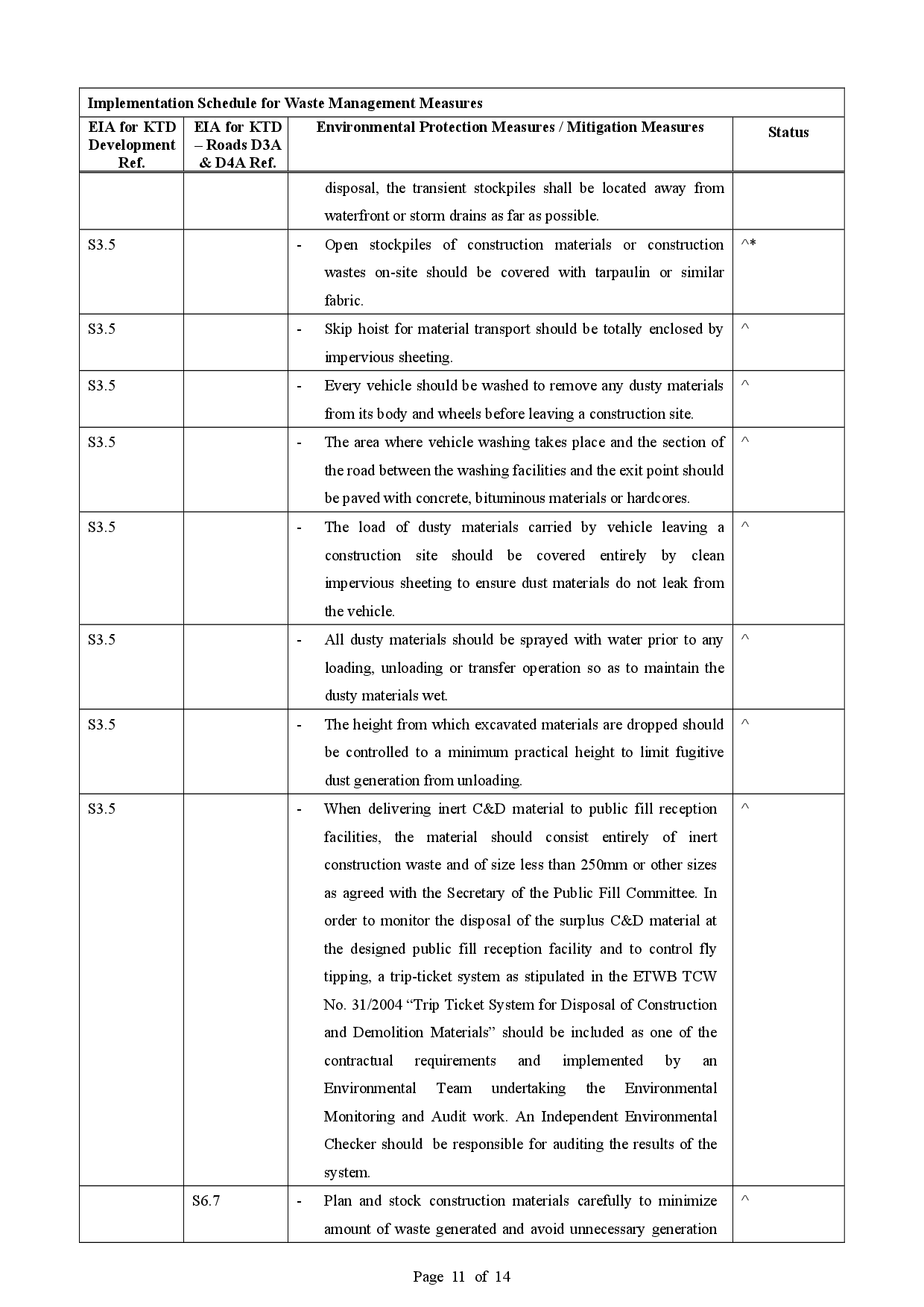

POC was reminded to cover the open stockpile during raining to prevent mud water / surface off to any discharge points. |

Action Taken:

The open stockpiles were covered. |

Closed-out 22 April 2021 |

|

22 April 2021 |

Observation:

The drip tray should be cleared regularly. |

Action Taken:

The stagnant water was cleared. |

Closed-out 29 April 2021 |

|

29 April 2021 |

NA |

NA |

NA |

6.4 The amount of wastes generated by the major site activities of the work contracts within the Project during the reporting month is shown in Appendix N.

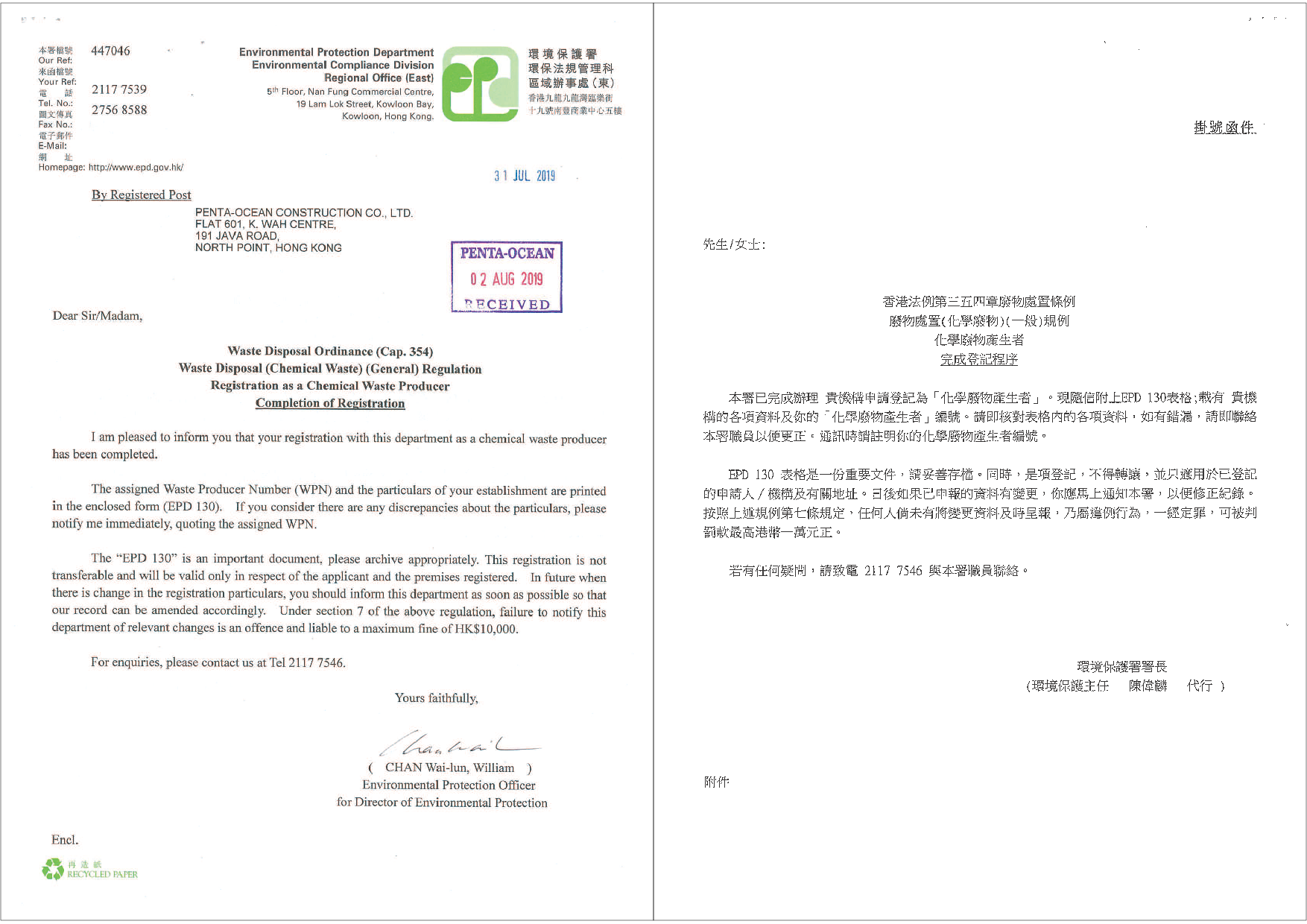

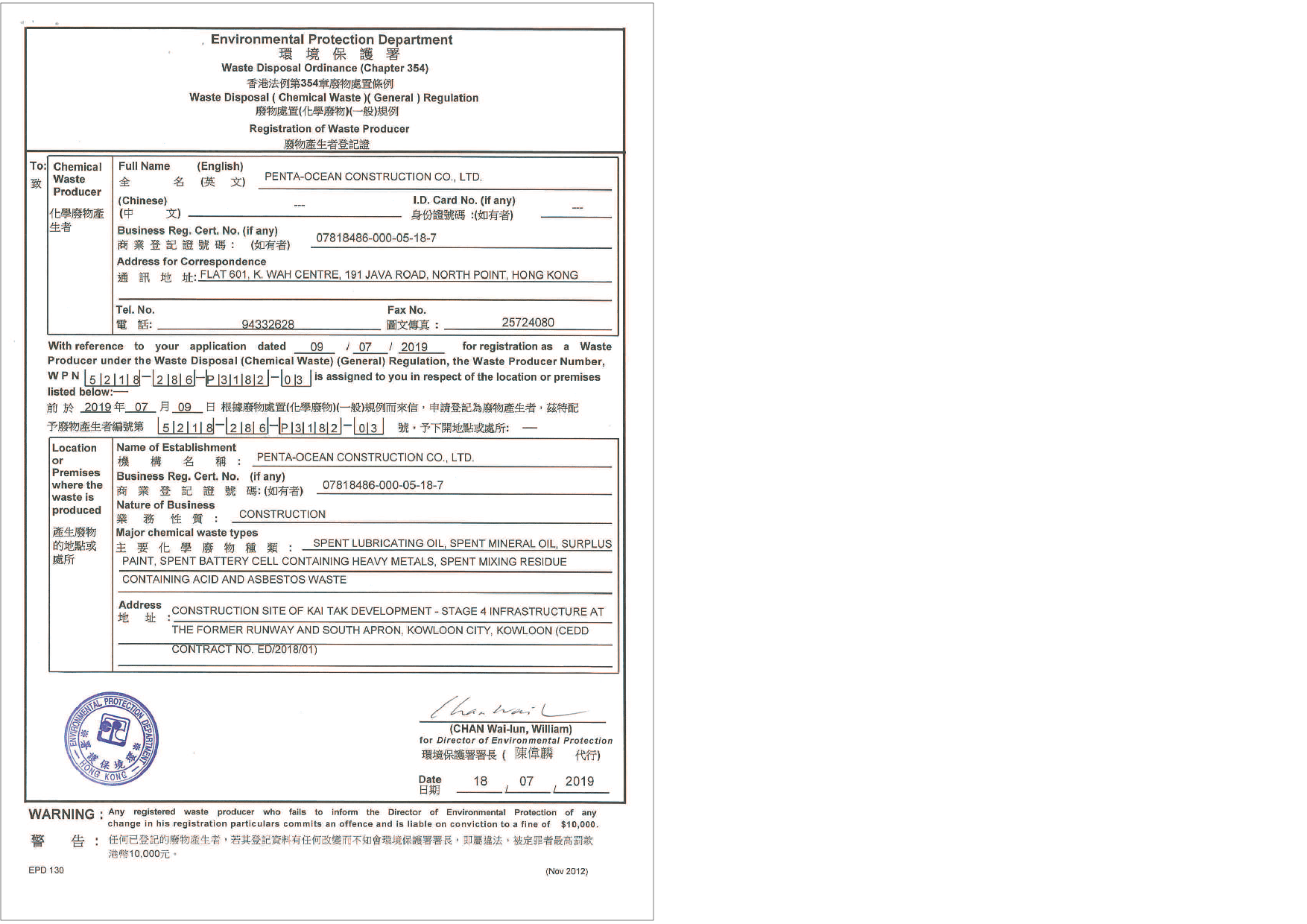

6.5 The Contractor was registered as a chemical waste producer for the Project. The Contractor was reminded that chemical waste containers should be properly treated and stored temporarily in designated chemical waste storage area on site in accordance with the Code of Practice on the Packaging, Labelling and Storage of Chemical Wastes.

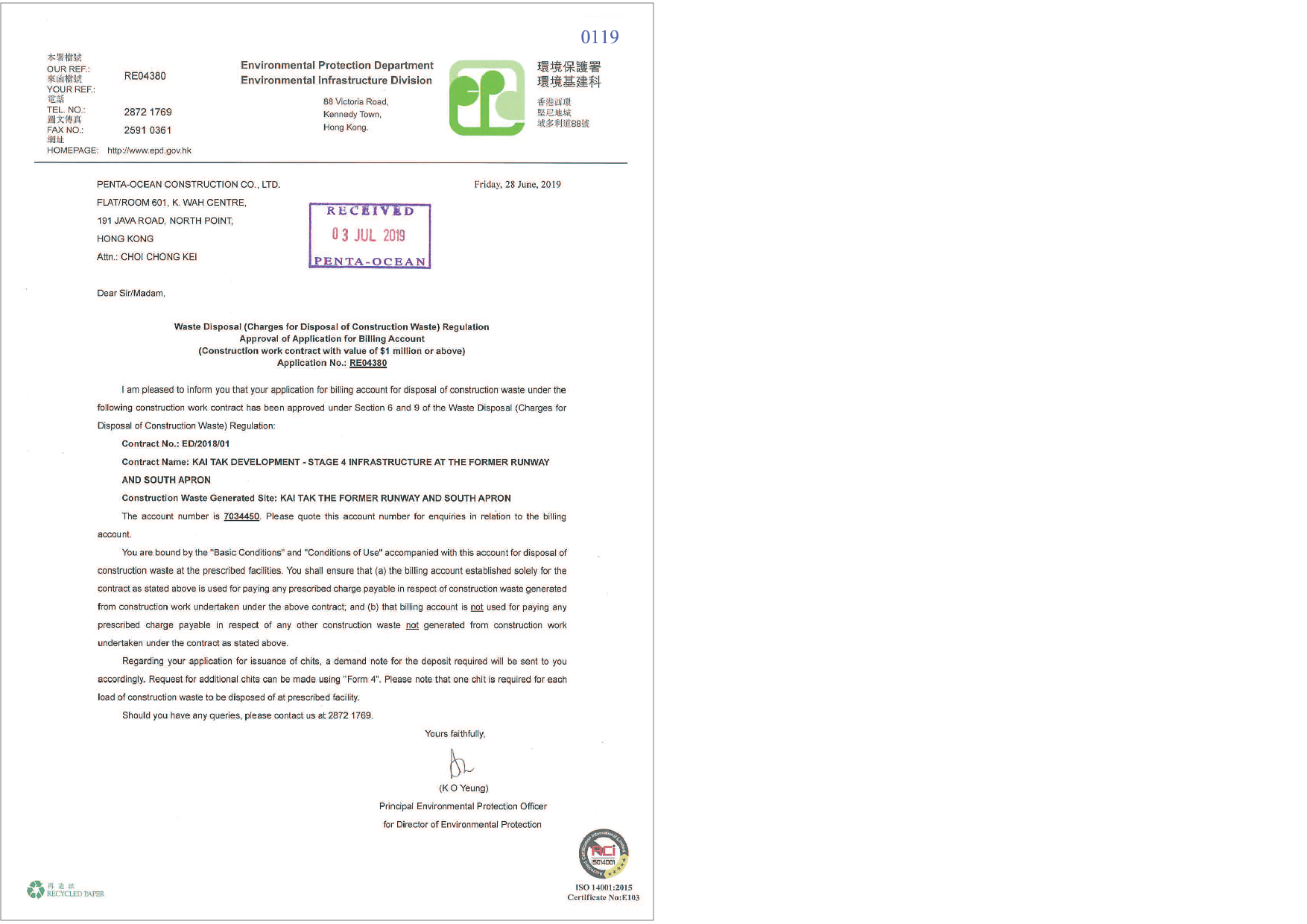

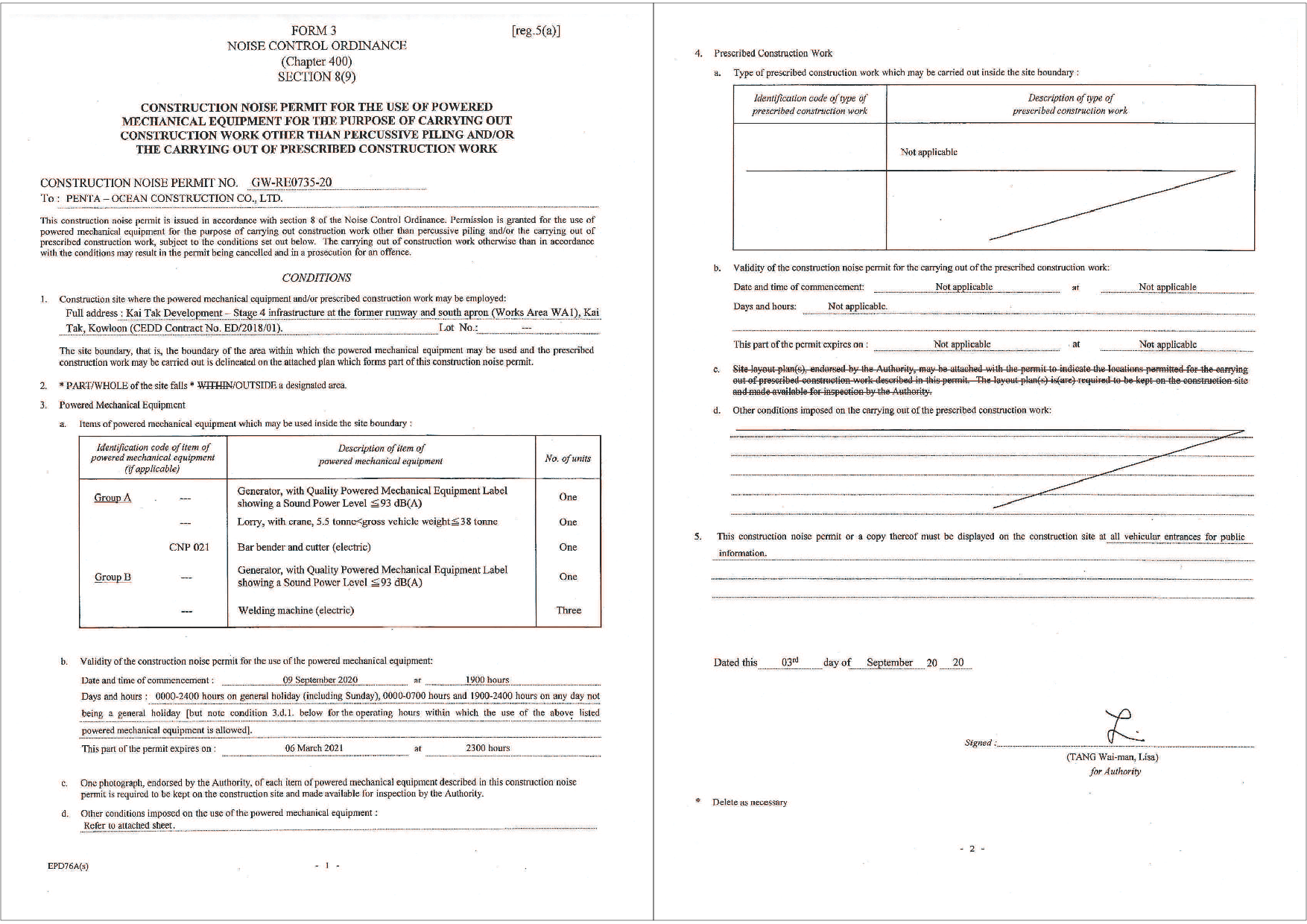

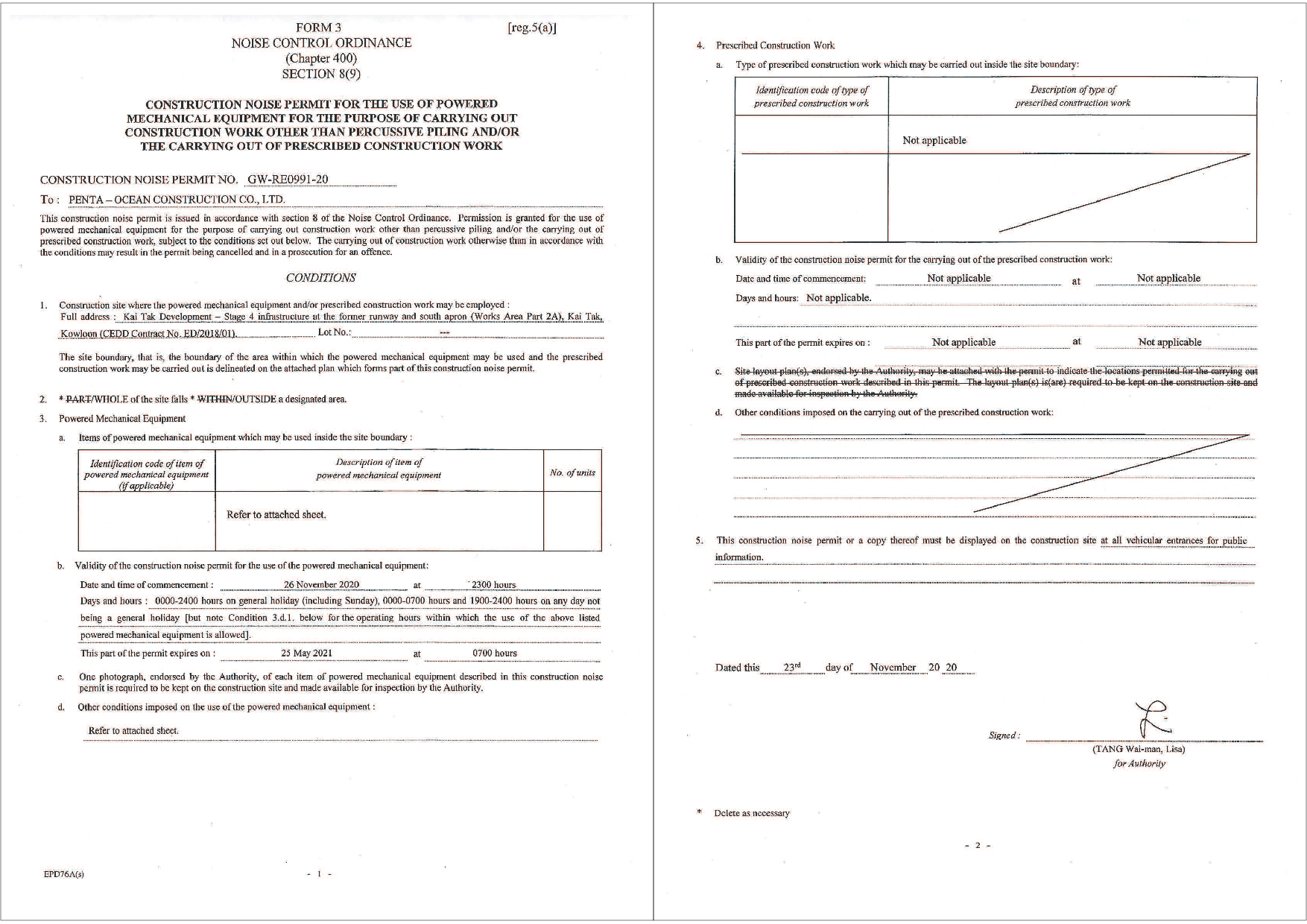

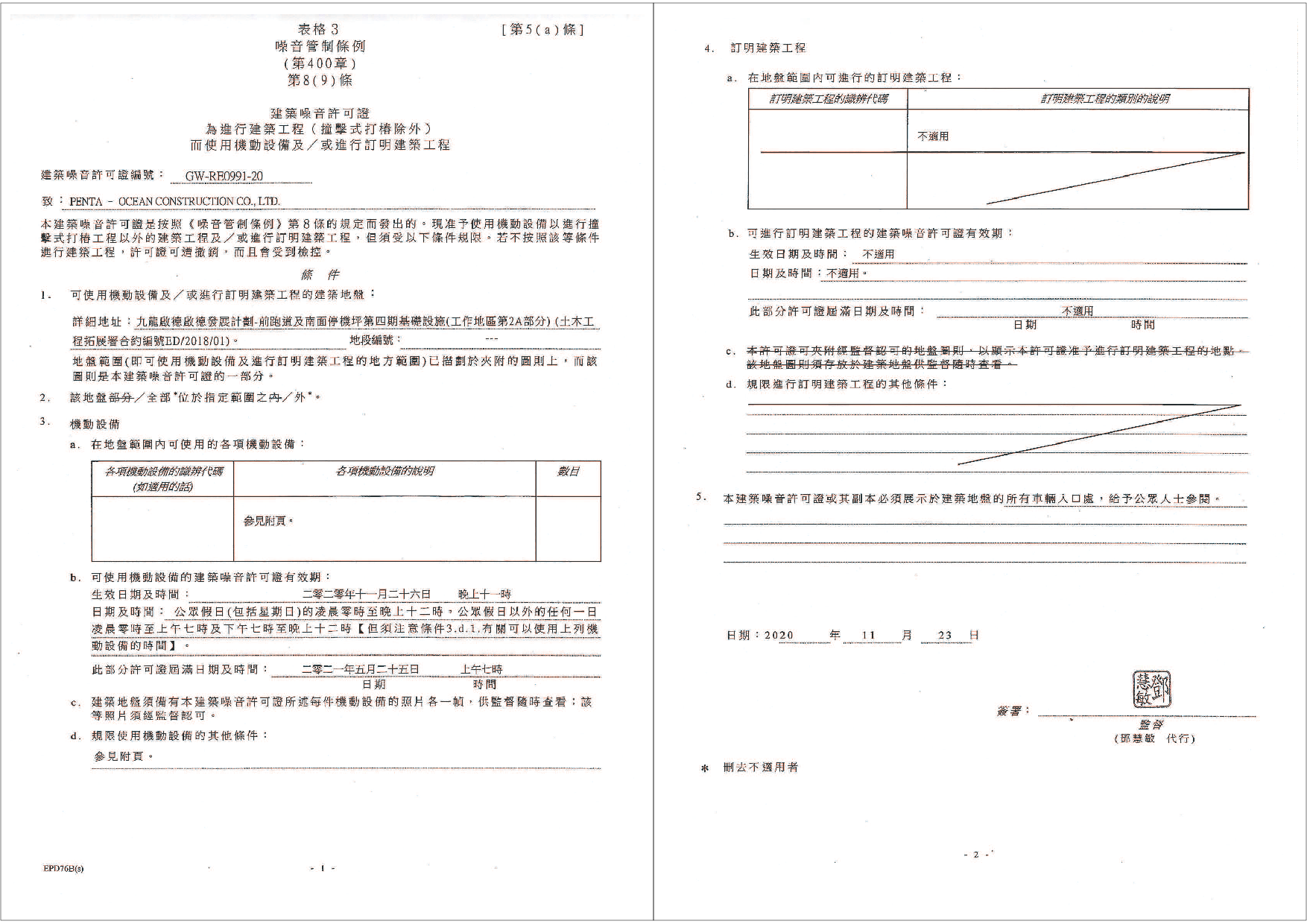

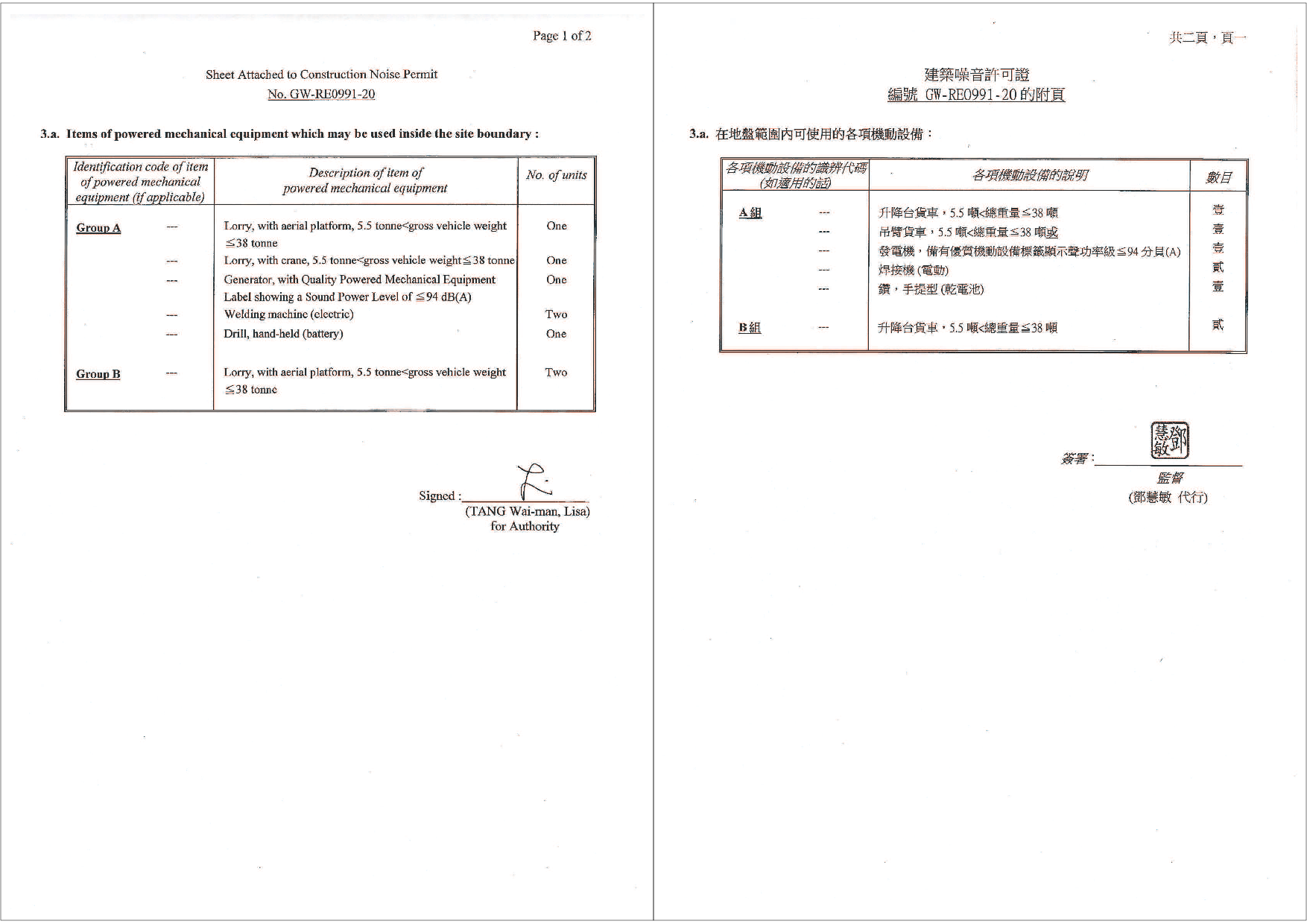

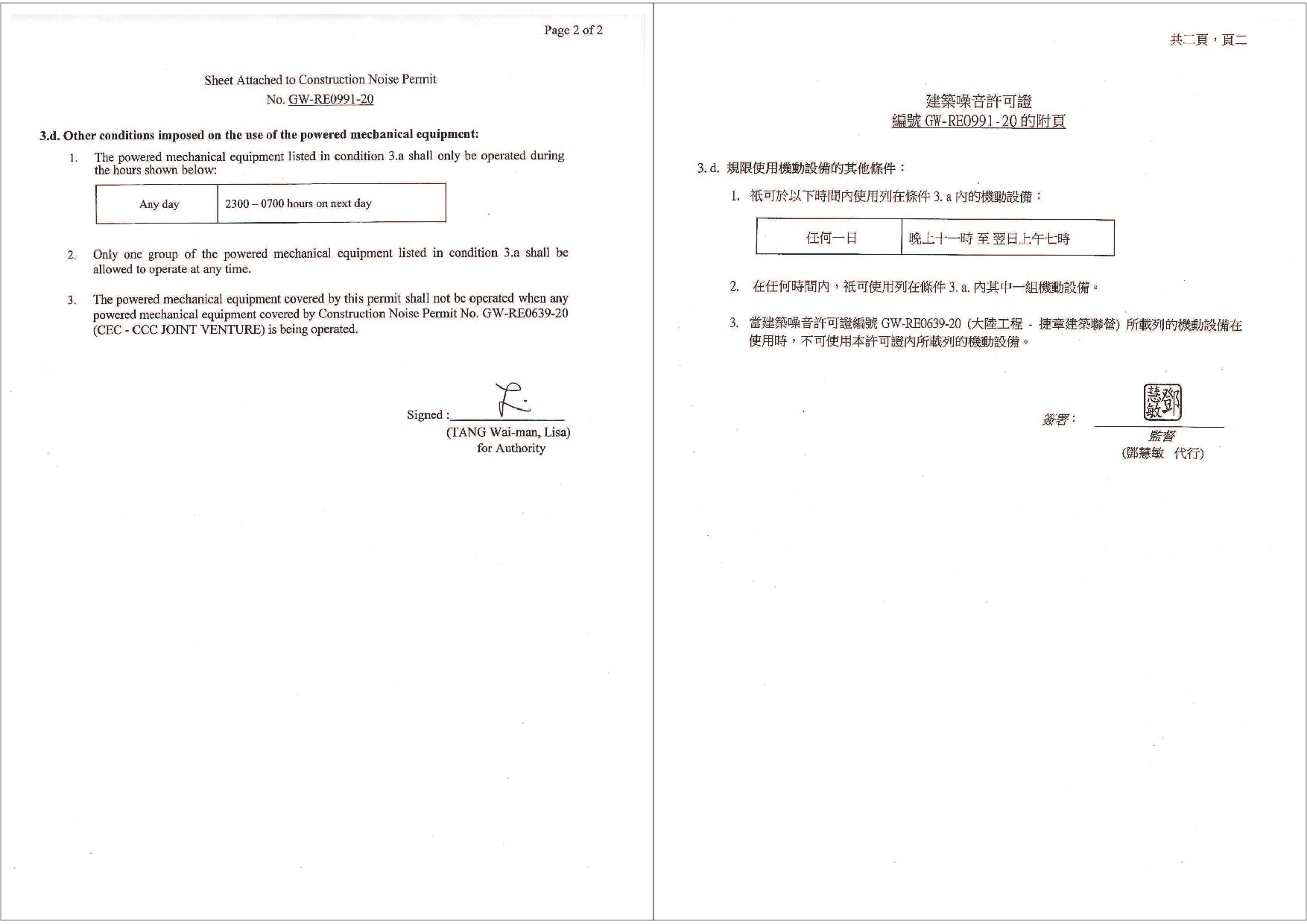

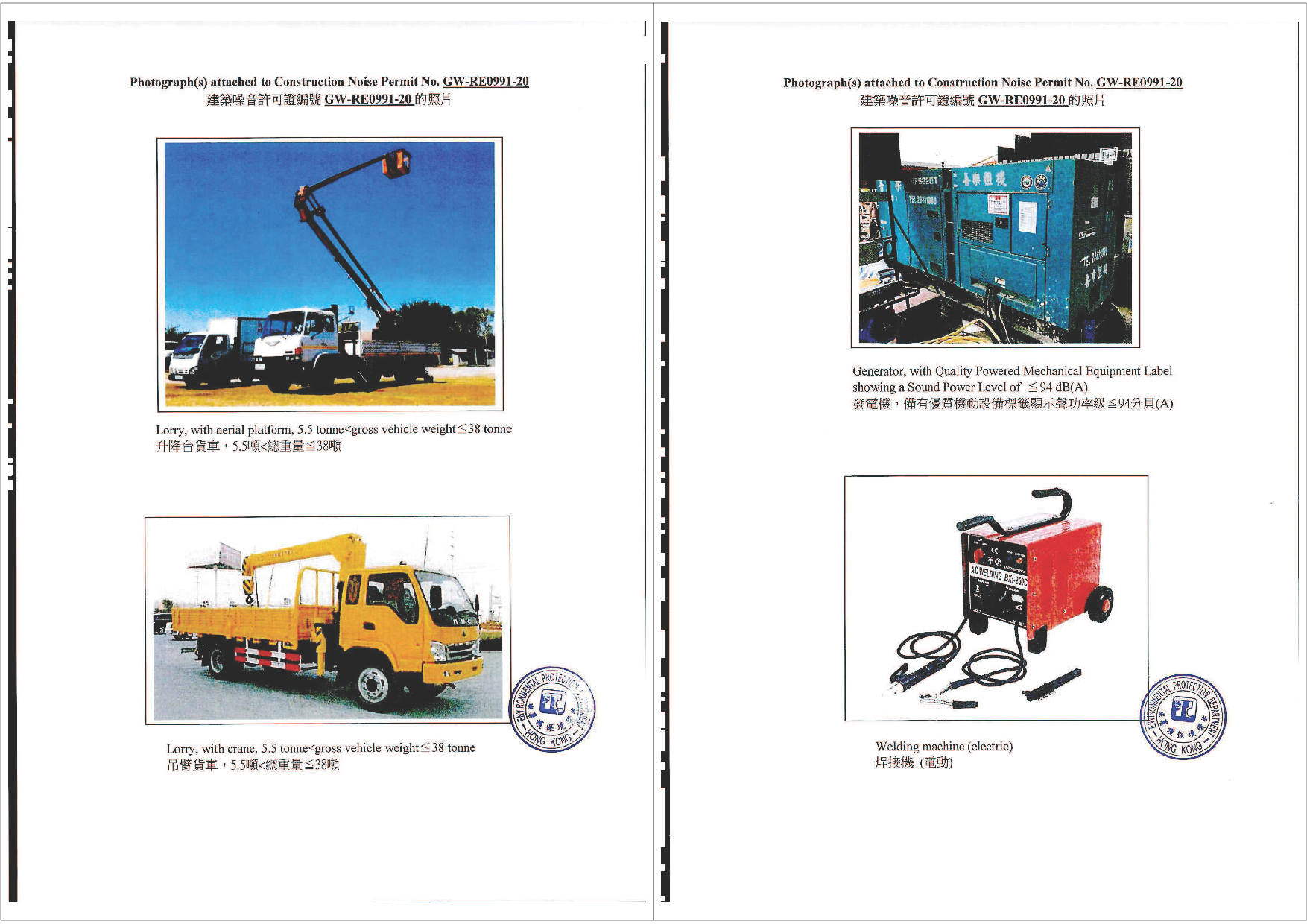

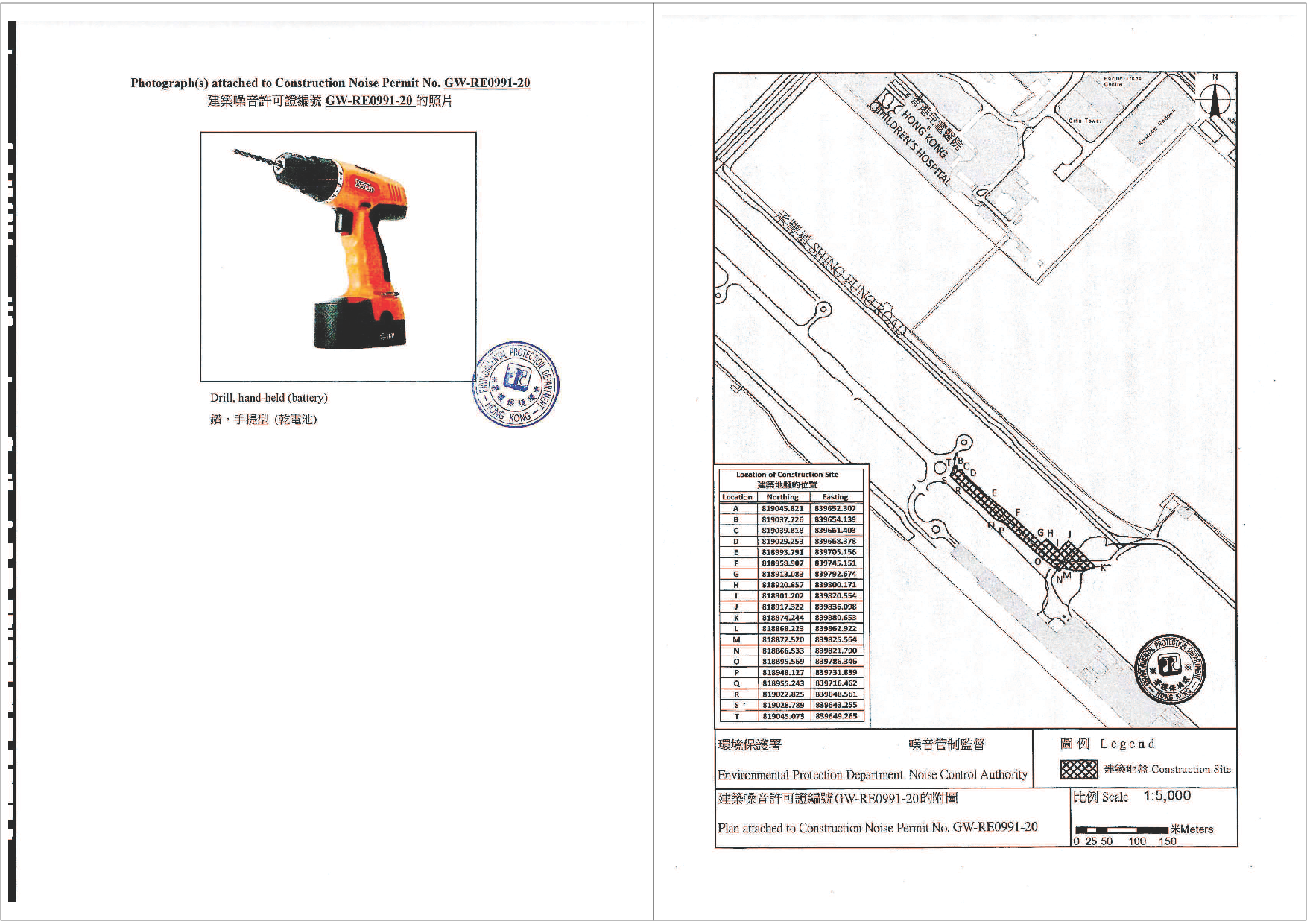

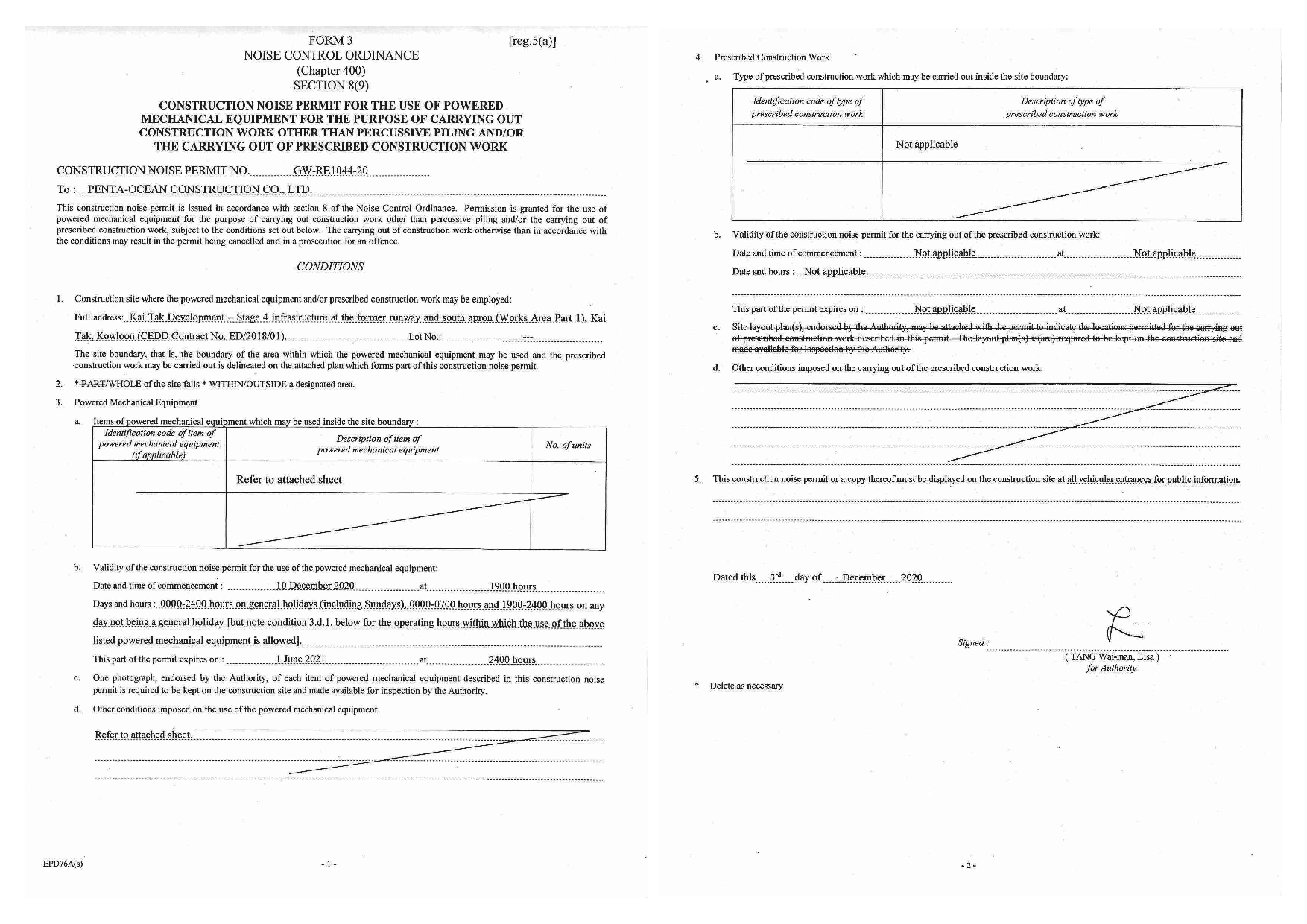

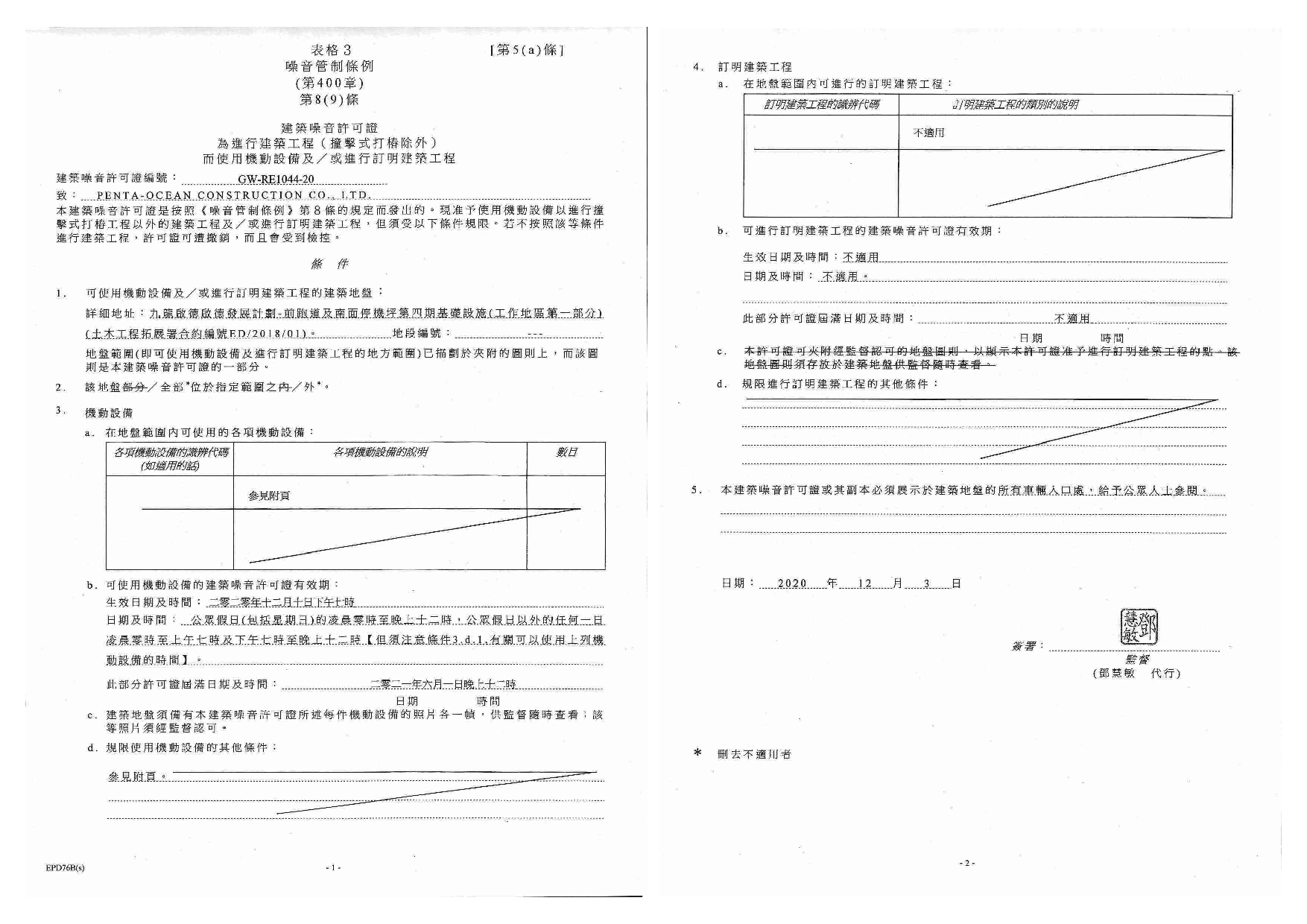

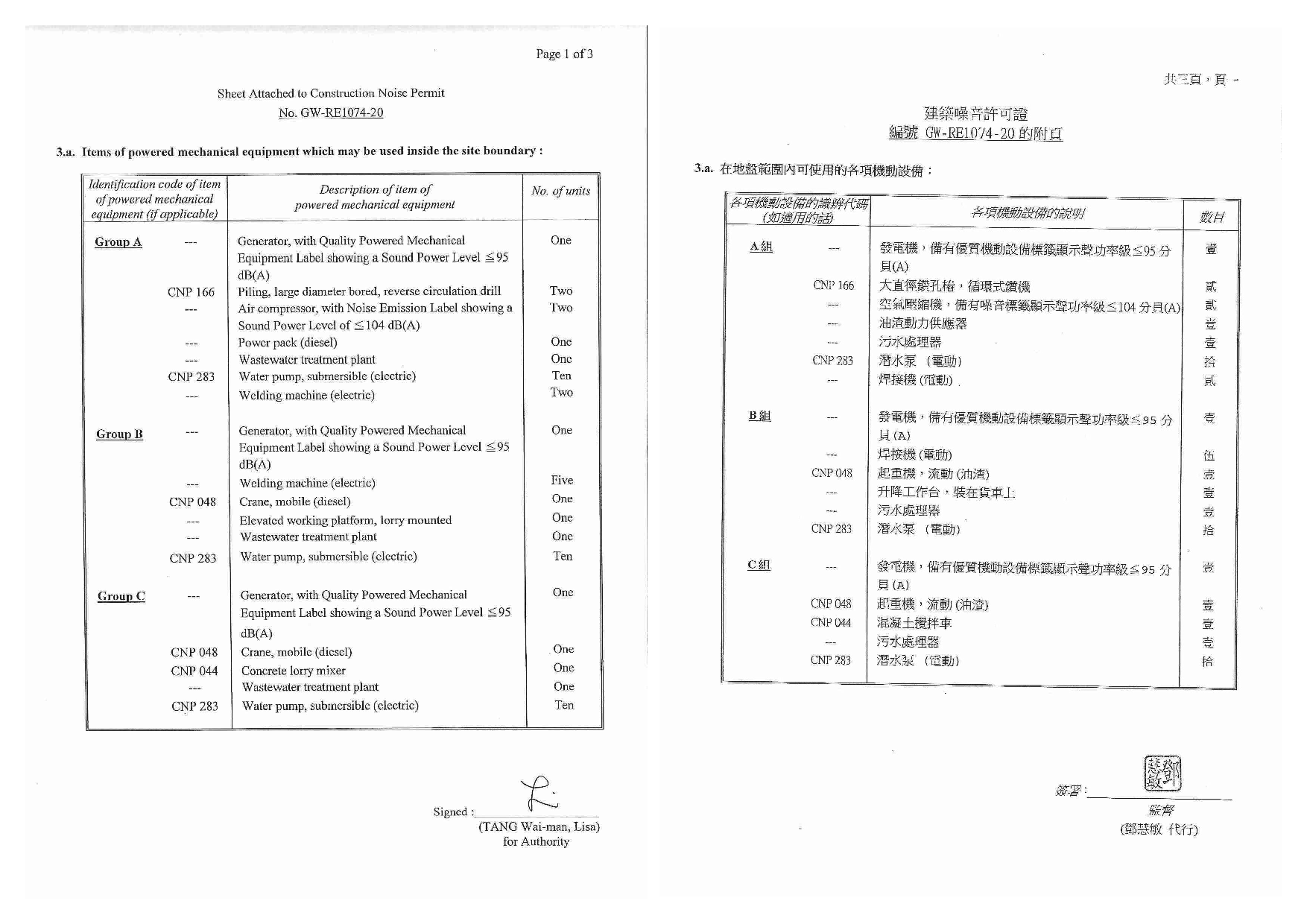

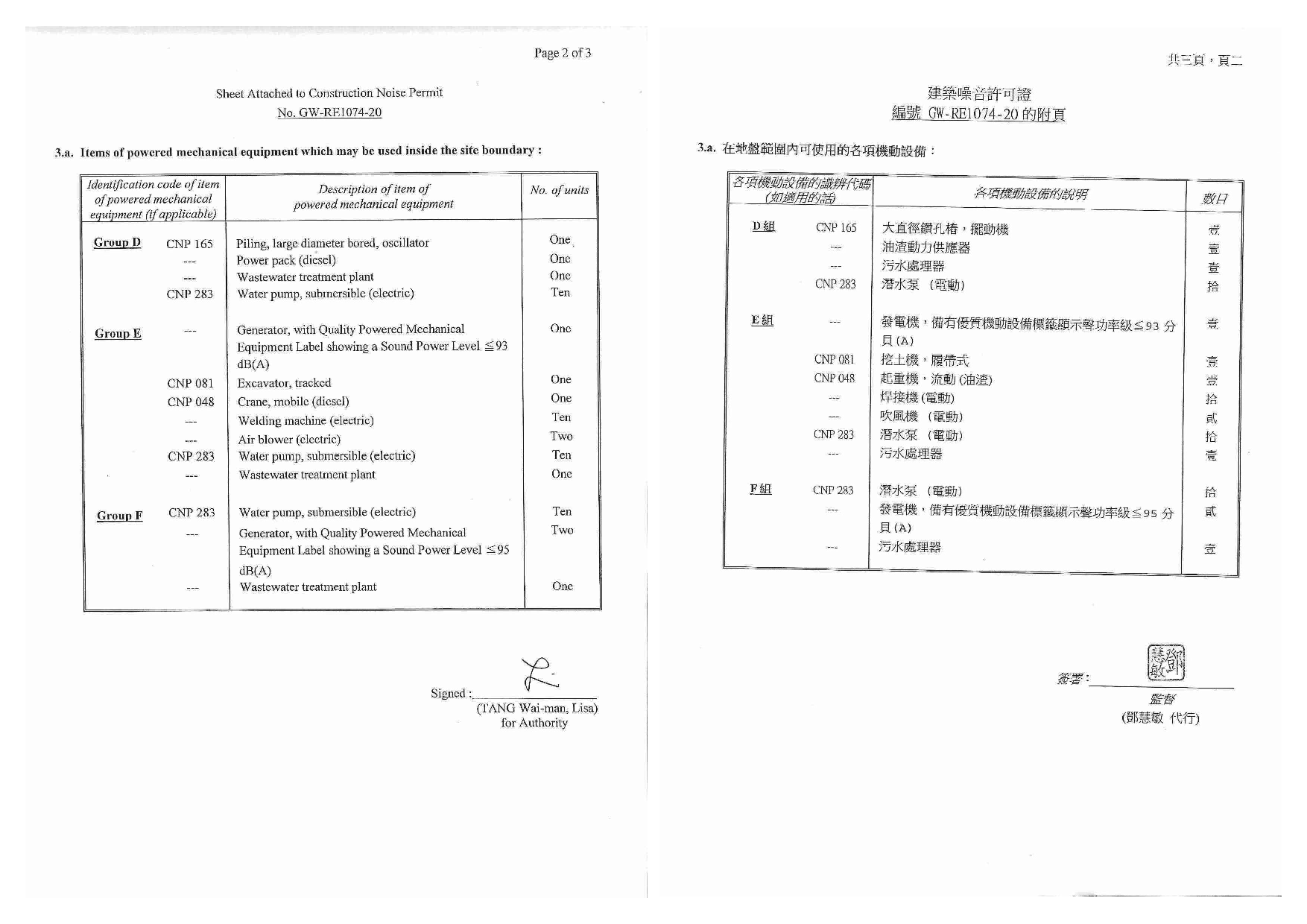

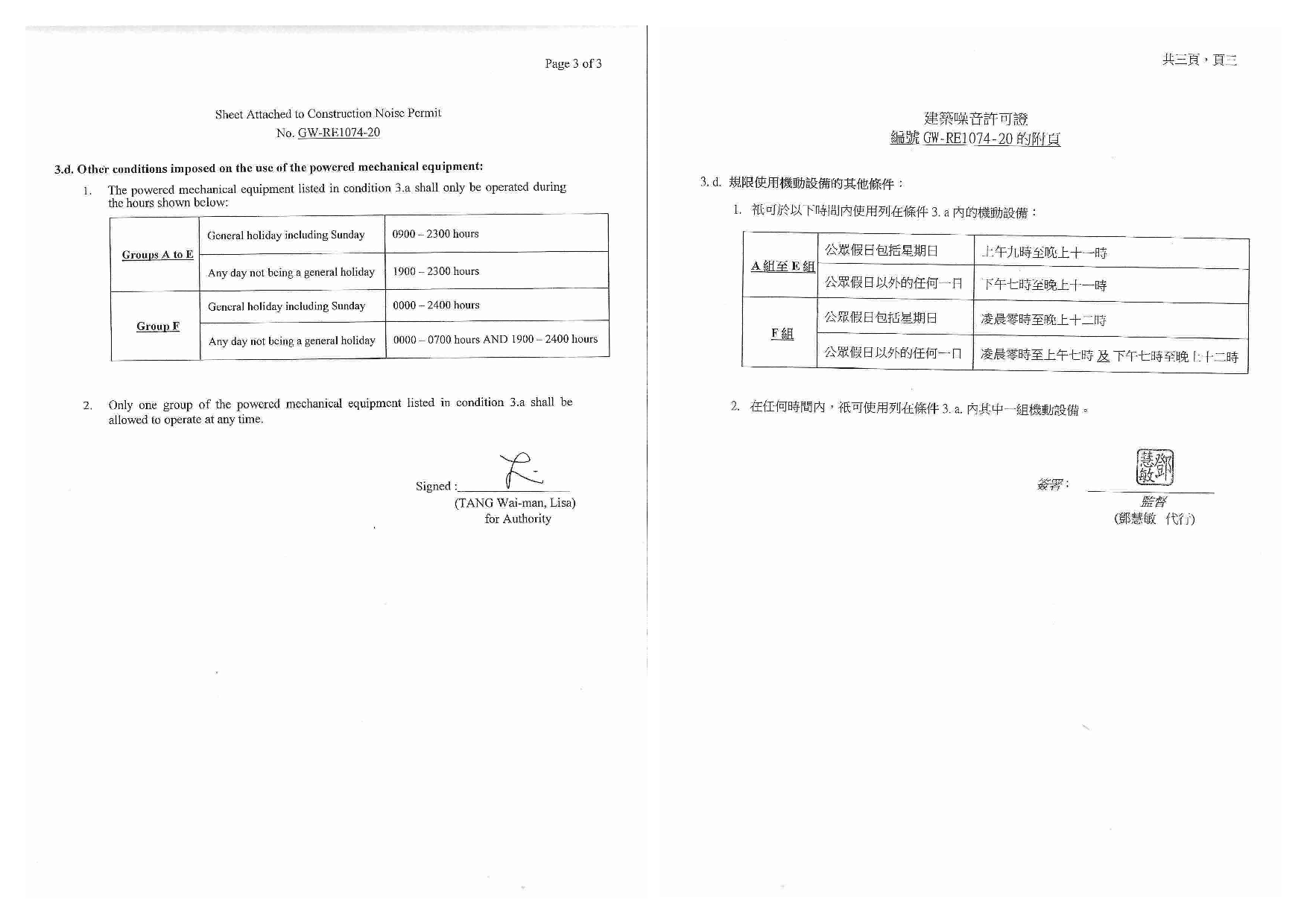

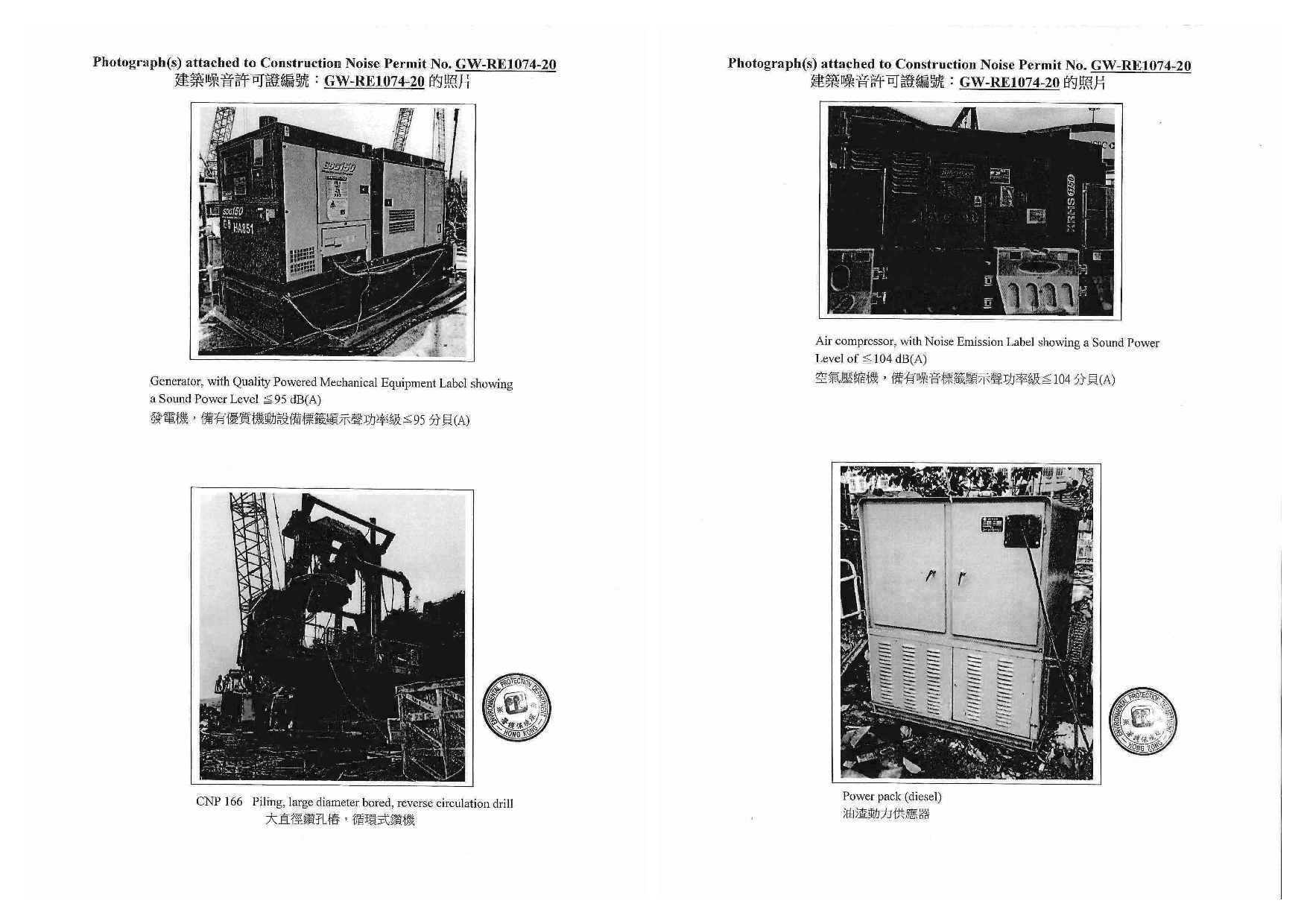

6.6 A summary of the relevant permits, licenses and/or notifications on environmental protection for the Project is shown in Table 6.2. Environmental licenses and notifications are reported in Appendix O.

|

Environmental Licenses, Notifications and Permits |

Ref. No. |

Valid Form |

Valid Till |

|

Environmental Permit under EIAO |

EP-337/2009 |

23 Apr 2009 |

N/A |

|

EP-445/2013 |

3 May 2013 |

N/A |

|

|

EP-445/2013/A |

13 Aug 2014 |

N/A |

|

|

Construction Dust Notification under APCO |

445956 |

6 June 2019 |

N/A |

|

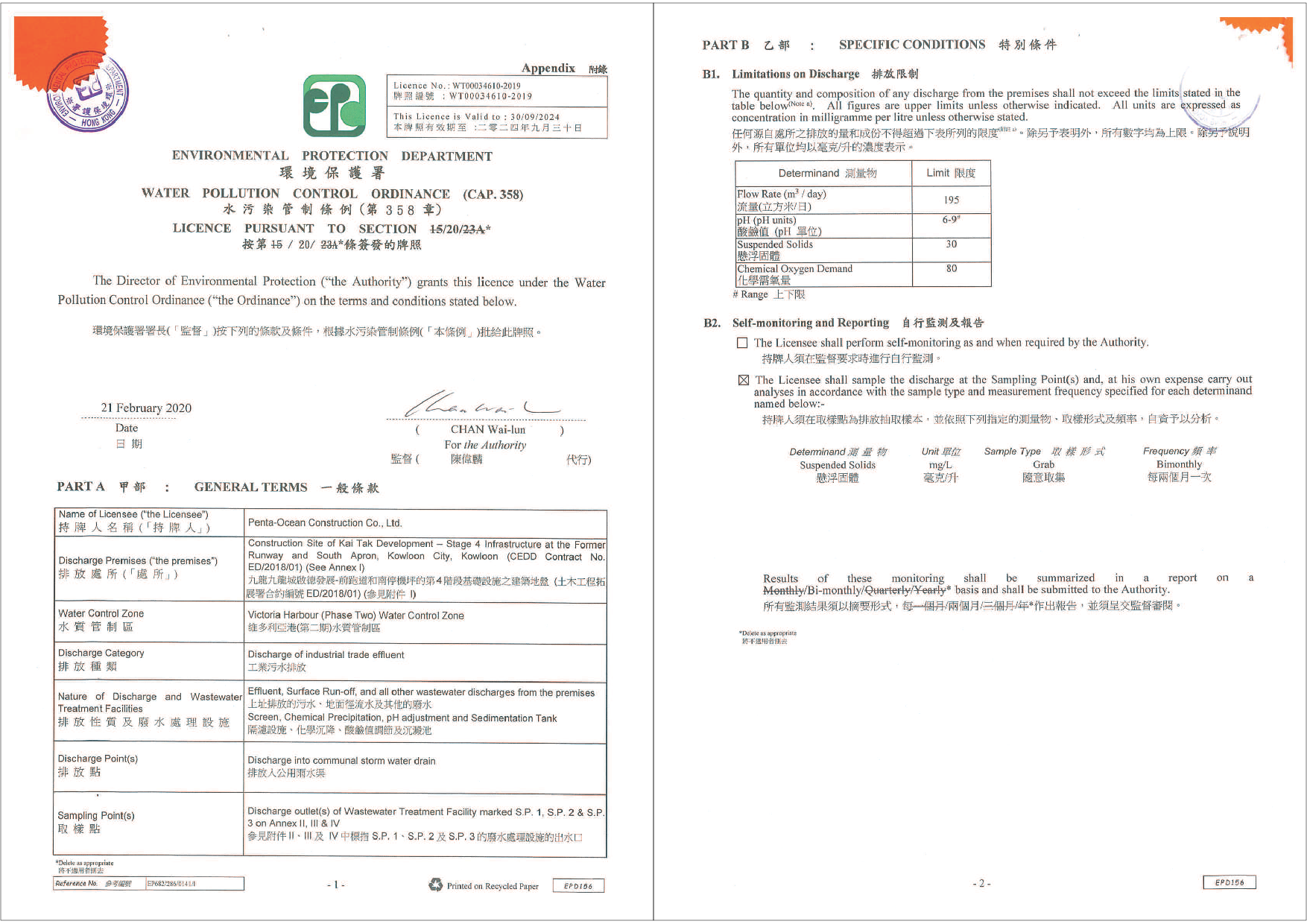

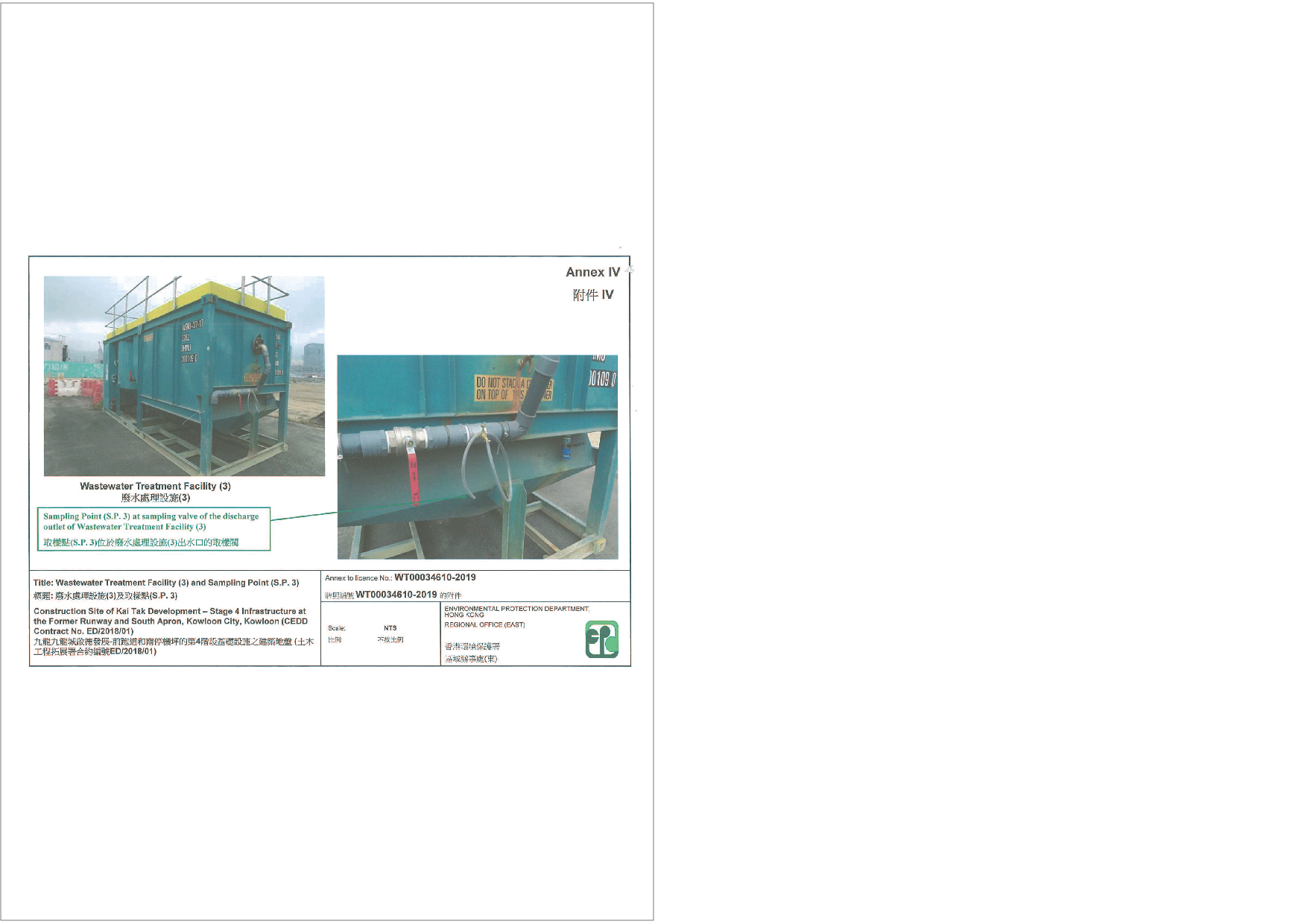

Wastewater Discharge License under WPCO |

WT00034610-2019 |

26 Sep 2019 |

30 Sep 2024 |

|

Waste Disposal Billing Account |

7034450 |

28 June 2019 |

N/A |

|

Registration as a Chemical Waste Producer |

5218-286-P3182-03 |

18 Jul 2019 |

N/A |

|

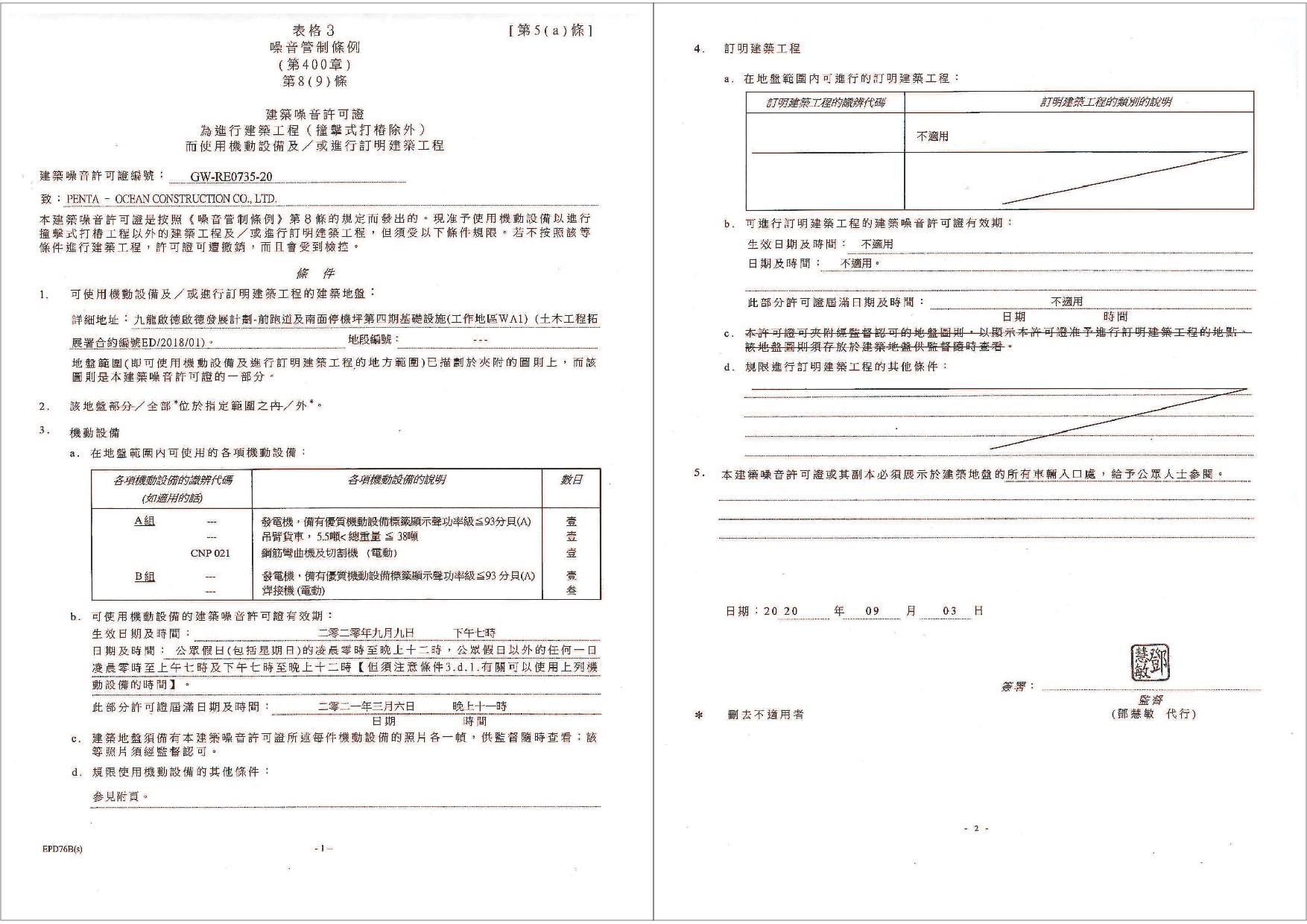

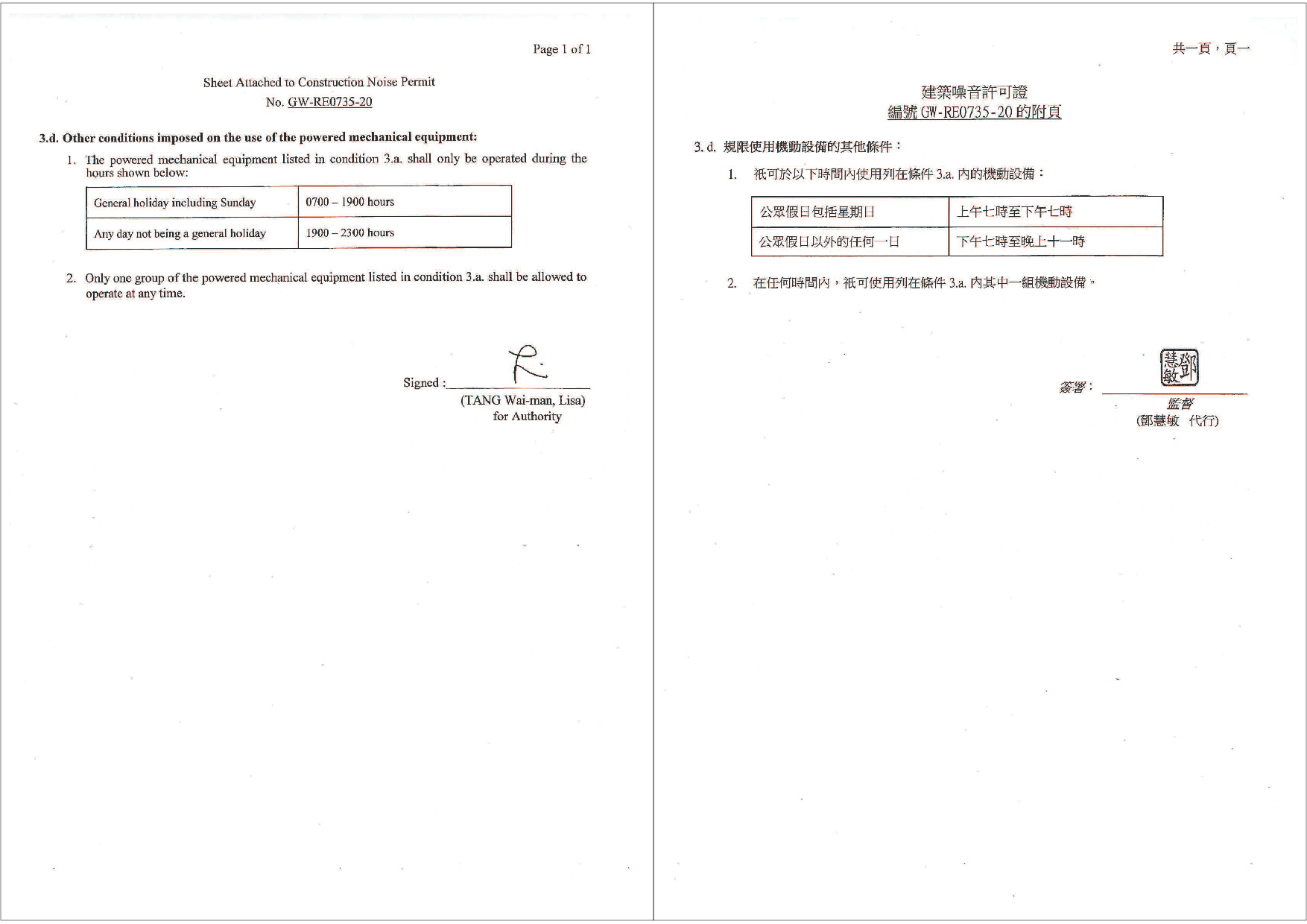

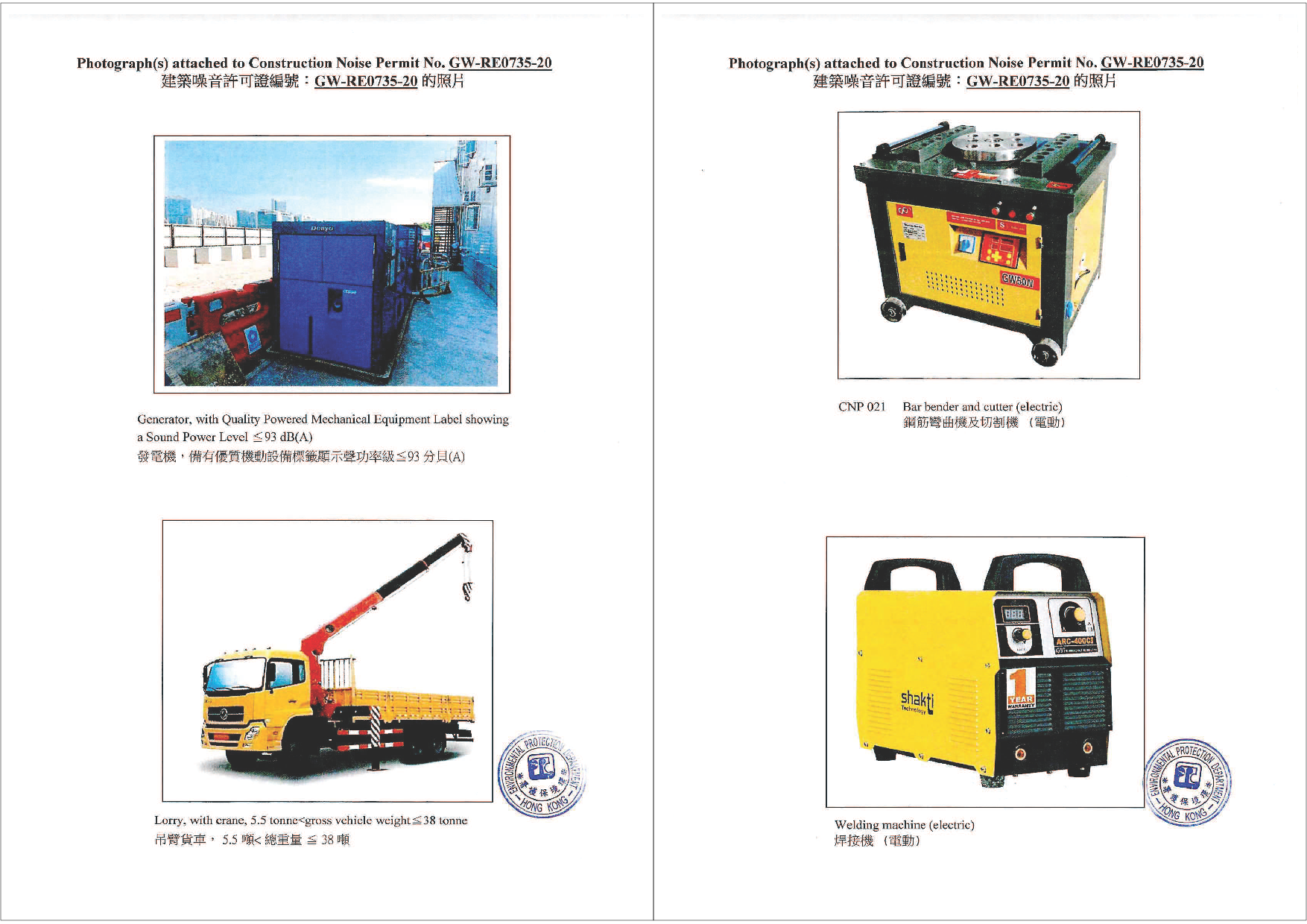

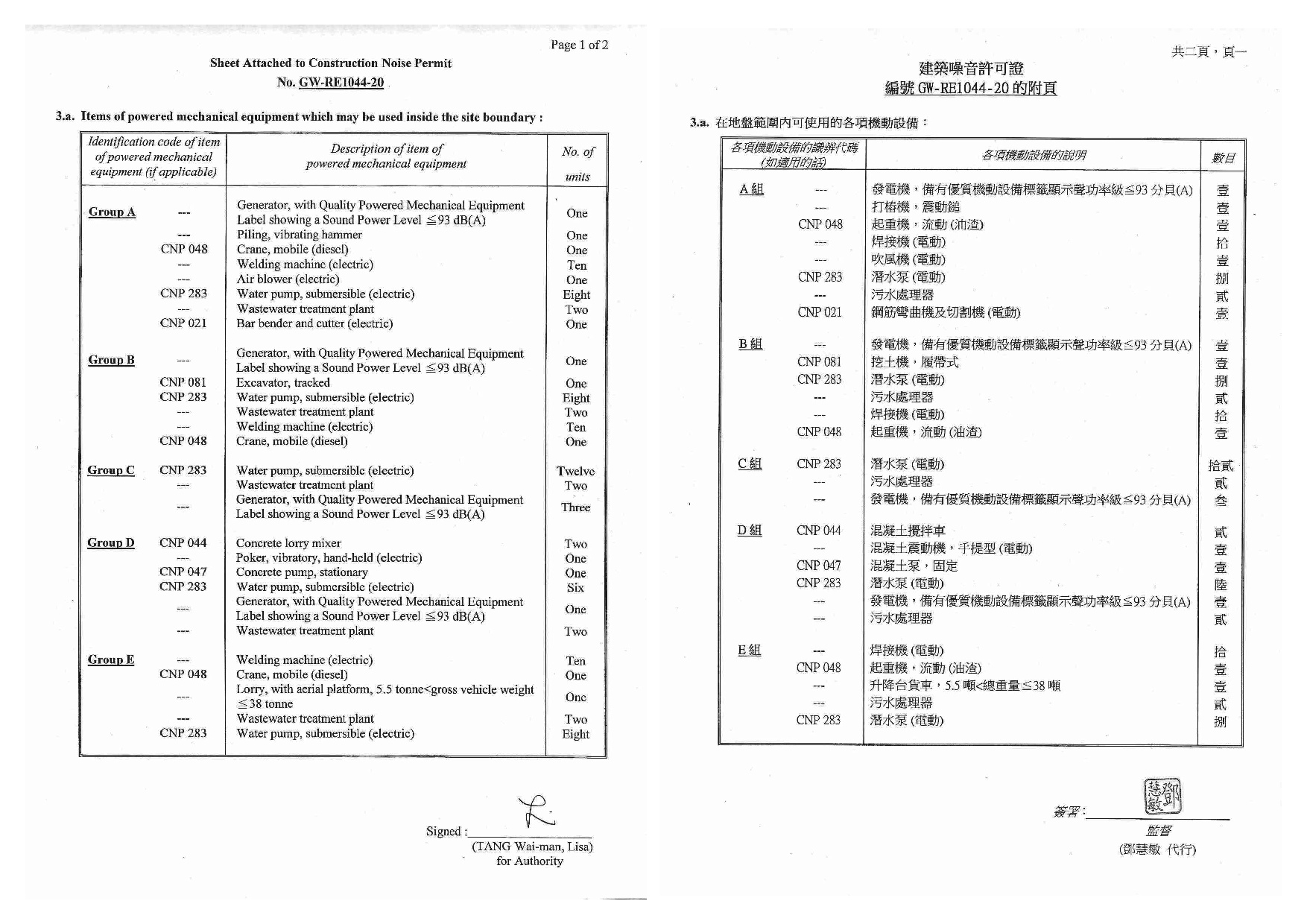

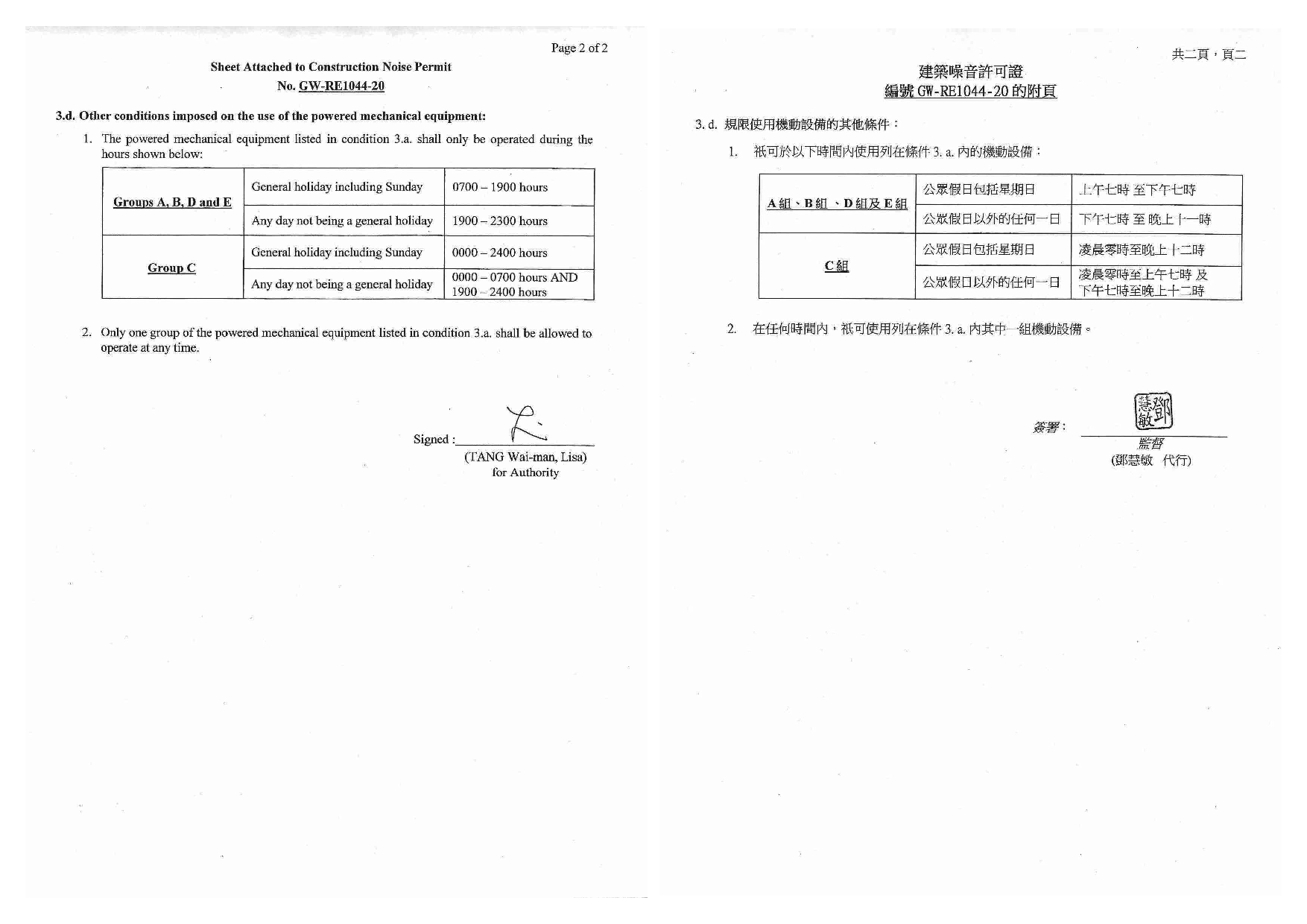

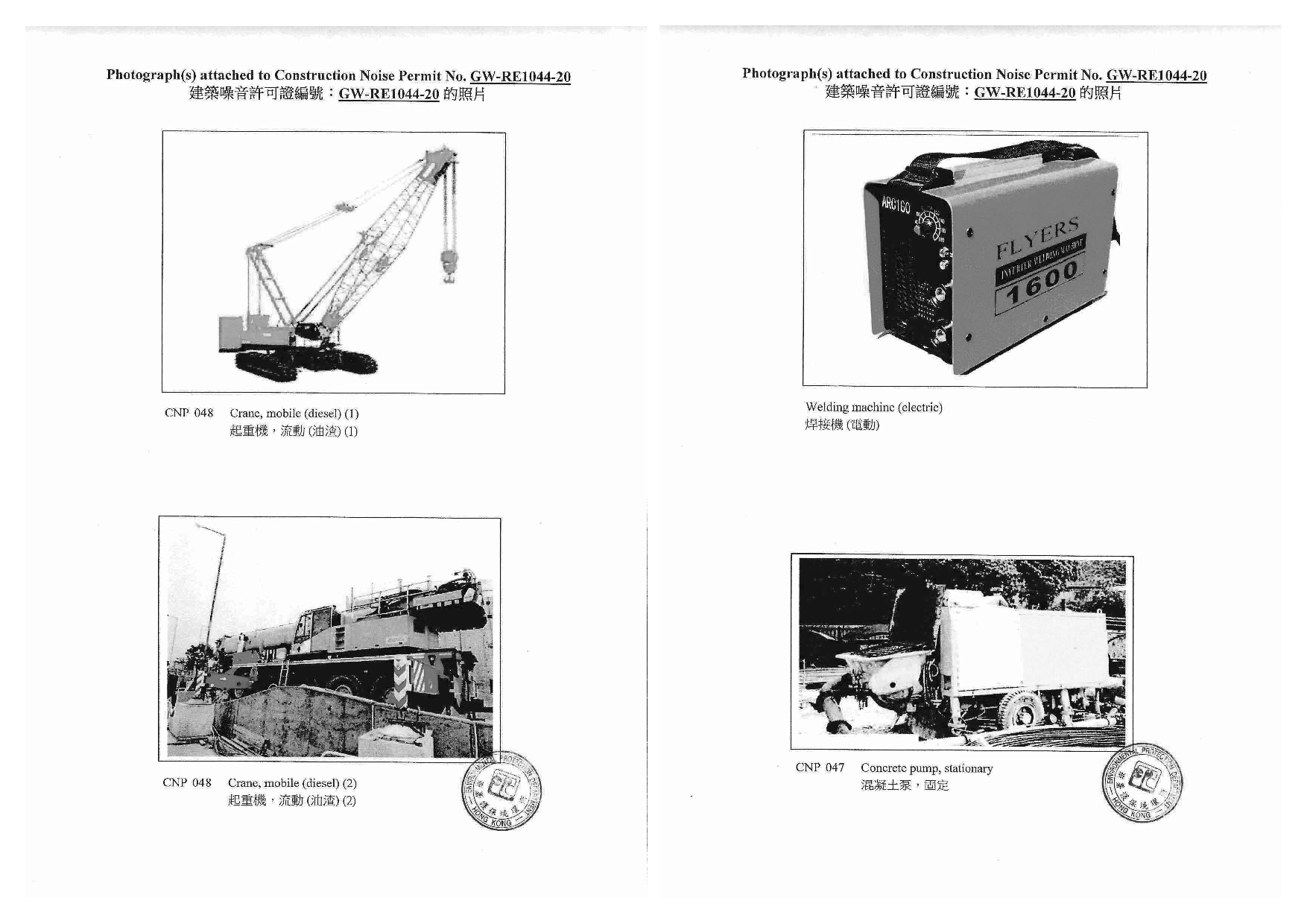

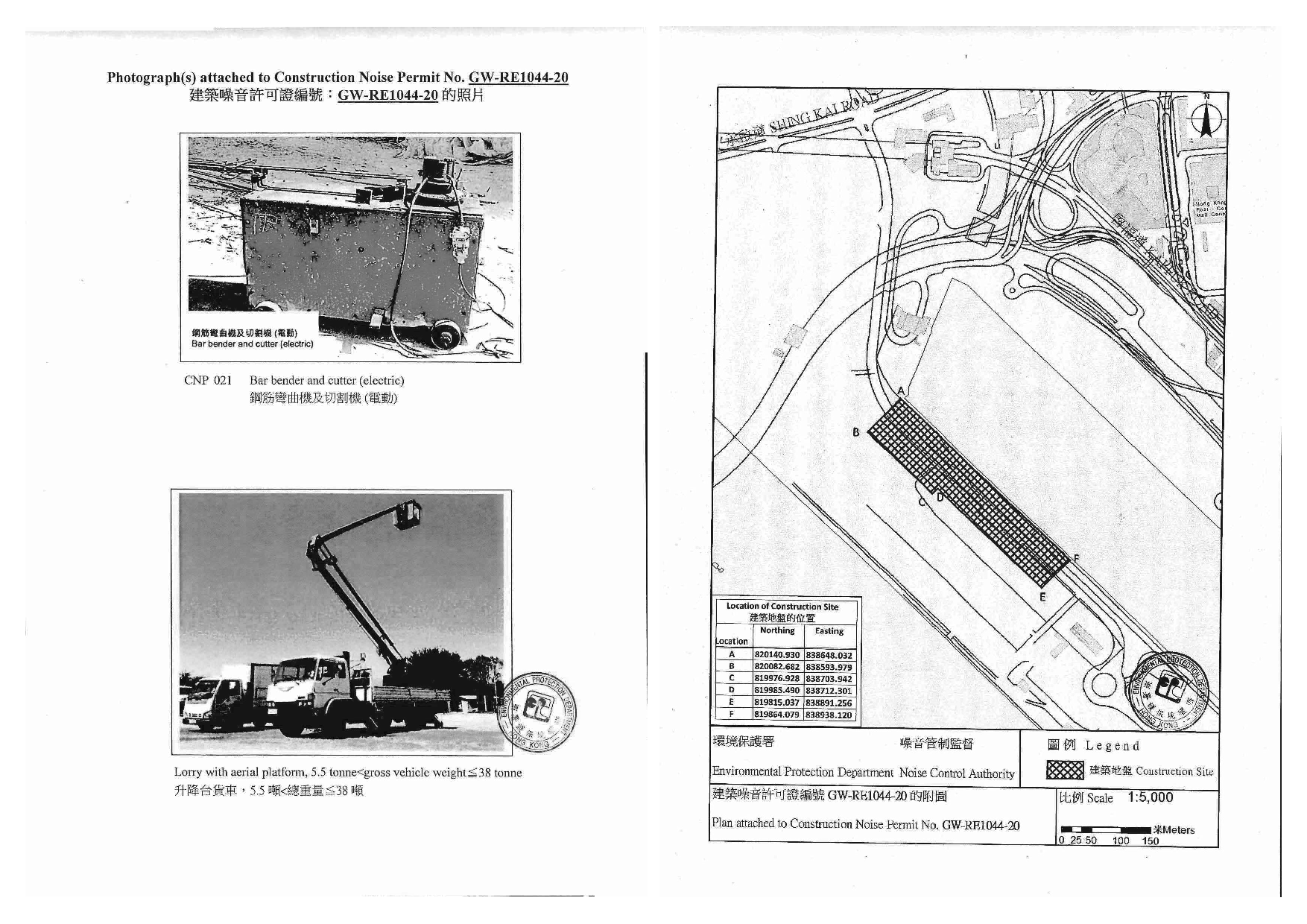

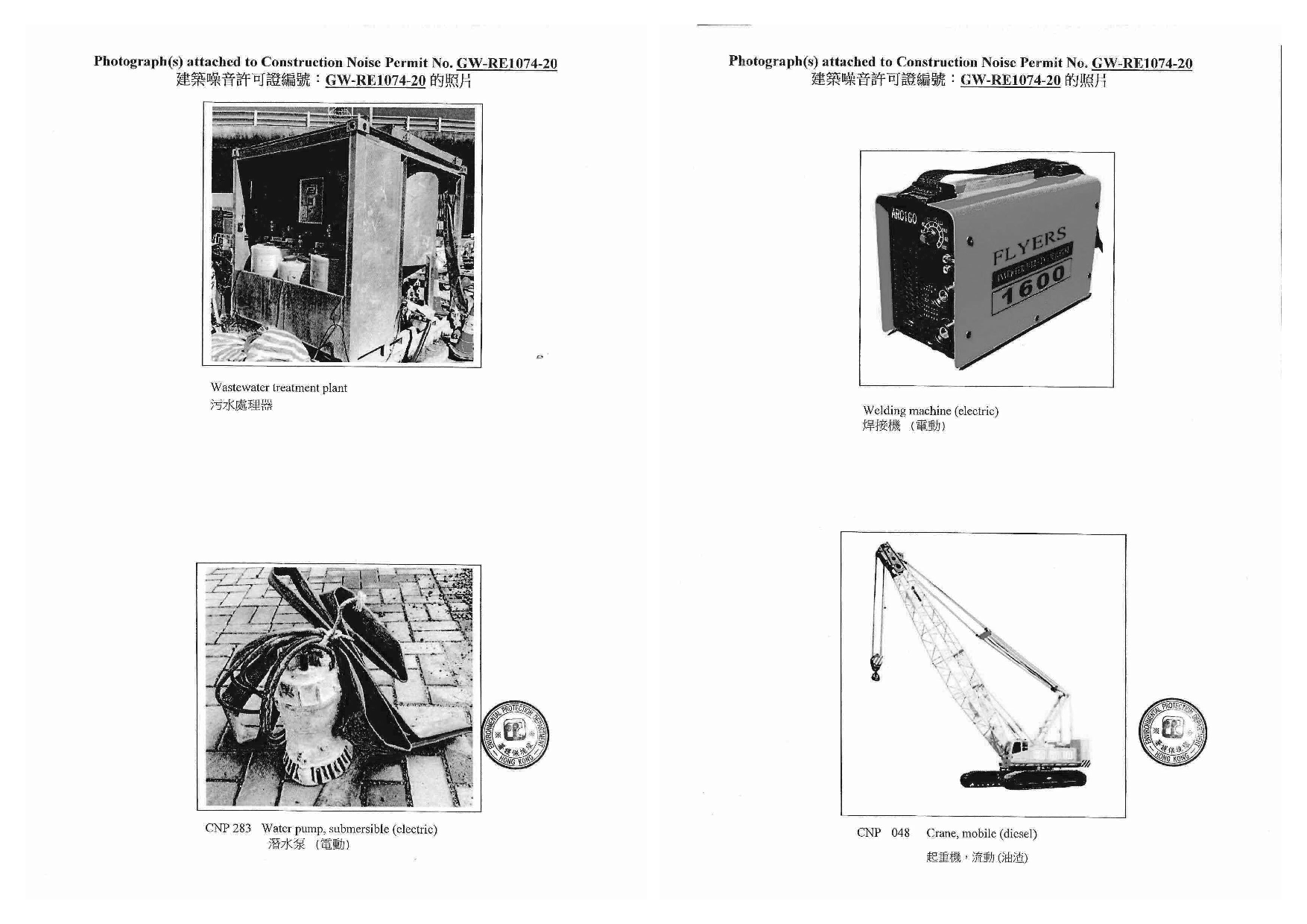

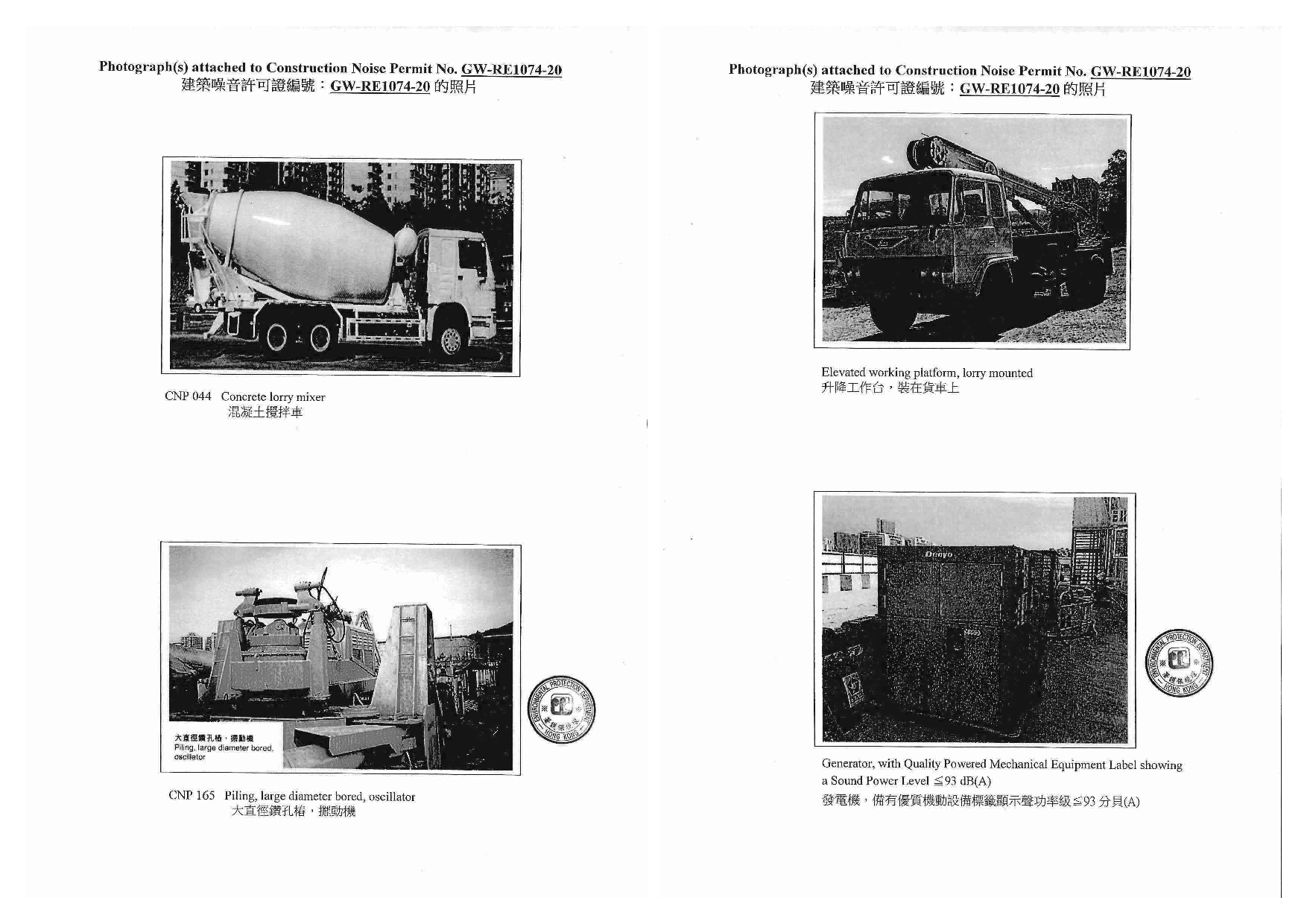

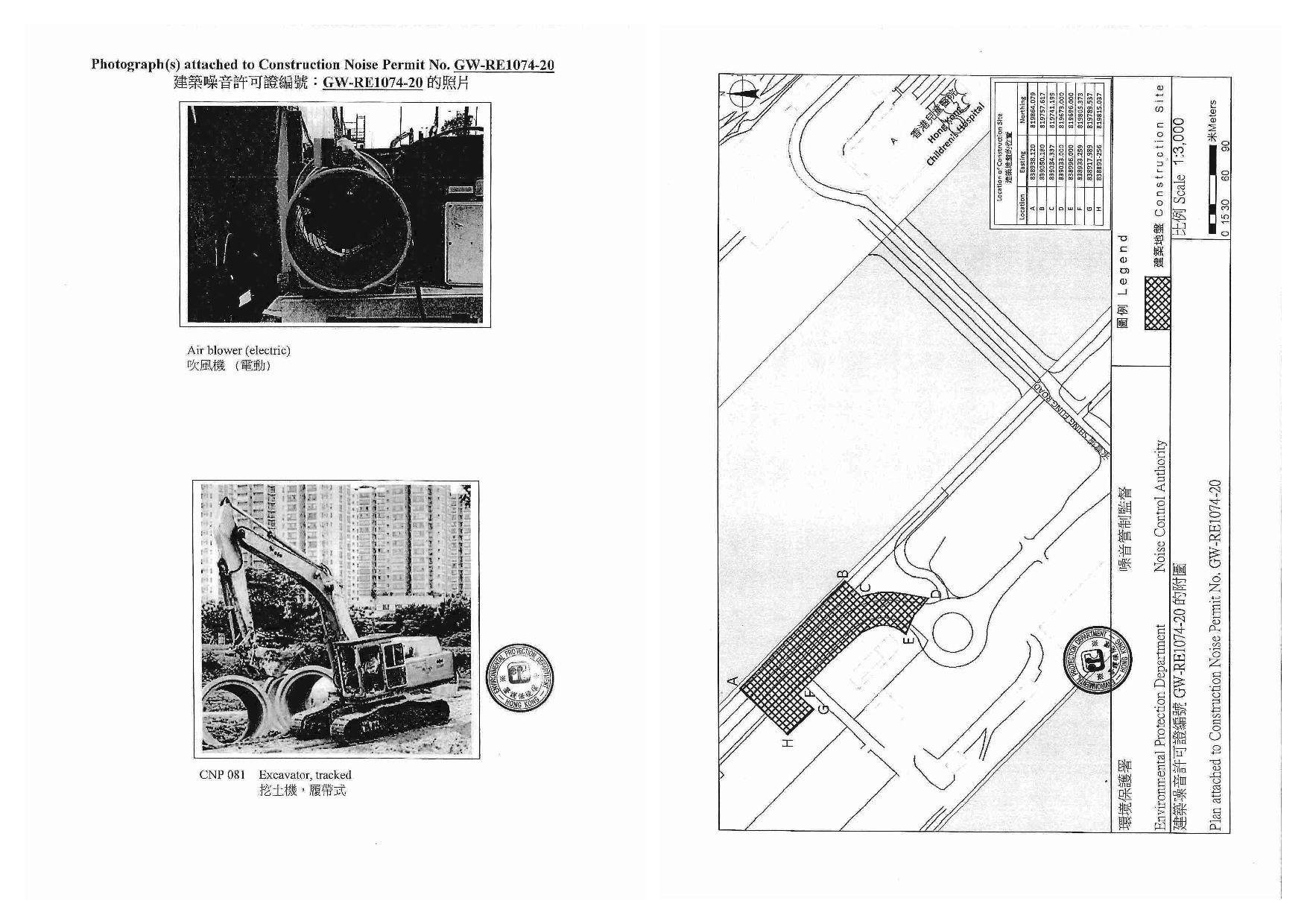

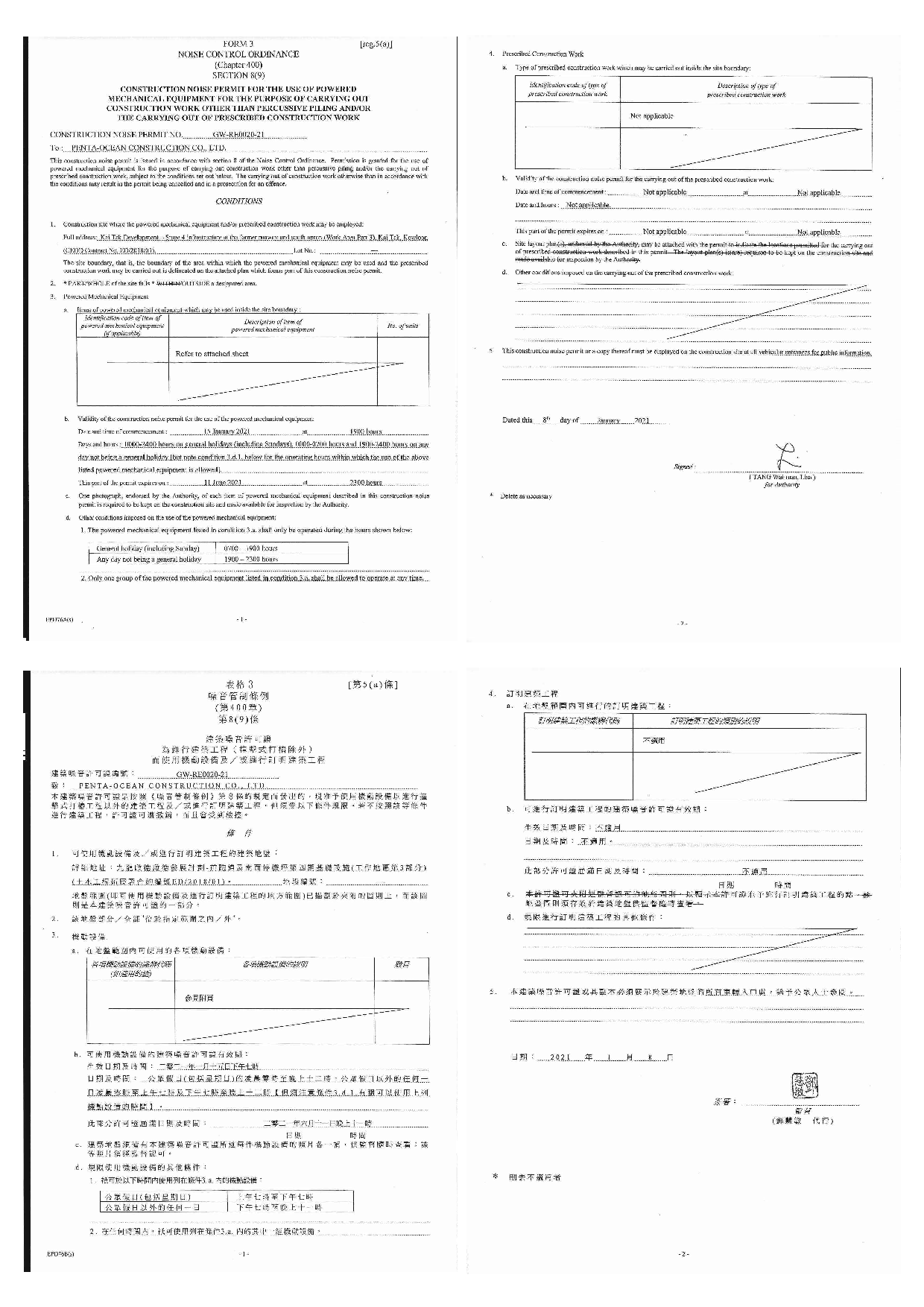

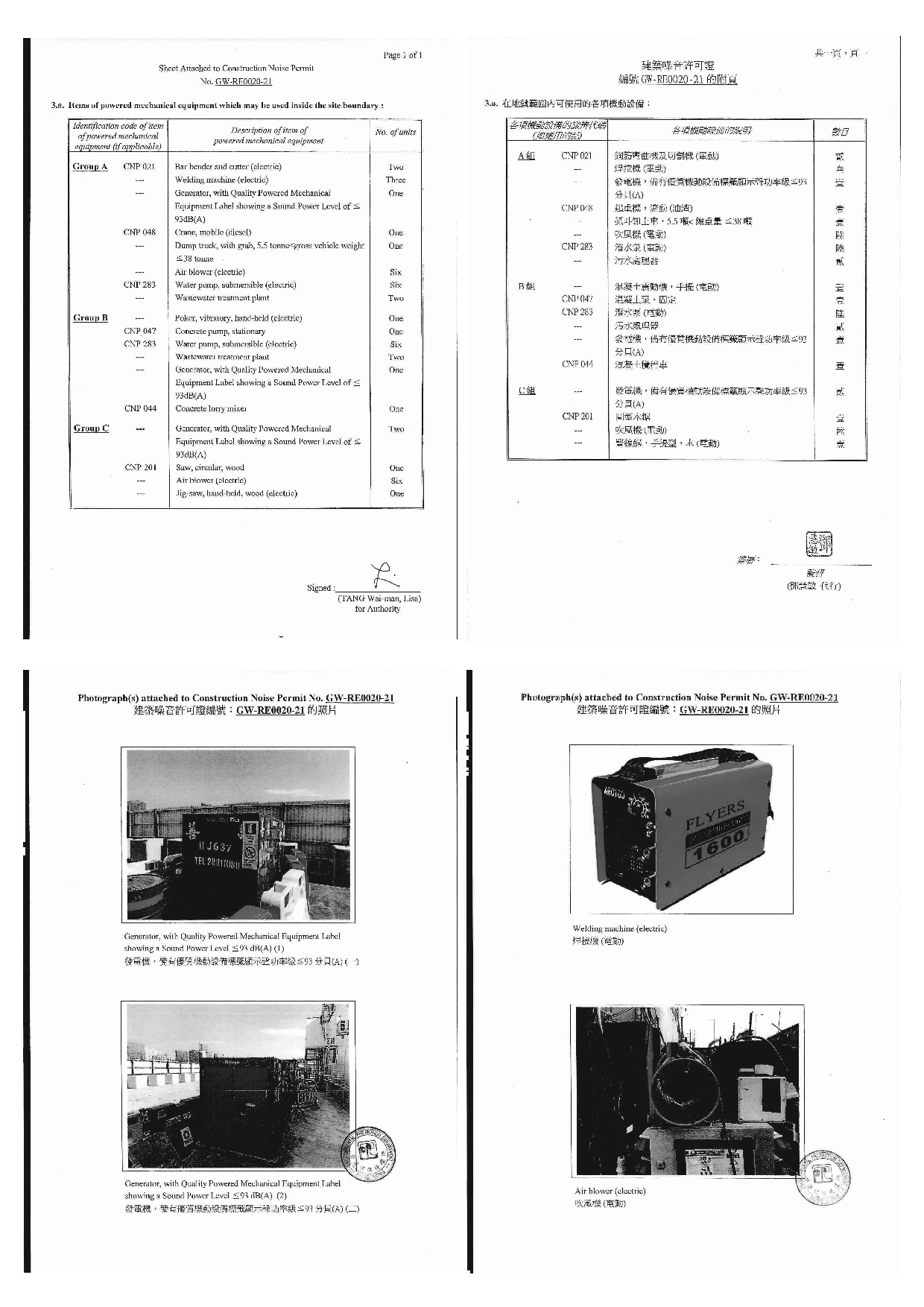

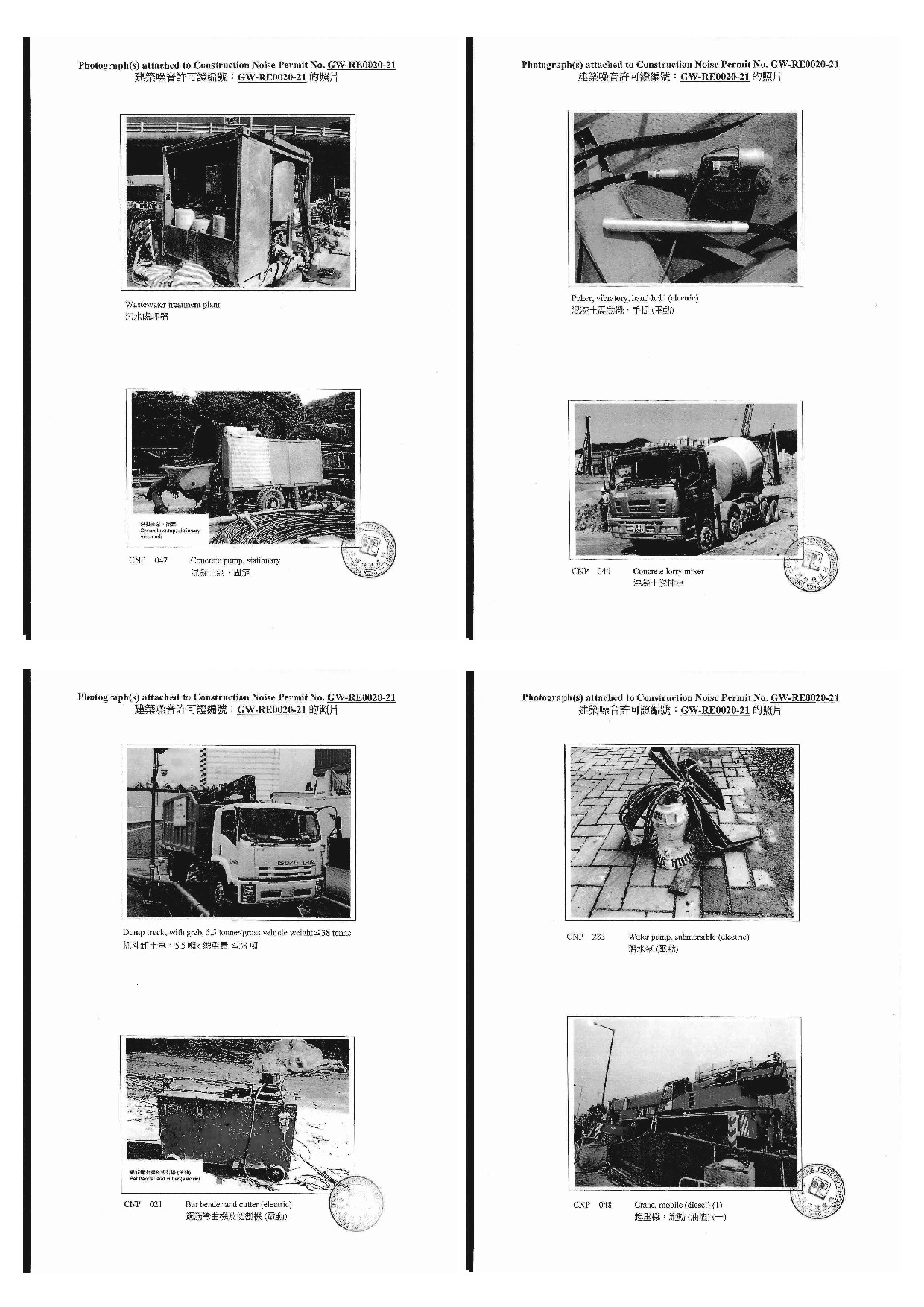

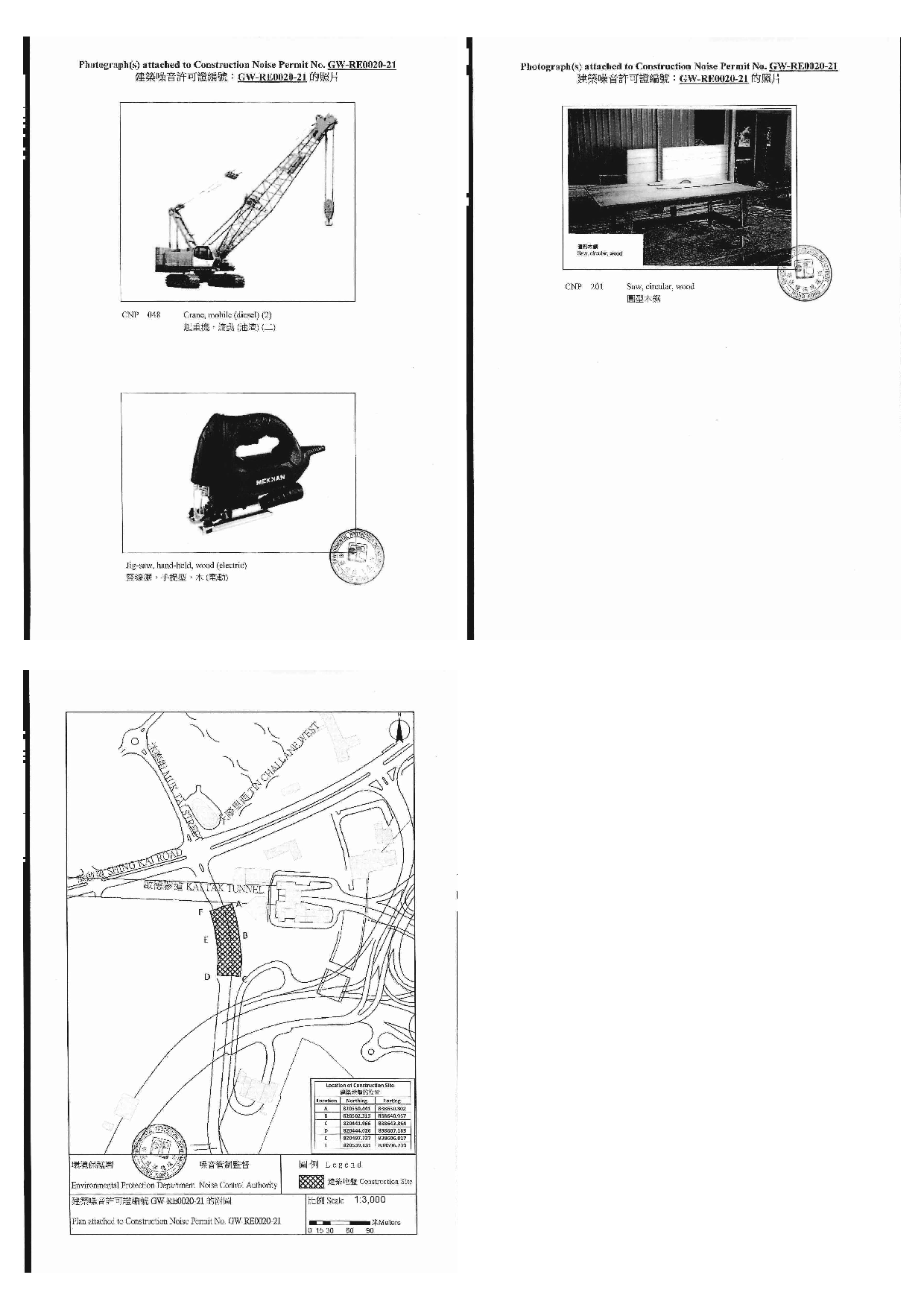

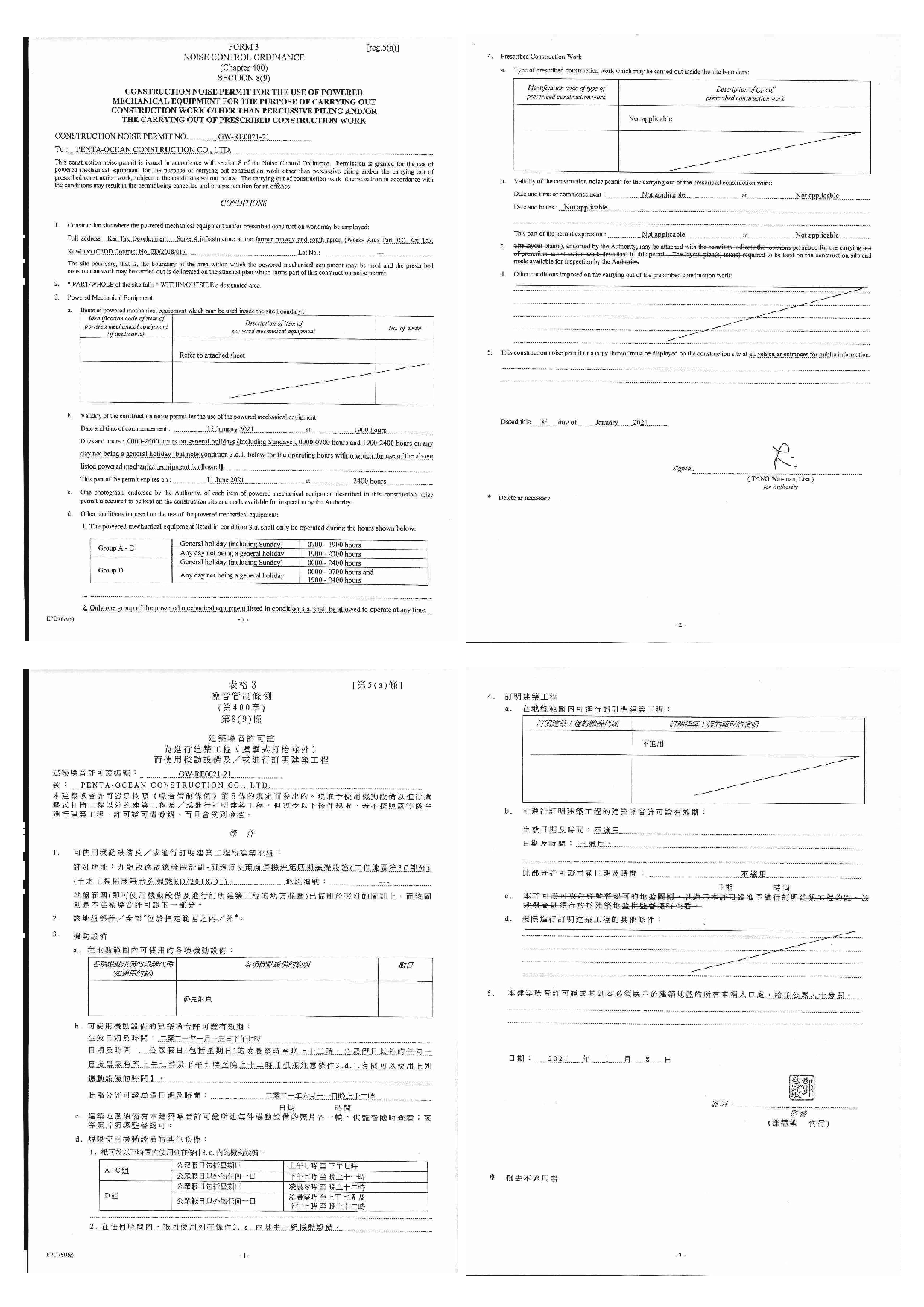

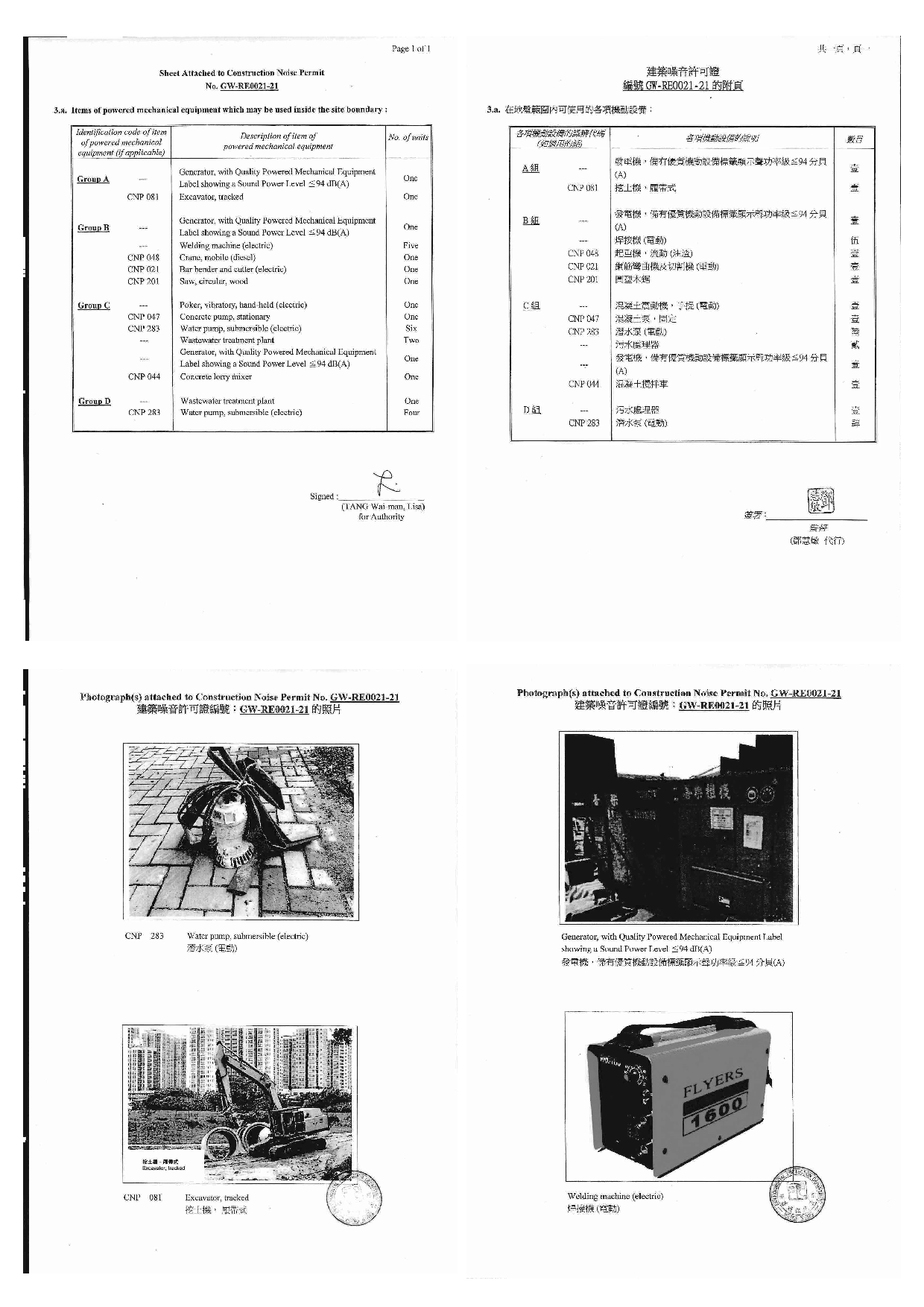

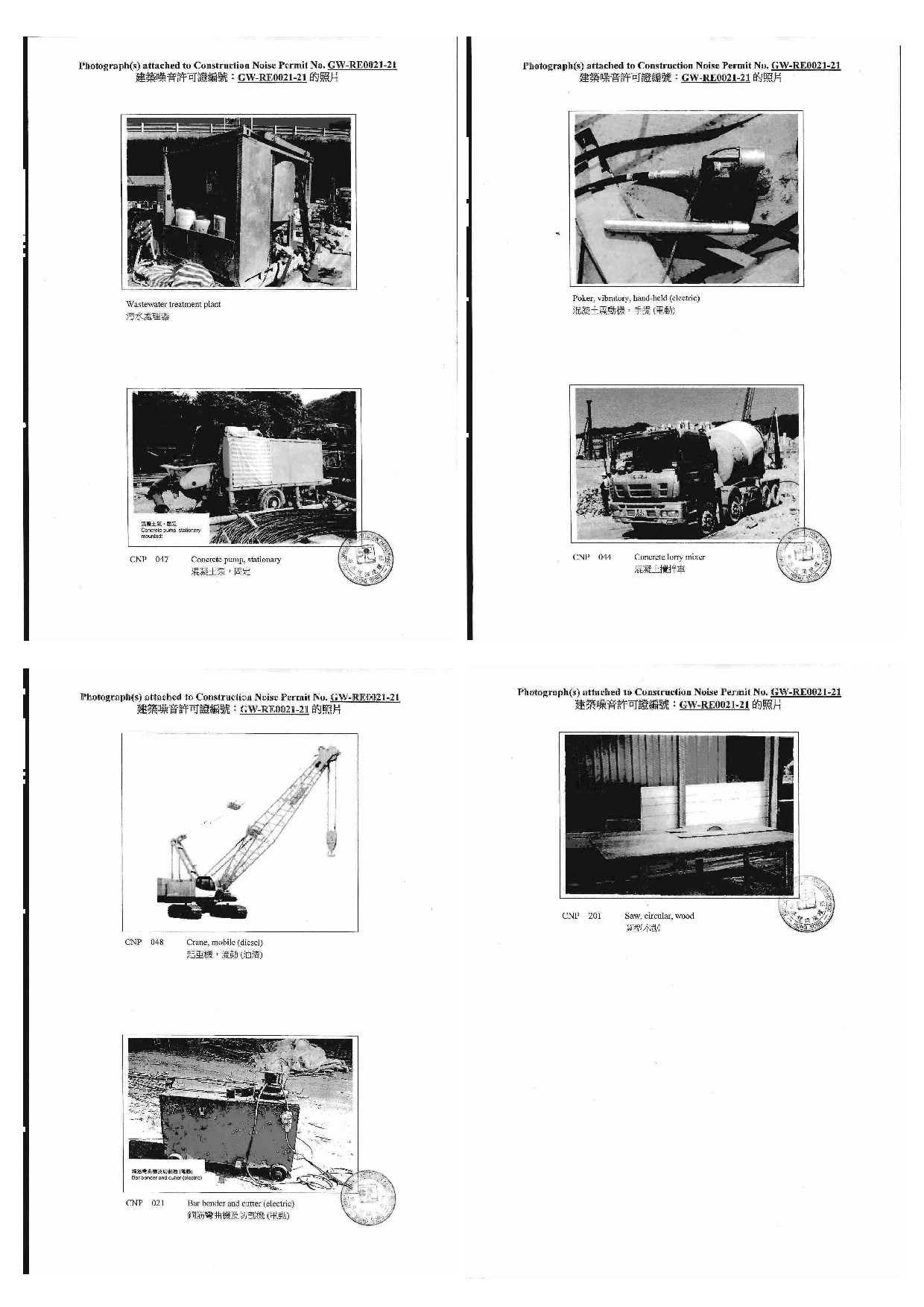

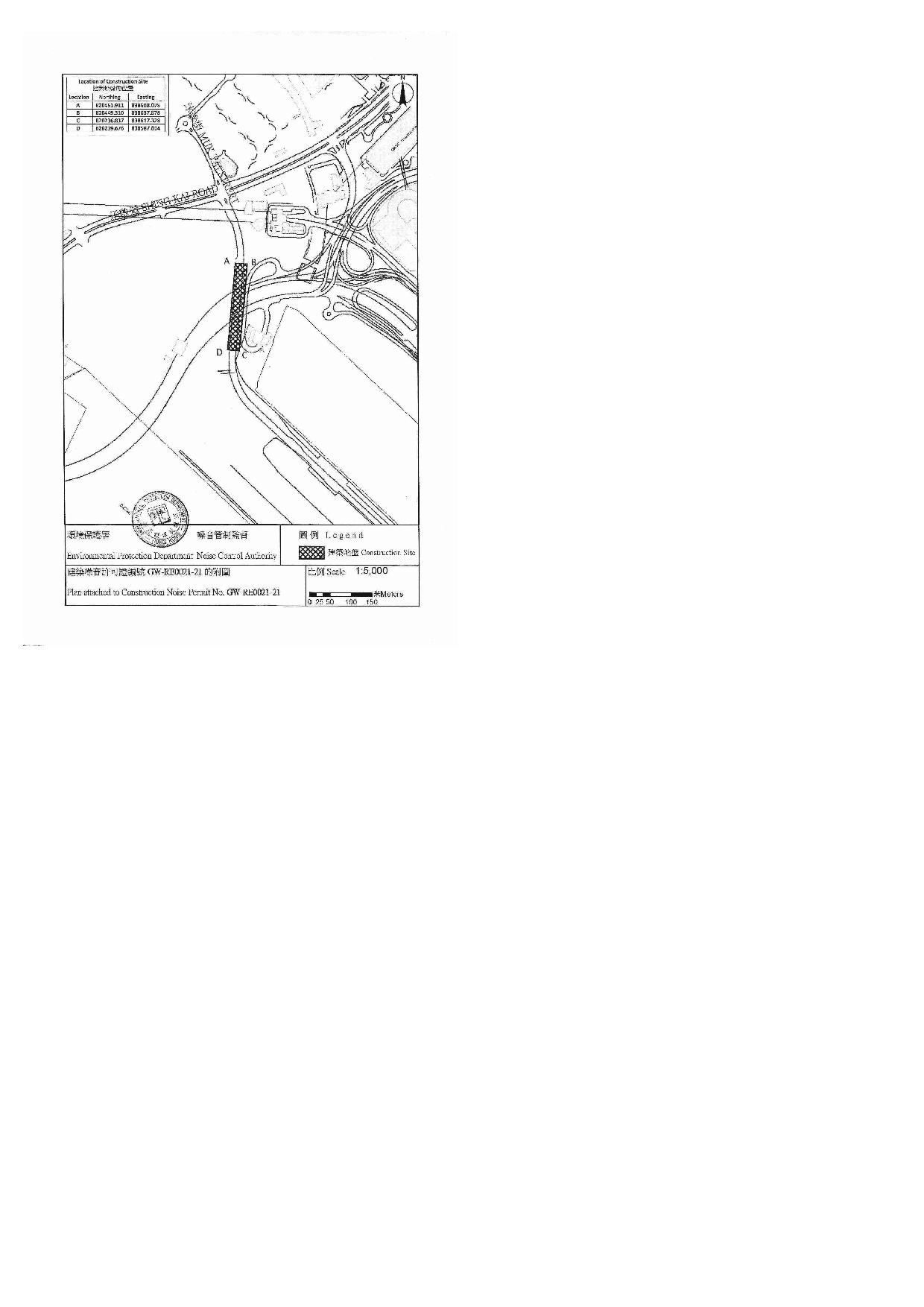

Construction Noise Permit |

26 Nov 2020 |

25 May 2021 |

|

|

GW-RE1044-20 |

10 Dec 2020 |

01 Jun2021 |

|

|

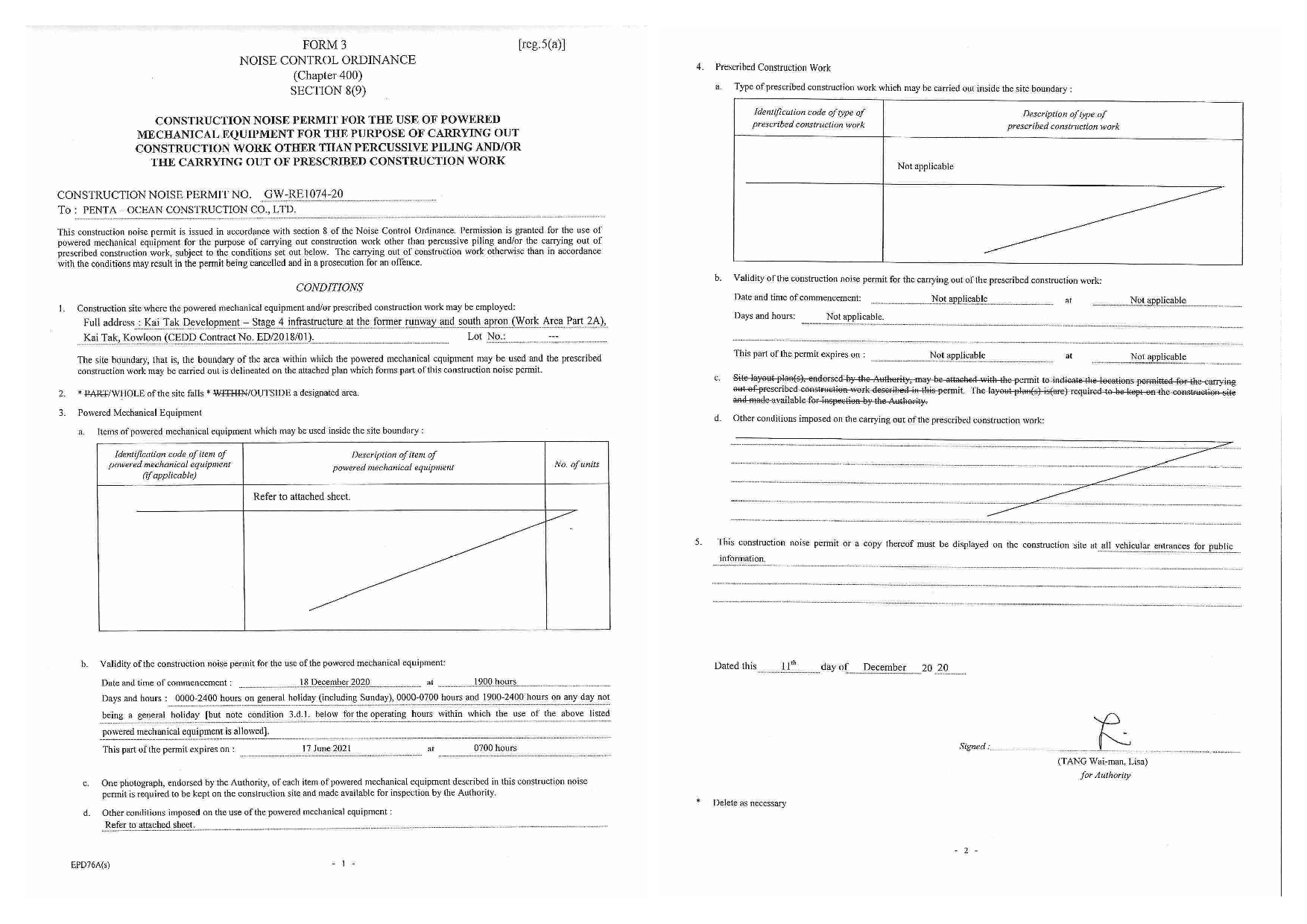

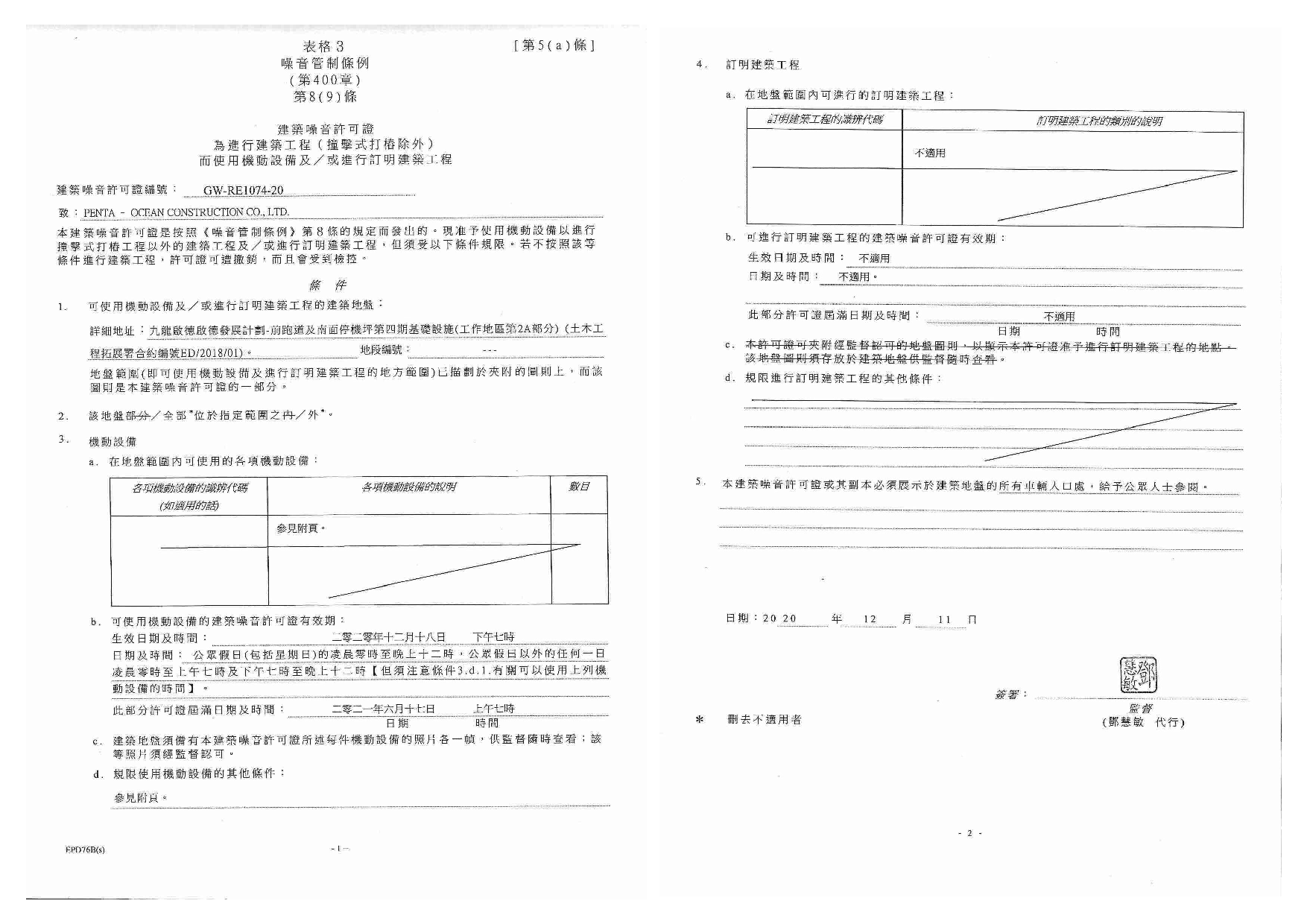

GW-RE1074-20 |

18 Dec 2020 |

17 Jun 2021 |

|

|

15 Jan 2021 |

11 Jun 2021 |

||

|

15 Jan 2021 |

11 June2021 |

||

|

GW-RE0360-21 |

20 Apr 2021 |

13 Oct 2021 |

|

|

28 Apr 2021 |

27 Oct 2021 |

6.7 The Contractor has implemented environmental mitigation measures and requires as stated in the EIA reports, the EP and the EM&A Manuals. The implementation status of the mitigation measures during the reporting month is summarized in Appendix P.

6.8 In response to the site audit findings, the Contractor carried out corrective actions with summary given in Appendix P.

6.9 No complaint was received in the reporting month. Summary of complaints in the reporting month is tabulated in Table 6.3.

|

Date of complaint received |

Date of complaint |

Description of complaint |

Investigation / Recommendations / Action take |

Close-out date / Status |

|

No complaint was received in the reporting month. |

NA |

NA |

NA |

NA |

6.10 Complaint log and Complaint Investigation report are shown in Appendix Q.

6.11 No notification of summons and successful prosecutions was received in the reporting month. Summary of summons and successful prosecutions in the reporting month is tabulated in Table 6.4.

|

Date of receiving notification of summons or prosecutions |

Date of event |

Description of event |

Action take |

Close-out date / Status |

|

No notification of summons and successful prosecutions were received in the reporting month. |

NA |

NA |

NA |

NA |

6.12 The summaries of cumulative environmental complaint, warning, summon and notification of successful prosecution for the Project is presented in Appendix Q.

7.1 The major construction activities and potential impacts in the next reporting month as follow:

|

Future key issues in the coming month |

Potential impact |

|

North Approach Ramp – Construction of wall, intermediate slab and column |

Noise and Air Quality |

|

Bridge D3 – Construction of pile cap and pier |

Noise and Air Quality |

|

North Depressed Road – Construction of wall & top slab / dismantling of wailing & strut of cofferdam |

Noise and Air Quality |

|

Underpass – Excavation and construction of base slab |

Noise and Air Quality |

|

South Approach Ramp – Installation of sheet pile and excavation |

Noise and Air Quality |

|

Landscaped Deck – Construction of bored piles |

Noise and Air Quality |

|

District Cooling System seawater intake box culvert - Construction of cofferdam and box structure |

Noise and Air Quality |

|

Noise barrier – Installation of steel structure and PMMA panel |

Noise and Air Quality |

|

Lift 3 – Construction of cofferdam for footing |

Noise and Air Quality |

|

Lift 4 – Excavation for footing |

Noise and Air Quality |

|

South Depressed Road – Excavation and Installation of Lateral Support works |

Noise and Air Quality |

7.2 The mitigation measures for environmental impact including Air Quality, Construction Noise, Water Quality, Chemical and Waste Management, Landscape and Visual shall be implemented:

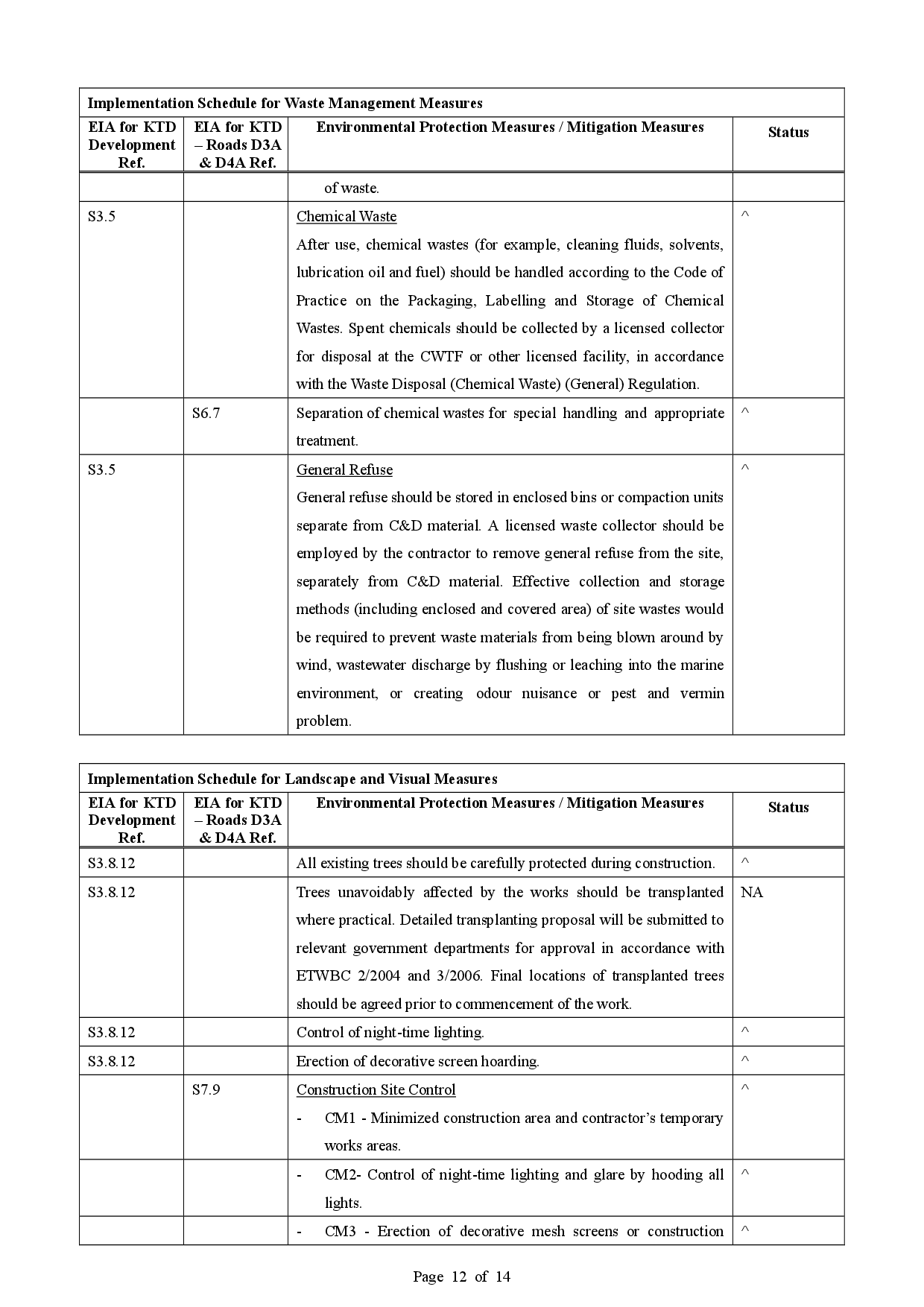

- Sufficient watering of the works site with the active dust emitting activities,

- Limitation of the speed for vehicles on unpaved site roads,

- Properly cover the stockpiles,

- Good maintenance to the plant and equipment,

- Use of quieter plant and Quality Powered Mechanical Equipment (QPME),

- Provide movable noise barriers,

- Appropriate desilting/ sedimentation devices provided on site for treatment before discharge,

- Well maintain the drainage system to prevent the spillage of wastewater during heavy rainfall,

- Onsite waste sorting and implementation of trip ticket system,

- Good management and control on construction waste reduction,

- Erection of decorative screen hoarding,

- Strictly following the Environmental Permits and Licenses, and

- Provide sufficient mitigation measures as recommended in Approved EIA Reports.

7.3 The tentative schedule for weekly site inspection and air quality and noise monitoring in the next month is provided in Appendix C.

8.1 Environmental monitoring works were performed in the reporting month and all monitoring results were checked and reviewed.

8.2 1-hour TSP monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

8.3 24-hour TSP monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

8.4 Construction noise monitoring was conducted as scheduled in the reporting month. No Action/Limit Level exceedance was recorded.

8.5 No complaint was received in the reporting month.

8.6 No notification of summons and successful prosecutions was received in the reporting month.

Figure

|

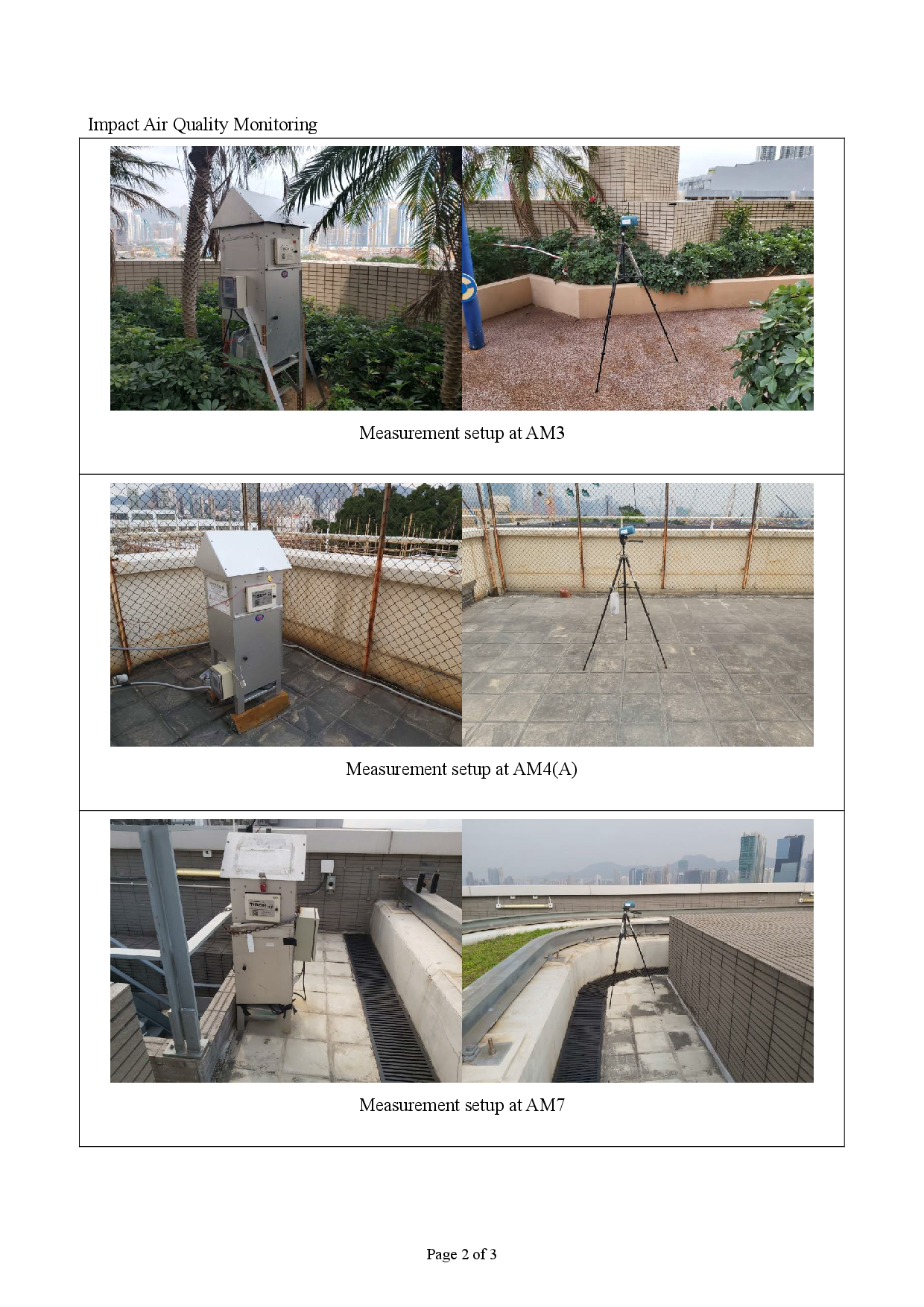

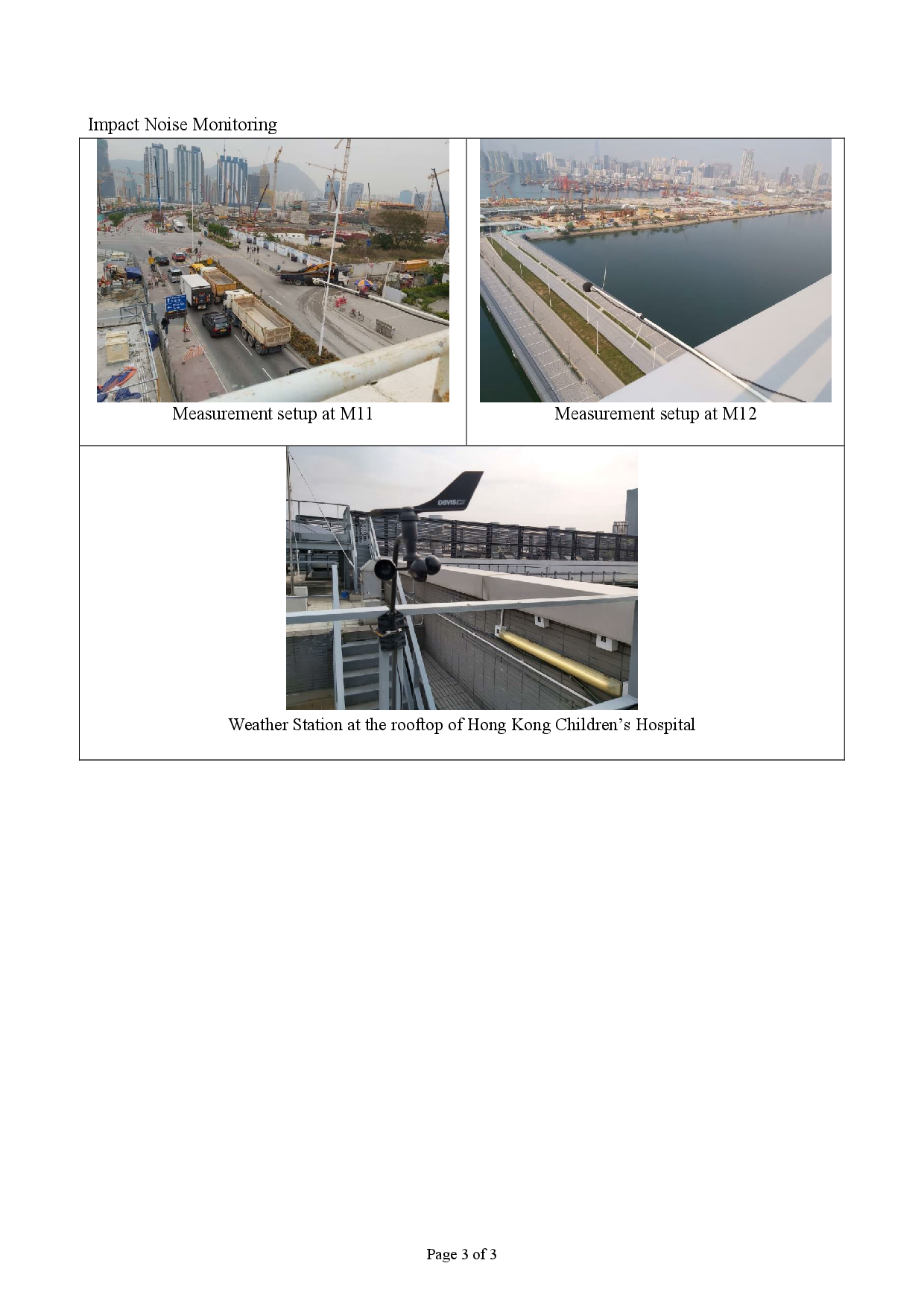

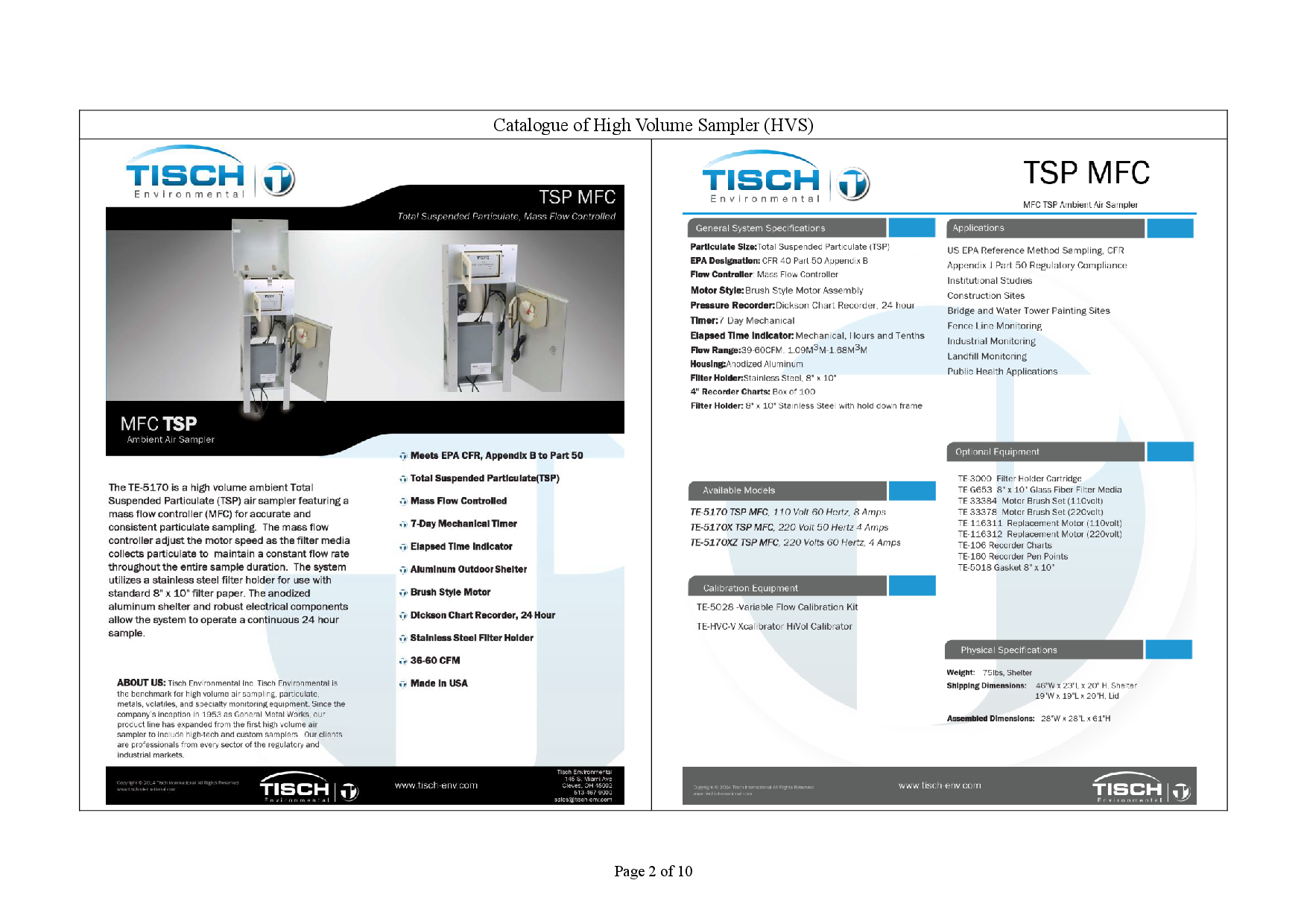

|